Method for preparing nano-sheet assembled bismuthyl bromide superstructure by adjusting and controlling surfactant

A technology of surfactant and bismuth oxybromide, which is applied in chemical instruments and methods, solution from normal temperature liquid solvent, single crystal growth, etc., can solve the problems of unfavorable environmental protection, rational application of resources, difficult control of product size, high production cost, etc. problem, to achieve good visible light photocatalytic performance, easy industrial operation, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

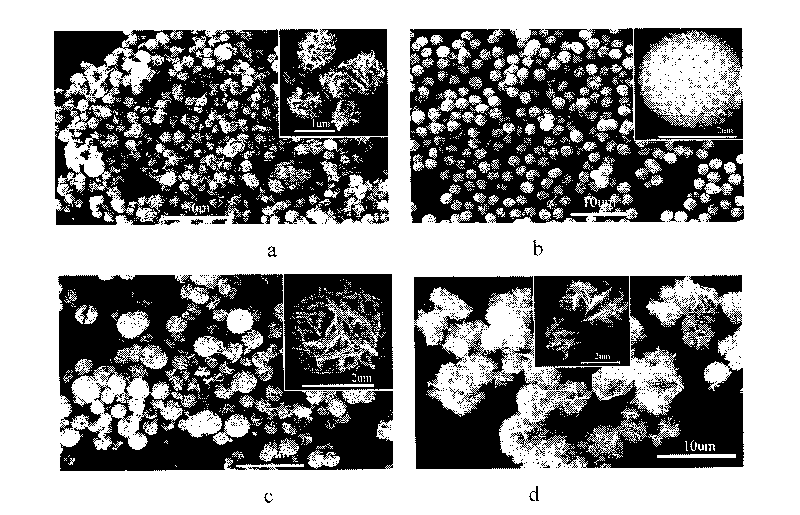

[0025] Example 1: Preparation of flake-like cross-assembled pompom-like and flower-like bismuth oxybromide superstructures

[0026] (1) In a 50ml beaker, add 9ml of ethylene glycol as a solvent, and add 0.5×10 -3 mol Bi(NO 3 ) 3 .5H 2 O, 0.5×10 -3 mol of CTAB and 0.2g of PEG4000, after stirring evenly, transfer the precursor into a 12ml reaction kettle with a straw, and seal the reaction kettle;

[0027] (2) Transfer the reaction kettle to a temperature-controlled furnace, control the reaction temperature to 120° C., and heat at this temperature for 3, 6, 18, and 24 hours respectively.

[0028] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0029] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

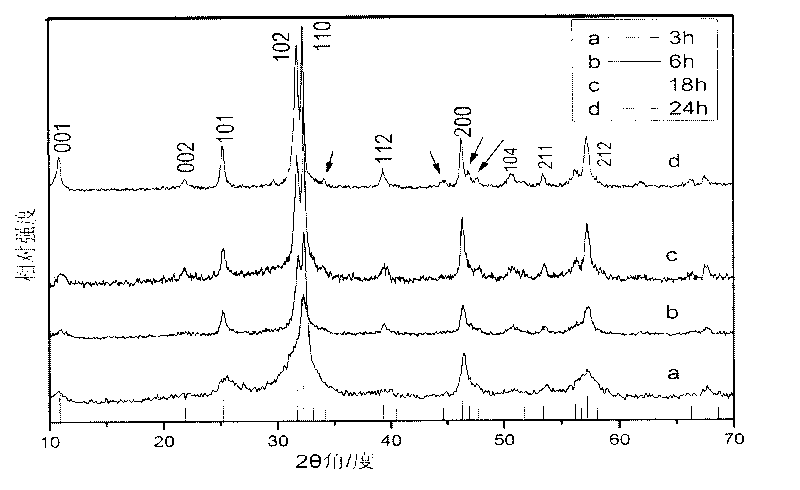

[0030] figure 1 The X-ray powder diffraction patterns of the products ...

Embodiment 2

[0031] Example 2: Preparation of rosette-shaped bismuth oxybromide superstructure

[0032] (1) Add 9ml of ethylene glycol as a solvent to a 50ml beaker, and add 0.5×10 -3 mol Bi(NO 3 ) 3 .5H 2 O, 0.5×10 -3 mol of CTAB and 0.2g of PVP4000, after stirring evenly, transfer the precursor into a 12ml reaction kettle with a straw, and seal the reaction kettle;

[0033] (2) Transfer the reaction kettle to a temperature-controlled furnace, control the reaction temperature to 120° C., and heat at this temperature for 6, 18, and 24 hours respectively.

[0034] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0035] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

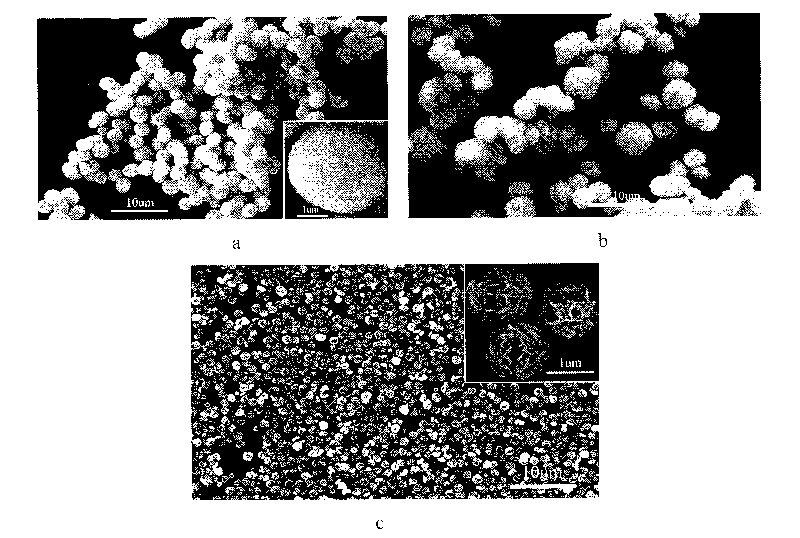

[0036] image 3 Shown are the SEM photographs of the products produced at a reaction temperature of 120°C and control...

Embodiment 3

[0037] Example 3: Preparation of pistachio-shaped and pistachio-shaped bismuth oxybromide superstructures

[0038] (1) In a 50ml beaker, add 9ml of ethylene glycol as a solvent, and add 0.5×10 -3 mol Bi(NO 3 ) 3 .5H 2 O, 0.5×10 -3 mol of NaBr and 0.2g of PVP4000, after stirring evenly, transfer the precursor into a 12ml reaction kettle with a straw, and seal the reaction kettle;

[0039] (2) Transfer the reaction kettle to a temperature-controlled furnace, control the reaction temperature to 120° C., and heat at this temperature for 2, 12, 24, and 48 hours respectively.

[0040] (3) After the reaction was completed, the reactor was taken out and cooled to room temperature naturally.

[0041] (4) Take out the precipitate obtained in the reaction, wash it three times with deionized water and absolute ethanol alternately, and centrifuge after each washing to obtain the desired product.

[0042] The SEM photo of the product ( image 3 a-d) show that: the reaction time is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com