A kind of two-component silicone structural adhesive for solar thermal power generation and preparation method thereof

A photothermal power generation, two-component technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reduced bonding strength, reduced cross-linking density of sealing materials, etc., to achieve Effects of improving tensile bond strength, increasing crosslink density, and improving moisture and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

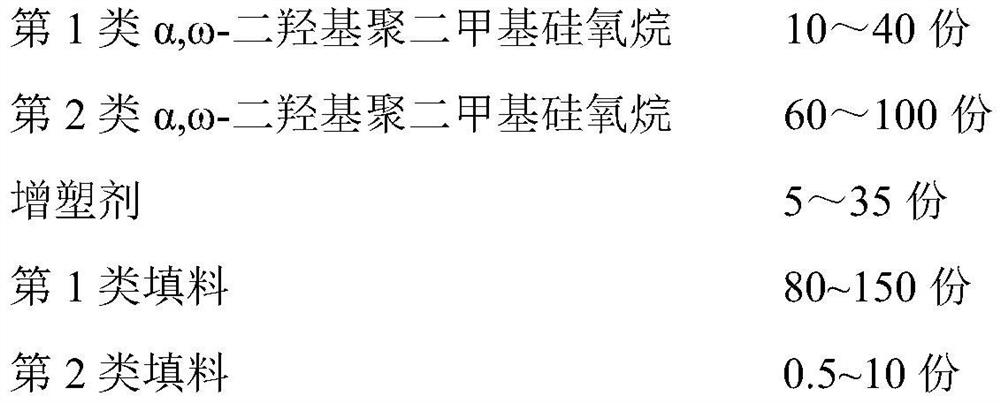

[0053] A component preparation

[0054] 20 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 700mPa·s, 80 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 20000mPa·s, 20 parts of a viscosity of 500mPa ·S polydimethylsiloxane, 30 parts of nano-active calcium carbonate, 50 parts of heavy calcium carbonate, and 5 parts of fumed white carbon black are uniformly dispersed and mixed under vacuum to prepare component A.

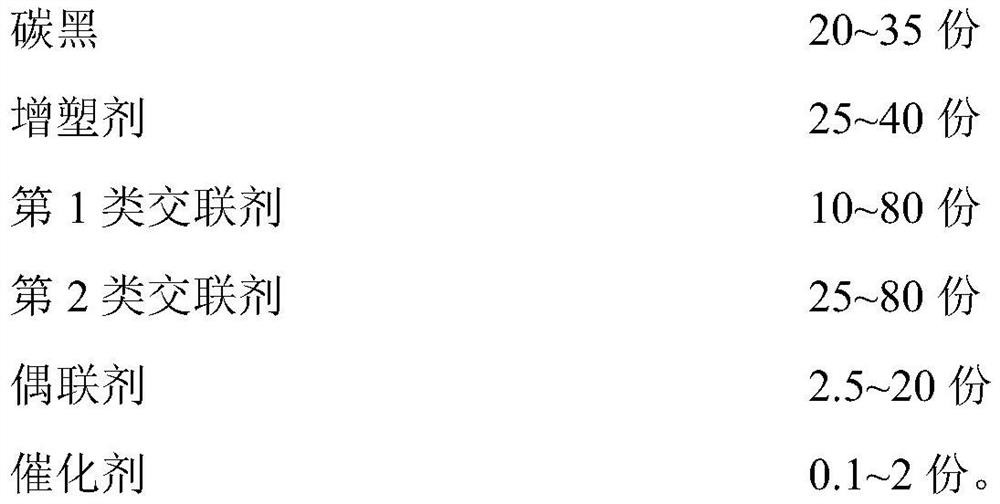

[0055] B component preparation

[0056] 30 parts of pigment carbon black, 40 parts of polydimethylsiloxane with a viscosity of 500mPa·s, 20 parts of the first type of crosslinking agent, 40 parts of tetraethyl orthosilicate, 10 parts of coupling agent, 2 parts of dibutyl The base tin laurate is uniformly dispersed and mixed under vacuum to prepare the B component.

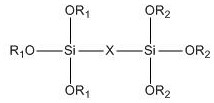

[0057] Among them, the first type of cross-linking agent adopts a cross-linking agent whose X is an ethyl group and R1 and R2 are a methyl structure, and its molecular struc...

Embodiment 2

[0063] A component preparation

[0064] Mix 10 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 700mPa·s, 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 20000mPa·s, 20 parts of a viscosity of 500mPa ·S polydimethylsiloxane, 100 parts of nano-active calcium carbonate, 50 parts of heavy calcium carbonate, and 2 parts of fumed white carbon black are uniformly dispersed and mixed under vacuum to prepare component A.

[0065] B component preparation

[0066] 30 parts of pigment carbon black, 40 parts of polydimethylsiloxane with a viscosity of 500mPa·s, 15 parts of first-class crosslinking agent, 40 parts of tetraethyl orthosilicate, 10 parts of coupling agent, 2 parts of dibutyl The base tin laurate is uniformly dispersed and mixed under vacuum to prepare the B component.

[0067] Among them, the first type of cross-linking agent adopts a cross-linking agent in which X is octyl, R1 and R2 are methyl structures, and its molecular structure is

...

Embodiment 3

[0073] A component preparation

[0074] 40 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 700mPa·s, 60 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 20000mPa·s, 10 parts of a viscosity of 500mPa ·S polydimethylsiloxane, 60 parts of nano-active calcium carbonate, 60 parts of heavy calcium carbonate, and 5 parts of fumed white carbon black are uniformly dispersed and mixed under vacuum to prepare component A.

[0075] B component preparation

[0076] 30 parts of pigment carbon black, 40 parts of polydimethylsiloxane with a viscosity of 500mPa·s, 20 parts of the first type of crosslinking agent, 40 parts of tetraethyl orthosilicate, 10 parts of coupling agent, 2 parts of dibutyl The base tin laurate is uniformly dispersed and mixed under vacuum to prepare the B component.

[0077] Among them, the first type of cross-linking agent adopts the cross-linking agent whose X is ethyl, R1 and R2 are ethyl structure, and its molecular structure is

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com