Reinforced sealing case based on MTCA standard and assembling method thereof

A chassis and standard technology, applied in the field of reinforced sealed chassis and its assembly based on MTCA standard, can solve the problems of electromagnetic leakage, difficult assembly, long time, etc., and achieve the effect of good assembly and maintainability, and good three-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

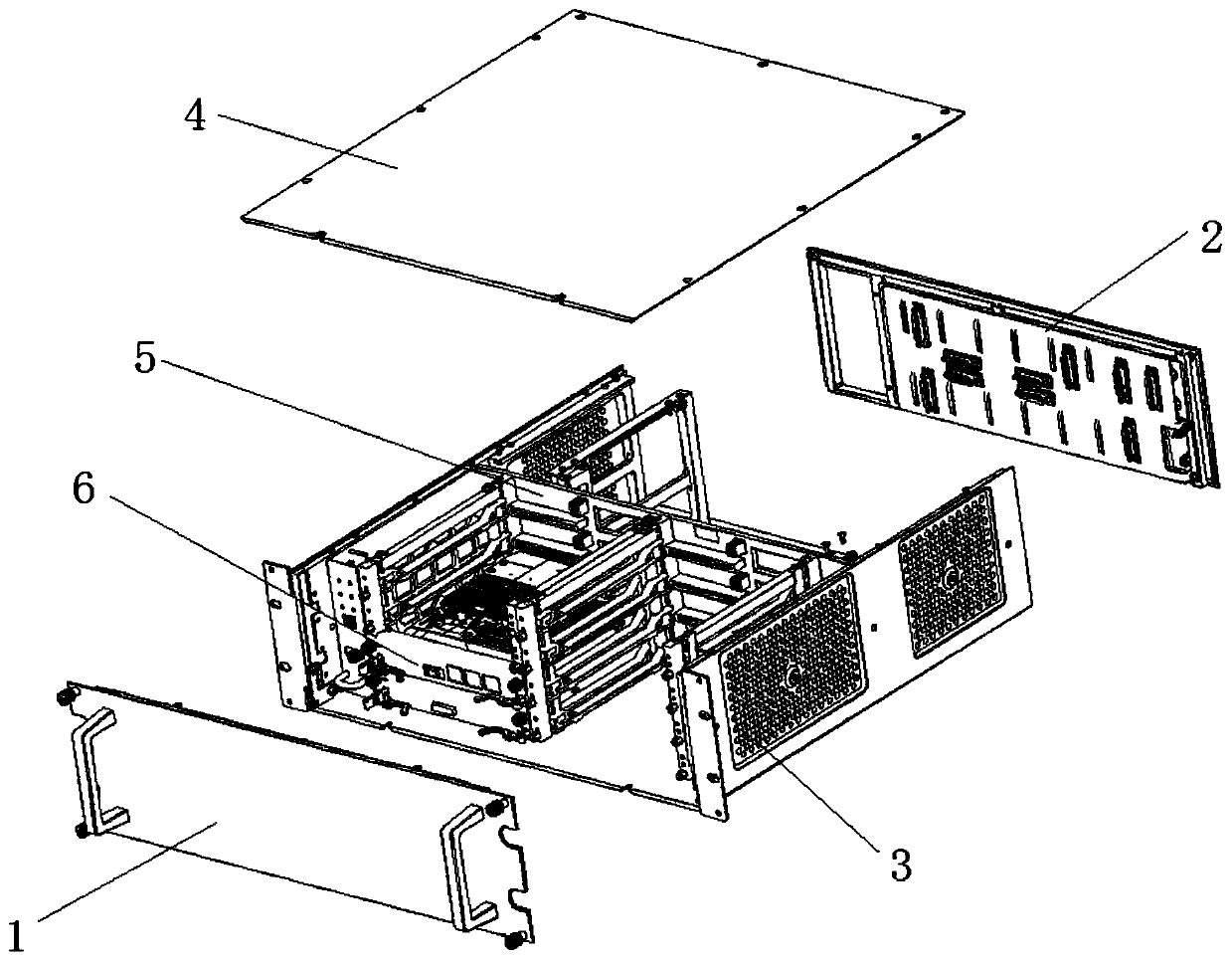

