Printing ink as well as preparation method and application thereof

An ink and urethane acrylate technology, which is applied in the field of light-curing screen printing ink preparation, can solve the problems of incomplete curing, the ink layer is easily broken into pieces, and the curing speed is slow, and achieves fast curing speed, low breaking strength, low brittleness and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

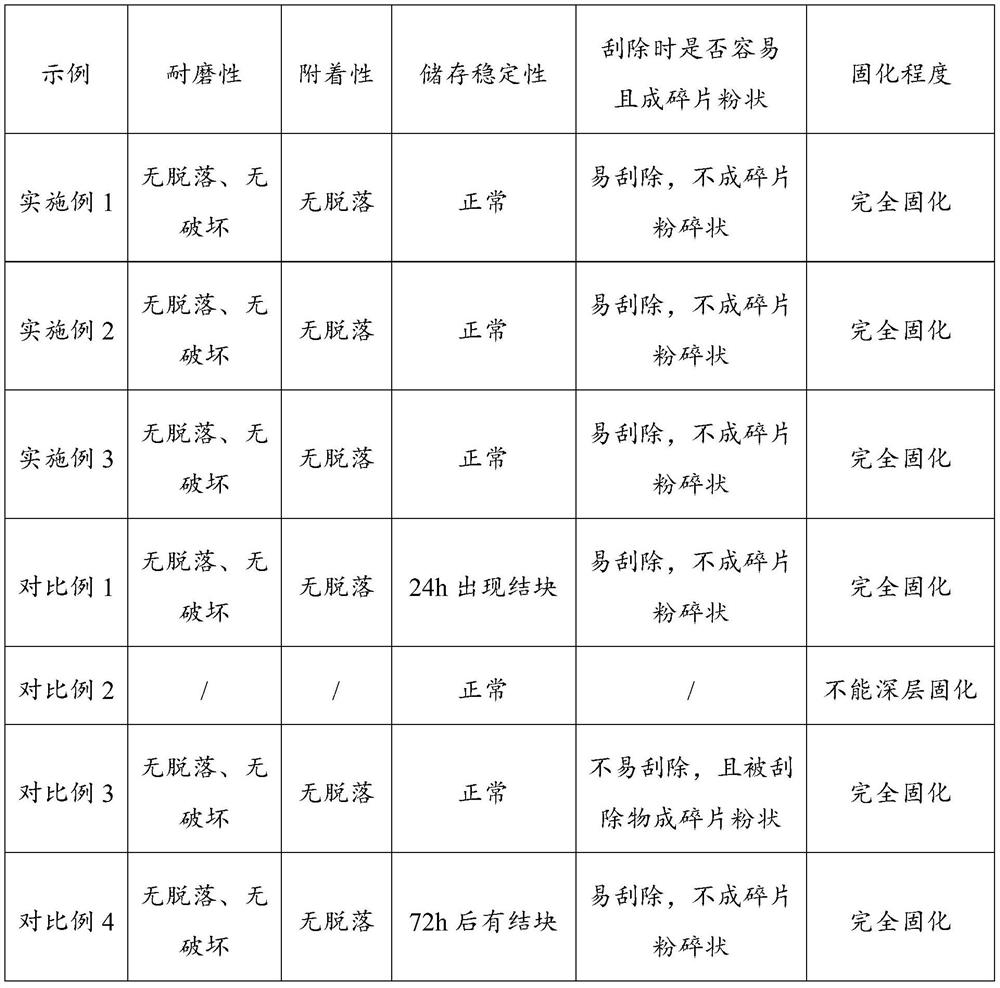

Examples

Embodiment 1

[0042]This embodiment provides an ink, including 3.5kg difunctionality polyether polyol urethane acrylate (SU530), 1.5kg modified epoxy acrylate (SE1701), 1.0kg methacrylate hydroxyethyl ester, 1.5kg Ethoxylated trimethylolpropane triacrylate, 0.25kg 2-hydroxy-2-methyl-1-phenyl-1-propanone, 0.35kg 2,4,6-trimethylbenzoyl-diphenyloxy Phosphine, 0.1kg benzophenone, 0.2kg active amine, 1.5kg coated silver paste, 0.05kg tris(N-nitroso-N-phenylhydroxylamine) aluminum salt, 0.02kg KS-66 and 0.03kg BYK333 ; Wherein, the coated silver paste of the present embodiment is FLQ3.

[0043] The preparation method of above-mentioned ink comprises the following steps,

[0044] (1) Mix the difunctional polyether polyol urethane acrylate, modified epoxy acrylate, methacrylate hydroxyethyl ester and ethoxylated trimethylolpropane triacrylate of the above quality, stir for 5 minutes until uniform, Stirring speed is 900 rev / min;

[0045] (2) Then add 2-hydroxy-2-methyl-1-phenyl-1-propanone, 2,4,6...

Embodiment 2

[0049] This embodiment provides an ink, including 4.0kg difunctional polyether polyol urethane acrylate (CN966H90), 1.0kg modified epoxy acrylate (EB3701), 1.0kg acryloylmorpholine, 1.0kg ethoxylated Methylolpropane triacrylate, 0.25kg 1-hydroxycyclohexyl phenyl ketone, 0.35kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 0.1kg benzophenone, 0.3kg Active amine, 2kg coated aluminum paste, 0.04kg tris(N-nitroso-N-phenylhydroxylamine) aluminum salt, 0.02kg K-750 defoamer and 0.03kg TEGO Rad-2200N leveling agent; among them, The coated aluminum paste in this embodiment is FLX4.

[0050] The preparation method of above-mentioned ink comprises the following steps,

[0051] (1) Mix the difunctional polyether polyol urethane acrylate, modified epoxy acrylate, acryloyl morpholine and ethoxylated trimethylolpropane triacrylate of the above quality, stir for 5 minutes until uniform, and the stirring speed is 900 rev / min;

[0052] (2) Then add 1-hydroxycyclohexyl phenyl ketone, 2,4,6...

Embodiment 3

[0056] This embodiment provides an ink, including 3.0kg difunctionality polyether polyol urethane acrylate (SU530), 2.0kg modified epoxy acrylate (SE1701), 3.0kg acryloyl morpholine, 0.3kg1-hydroxyl ring Hexyl phenyl ketone, 0.3kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 0.2kg benzophenone, 0.1kg active amine, 1.0kg coated silver paste, 0.03kg three (N-nitroso-N-phenylhydroxylamine) aluminum salt 0.02kg KS-66 defoamer and 0.03kg TEGORad-2200N leveling agent; wherein, the coated silver paste of the present embodiment is FLQ3.

[0057] The preparation method of above-mentioned ink comprises the following steps,

[0058] (1) Mix the difunctional polyether polyol urethane acrylate, modified epoxy acrylate, and acryloyl morpholine of the above quality, stir for 5 minutes until uniform, and the stirring speed is 900 rpm;

[0059] (2) Then add 1-hydroxycyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, benzophenone, active amine, three (N-nitroso- N-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com