Patents

Literature

41results about How to "Good tailoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical dosage form

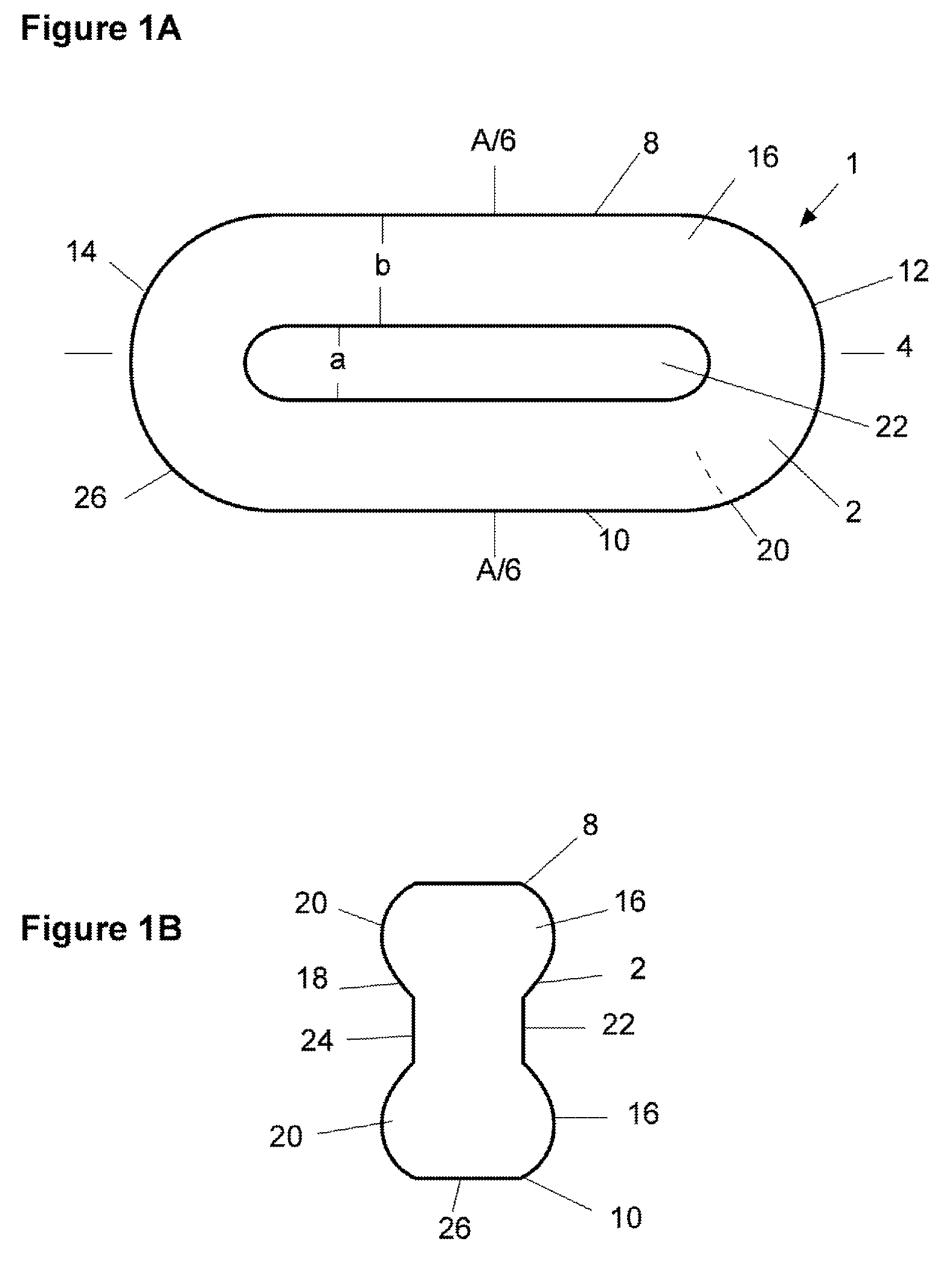

ActiveUS20090202634A1Improved controlled releaseEasy to adjustBiocideOrganic active ingredientsControlled releaseBreaking strength

