Polyurethane reinforced material for inorganic modified ores and preparation method thereof

A reinforcement material and inorganic modification technology, applied in the field of polyurethane materials, can solve problems such as high reaction temperature, high smoke density, and potential safety hazards, and achieve the effects of reducing reaction temperature, low odor, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

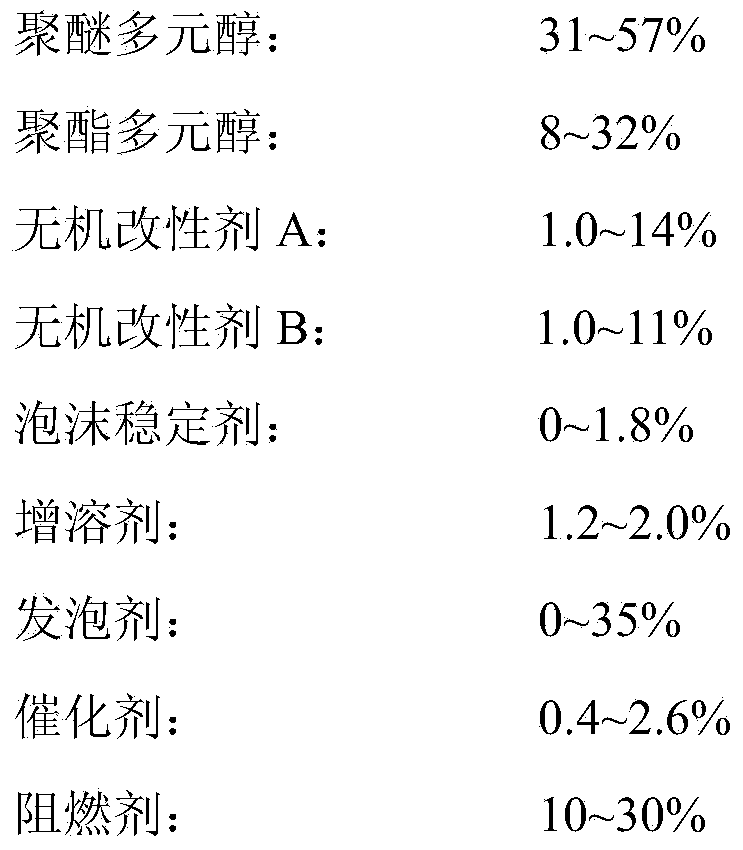

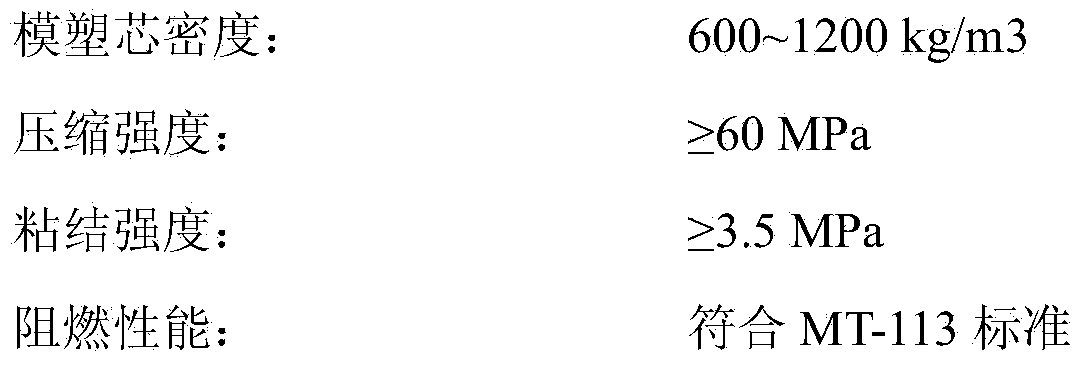

Method used

Image

Examples

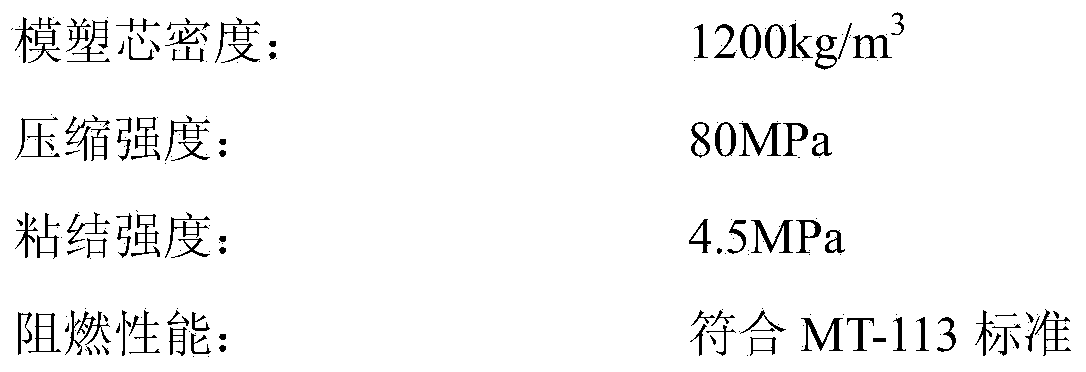

Embodiment 1

[0036] To prepare 100 kg of component A, weigh: 45 kg polyether polyol, 15 kg polyester polyol, 10 kg inorganic modifier A, 5 kg inorganic modifier B, solubilizer OP-101.5 kg, catalyst Dibutyltin dilaurate 0.625 kg, catalyst 2,4,6-tris(dimethylaminomethyl)phenol 1.25 kg, catalyst pentamethyldiethylene triamine 0.625 kg, flame retardant trichloropropyl phosphate 21 kg. Put the weighed polyether polyol and polyester polyol into the mixing kettle and stir, then add the weighed inorganic modifier A, inorganic modifier B, solubilizer, catalyst, and flame retardant, and stir at room temperature. Even, after sampling and testing qualified, it can be packed into barrels.

[0037] Prepare 100 kilograms of component B and weigh: 60 kilograms of polymethylene polyphenyl polyisocyanate, 20 kilograms of diphenylmethane diisocyanate, and 20 kilograms of compound modifier.

[0038] among them:

[0039] Polyether polyol adopts polypropylene oxide ether polyol with a functionality of 8, and a mol...

Embodiment 2

