Nonisocyanate polyurethane

A non-isocyanate, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of long residual time of isocyanate, non-volatile, difficult to eliminate odor, etc., to reduce human injury, long usable time, flexibility excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 non-isocyanate polyurethane

[0038] A component (weight in kilograms):

[0039] raw material name Raw material consumption Acrylic Urethane Resin 70 Defoamer 0.3 Leveling agent A 0.1 Leveling agent B 0.3 Rheology Additives 0.3 Substrate wetting agent 1 N-butyl acetate 18 Propylene glycol methyl ether acetate 10 total 100

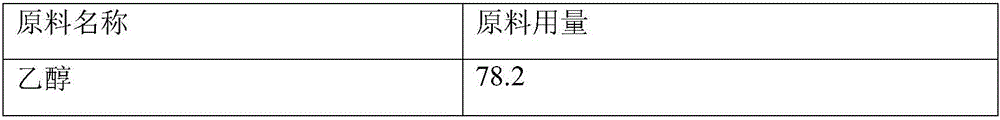

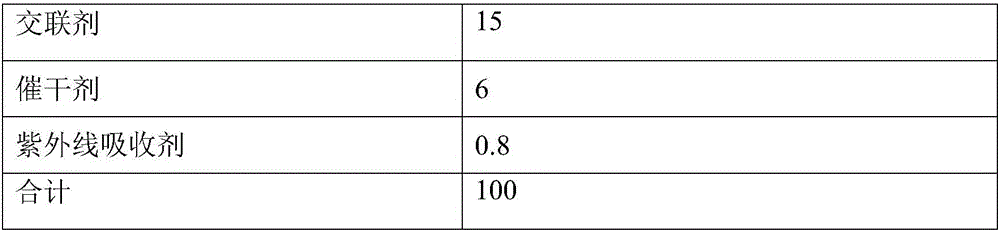

[0040] B component (weight in kilograms):

[0041]

[0042]

[0043] C component (weight in kilograms):

[0044] raw material name Raw material consumption N-butyl acetate 68 Propylene glycol methyl ether acetate 32 total 100

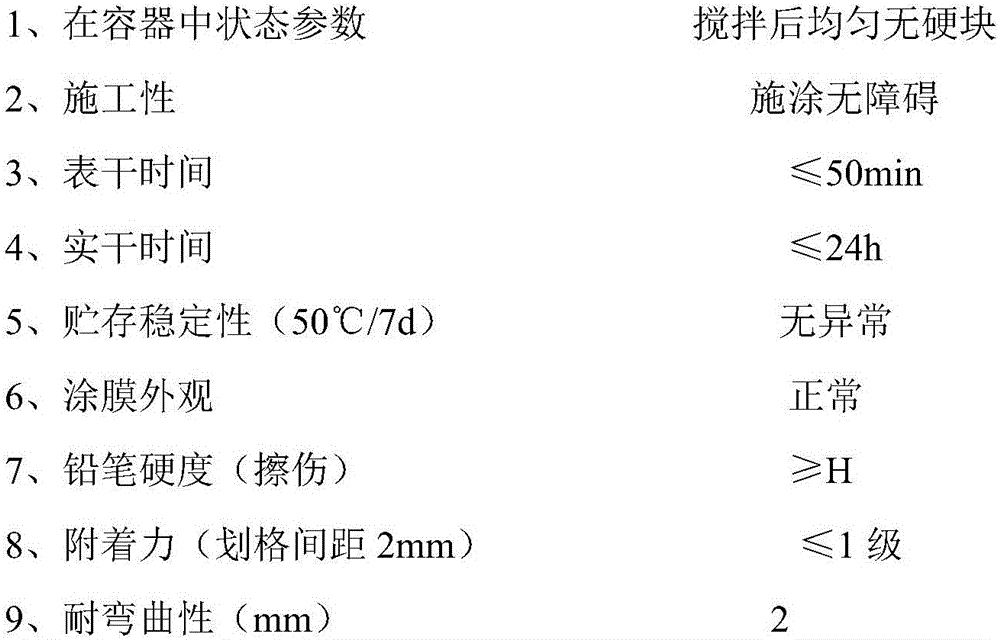

[0045] Production process: Component A: Add resin, defoamer, leveling agent, rheological additive, substrate wetting agent and some solvents and stir at high speed for 20 minutes until uniform → add the remaining solvent and stir at medium speed for 10 minutes to obtain A component. Component B: Mix etha...

Embodiment 2

[0051] Embodiment 2 non-isocyanate polyurethane

[0052] A component (weight in kilograms):

[0053] raw material name Raw material consumption Acrylic Urethane Resin 73 Defoamer 0.5 Leveling agent A 0.1 Leveling agent B 0.3 Rheology Additives 0.5 Substrate wetting agent 0.6 N-butyl acetate 15 Propylene glycol methyl ether acetate 10 total 100

[0054] B component (weight in kilograms):

[0055]

[0056]

[0057] C component (weight in kilograms):

[0058] raw material name Raw material consumption N-butyl acetate 70 Propylene glycol methyl ether acetate 30 total 100

[0059] Production process: Component A: Add resin, defoamer, leveling agent, rheological additive, substrate wetting agent and some solvents and stir at high speed for 20 minutes until uniform → add the remaining solvent and stir at medium speed for 10 minutes to obtain A component. Component B: Mix et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com