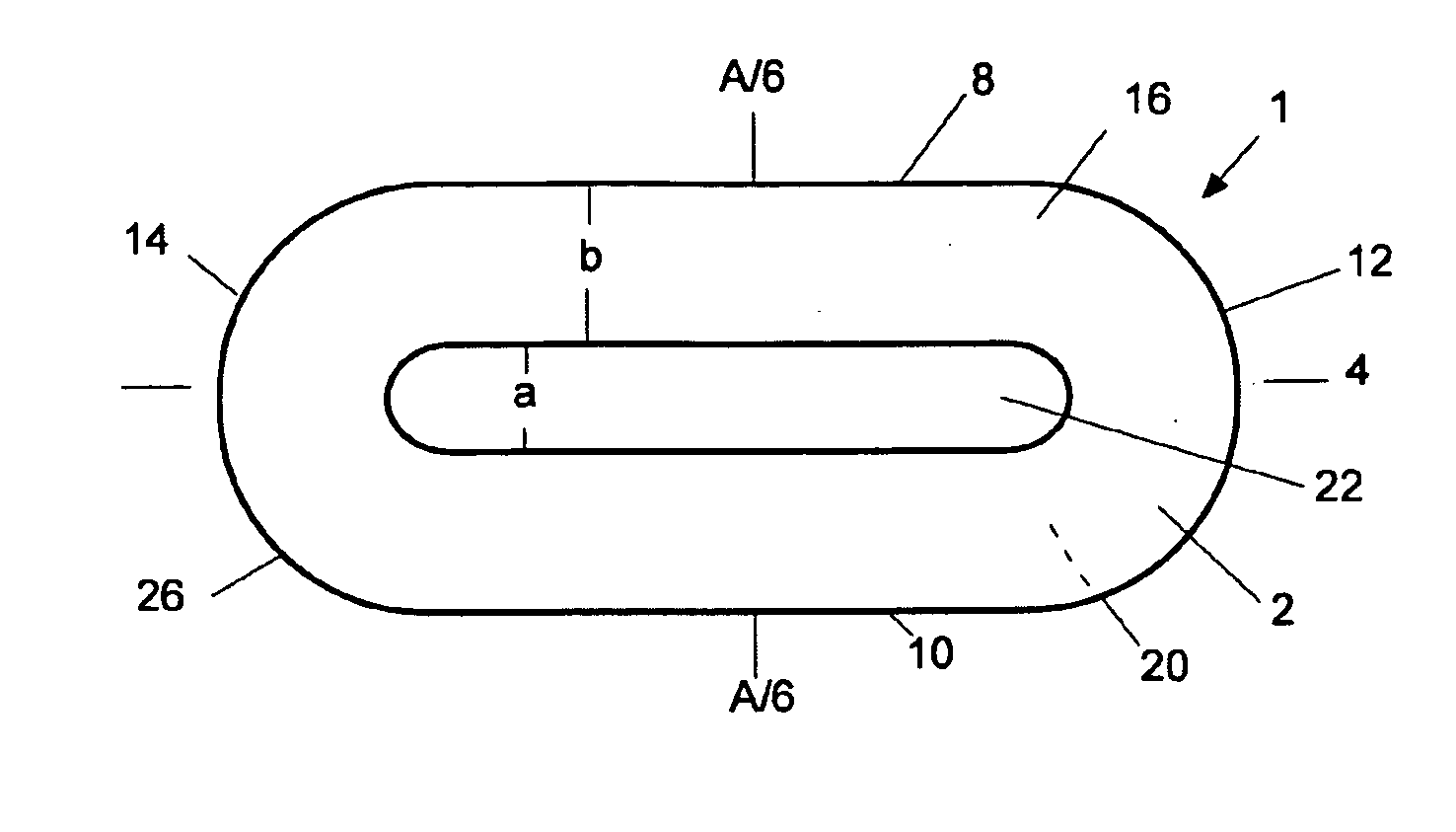

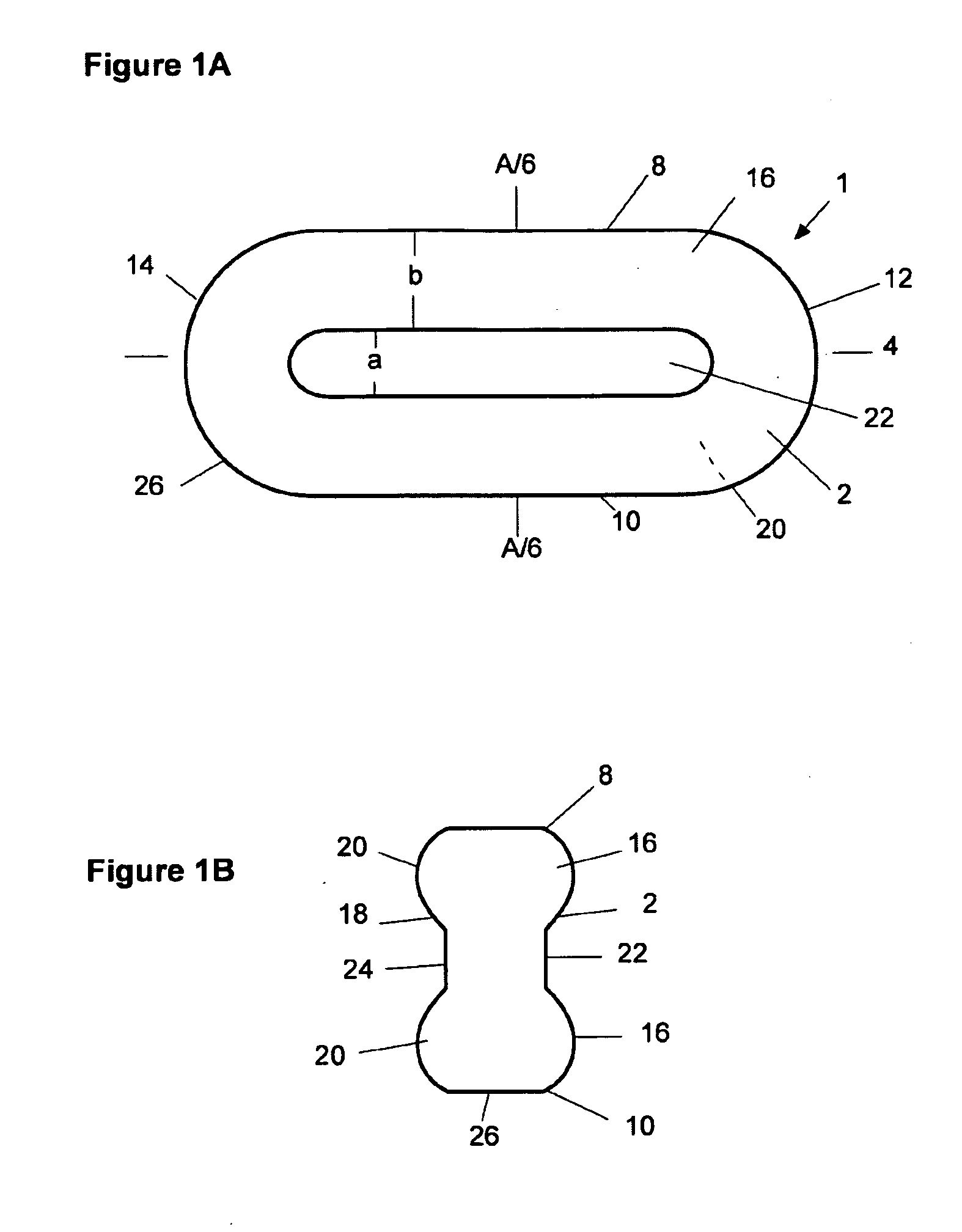

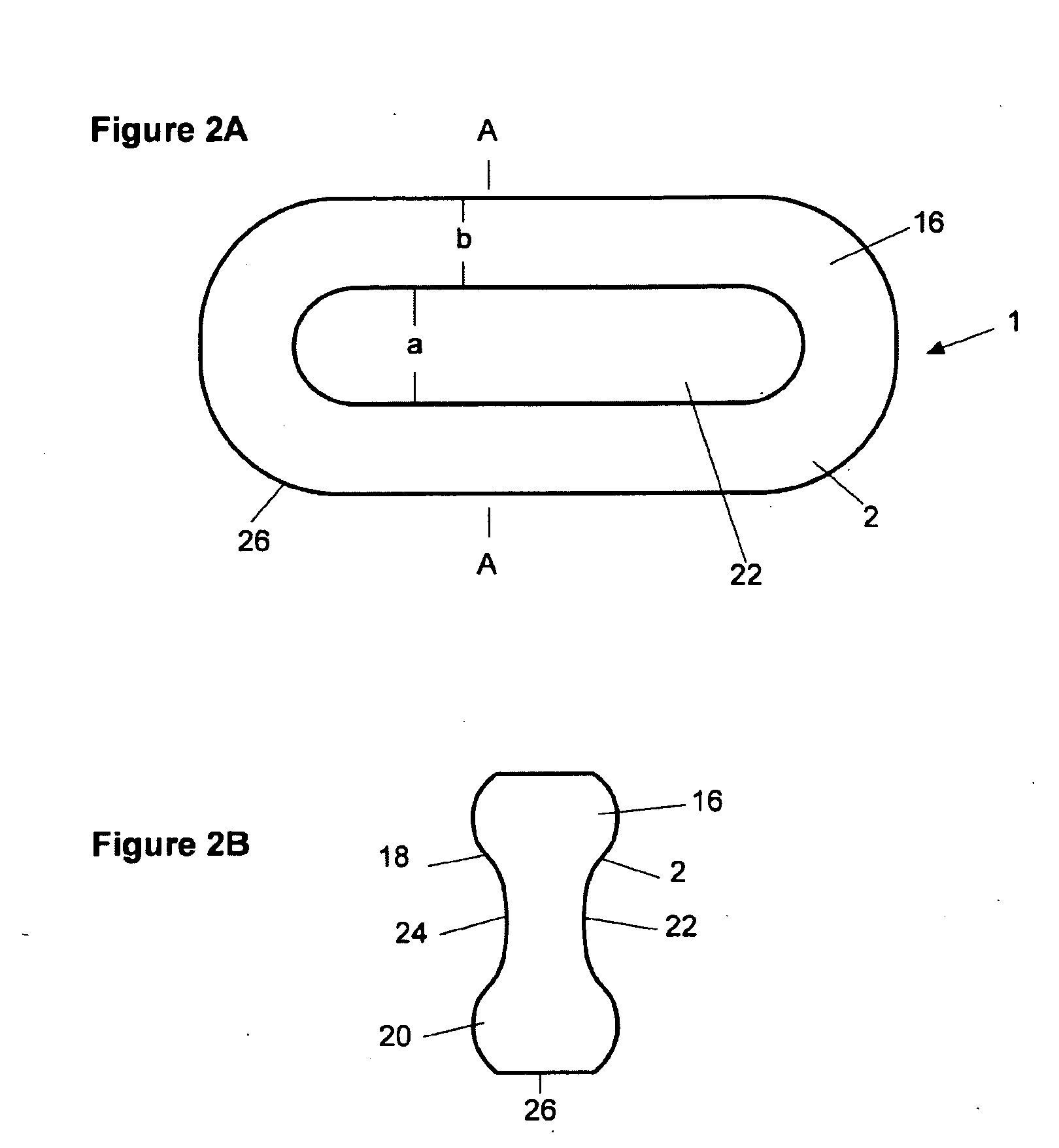

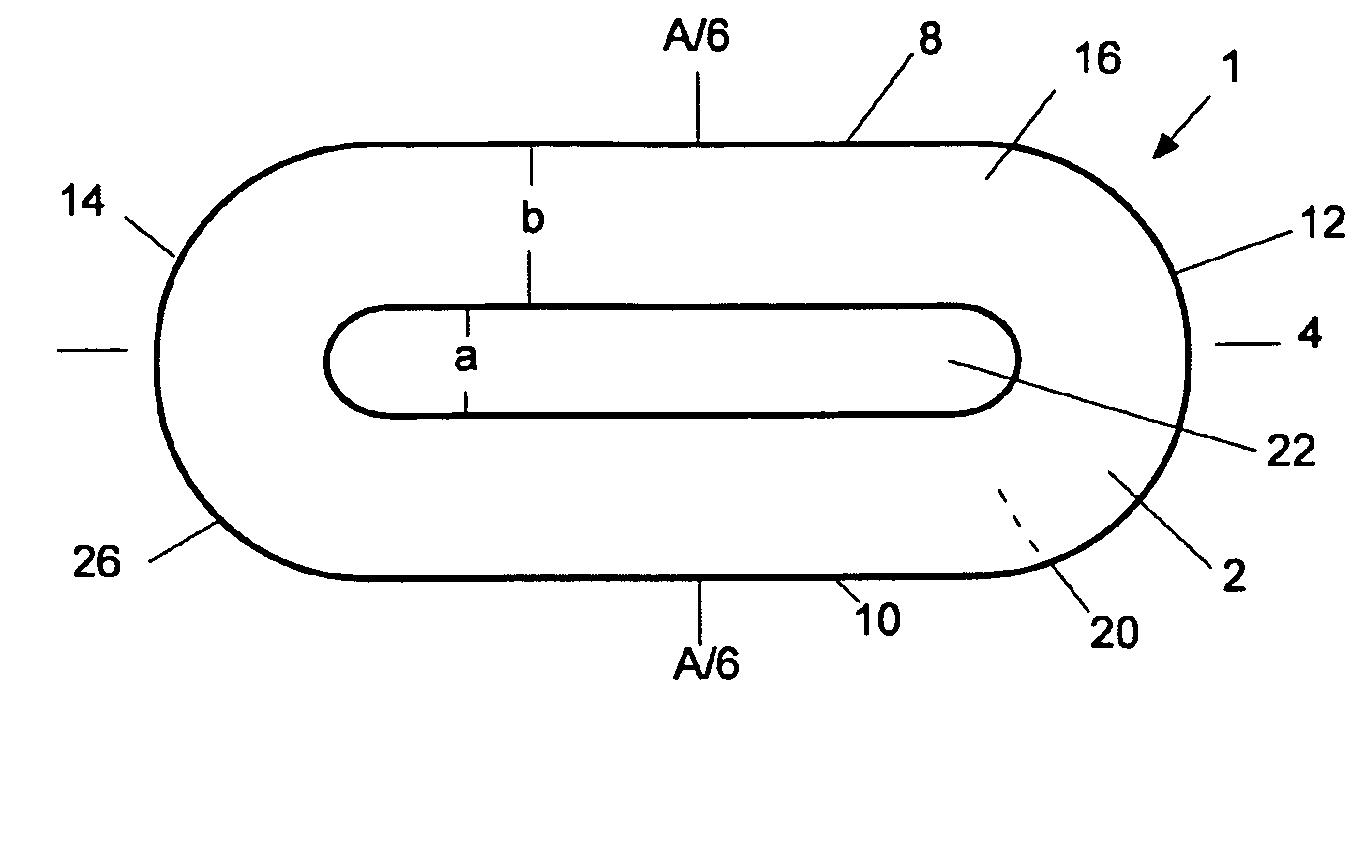

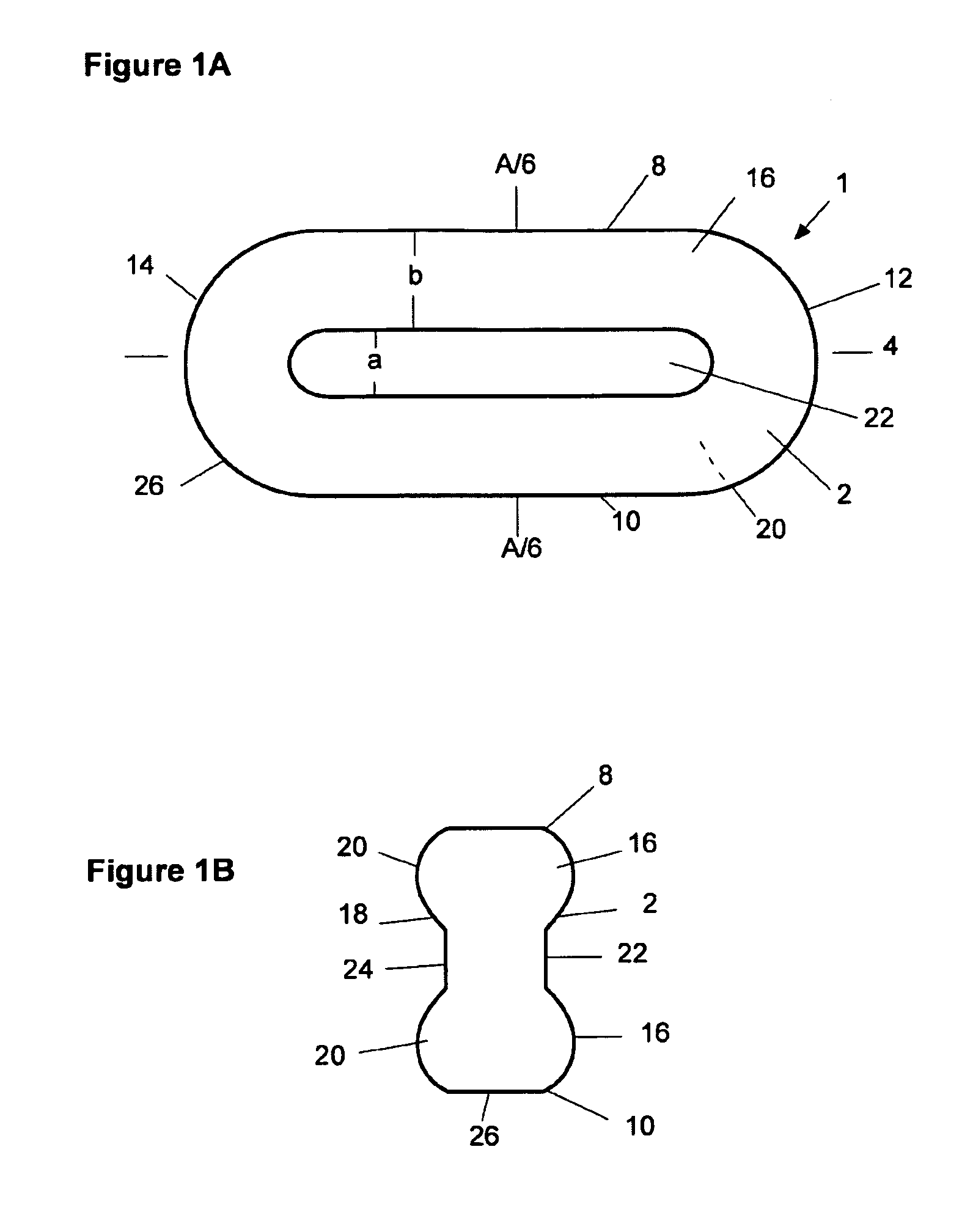

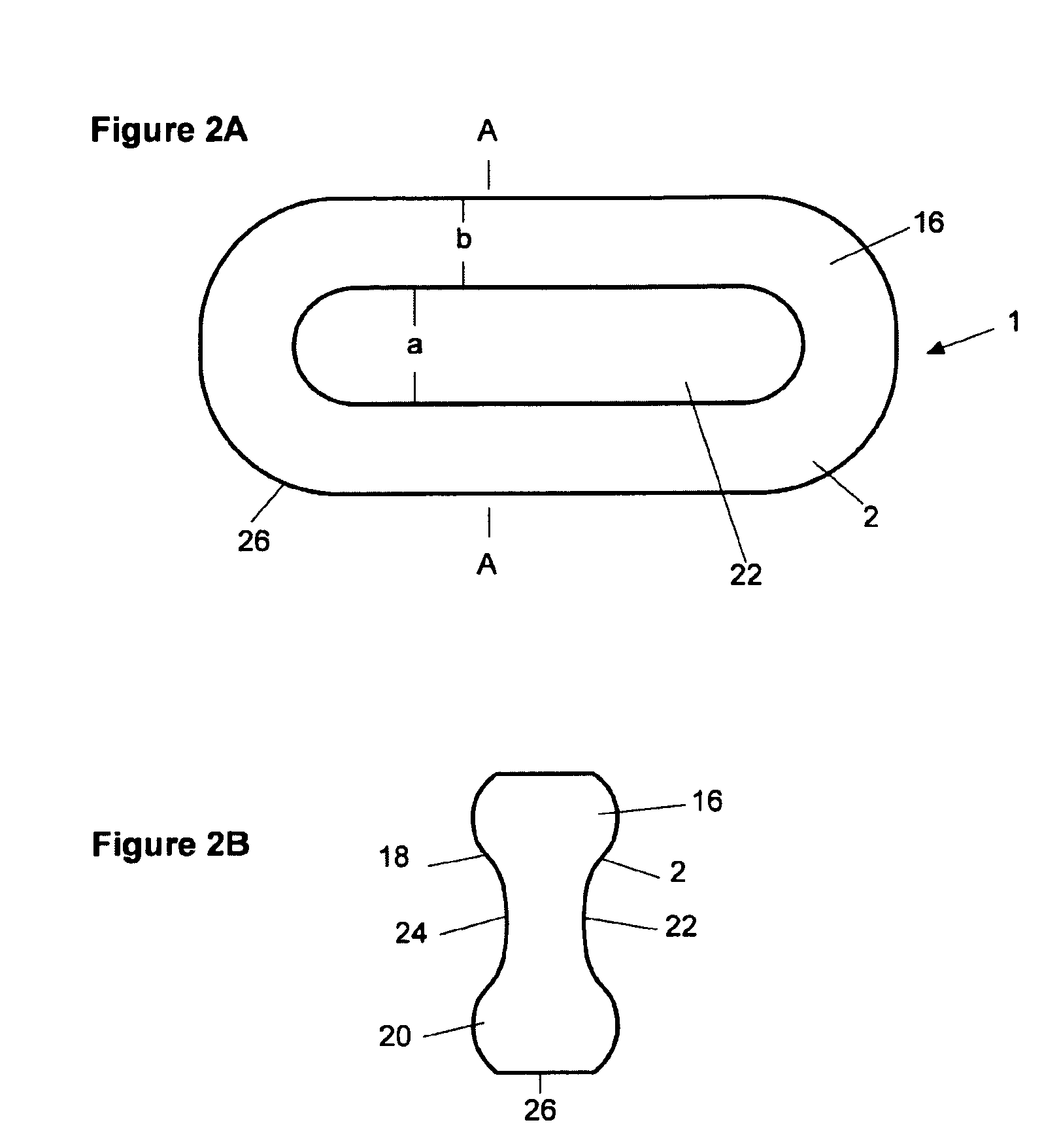

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

Pharmaceutical dosage form

ActiveUS8383152B2Improved controlled releaseEasy to adjustOrganic active ingredientsBiocideControlled releaseBreaking strength

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

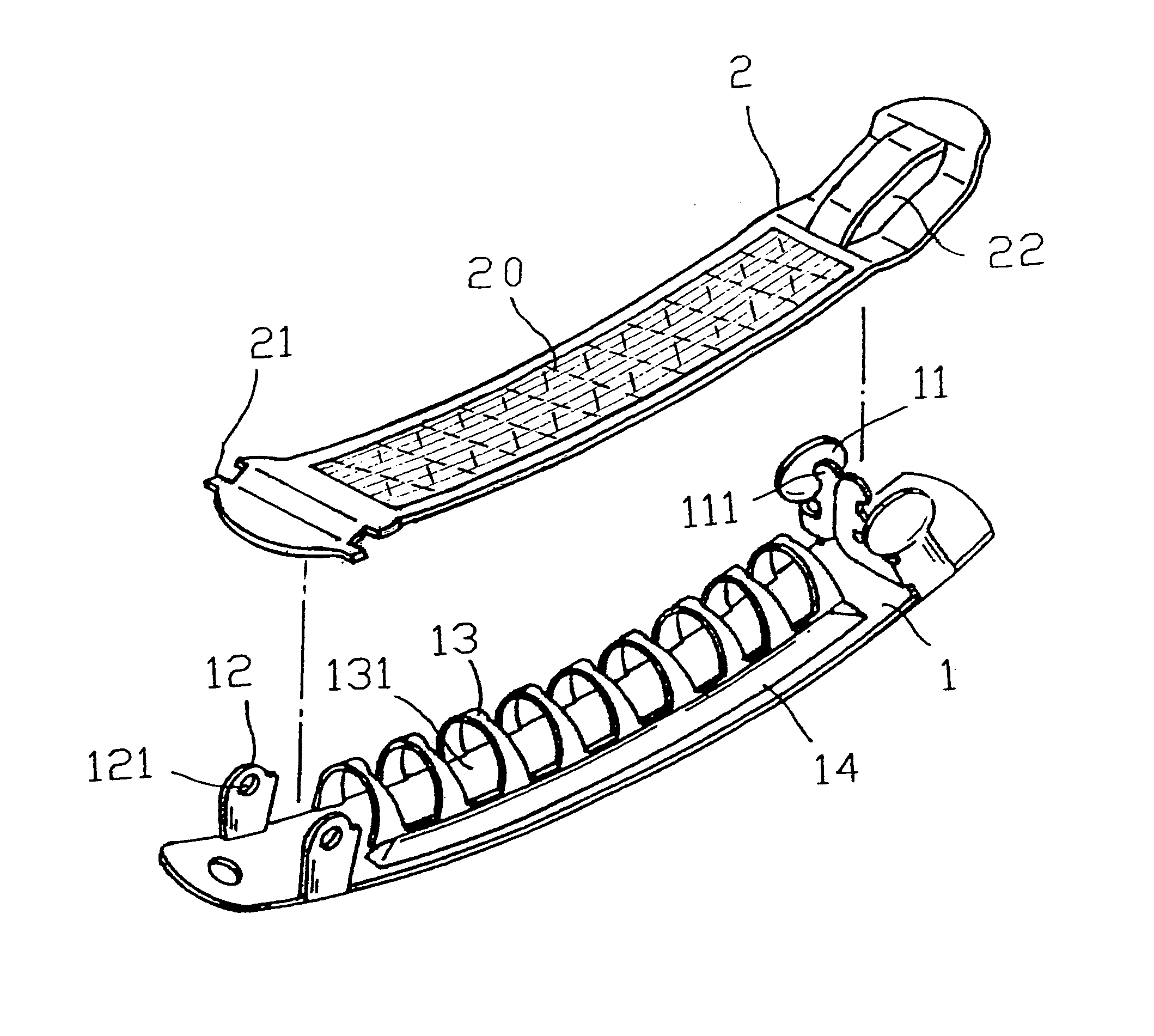

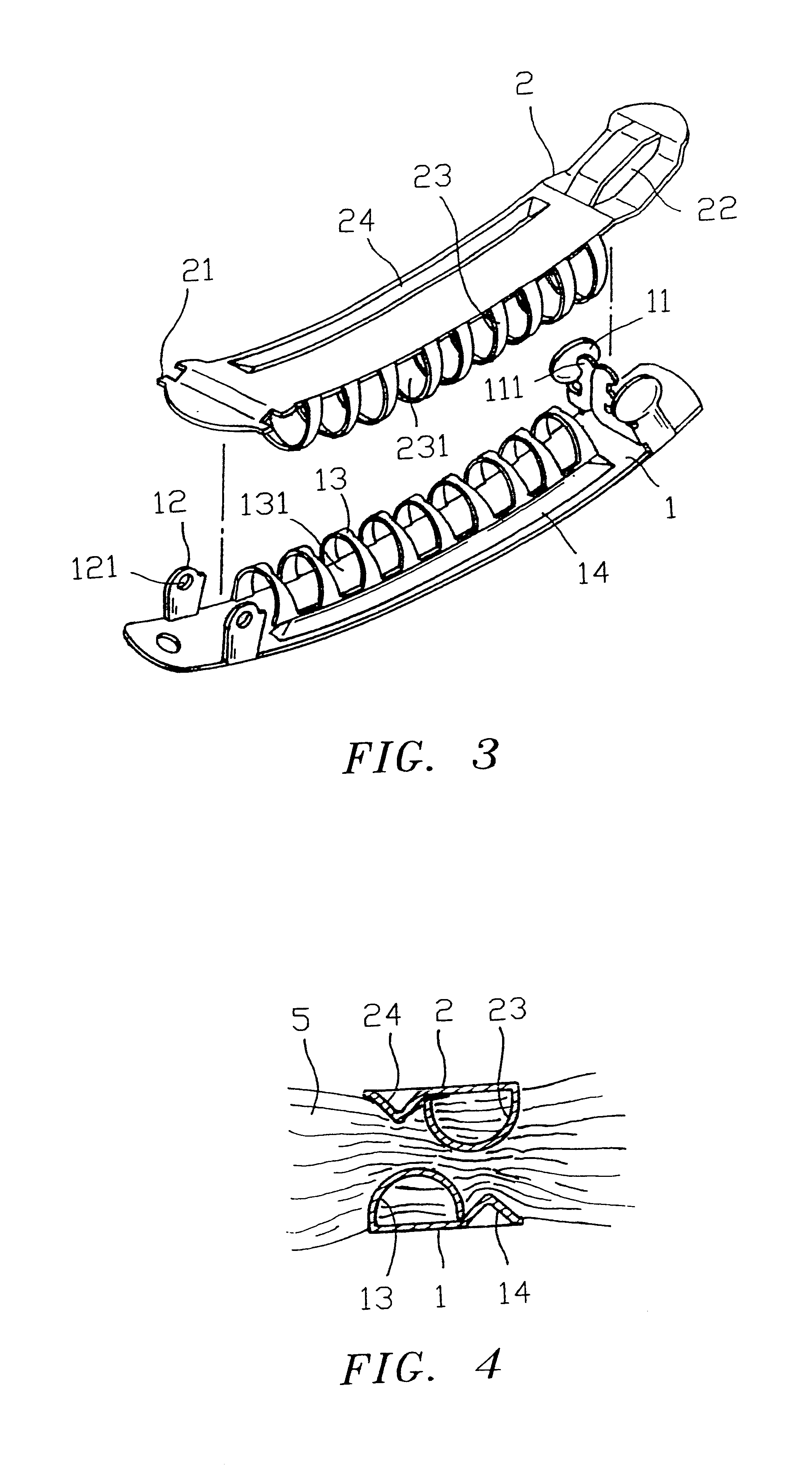

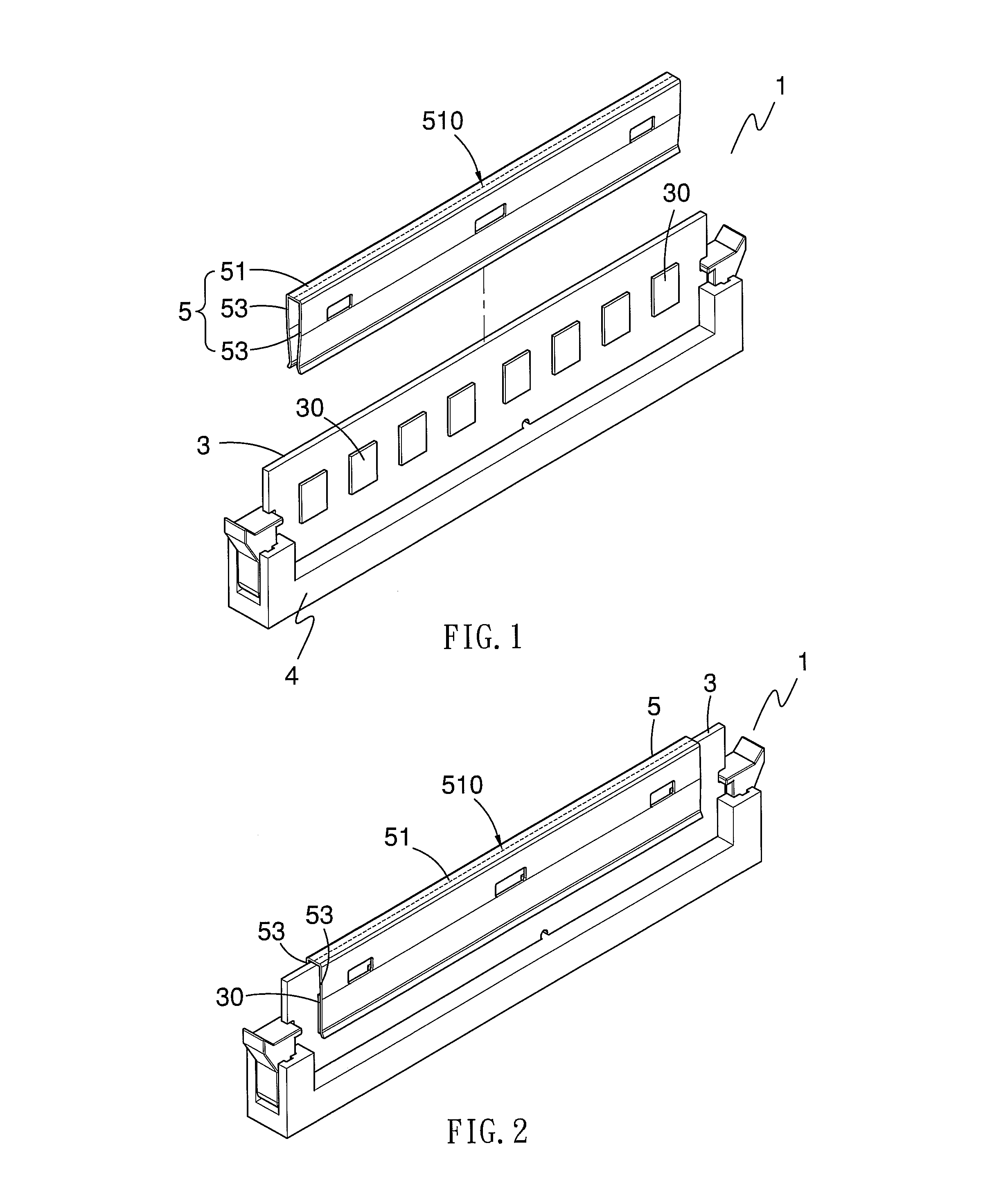

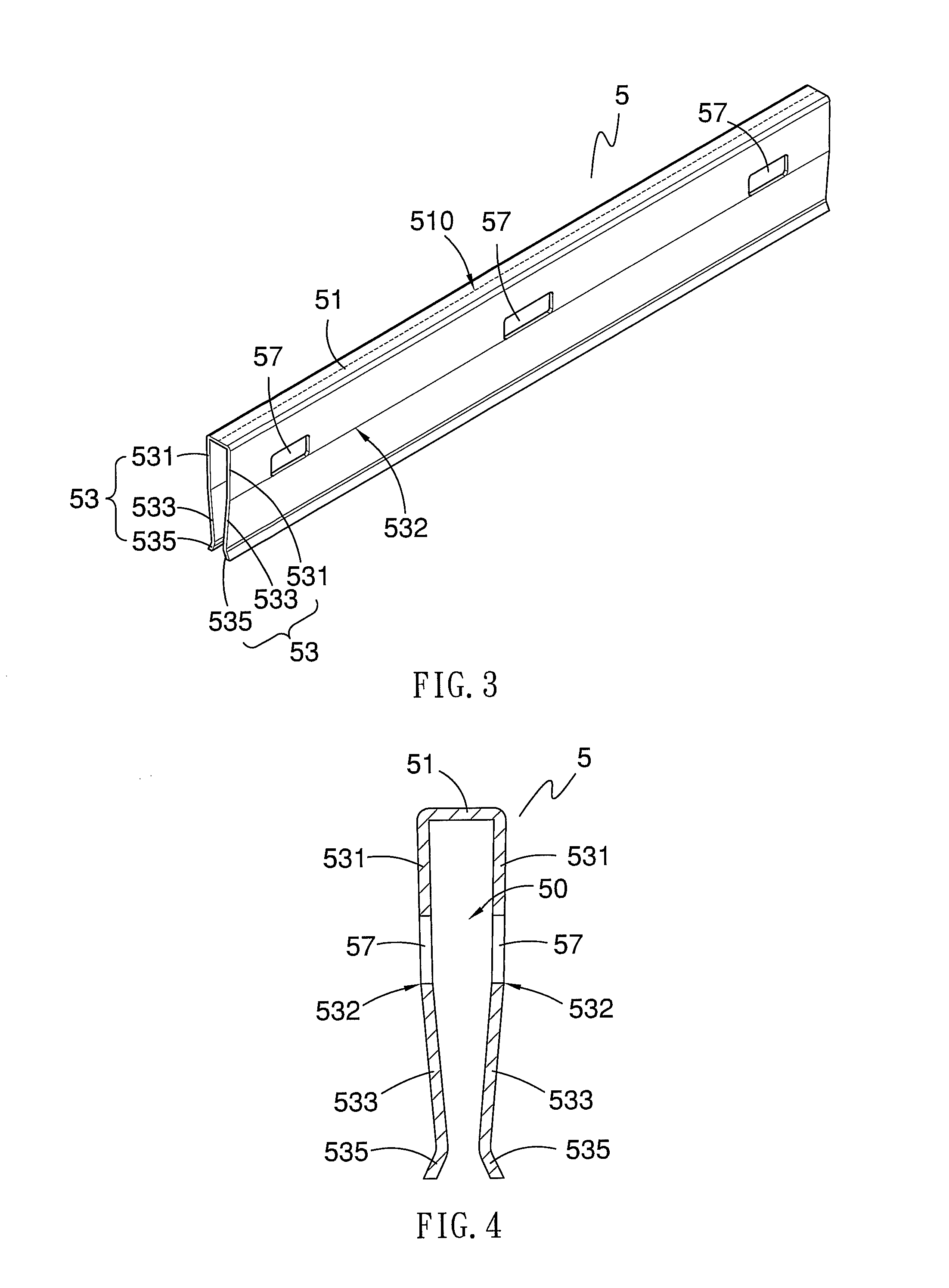

Hair clip

InactiveUS6668841B1Simplify hair clip structureImprove clipping effectCurling devicesDistortionEngineering

Present invention relates to a hair clip that mainly comprises: a base plate and an upper clip plate. Multiple equally spaced curved strips are equipped along the length of base plate. Such curved strips further form multiple rooms on base plate. Application of present invention allows hairs to be distributed evenly within the rooms and clips hairs firmly between upper clip plate and base plate to prevent hairs from distortion and damage. In addition, by eliminating middle clip plate the production cost is lowered.

