Fluorine-containing silicone coating glue and preparation method thereof

The technology of coating adhesive and silicone is applied in the field of fluorine-containing silicone coating and its preparation. Corrosion and other performance issues are not good enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

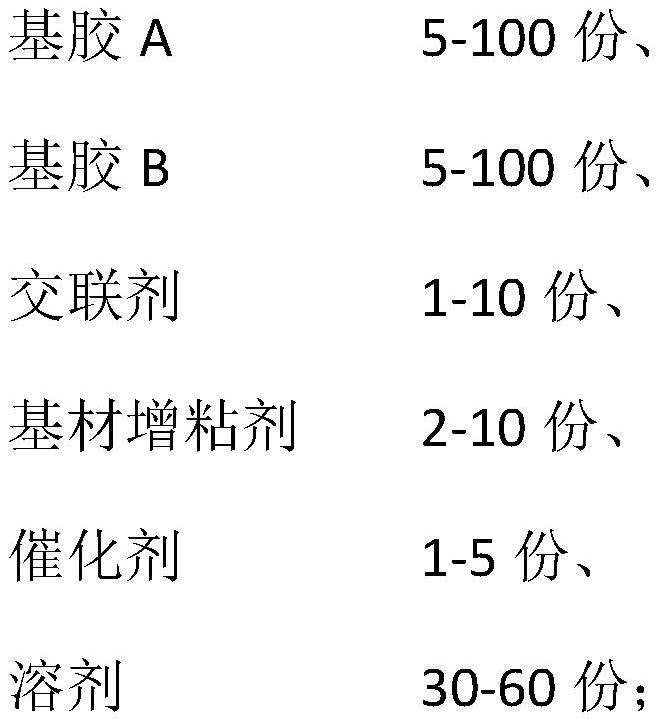

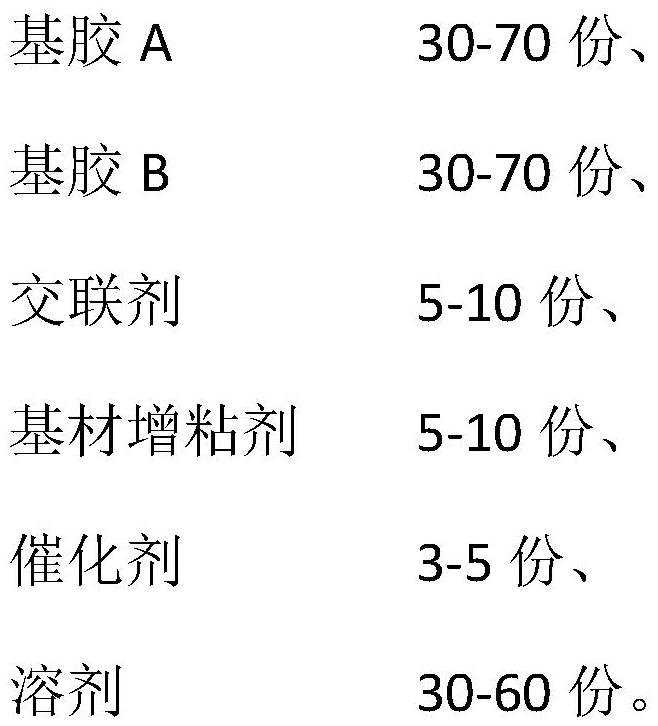

Method used

Image

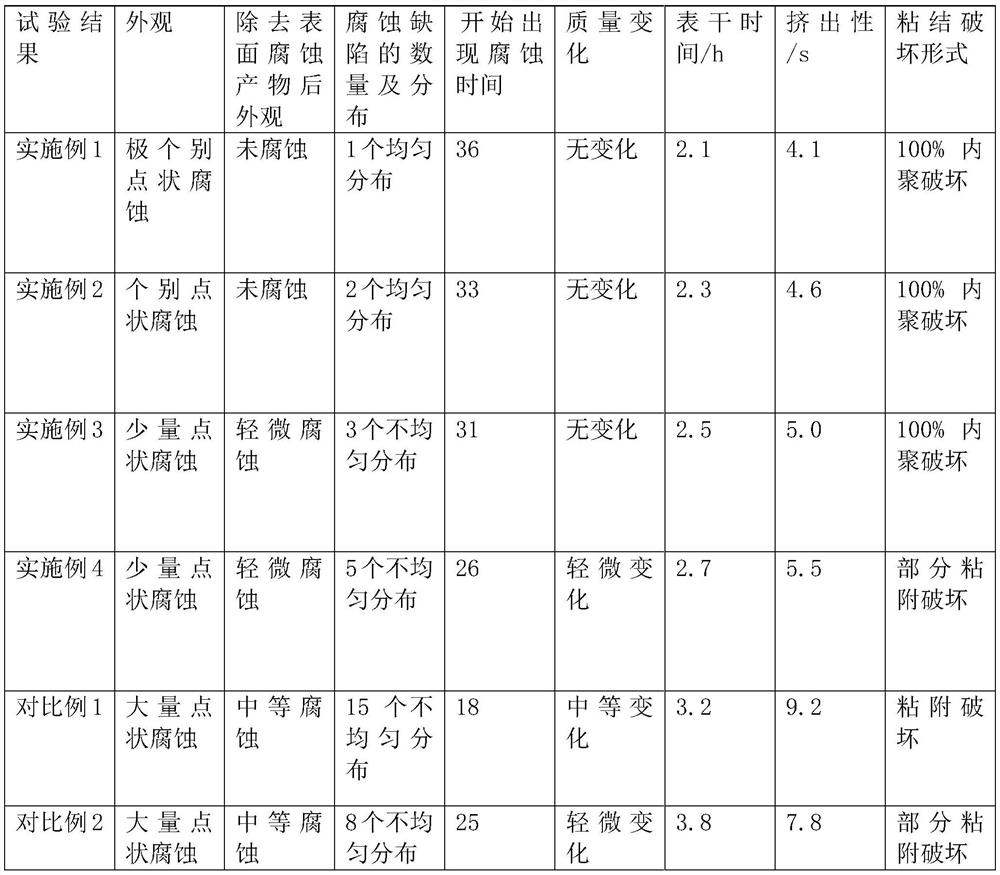

Examples

Embodiment 1

[0049] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0050] (1) Prepare substrate tackifier

[0051] (3,3,3-trifluoropropyl)methyldimethoxysilane, (3,3,3-trifluoropropyl)methyltrimethoxysilane and γ-aminopropyltrimethoxysilane according to The molar ratio is 4:3:3 and mixed and stirred to obtain a mixture.

[0052] Add dropwise an aqueous solution of hydrochloric acid accounting for 30wt% of the total weight of the mixture in the mixture, the concentration of the aqueous solution of hydrochloric acid is 2wt%, the dropping time is controlled at 2h, and the reaction temperature is controlled at 55°C. After the dropwise addition, continue to keep warm React for 2 hours, then wash with water for 3 times, separate the oil layer and dry it, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0053] (2) Preparation of fluorine-...

Embodiment 2

[0056] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0057] (1) Prepare substrate tackifier

[0058] Mix and stir (3,3,3-trifluoropropyl)methyldimethoxysilane and γ-aminopropyltrimethoxysilane at a molar ratio of 1:1 to obtain a mixture.

