Quality determination and identification method of material for moxibustion therapy

A technology of quality measurement and heat release, which is applied in the field of quality measurement and identification of moxibustion materials, can solve the problems of inaccurate judgment, limited methods of moxibustion material moxa, and easy to produce deviations, etc., to achieve short and accurate testing High performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

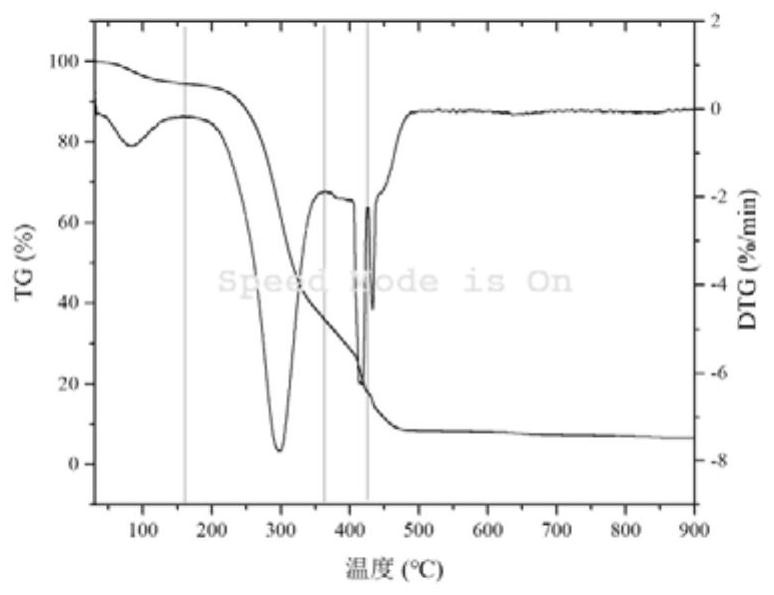

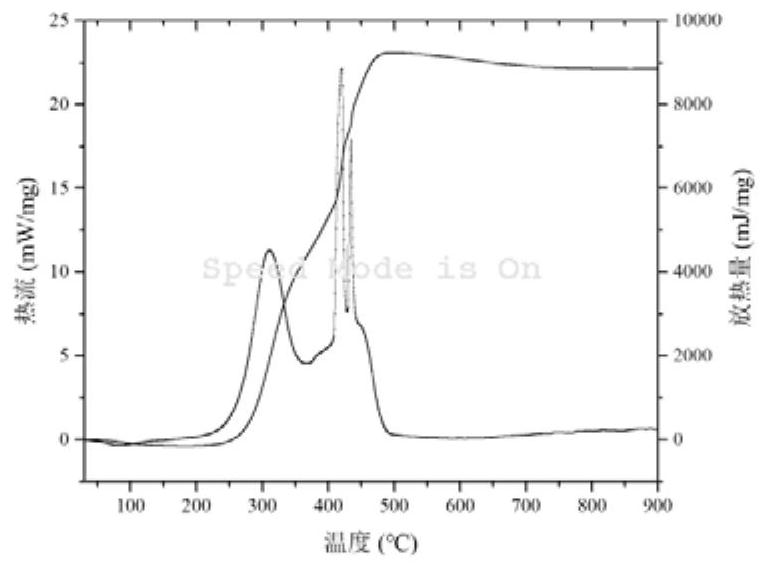

[0070] Weigh about 7mg of one-year-old moxa from a real estate in Jiangxi (the ratio of leaf to cashmere is 5:1), and put it into the Al 2 o 3 In the crucible, set the temperature program range to 28-900°C, the heating rate to 10°C / min, the reaction gas to be oxygen, and the flow rate to be 20mL / min, to obtain the data of the change of sample mass and heat flow with time, After normalization, we get figure 1 with figure 2 .