Owner:CHOU KUO HUA

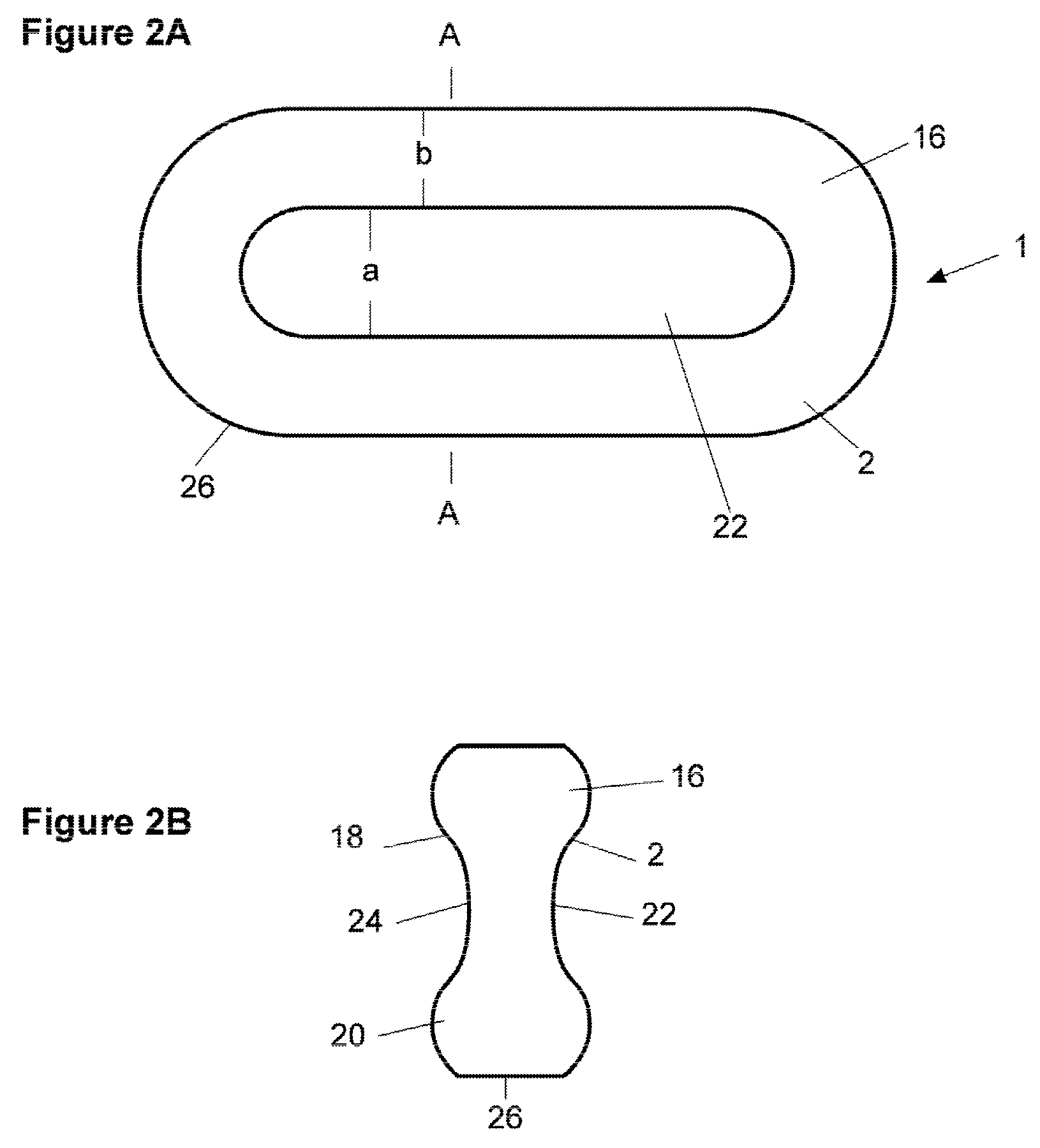

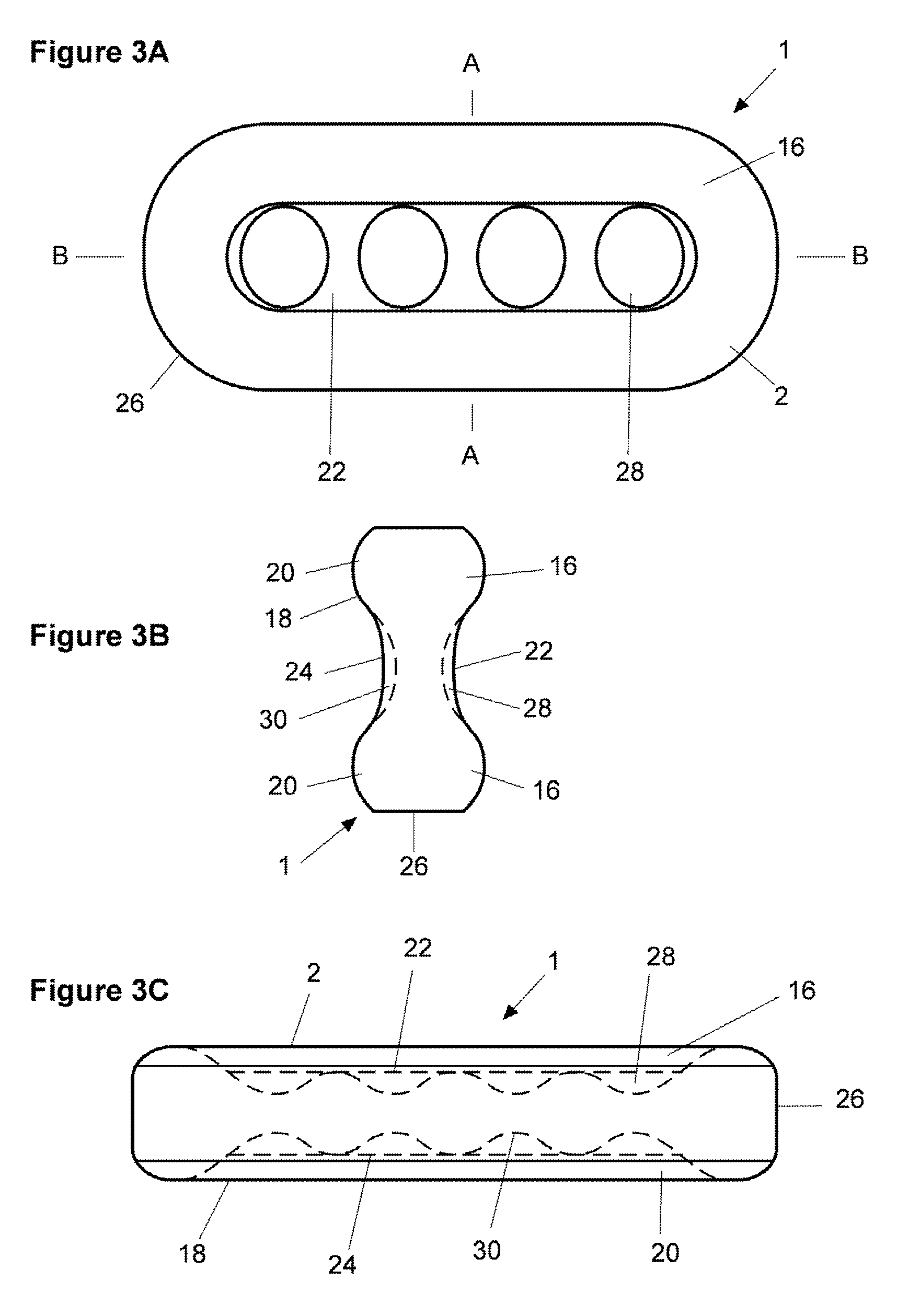

Pharmaceutical dosage form

InactiveUS20130251759A1Improved controlled releaseEasy to adjustOrganic active ingredientsNervous disorderControlled releaseBreaking strength

The invention relates to a pharmaceutical dosage form, preferably with controlled release of a pharmacologically active compound (A) contained therein, the pharmaceutical dosage form very preferably being tamper-resistant and most preferably having a breaking strength B1 of at least 500 N in direction of extension E1 and having a breaking strength B2 of less than 500 N in direction of extension E2.

Owner:GRUNENTHAL GMBH

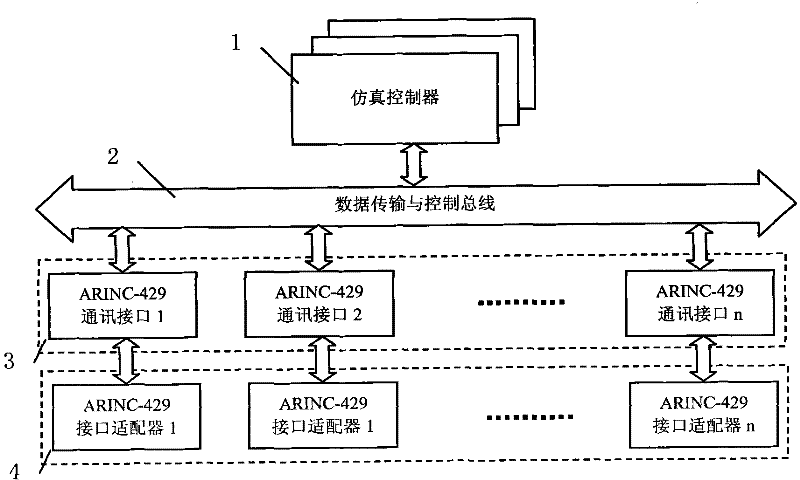

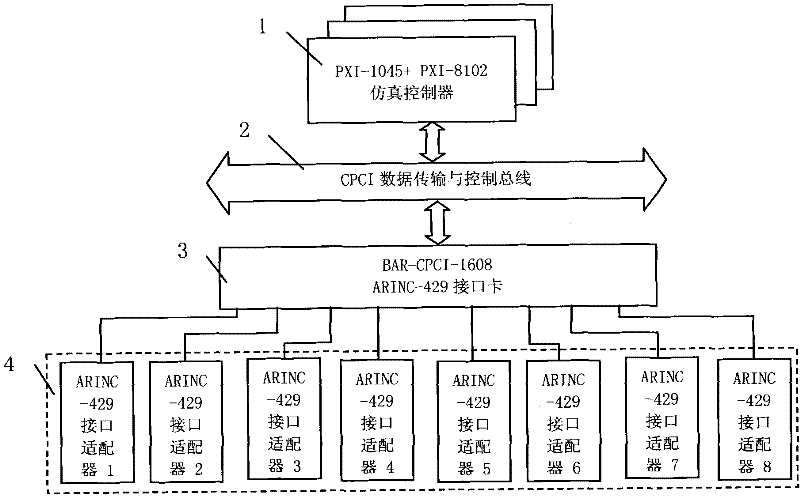

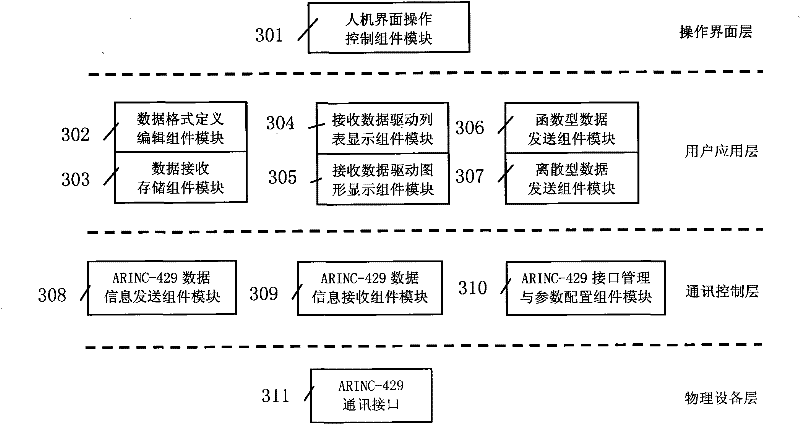

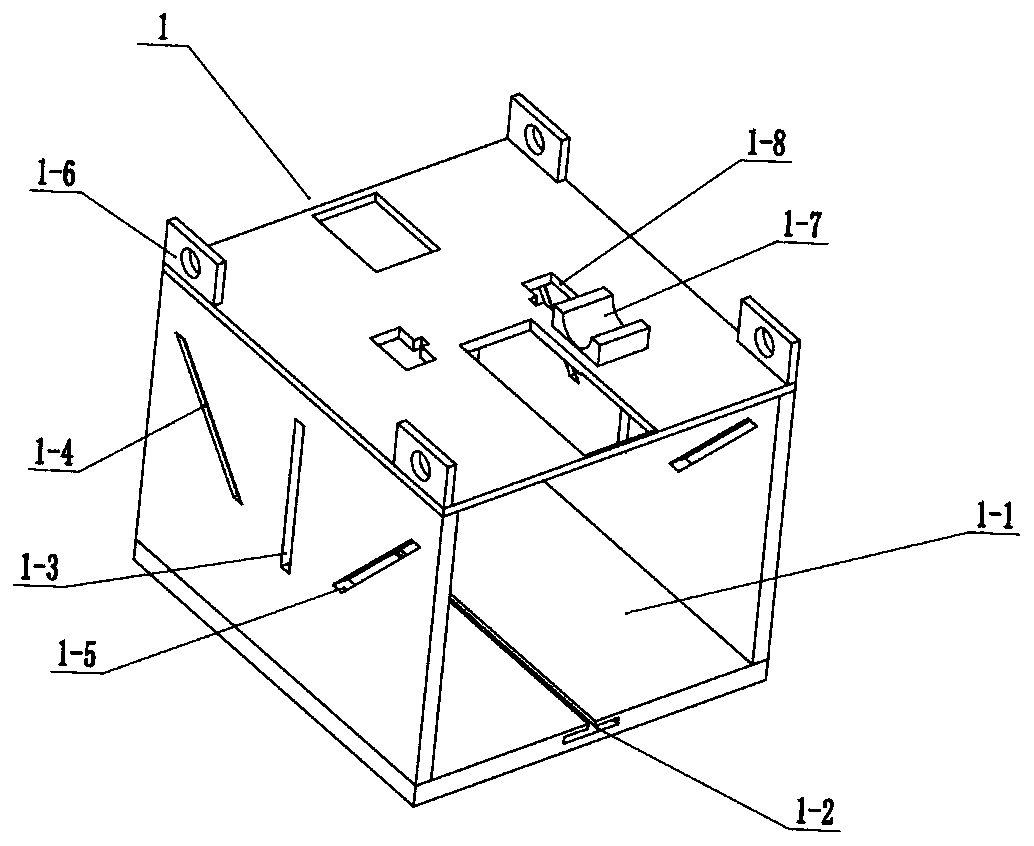

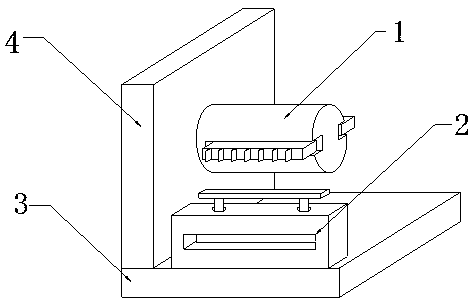

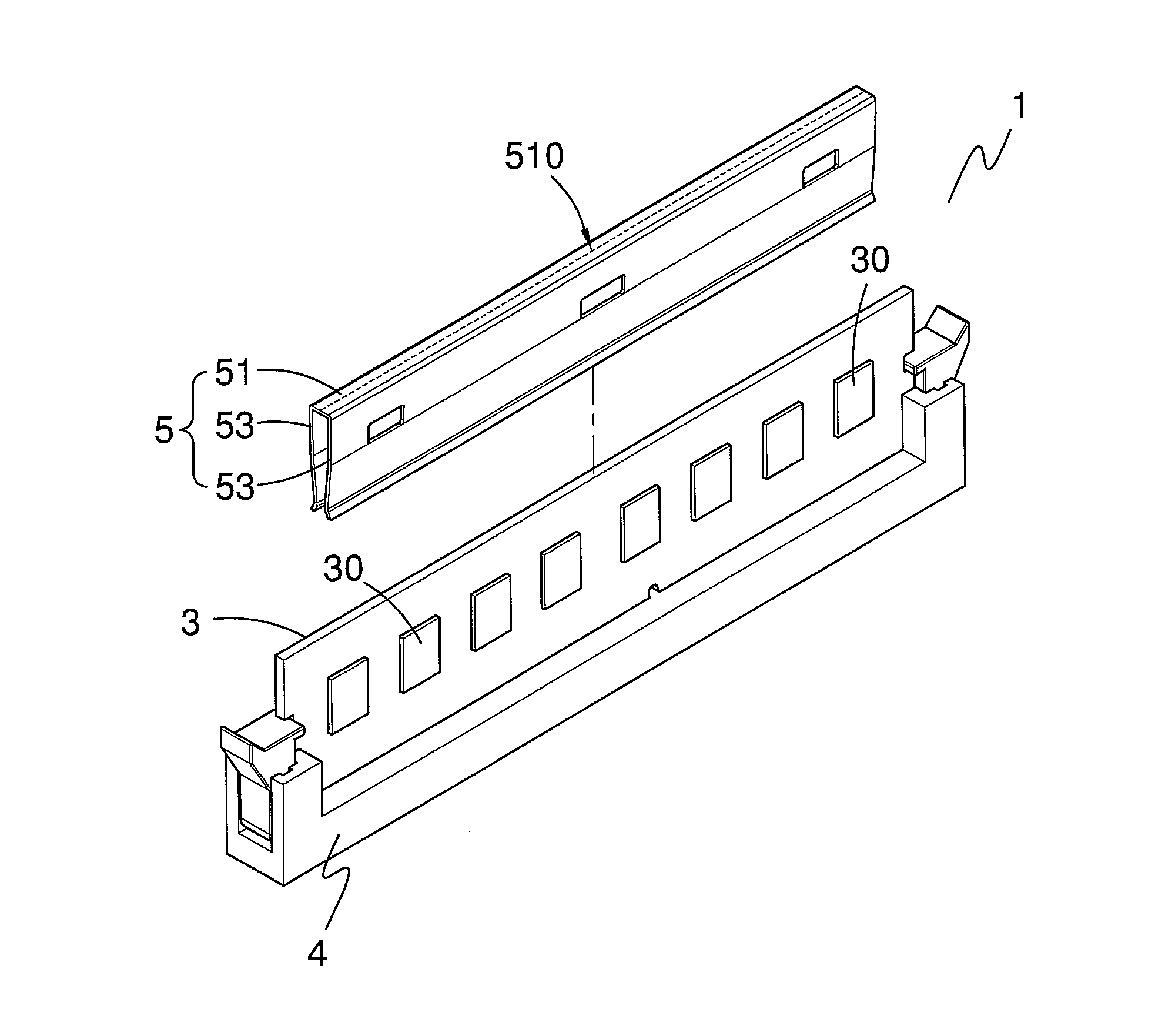

A kind of arinc429 data bus emulation test system

InactiveCN102289208AFunction increaseCompact and reasonable structureSimulator controlExtensibilityCommunication interface

An ARINC429 data bus simulation test system belongs to the technical field of simulation test. It is characterized in that the ARINC429 data bus simulation and test environment is formed by the simulation controller [1], the data transmission and control bus [2], the ARINC 429 communication interface [3] and the ARINC 429 interface adapter [4], and the simulation controller [ 1] Through data transmission and control bus [2] control ARINC429 communication interface [3] to realize the transmission and reception of data information, simulate the generation and transmission process of information flow of airborne equipment such as airborne flight control system and avionics system, and receive Other airborne equipment information flow and display. The invention has the advantages of complete system function, reasonable layout, compact structure, reliable operation, convenient use, good expansibility and tailorability.

