Intelligent conveying system of particle pump and test run method of intelligent conveying system

A technology for intelligent conveying and particle pumps, applied in pump testing, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as increasing product costs, low intelligence level, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

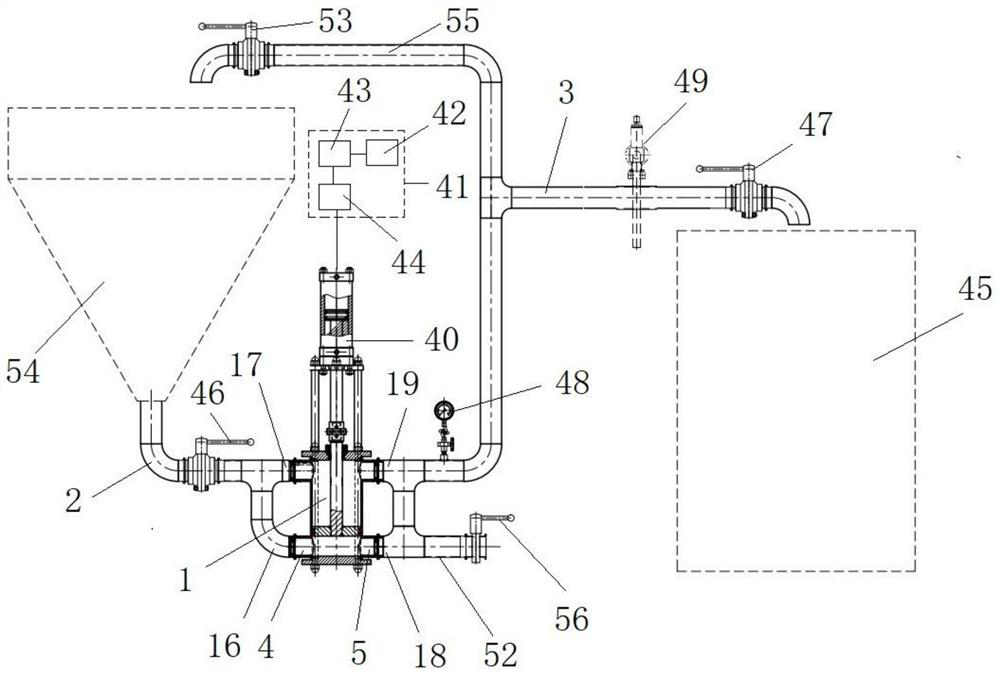

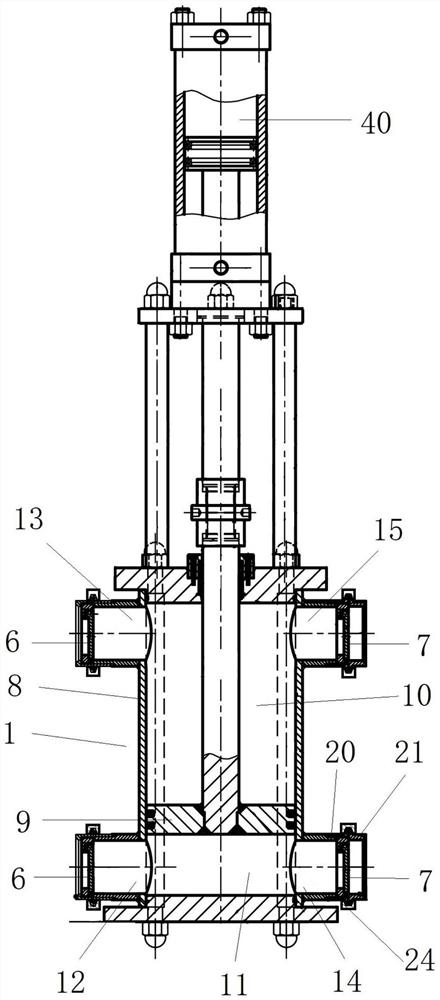

[0034]An intelligent conveying system of a particle pump, which includes a piston pump 1, a liquid inlet pipeline 2, a liquid outlet pipeline 3, a material receiving barrel 45, and a hydraulic system 41, and the piston pump 1 is provided with at least one liquid inlet 4 and at least one A liquid outlet 5, the liquid inlet pipe 2 communicates with the liquid inlet 4 of the piston pump 1, one end of the liquid outlet pipe 3 communicates with the liquid outlet 5 of the piston pump 1, and the other end extends into the connection On the barrel 45, the liquid inlet pipe 2 is provided with a first switch 46 for opening or closing the liquid inlet pipe 2, and the liquid outlet pipe 3 is provided with a pressure detection device 48, a throttle valve 49, and a Open or close the second switch 47 of the liquid outlet pipeline 3, the hydraulic system 41 includes a hydraulic cylinder 40 for driving the piston pump 1, and a hydraulic station for supplying oil to the hydraulic cylinder 40, an...

Embodiment 2

[0049] A test method for an intelligent conveying system of a particle pump is characterized in that it comprises the following steps:

[0050] (1) The clean water medium is used for the first test, the no-load test is carried out first, and then the throttle valve 49 is adjusted to carry out a multi-stage boost test;

[0051] (2) The follow-up test adopts the medium containing fruit particles, first carries out the no-load test, then adjusts the throttle valve 49, and carries out the multi-stage boost test; under each pressure section, all carry out the test of various viscosity medium, and pass After measuring and calculating the volumetric efficiency value of the material volume of the receiving tank 45 within a certain period of time, it is judged whether the volumetric efficiency value is greater than the first set value, and if so, the viscosity of the corresponding medium under the corresponding pressure section and the frequency conversion corresponding to the volumetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com