Method for measuring interlocking capability of coarse aggregate

A test method, coarse aggregate technology, applied in the direction of applying stable shear force to test material strength, measuring device, analyzing material, etc., can solve the problem of inability to distinguish shear capacity, evaluation method of asphalt mixture skeleton strength Unreasonable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

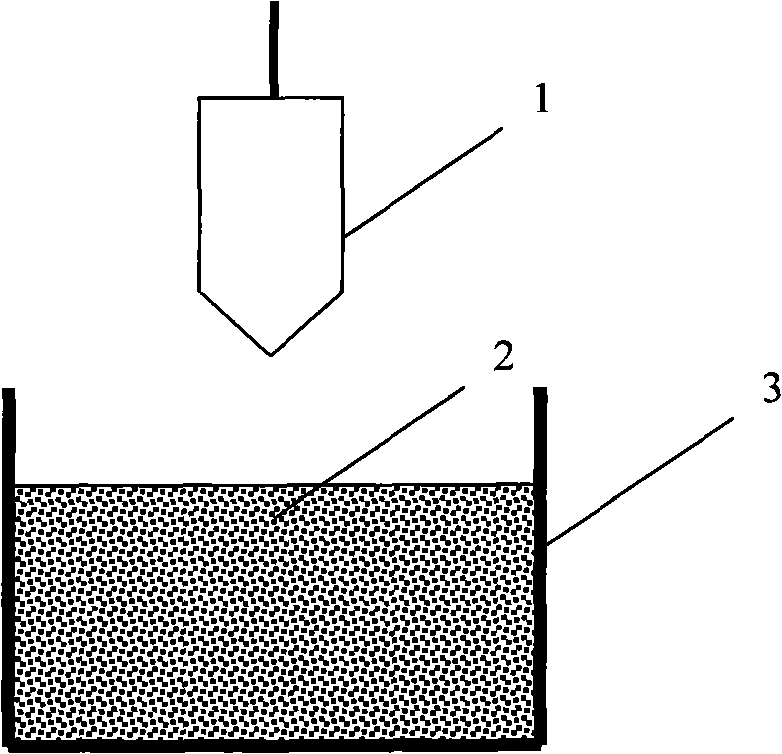

Method used

Image

Examples

Embodiment

[0037] 1.1 single particle size

[0038] According to the test method of the present invention, the difference of material cone penetration energy under the condition of single particle size is compared.

[0039] The material used in the test is basalt produced in Zhangjiakou, Hebei, and all technical indicators meet the requirements of "Technical Standards for Highway Asphalt Pavement Construction". First, the bulk density of aggregates with a single particle size was measured by a tamping tester, and the respective mineral void ratios were calculated. The results are shown in Table 1. It can be seen that with the increase of the particle size, the gap ratio of the mineral material in the compacted state gradually decreases.

[0040] Table 1 Mineral material void ratio and cone penetration energy test results

[0041]

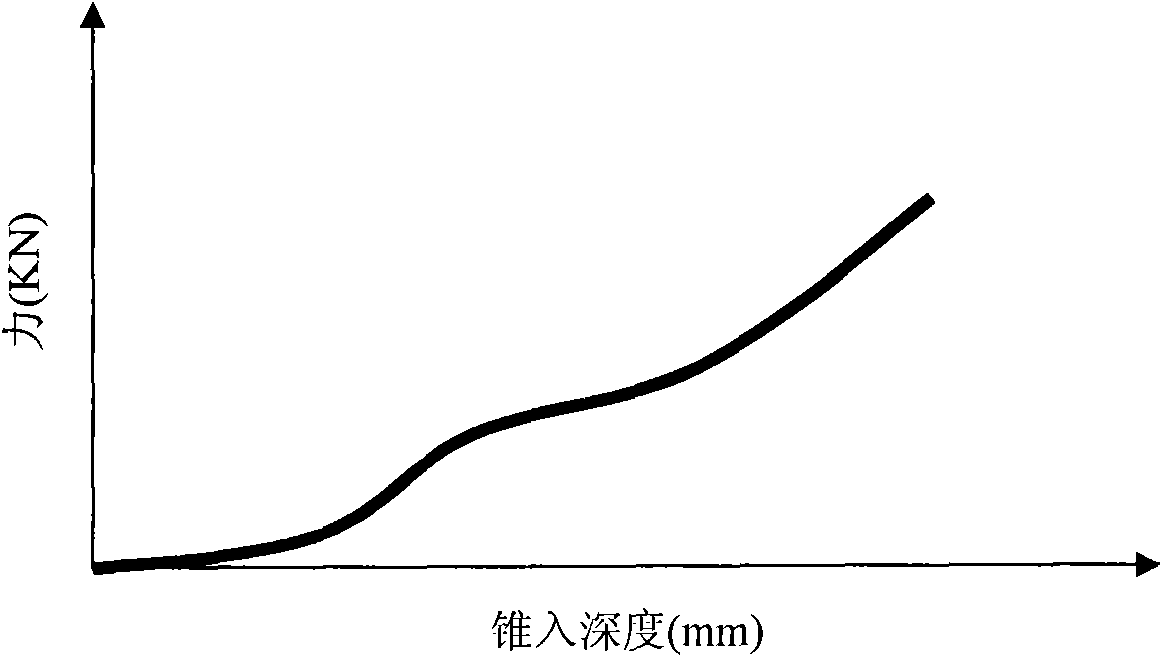

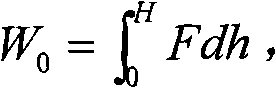

[0042] According to the method of the present invention, the cone penetration test is carried out on each compacted aggregate with a single particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com