Owner:支怡 +1

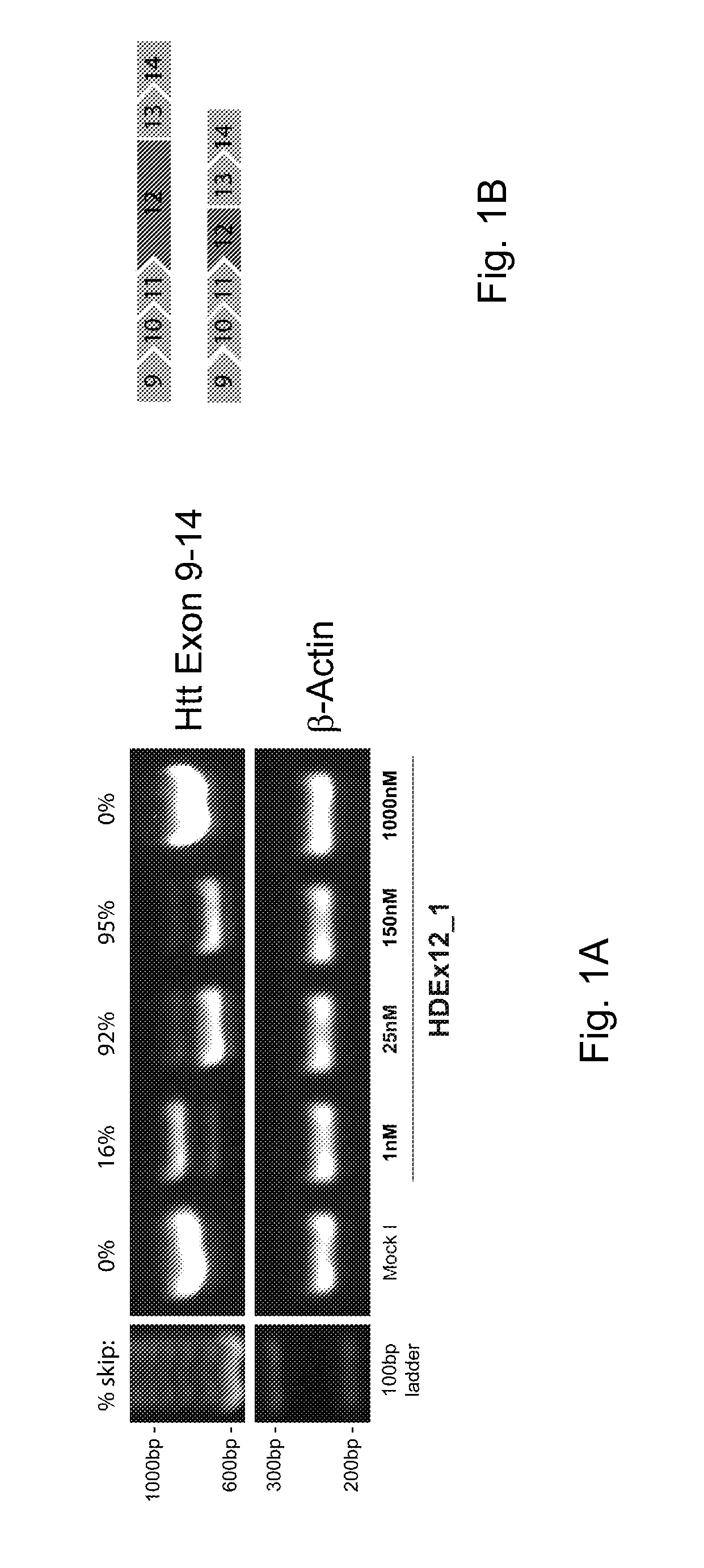

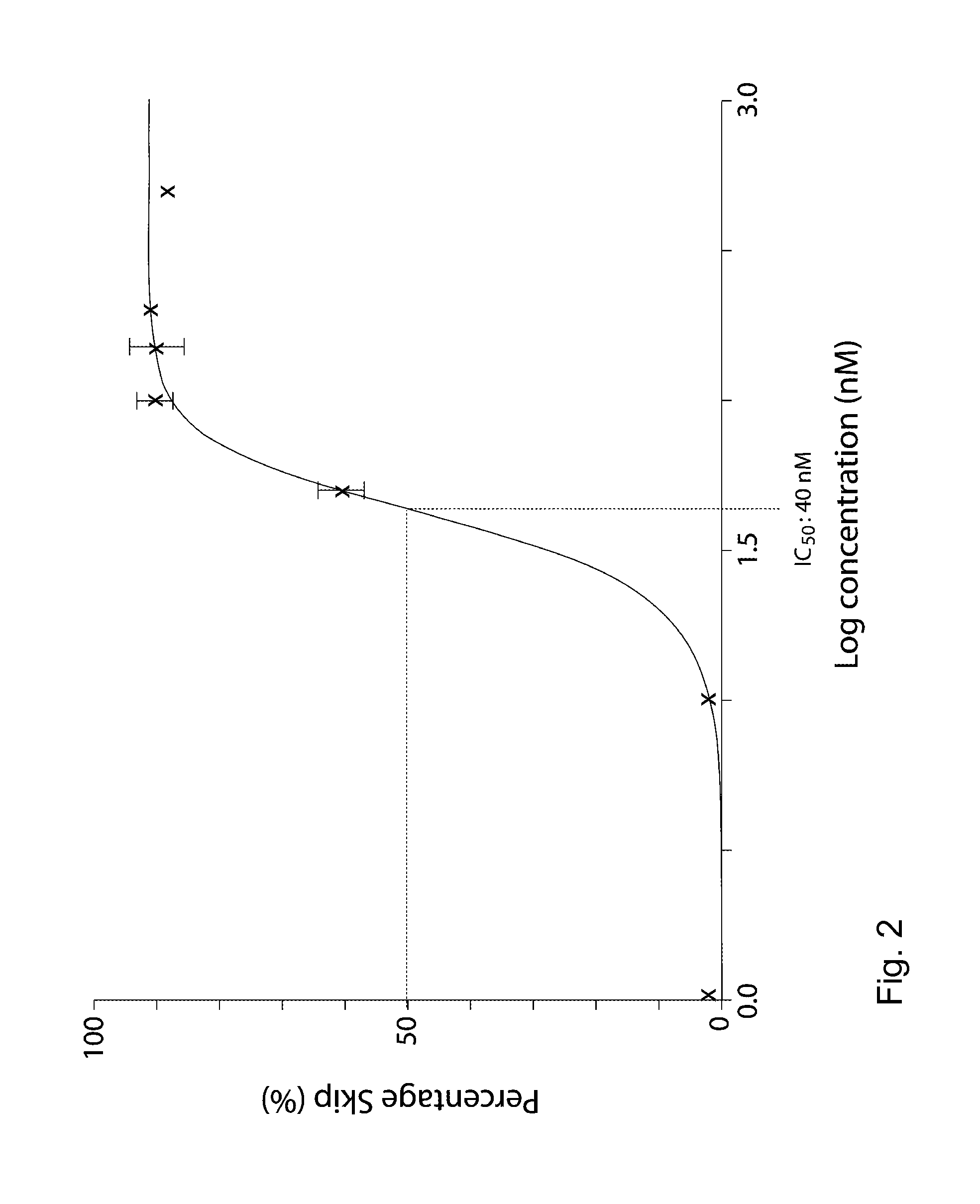

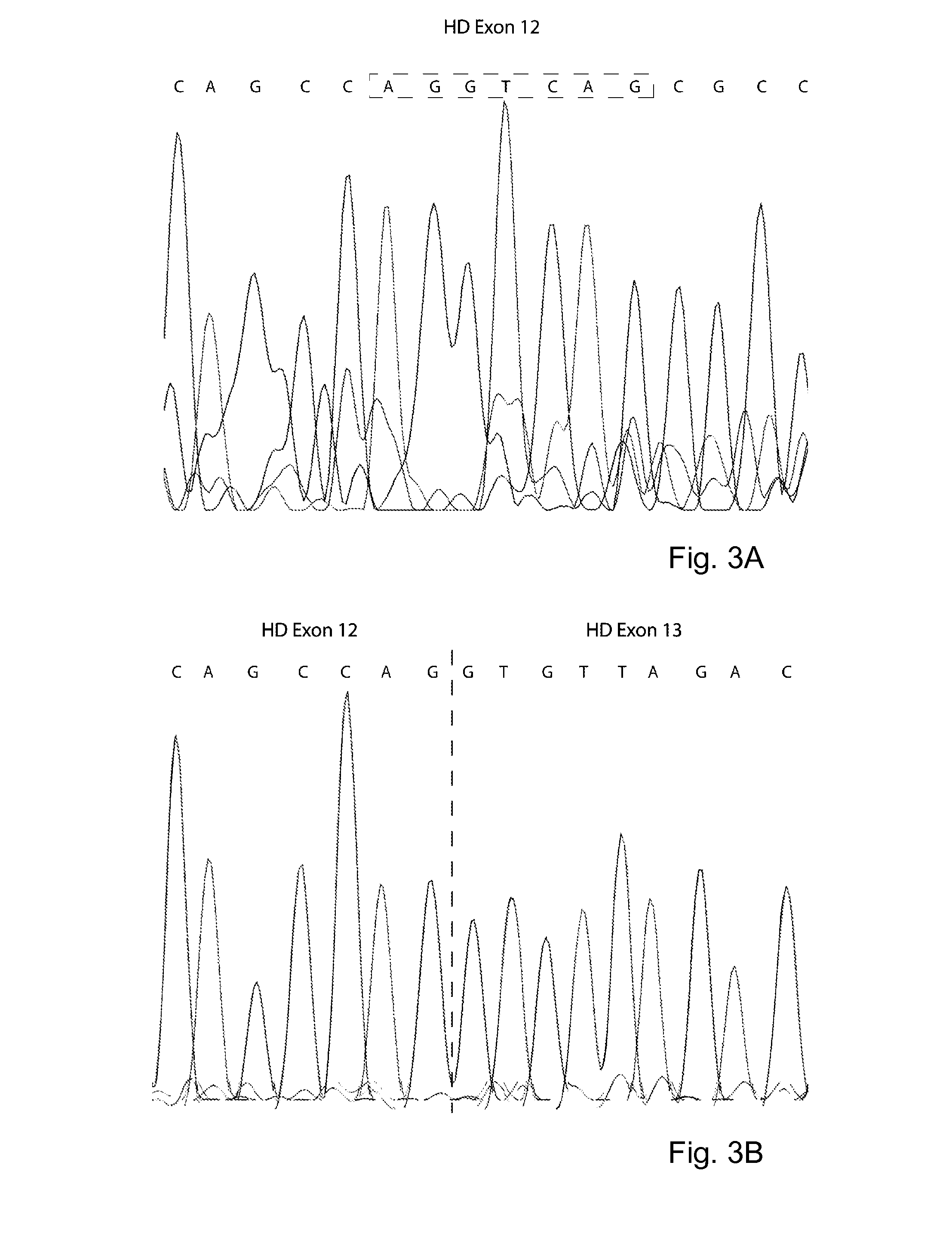

Antisense oligonucleotide directed removal of proteolytic cleavage sites from proteins

ActiveUS20130198877A1Improve the level ofLow toxicitySplicing alterationNervous disorderPrecursor mRNAProteolysis

Described are means and methods for removing a proteolytic cleavage site from a protein, the method comprising providing a cell that expresses pre-mRNA encoding the protein with an anti-sense oligonucleotide that induces skipping of the exonic sequence that encodes the proteolytic cleavage site, and allowing translation of mRNA produced from the pre-mRNA.

