Dedusting and rewinding device

A technology of dust removal device and rewinding roller, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of being easily inhaled by the human body, affecting the quality of printed products, injury, etc., so as to protect the health of the body. , Good printing effect, clear pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

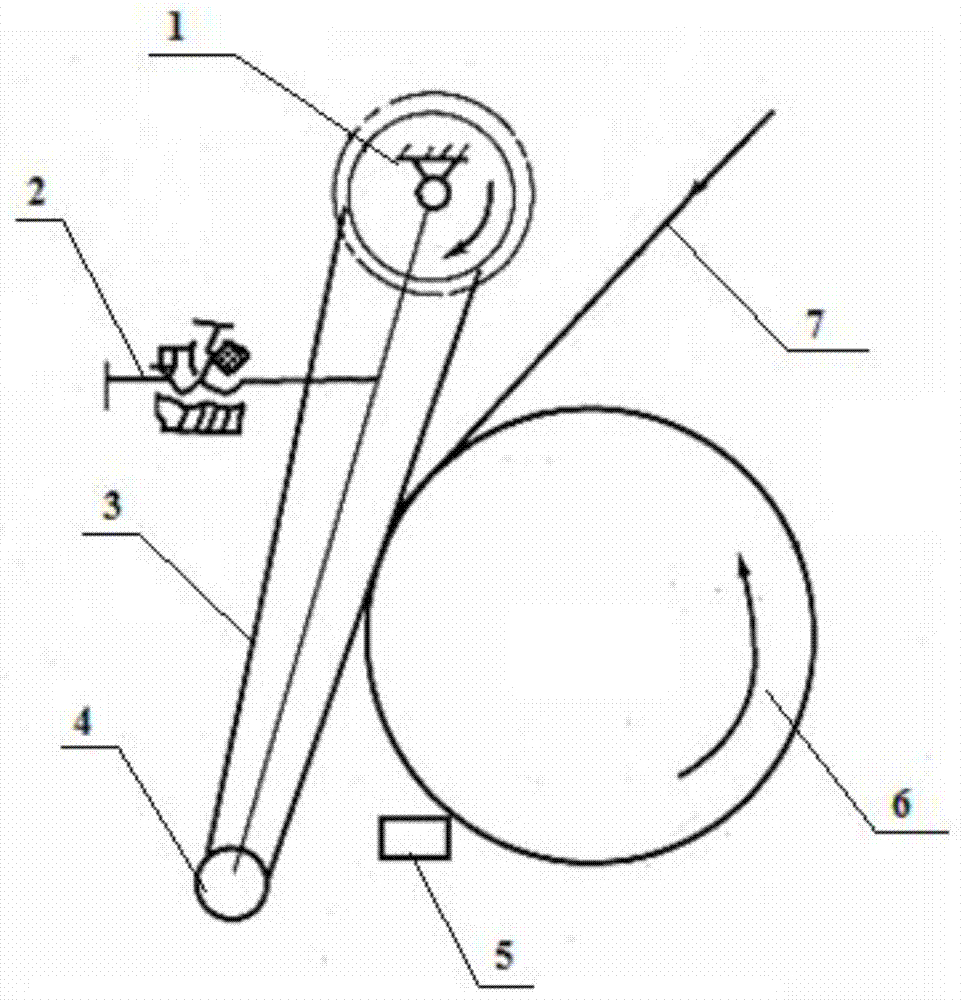

[0014] Such as figure 1 As shown, a dust removal and rewinding device includes a rewinding roller 6, and the rewinding roller 6 is driven by a motor 1 to rewind a paper tape 7, and one end of a belt 3 connected to the motor 1 is fixed on a pulley 4 , the belt 3 is in contact with the surface of the rewinding roller 6, and a dust removal device 5 is provided below the rewinding roller. The dust removal and rewinding device is also provided with an adjusting device 2 for adjusting the pressure between the belt 3 and the rewinding roller 6 . The adjusting device 2 is a handle, and one end of the handle abuts against the middle connecting line of the belt 3 .

[0015] The present invention drives the rewinding roller 6 to rewind the paper tape 7 through the motor 1, and the rewinding is stable, which can ensure that the paper tape is rolled flat. The pressure between the belt 3 and the rewinding roller 6 is adjusted through the handle, and the pressure adjustment is convenient. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com