[0047] To prepare 100 kg of component A, weigh: 50 kg of polyether polyol, 8 kg of polyester polyol, 8 kg of inorganic modifier A, 3 kg of inorganic modifier B, and foam stabilizer AK-88721 kg. Blowing agent 1,1-dichloro-1-fluoroethane 5 kg, solubilizer OP-101.7 kg, catalyst dibutyltin dilaurate 0.65 kg, catalyst 2,4,6-tris(dimethylaminomethyl) ) 1.35 kg of phenol, 0.6 kg of pentamethyldiethylene triamine catalyst, 20.7 kg of flame retardant trichloropropyl phosphate. Put the weighed polyether polyol and polyester polyol into the mixing kettle and stir, then add the weighed inorganic modifier A, inorganic modifier B, foam stabilizer, foaming agent, solubilizer, and catalyst. , Stir the flame retardant evenly at room temperature, and after the sampling test is qualified, it can be packed into barrels.

[0048] Prepare 100 kilograms of component B and weigh them separately: 70 kilograms of polymethylene polyphenyl polyisocyanate, 10 kilograms of diphenylmethane diisocyanate, and 2...

Embodiment 3

[0058] To prepare 100 kg of component A, weigh: 50 kg of polyether polyol, 8 kg of polyester polyol, 8 kg of inorganic modifier A, 2 kg of inorganic modifier B, and foam stabilizer AK-88721 kg. Blowing agent 1,1-dichloro-1-fluoroethane 7 kg, solubilizer OP-101.7 kg, catalyst dibutyltin dilaurate 0.65 kg, catalyst 2,4,6-tris(dimethylaminomethyl) ) 1.35 kg of phenol, 0.6 kg of pentamethyldiethylene triamine catalyst, 19.7 kg of flame retardant trichloropropyl phosphate. Put the weighed polyether polyol and polyester polyol into the mixing kettle and stir, then add the weighed inorganic modifier A, inorganic modifier B, foam stabilizer, foaming agent, solubilizer, and catalyst. , Stir the flame retardant evenly at room temperature, and after the sampling test is qualified, it can be packed into barrels.

[0059] Prepare 100 kilograms of component B and weigh them separately: 65 kilograms of polymethylene polyphenyl polyisocyanate, 10 kilograms of diphenylmethane diisocyanate, and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com