Owner:ACADEMISCH ZIEKENHUIS BIJ DE UNIV VAN AMSTERDAM ACADEMISCH MEDISCH CENT

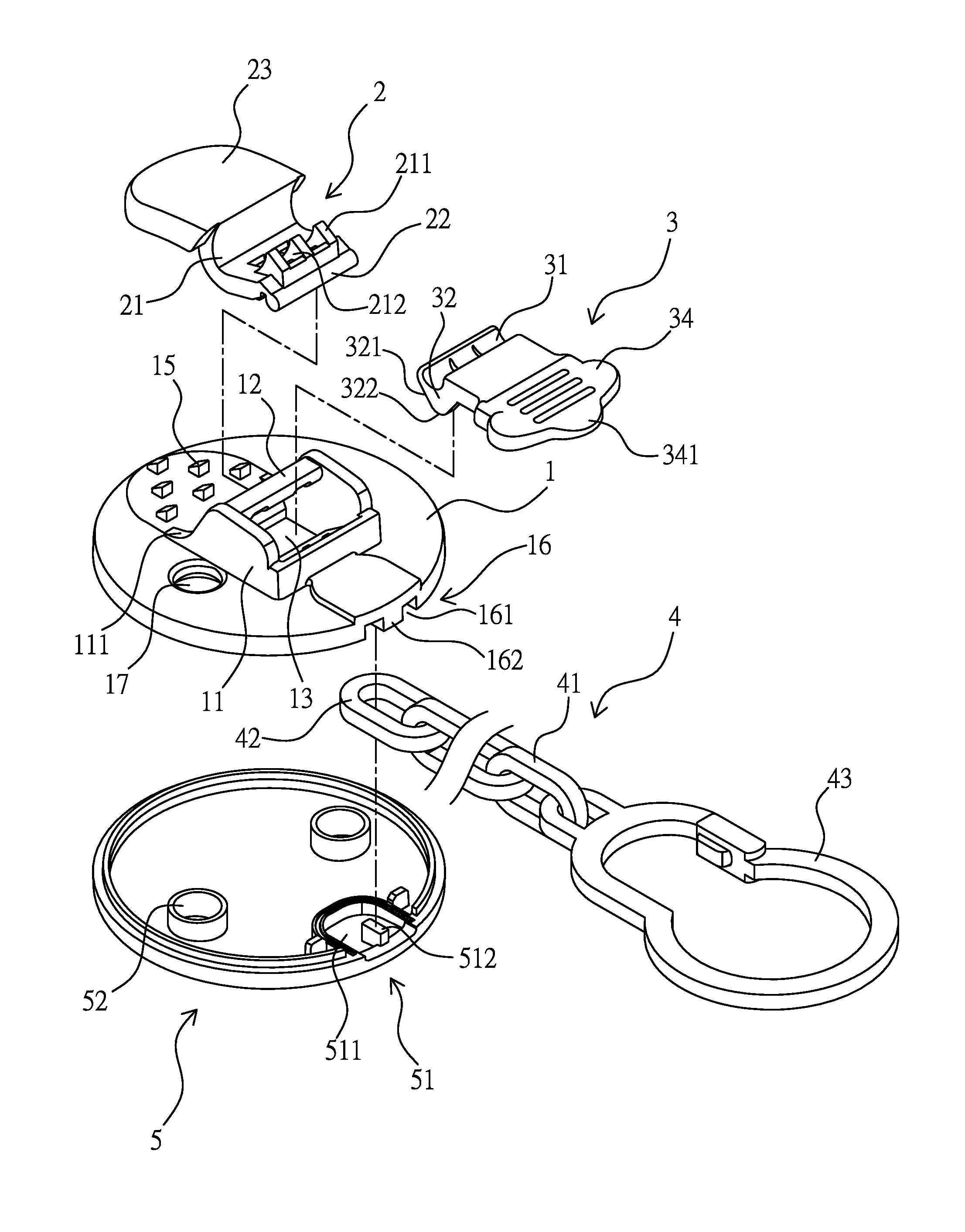

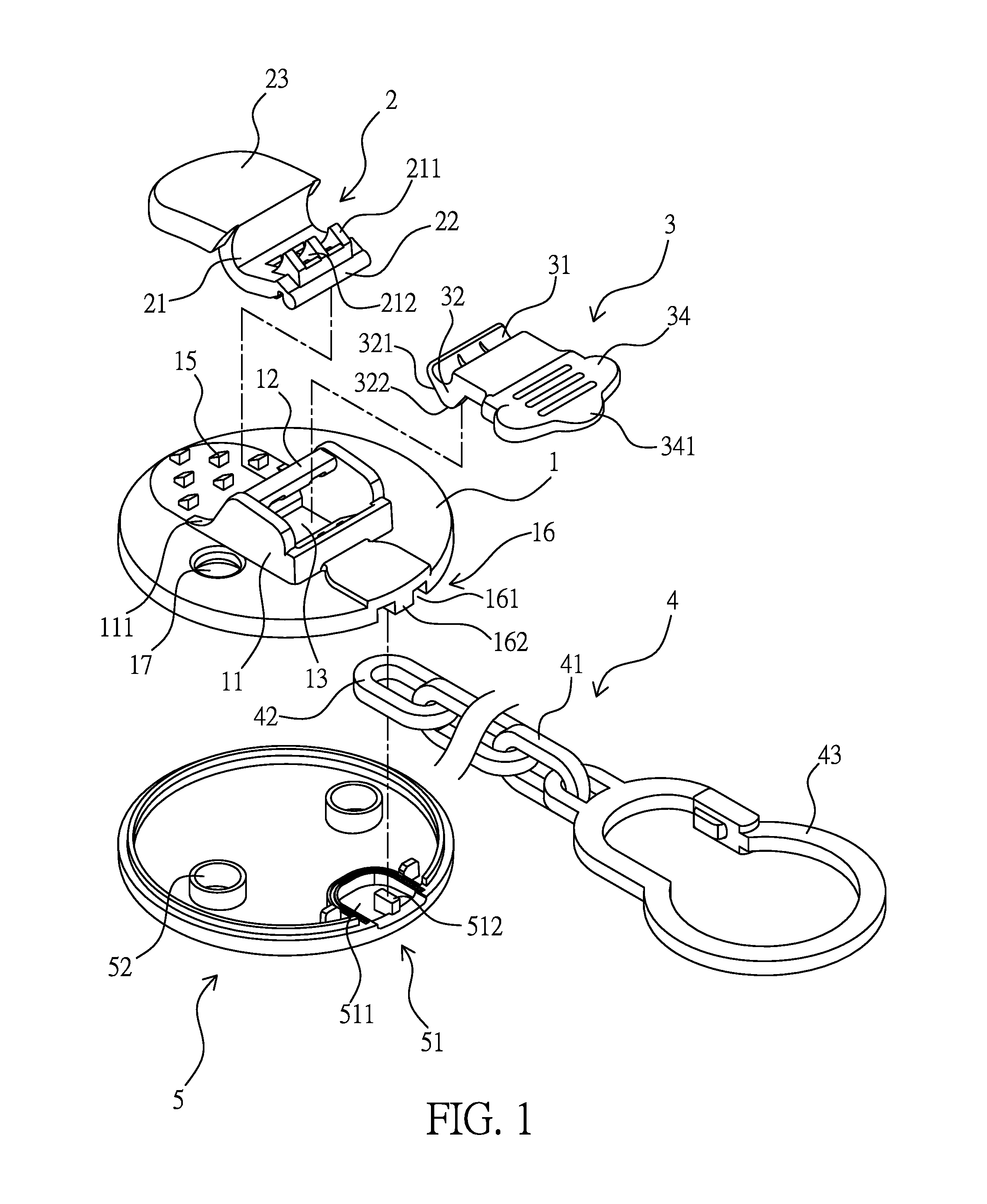

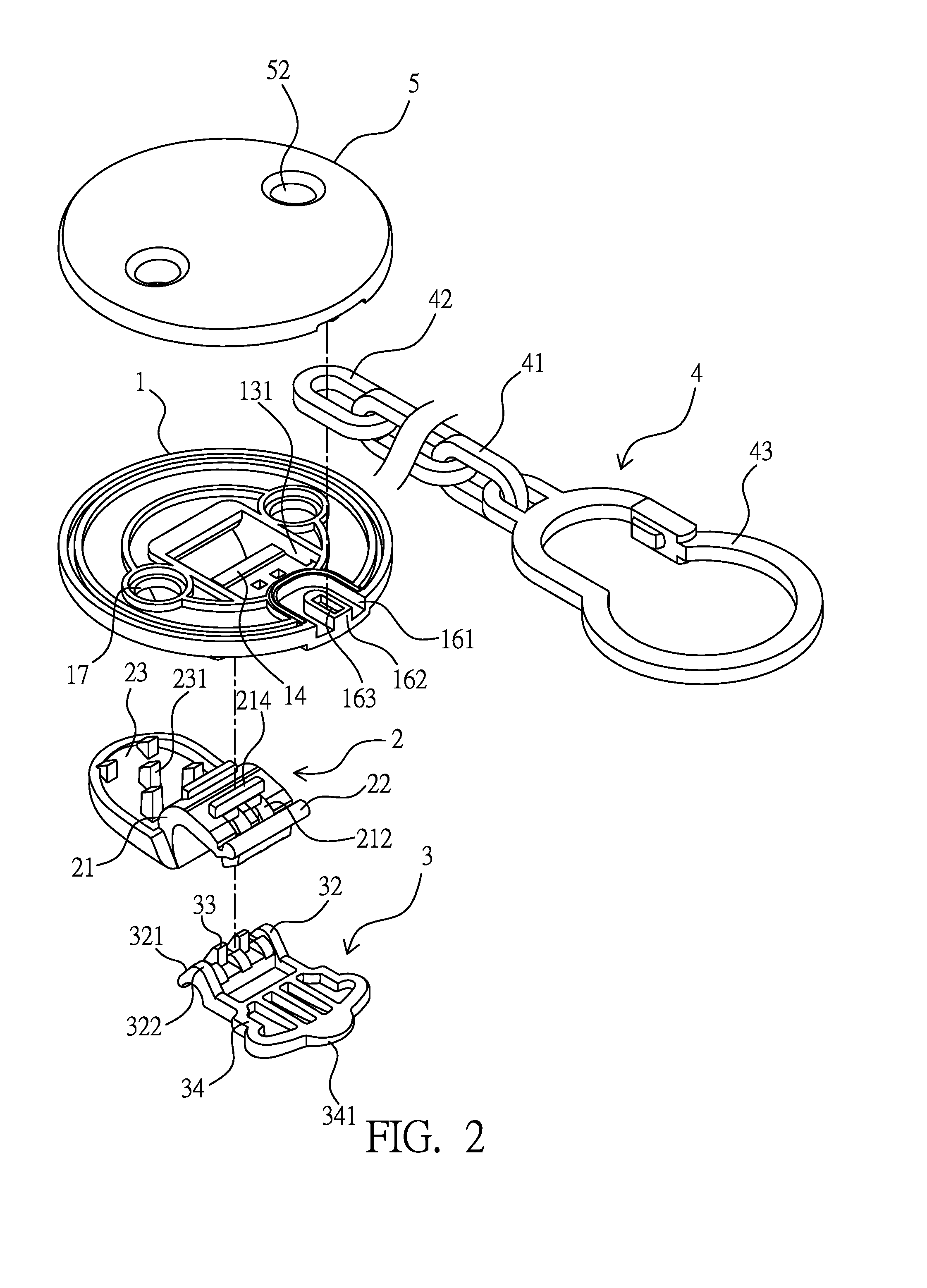

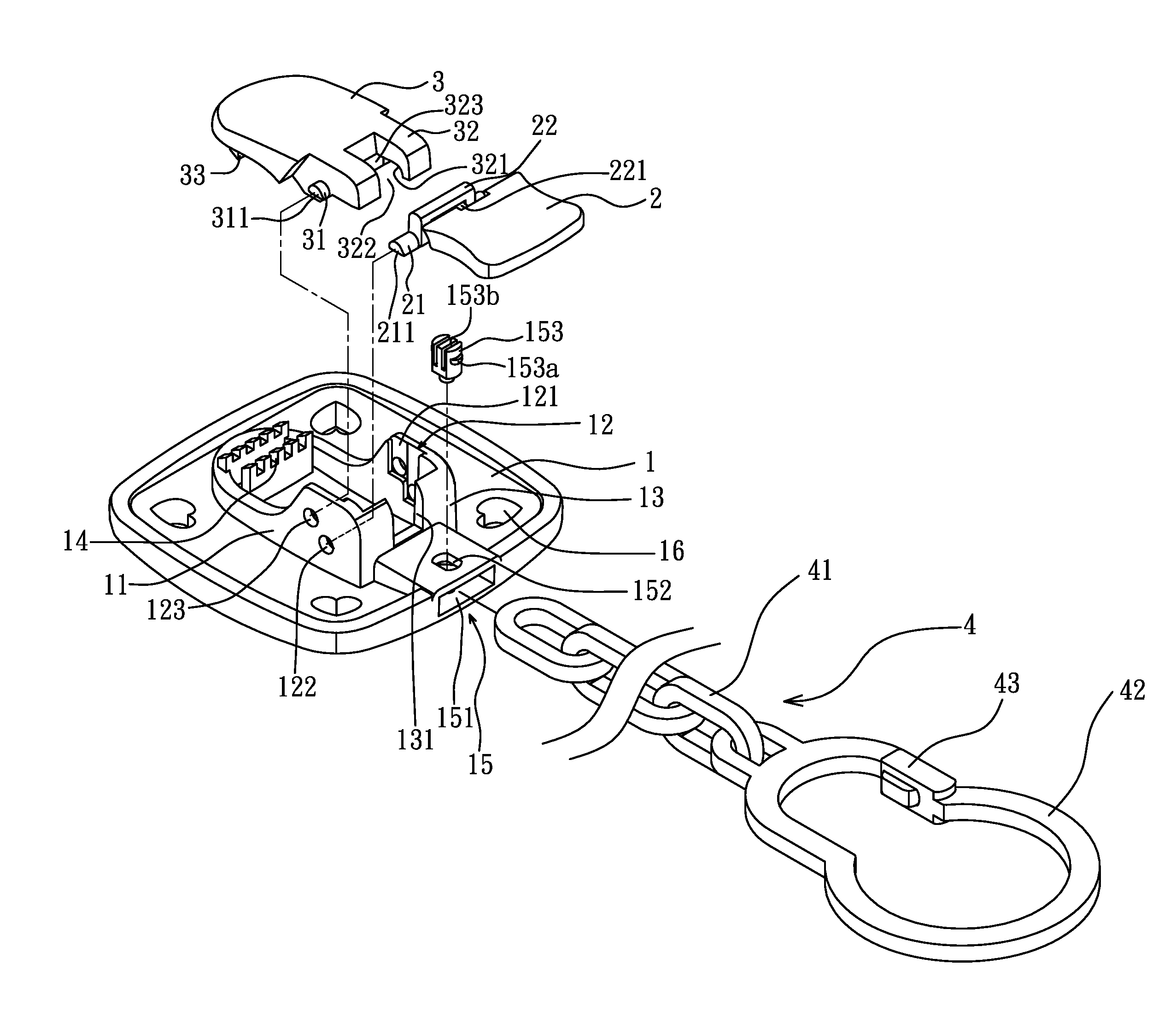

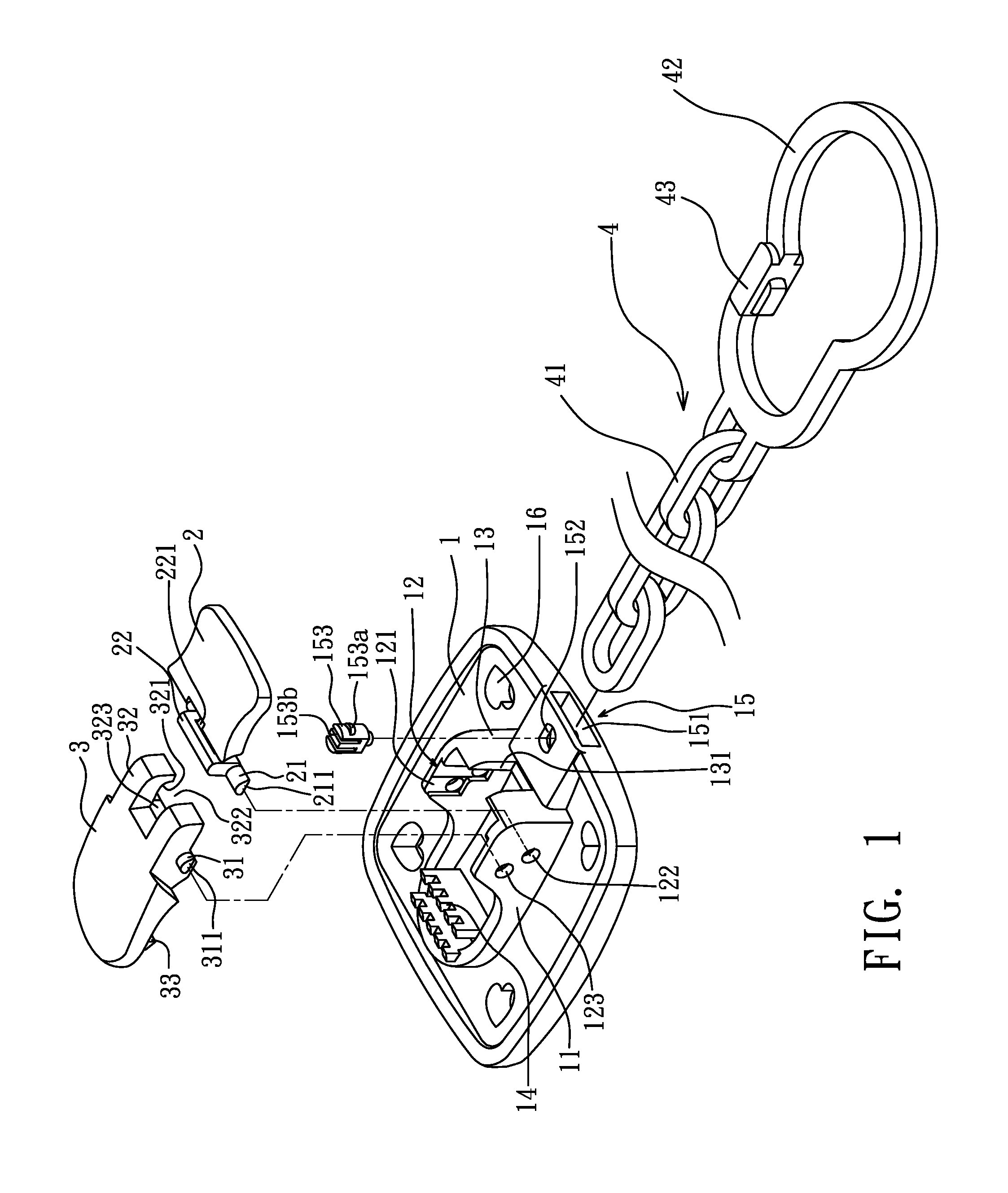

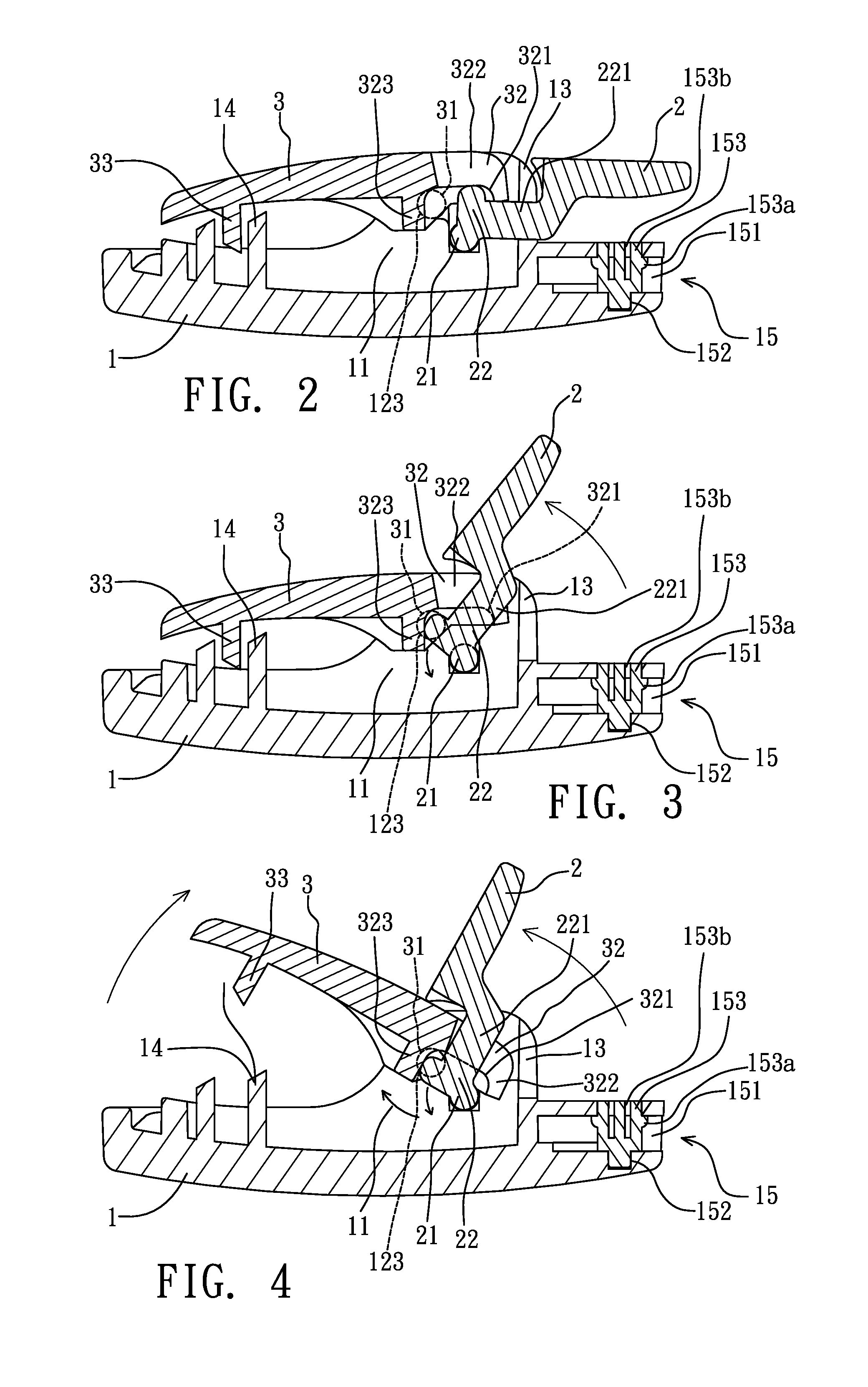

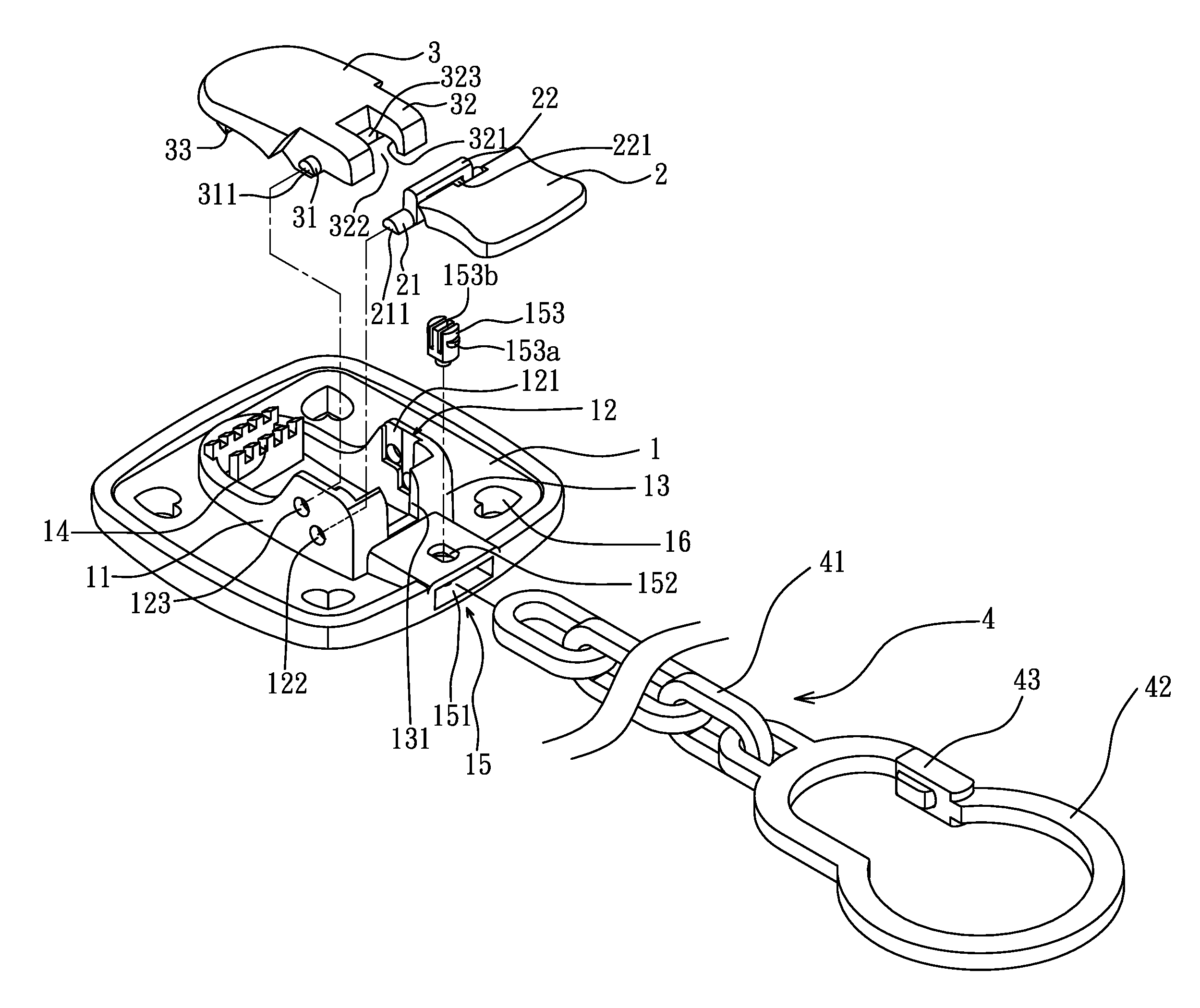

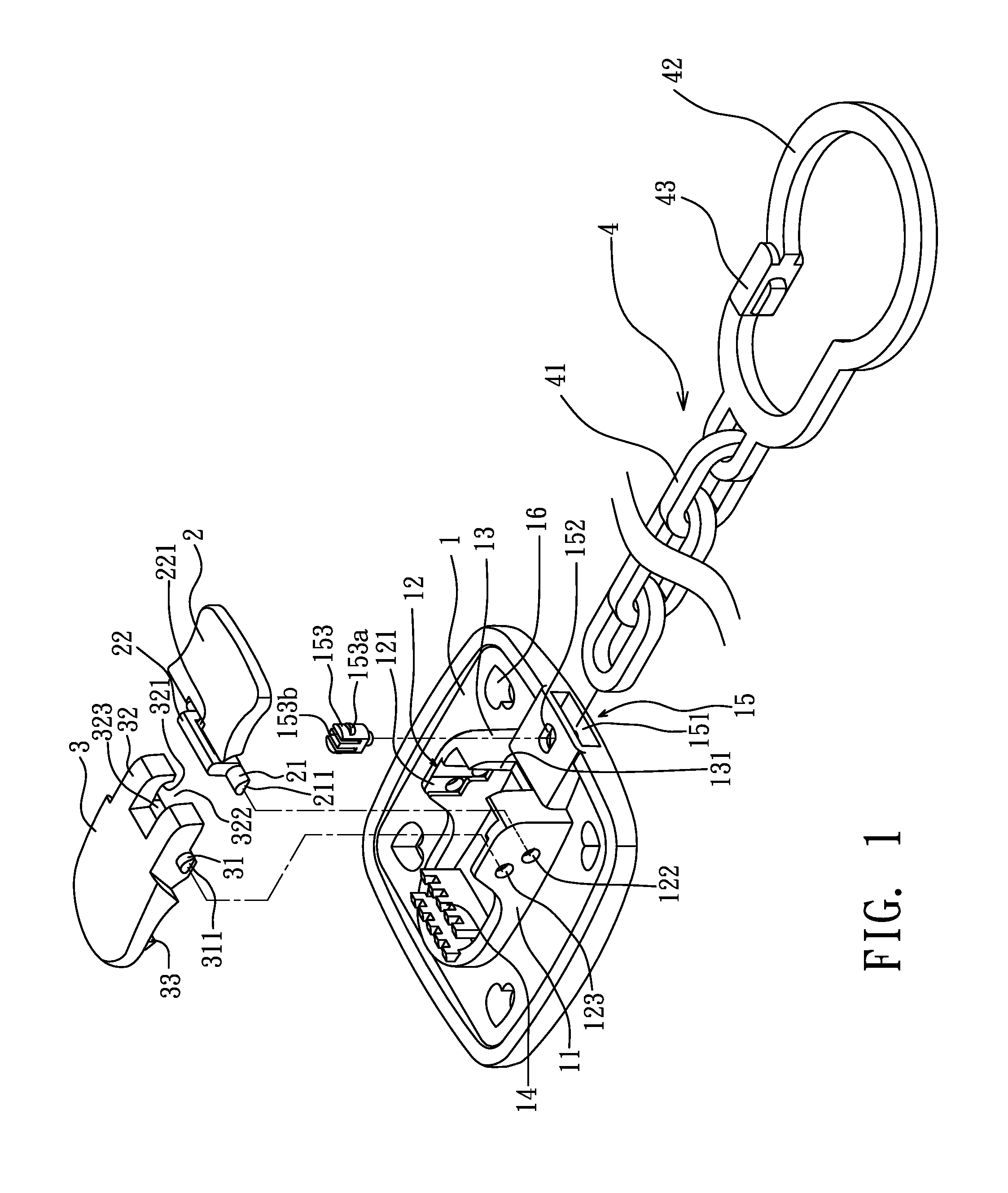

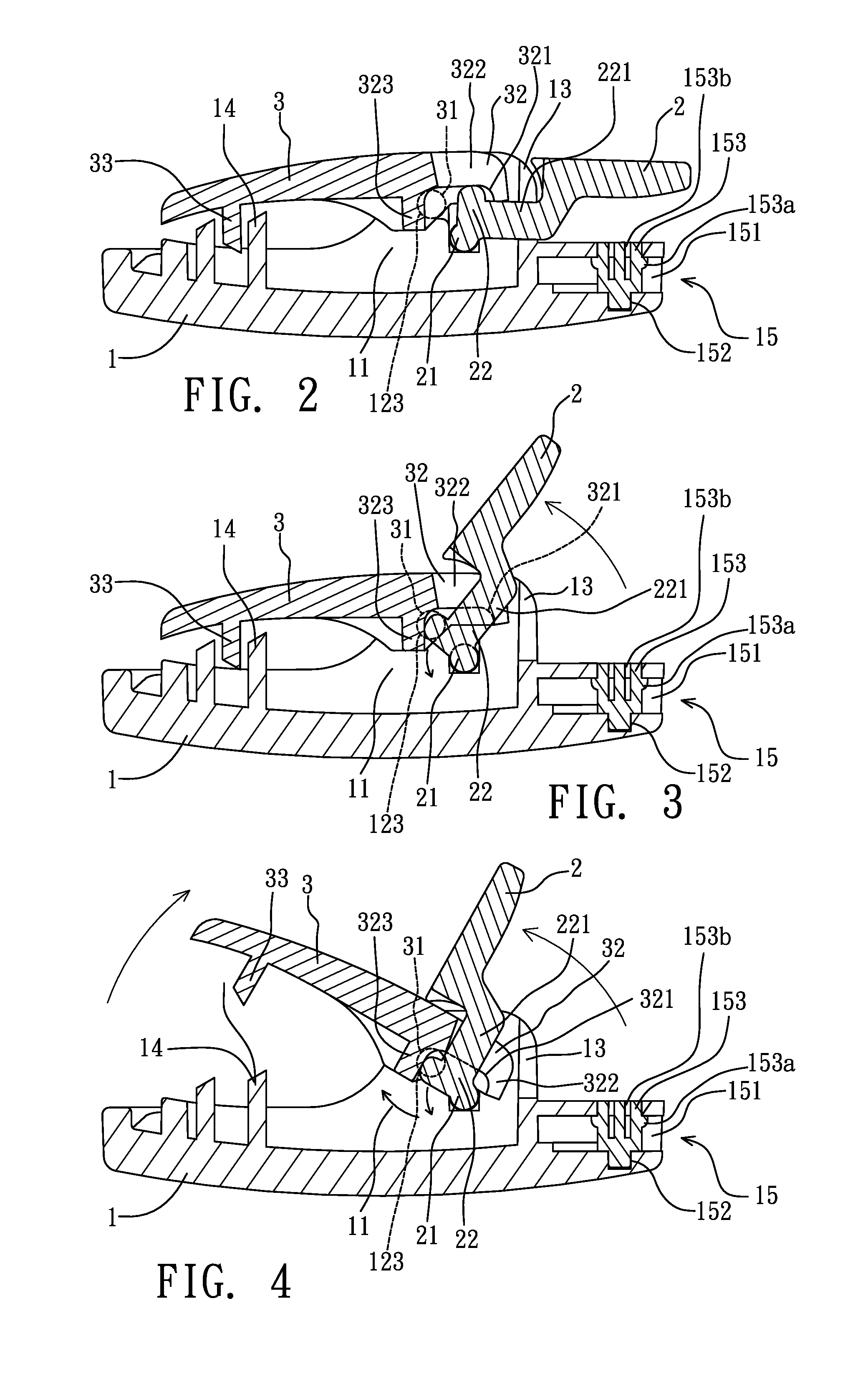

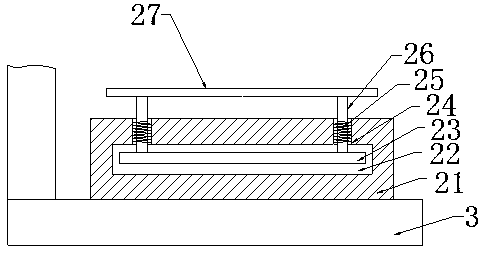

Pacifier clip

ActiveUS8806726B1Reduce assemble procedureProduction cost be reduceSnap fastenersTravelling carriersPacifierEngineering

The present invention relates to a pacifier clip, which comprises a base sheet, a mobile clipping member, a pulling member and a tying tool. When the pulling member is pulled, in the rotating motion, an angled flange of the pulling member utilizes an eccentric action to optionally allow an angled part or an inclined cutting plane of the angled flange to be abutted against or adjacent to an oblique support arm of the mobile clipping member, so a passive sheet of the mobile clipping member is downwardly moved or upwardly raised, and tooth rows of the passive sheet and tooth lines of the base sheet are engaged for forming a clipping status or forming a gap in between for forming a releasing status.

Owner:TIEN CHUNG ENT

Differentiation of Human Embryonic and Induced Pluripotent Stem Cells

InactiveUS20110229440A1Easy to unifyPromote progressBiocideSkeletal disorderEmbryoHuman Induced Pluripotent Stem Cells

Owner:UNIV OF CONNECTICUT