[0059] In the mixture, add dropwise an aqueous solution of potassium hydroxide accounting for 25wt% of the total weight of the mixture, the concentration of the aqueous solution of potassium hydroxide is 2.5wt%, the dropping time is controlled at 1.5h, and the reaction temperature is controlled at 60° C., dropwise After the addition is complete, continue to keep warm for 3 hours, then wash with water for 3 times, separate the oil layer and dry it, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0060] (2) Preparation of fluorine-containing silicone coating glue

[0061] Mix 60 part...

Embodiment 3

[0063] This example provides a fluorine-containing silicone coating glue and its preparation method, the steps are as follows:

[0064] (1) Prepare substrate tackifier

[0065] (3,3,3-trifluoropropyl)methyldiethoxysilane, (3,3,3-trifluoropropyl)methyltriethoxysilane and γ-aminopropyltriethoxy The silane is mixed and stirred according to the molar ratio of 1:1:1 to obtain a mixture.

[0066] In the mixture, add dropwise an aqueous solution of hydrochloric acid accounting for 35wt% of the total weight of the mixture, the concentration of the aqueous solution of hydrochloric acid is 1.5wt%, the time for dropping is controlled at 2h, and the reaction temperature is controlled at 60°C. After the dropwise addition, continue Insulate and react for 3 hours, then wash with water for 3 times, separate the oil layer and dry, and finally remove the low boilers by distillation under reduced pressure at 80°C and -0.095Mpa to obtain the substrate tackifier.

[0067] (2) Preparation of fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com