High-heat-conduction halogen-free expansion flame-retardant epoxy resin pouring sealant and preparation method thereof

An epoxy resin, intumescent flame retardant technology, used in epoxy resin adhesives, adhesives, polymer adhesive additives, etc. Low production cost, small amount of flame retardant, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

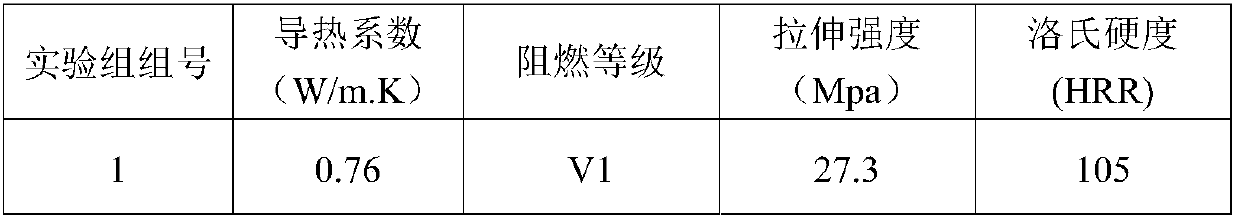

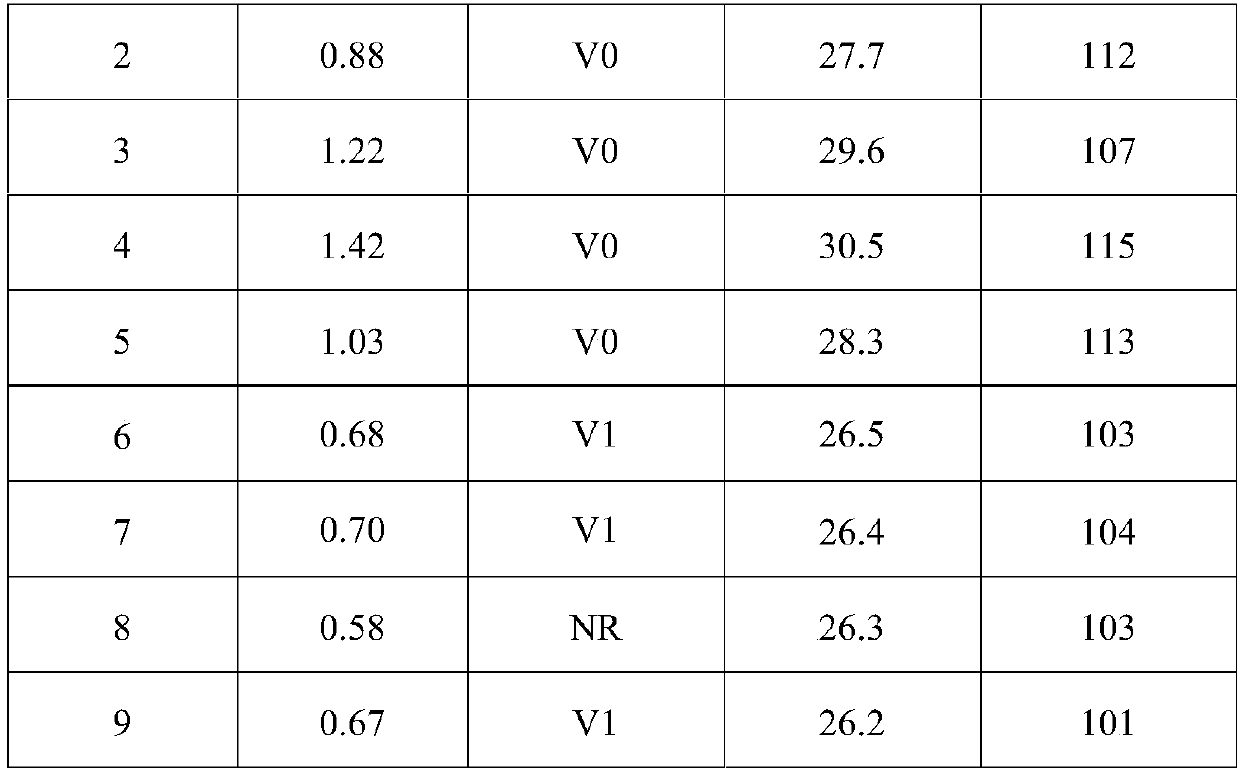

Examples

preparation example Construction

[0021] The preparation method of the high thermal conductivity halogen-free expansion flame-retardant epoxy resin potting compound provided by the embodiment of the present invention includes:

[0022] Preparation of the first epoxy component:

[0023] (1) In parts by weight, weigh 100-120 parts of epoxy resin, 10-15 parts of toughening agent; 8-20 parts of epoxy reactive diluent, 0.5-1.0 parts of dispersing anti-sedimentation agent, and 0.5-1.0 parts of the agent are mixed to form the first mixture;

[0024] Preferably, the epoxy resin includes DER331 epoxy resin and TDE85 epoxy resin, and the mass ratio of DER331 epoxy resin to TDE85 epoxy resin is 4:1. Among them, the room temperature curing agent can be used in conjunction with DER331 epoxy resin. Certain properties, such as chemical resistance and glass transition temperature, can be improved by curing DER331 epoxy resin at elevated temperatures. The overall performance of TDE85 epoxy resin is good, the increase of fun...

Embodiment 1

[0042] This embodiment provides a method for preparing a high thermal conductivity halogen-free expansion flame-retardant epoxy resin potting compound, including the following preparation steps:

[0043] Preparation of the first epoxy component:

[0044] (1) In parts by weight, 100 parts of DER331 and TDE85 epoxy resins were weighed at a mass ratio of 4:1, and 12 parts of liquid silicone rubber and active nano-calcium carbonate were weighed at a mass ratio of 1:1. 10 parts of propane phenyl ether, 0.7 parts of dispersing and anti-settling agent, and 1 part of defoaming agent were mixed and stirred at high speed for 20 minutes to form the first mixture;

[0045] (2) In parts by weight, 40 parts of mixtures of zinc oxide and boron nitride modified by coupling agent A151 are used to prepare high thermal conductivity filler components, wherein the mass ratio of zinc oxide and boron nitride is 9: 1. The mass ratio of coupling agent A151 to the mixture is 2:98, stir at high speed f...

Embodiment 2

[0051] This embodiment provides a method for preparing a high thermal conductivity halogen-free expansion flame-retardant epoxy resin potting compound, including the following preparation steps:

[0052] Preparation of the first epoxy component:

[0053] (1) In parts by weight, 110 parts of DER331 and TDE85 epoxy resins were weighed at a mass ratio of 4:1, and 10 parts of liquid silicone rubber and active nano-calcium carbonate were weighed at a mass ratio of 1:1. 13 parts of propane phenyl ether, 1 part of dispersing anti-sedimentation agent, and 1 part of defoamer were mixed and stirred at high speed for 20 minutes to form the first mixture;

[0054] (2) In parts by weight, 50 parts of mixtures of zinc oxide and boron nitride modified by coupling agent A151 are used to prepare high thermal conductivity filler components, wherein the mass ratio of zinc oxide and boron nitride is 3: 1. The mass ratio of coupling agent A151 to the mixture is 2:98, stir at high speed for 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com