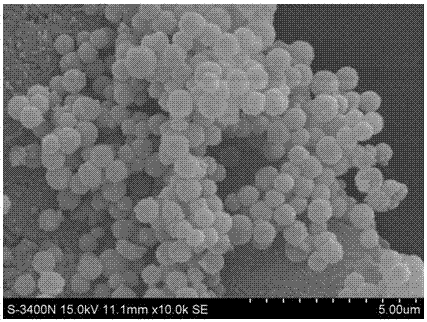

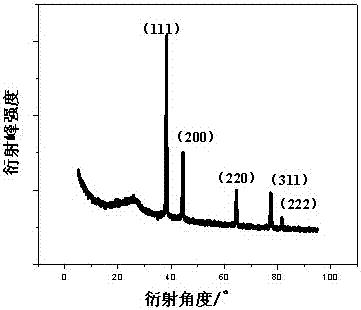

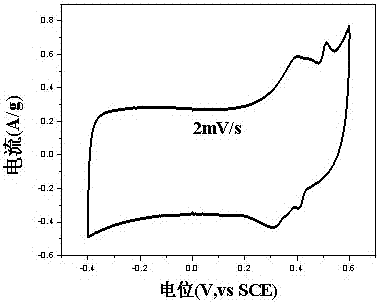

Method for preparing polypyrrole/sliver nano composite material

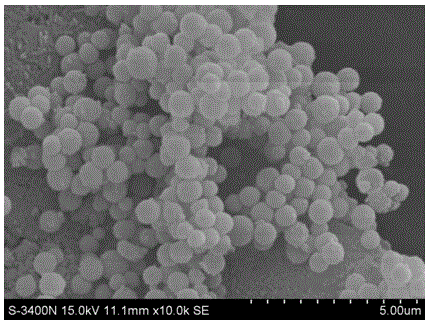

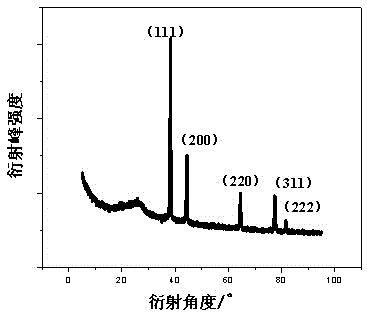

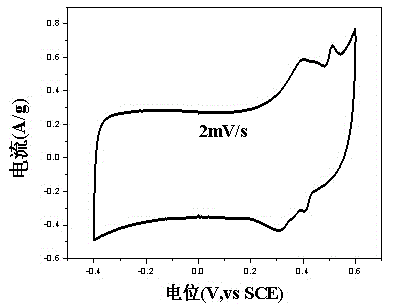

ActiveCN104599862AImprove conductivityAct as an inducerMaterial nanotechnologyHybrid capacitor electrodesCapacitancePolypyrrole

The invention relates to a method for preparing a polypyrrole / sliver nano composite material; the method comprises the steps: mixing pyrrole monomers and silver nitrate solution into a system and dropwise adding trisodium citrate aqueous solution in a stirring condition; after the dropwise adding is finished, continuously stirring for 10-30 min, dropwise adding ferric trichloride aqueous solution and reacting for 4-12h; at the end of the reaction, pumping and filtering reaction solution; washing an obtained filter cake with ethyl alcohol and de-ionized water for twice or three times; and drying to obtain spherical or sphere-like polypyrrole / sliver nano composite material with particle size of 100-250nm, pore diameter of 3-15nm and pore volume of 0.283-0.356 cm3 / g. The preparation method does not need expensive equipment and instruments, is simple and has lower requirement on the reaction environment and low production cost. The prepared polypyrrole / sliver nano composite material is used as the electrode material of supercapacitors and has excellent specific capacitance performance and thermal stability.