[0071] The thermal degradation process of moxa is divided into four stages. Stage I (28°C-160°C) is the stage of water evaporation and loss of volatile substances, Stage II (160°C-363°C) is the stage of oxidative decomposition and combustion, stage III (363 ℃~426℃) and IV (426℃~900℃) are the stages of charring combustion and burnout. Stage II is the main thermal degradation stage, with a weight loss rate of 59.0% and a maximum weight loss rate of 7.8% / min; the sum of the weight loss rates of stages III and IV is 27.5%, and a maximum weight loss rate ...

Embodiment 2

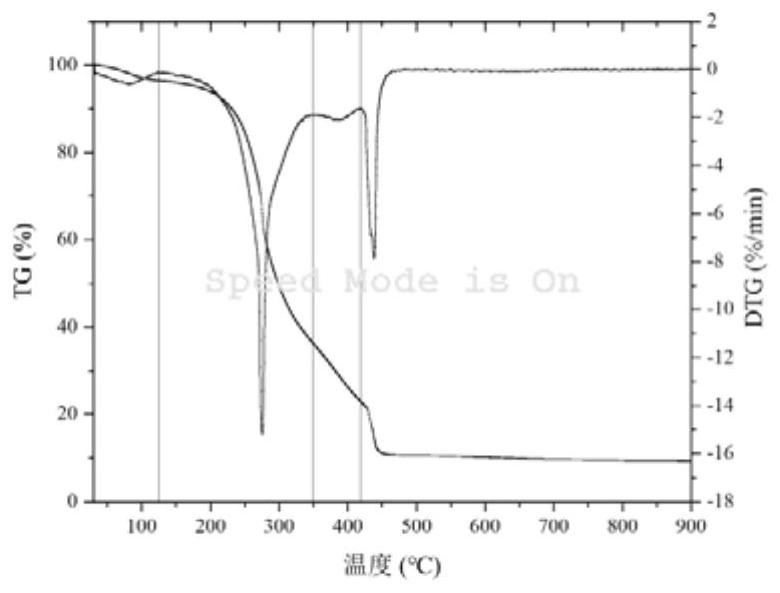

[0074] Weigh about 8 mg of one-year-old moxa from a real estate in Jiangxi (the ratio of leaf to cashmere is 10:1), and put it into the Al 2 o 3 In the crucible, set the temperature program range to 35-900°C, the heating rate to 10°C / min, the reaction gas to be air, and the flow rate to be 100mL / min, to obtain the data on the change of sample mass and heat flow with time, After normalization, we get image 3 with Figure 4 .

[0075] The thermal degradation process of moxa is divided into four stages. Stage I (35°C-124°C) is the stage of water evaporation and loss of volatile substances. Stage II (124°C-345°C) is the stage of oxidative decomposition and combustion. Stage III (345°C) ℃~419℃) and IV stage (419℃~900℃) are charring combustion and burnout stages. The weight loss rate of stage II was 60.1%, and the maximum weight loss rate was 15.2% / min; the sum of the weight loss rates of stage III and IV was 25.7%, and the maximum weight loss rate was 7.7% / min. The ratio of w...

Embodiment 3

[0078] Weigh two parts of about 7.5 mg of one-year-old moxa from a real estate in Henan (the ratio of leaf to cashmere is 5:1), put them into the crucibles of thermogravimetric (TG) and differential thermal analyzer (DSC) respectively, and set the temperature program range to 30 ℃~900℃ and 100℃~600℃, the heating rate is 10℃ / min, the reaction gas is air, and the flow rate is 100mL / min, the data of the change of sample mass and the change of heat flow with time are obtained, and the After sorting, the result is as follows Figure 5 with Image 6 shown.

[0079] The thermal degradation process of moxa is divided into four stages. Stage I (30°C-136°C) is the stage of water evaporation and loss of volatile substances. Stage II (136°C-368°C) is the stage of oxidative decomposition and combustion. Stage III (368°C) ℃~434℃) and stage IV (434℃~900℃) are the stages of charring combustion and burnout. The weight loss rate of stage II was 57.9%, and the maximum weight loss rate was 7.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com