Test method for endurance of photovoltaic component in hot and humid environments

A technology of photovoltaic modules and testing methods, applied in the monitoring of photovoltaic systems, optical testing flaws/defects, photovoltaic power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

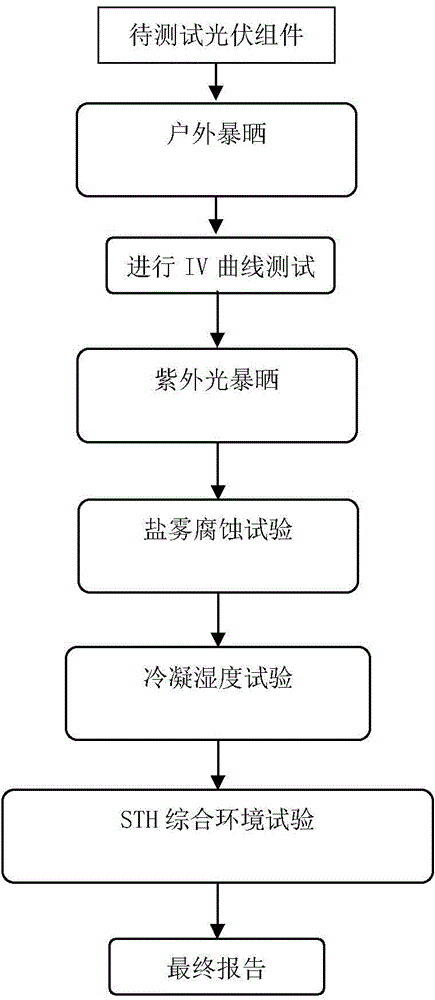

[0028] Such as figure 1 As shown, it is a method for testing the durability of a photovoltaic module in a hot and humid environment according to the present invention. This test sequence requires at least one photovoltaic module as the photovoltaic module to be tested, and another photovoltaic module as the control module.

[0029] After receiving the photovoltaic modules to be tested, enter the laboratory testing process, and carry out numbering and visual inspection of the photovoltaic modules to be tested.

[0030] Include the following steps:

[0031] ⑴ Expose the photovoltaic modules to be tested in the open circuit state outdoors to avoid performance attenuation of photovoltaic modules caused by early light-induced attenuation;

[0032] The photovoltaic modules to be tested are placed on an outdoor static shelf under open-circuit conditions, and exposed to natural light in an open-circuit state to ensure that the total irradiance of the photovoltaic modules to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com