Owner:SHANGHAI INST OF TECH

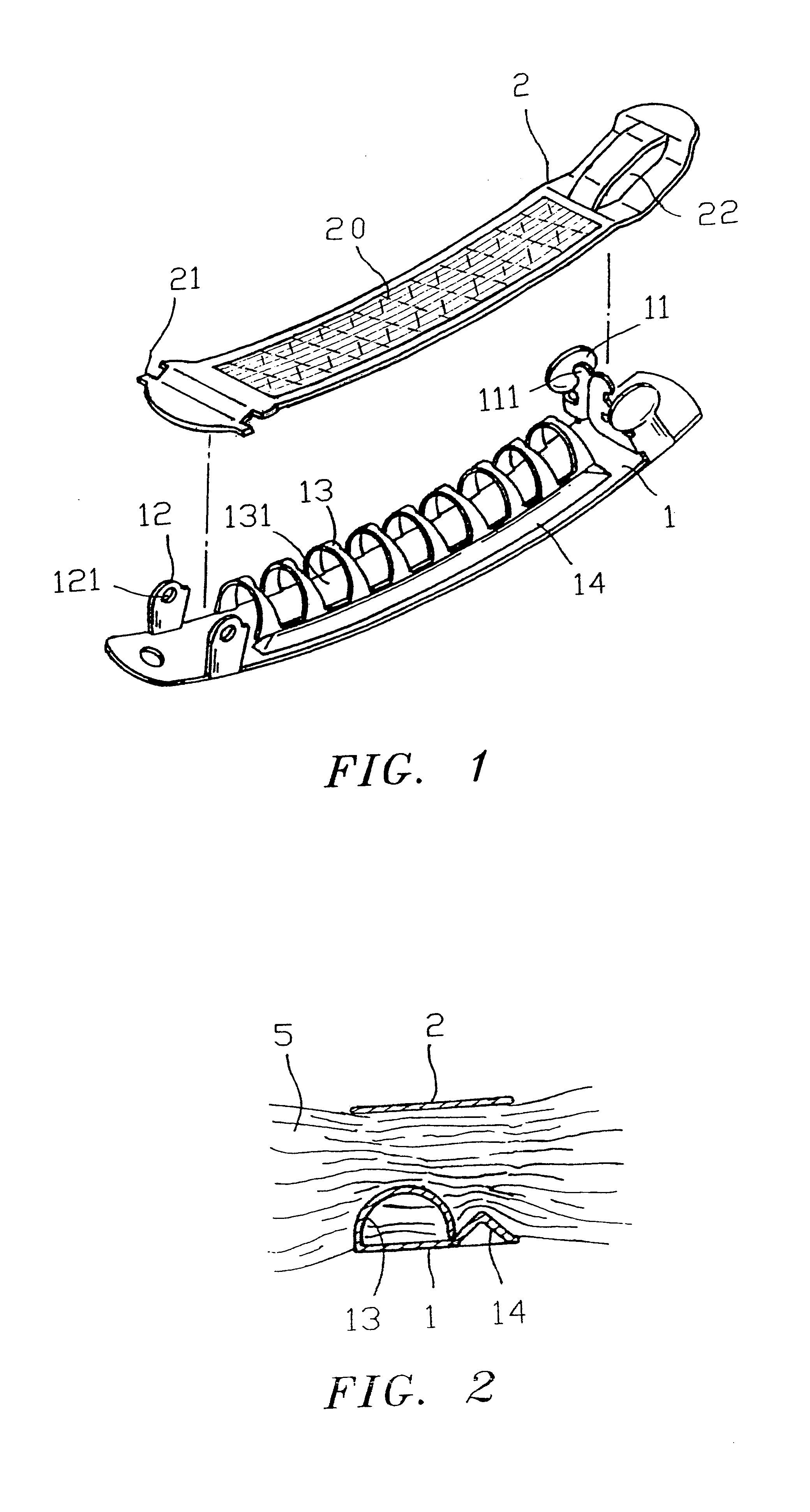

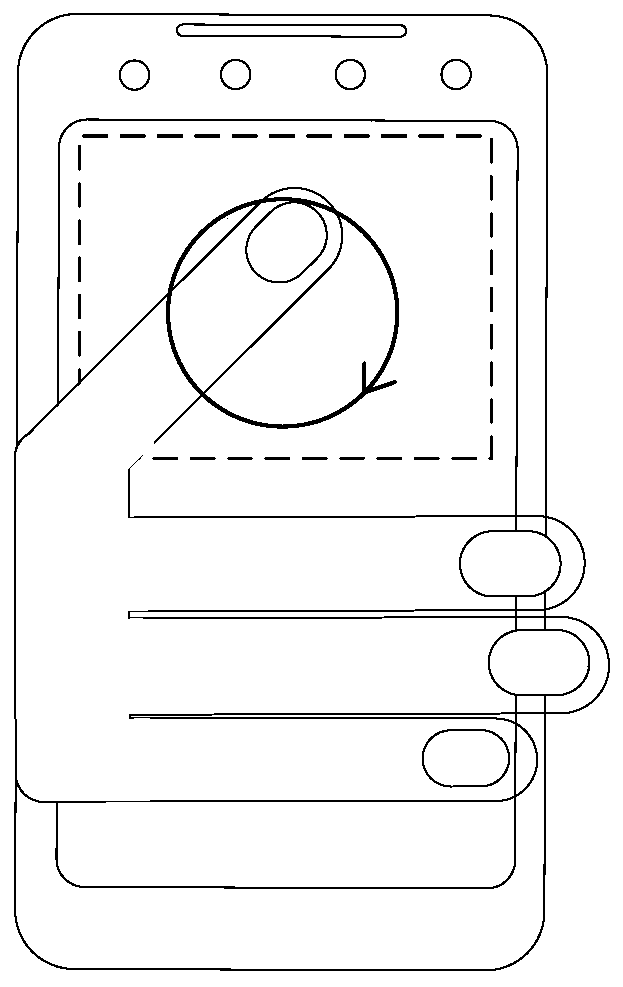

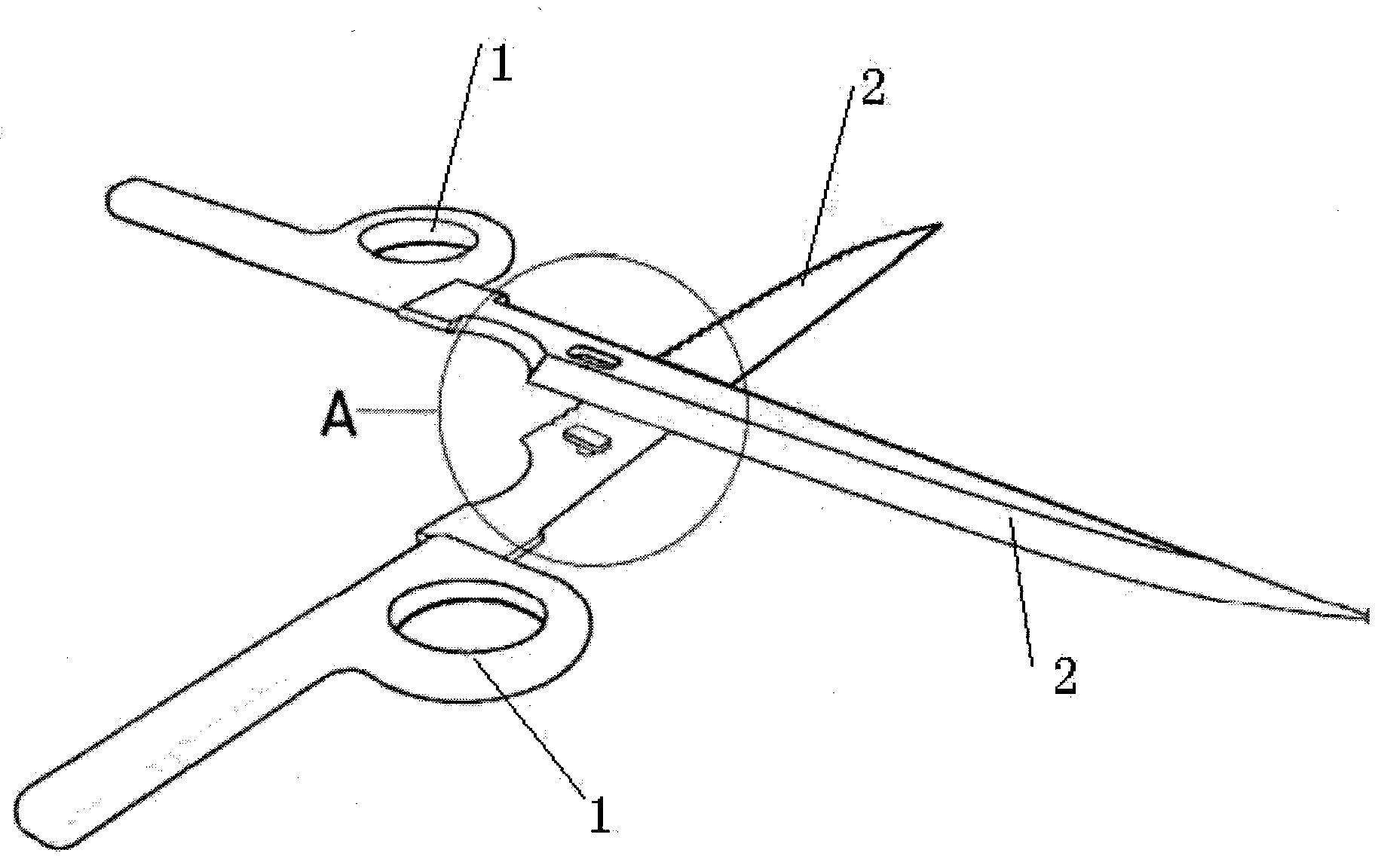

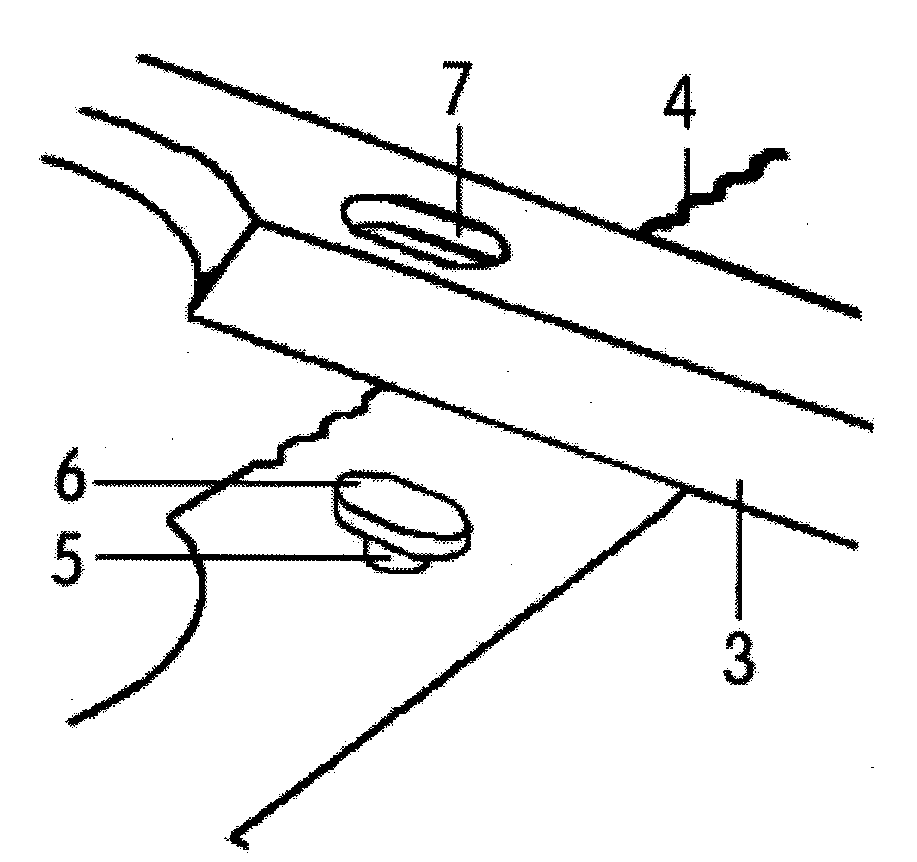

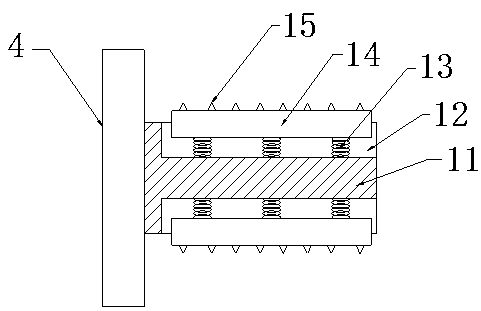

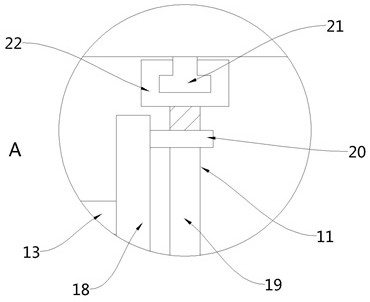

Pacifier clip

InactiveUS20120036682A1Facilitated releaseGood tailoringSnap fastenersClothes buttonsMobile endMechanical engineering

The present invention relates to a pacifier clip, consists of a base board, a pulling sheet, a mobile clipping sheet and a connection tool. When the pulling sheet is pulled, through the leverage effect the swivel rod optionally abuts against the bottoms of the support arms or swivels the passive sheet while the swivel rod is rotated, so the mobile end of the mobile clipping sheet generates an upward or downward movement, and the teeth lines of the mobile end and the teeth rows of the base board are engaged or forms a slit. When the mobile clipping sheet of the pacifier clip is clipped on a thicker object, through the leverage effect, the pair of support arms of the mobile clipping sheet applies a clockwise force to the swivel rod disposed below the support arms, so the abutting force between the two components is enhanced and the clipping effect is also increased.

Owner:TIEN CHUNG ENT

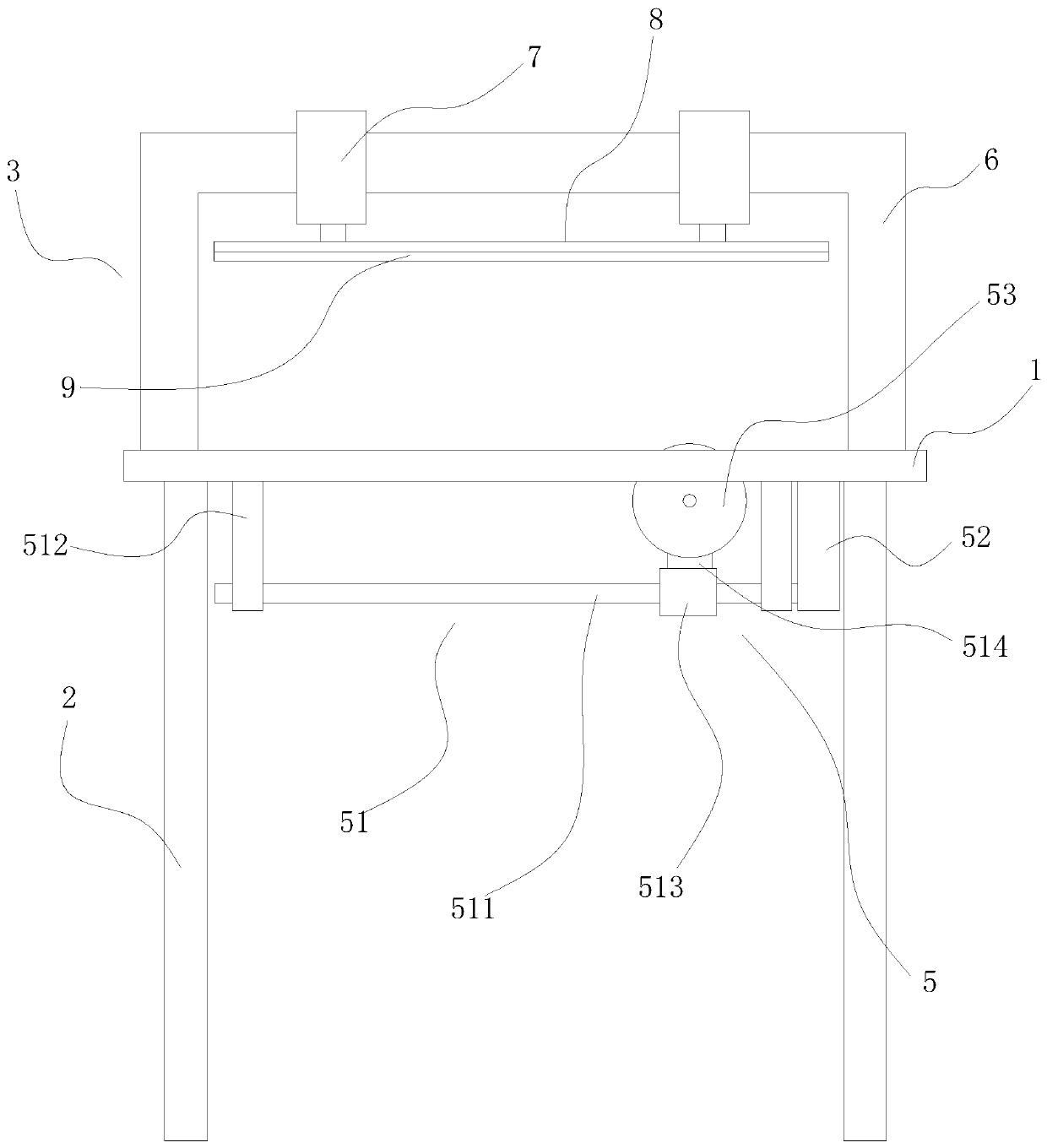

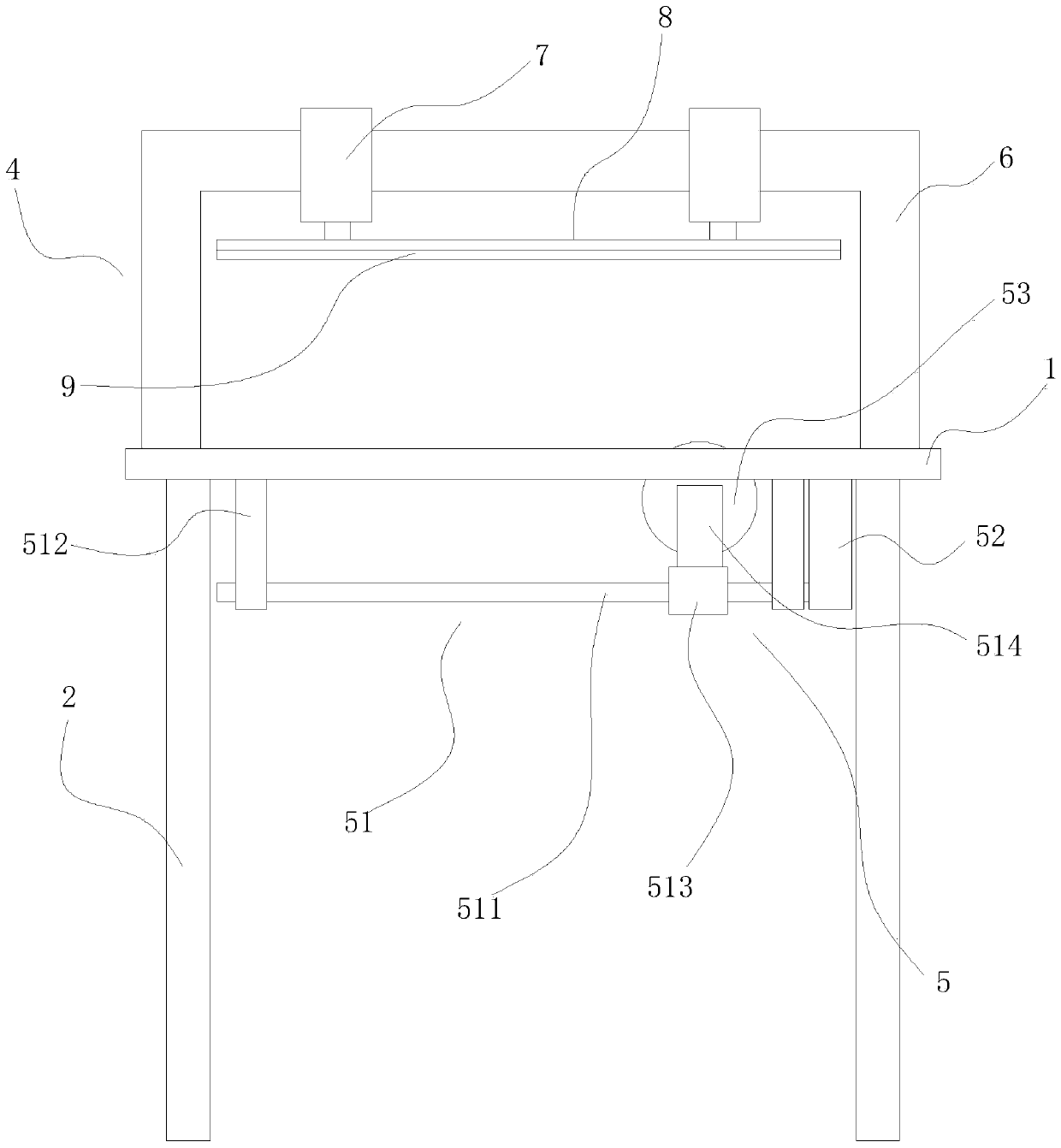

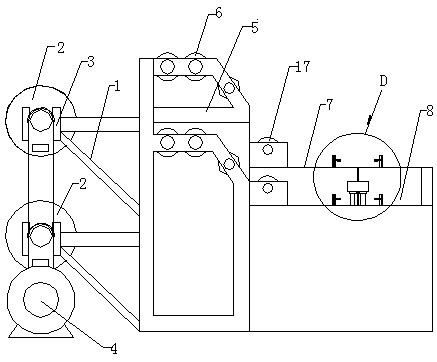

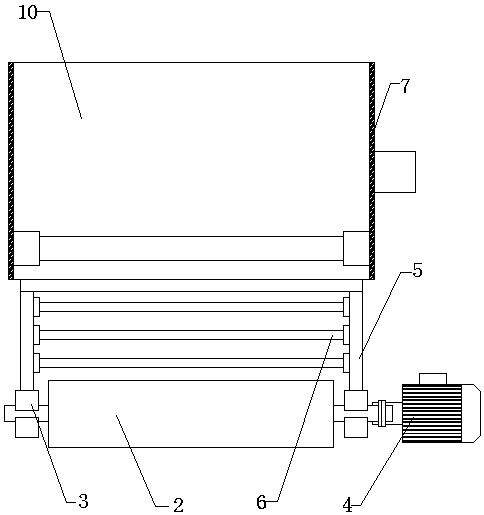

Underwear fabric manufacturing system and method and underwear fabric

ActiveCN110965311AStretch and cut evenlyGood tailoringSevering textilesUndergarmentsFiberCotton cloth

The invention belongs to the underwear fabric processing field, and more specifically relates to an underwear fabric manufacturing system and method and an underwear fabric. The processing method comprises the following steps of enabling a receiving combined cutting base to slide to a specified position in a fixed cutting base, and enabling the cloth to intermittently pass between the receiving combined cutting base and a combined cropper, wherein the receiving combined cutting base, a drive connector, two tilt drive extrusion fixers, an upper connection driver and a combined cropper are included; connecting the drive connector to a power supply to drive the two tilt drive extrusion fixers to rotate, so that the two tilt drive extrusion fixers synchronously reciprocate on the fixed cuttingbase, thus the intermittently passing cloth is extruded at the two ends of the receiving combined cutting base, and clamping and fixing the stopped cloth; and driving the fixed cutting base on the upper connection driver and the combined cropper to vertically reciprocate. According to the underwear fabric processed by the method, the compositions of the fabric are 30% cotton, 30% silk and 40% chemical fiber.

Owner:江苏虞美人纺织品有限公司

Pacifier clip

The present invention relates to a pacifier clip, consists of a base board, a pulling sheet, a mobile clipping sheet and a connection tool. When the pulling sheet is pulled, through the leverage effect the swivel rod optionally abuts against the bottoms of the support arms or swivels the passive sheet while the swivel rod is rotated, so the mobile end of the mobile clipping sheet generates an upward or downward movement, and the teeth lines of the mobile end and the teeth rows of the base board are engaged or forms a slit. When the mobile clipping sheet of the pacifier clip is clipped on a thicker object, through the leverage effect, the pair of support arms of the mobile clipping sheet applies a clockwise force to the swivel rod disposed below the support arms, so the abutting force between the two components is enhanced and the clipping effect is also increased.