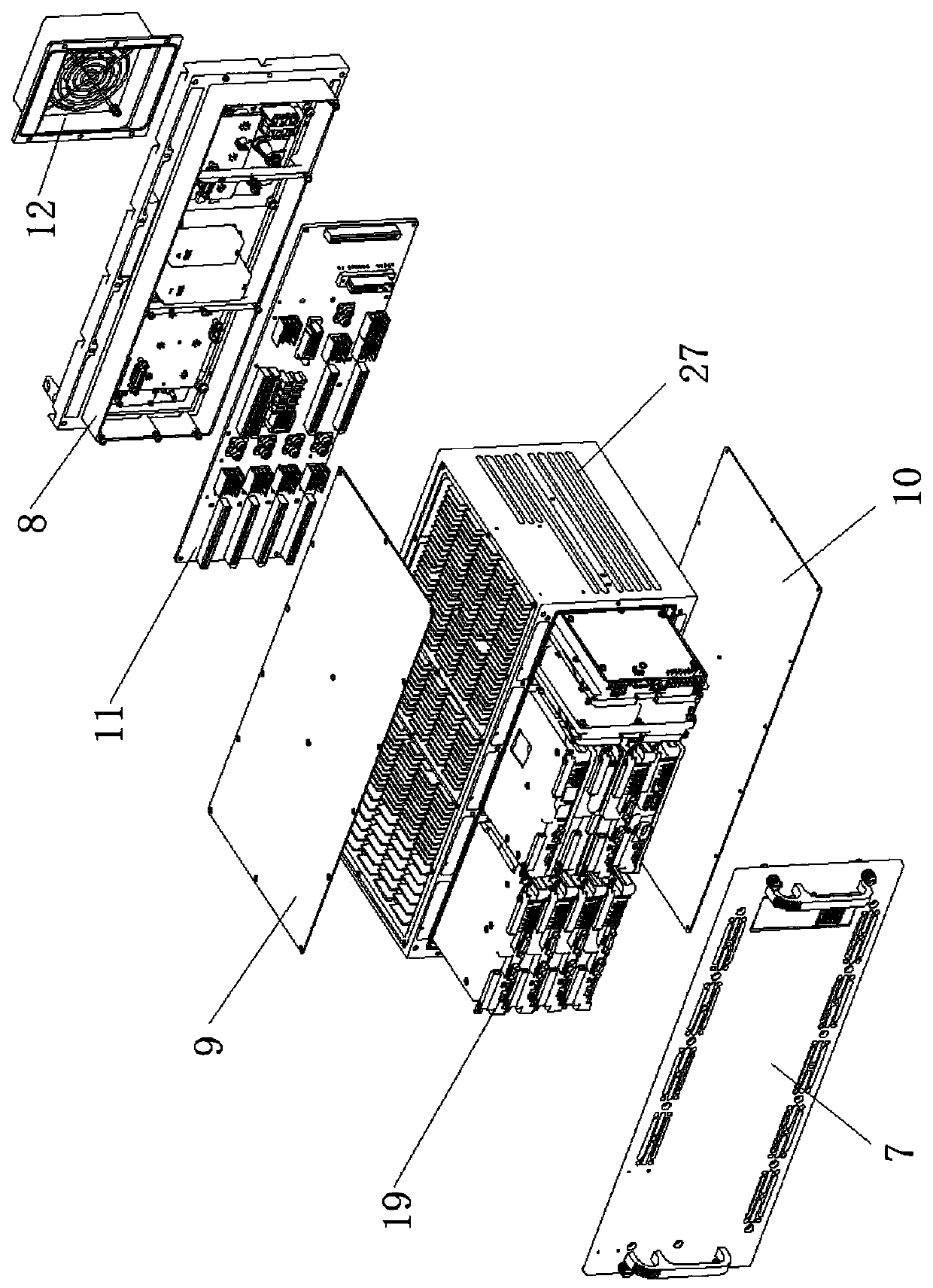

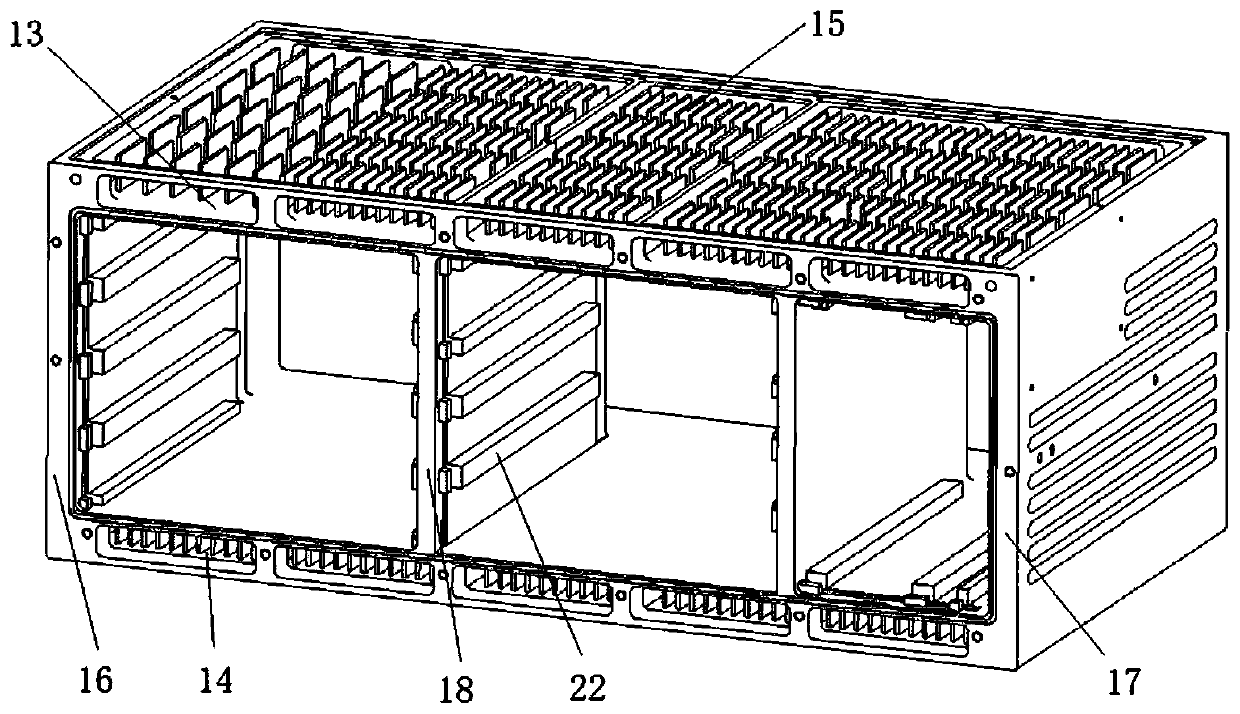

[0060] Such as Figure 2-4 , in order to improve the environmental adaptability of current electronic equipment such as communication or navigation, especially military communication or navigation under harsh environmental conditions, so that the equipment has excellent assembly and maintainability, three-proof ability, heat dissipation ability, Anti-vibration and anti-shock ability, structural electromagnetic compatibility ability, a new type of reinforced and sealed chassis design based on MTCA standard design is proposed. The specific design implementation is as follows:

[0061] 1. Overall structure design

[0062] The whole machine adopts a standard 19-inch rack-mounted 4U chassis, and the external interface (aviation plug connector) is set on the rear panel assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com