Owner:TIEN CHUNG ENT

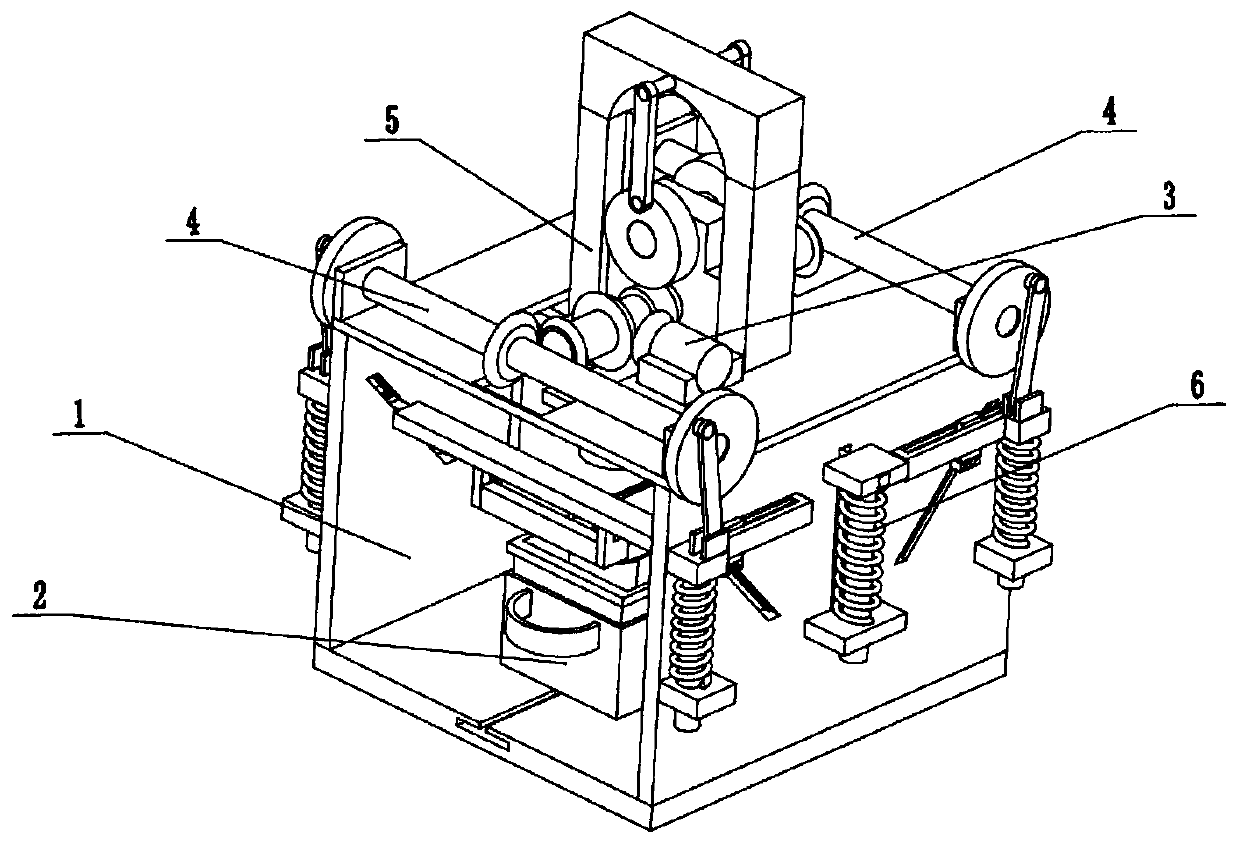

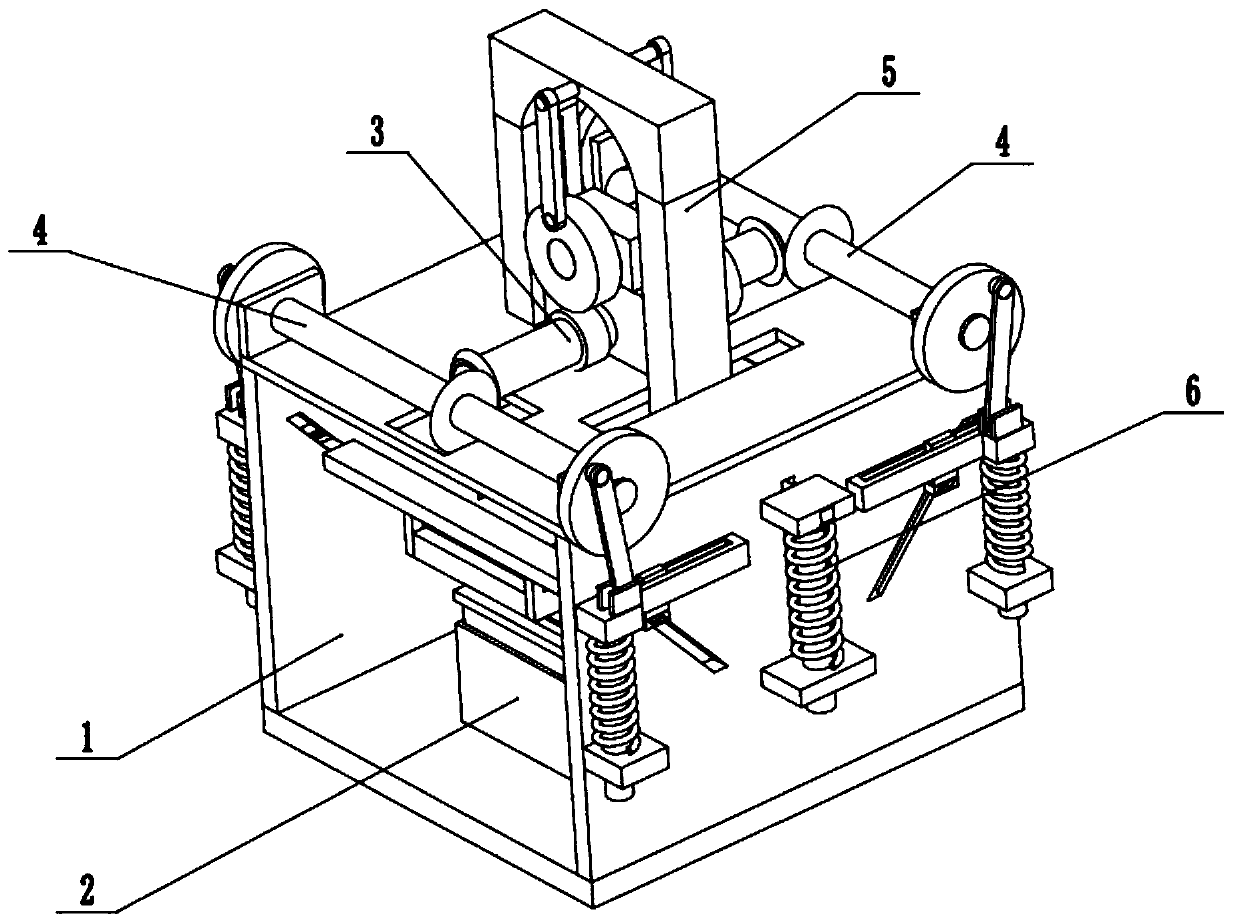

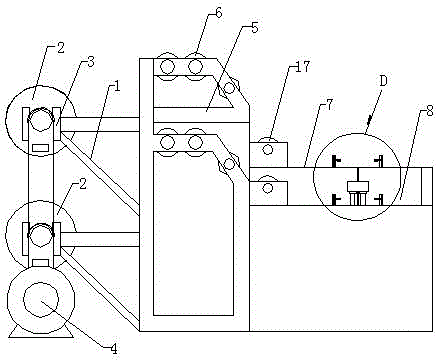

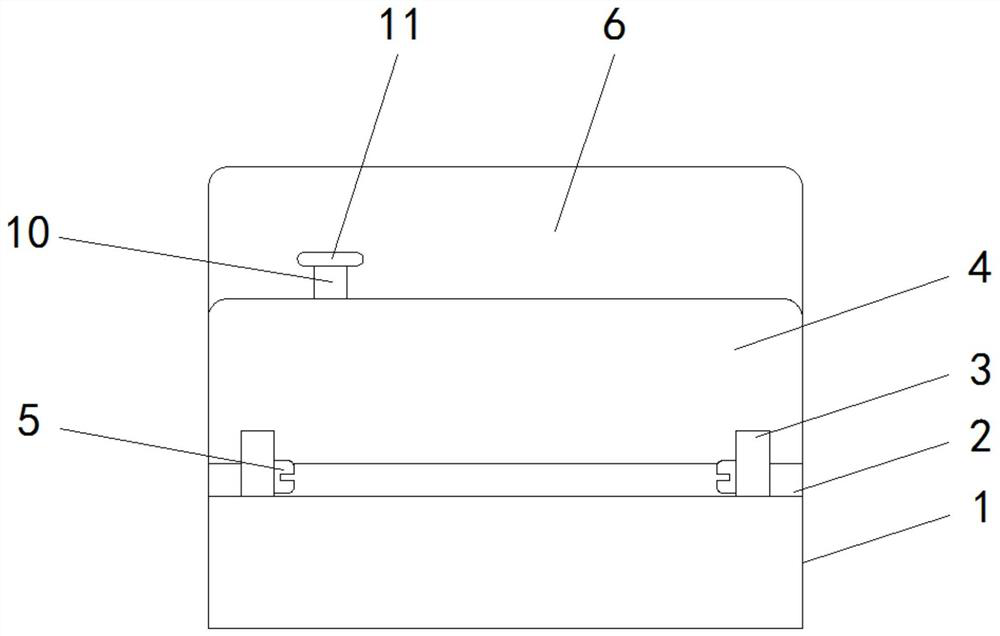

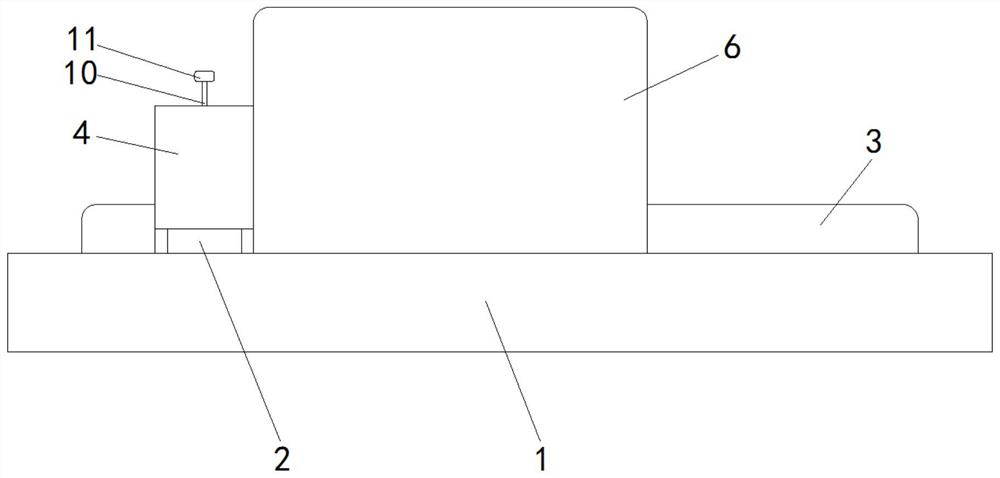

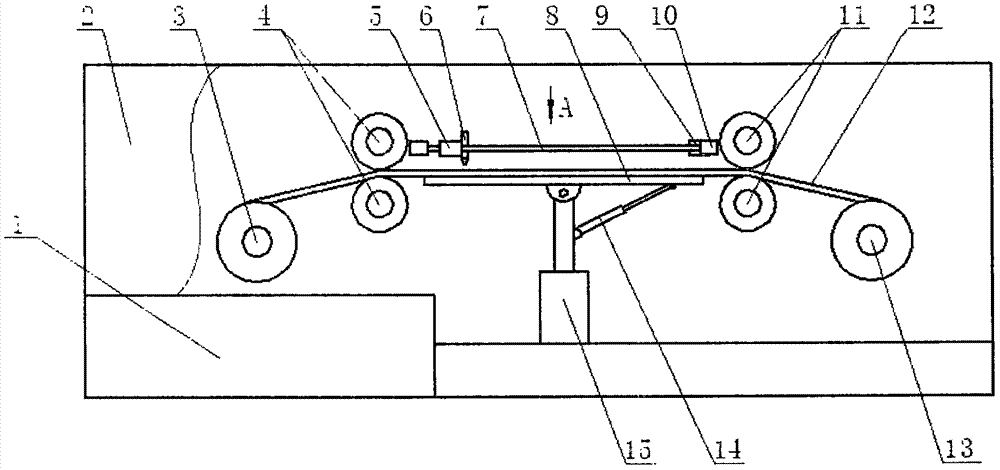

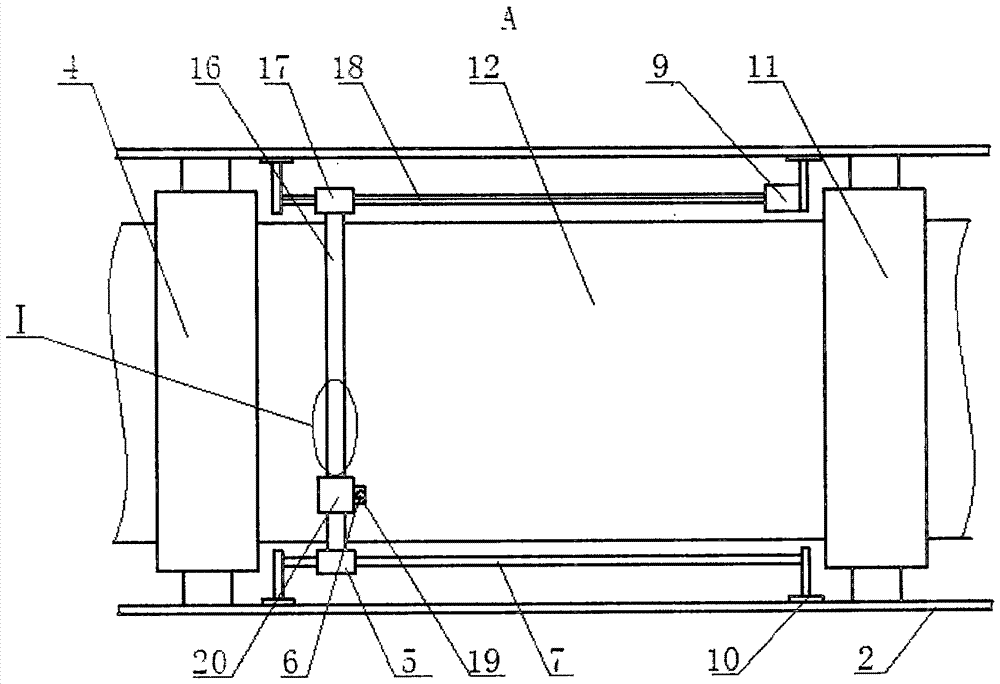

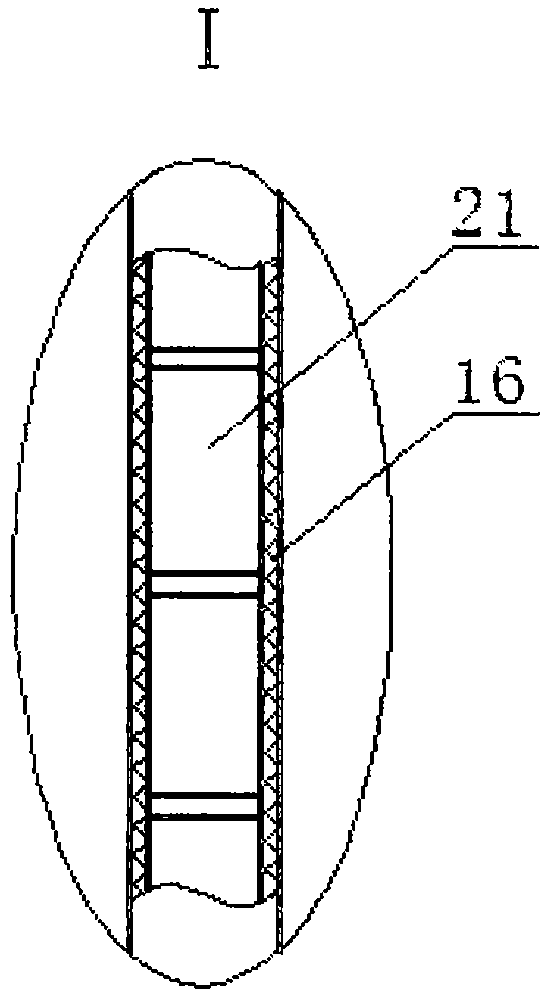

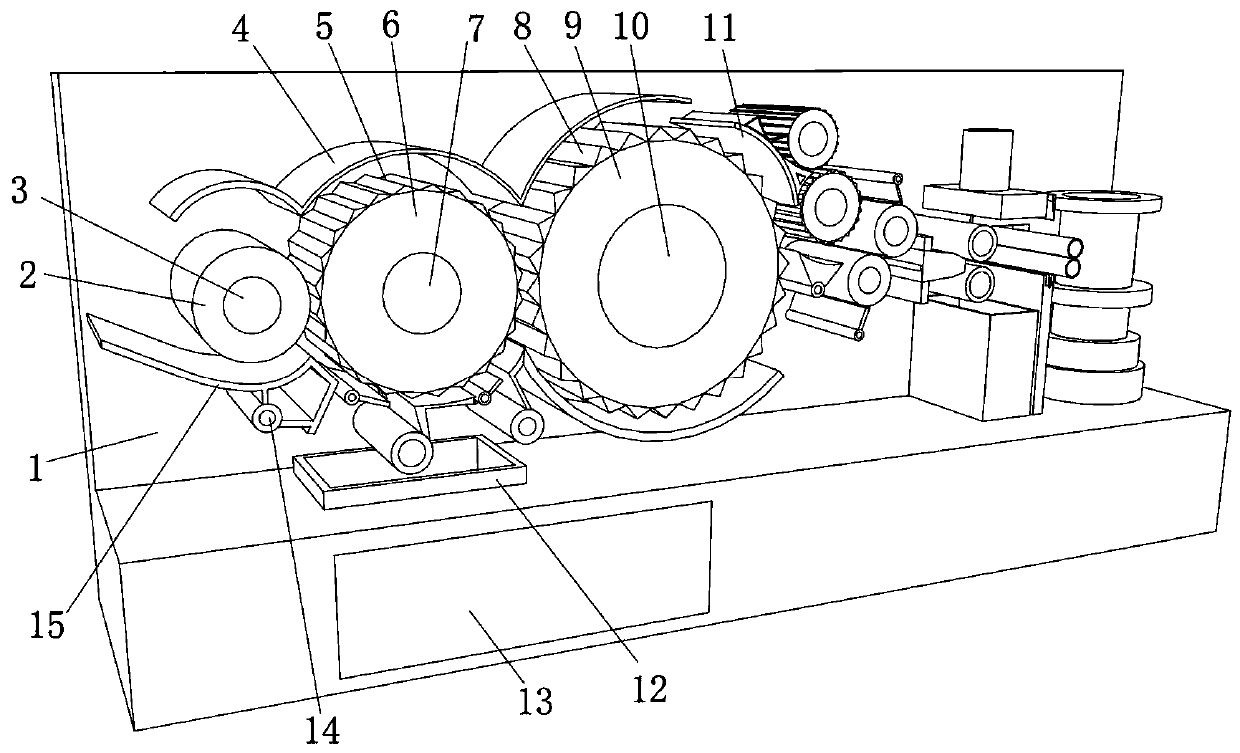

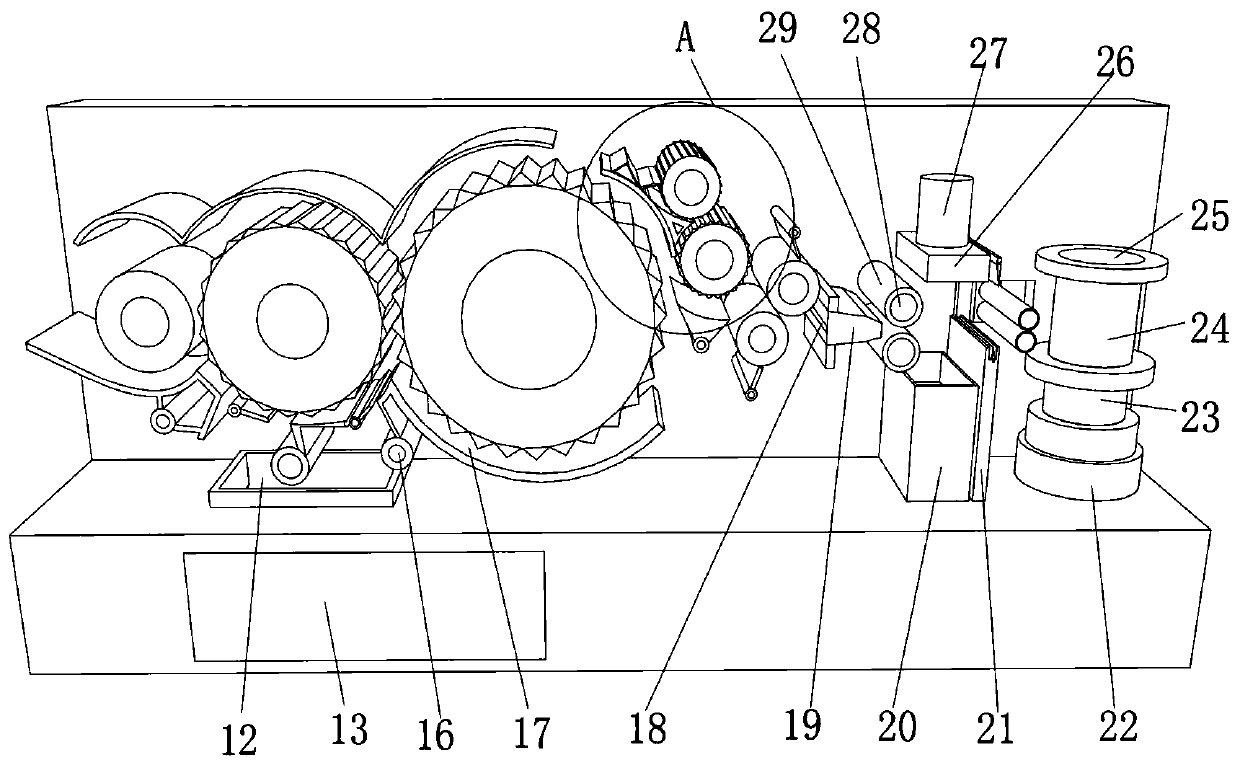

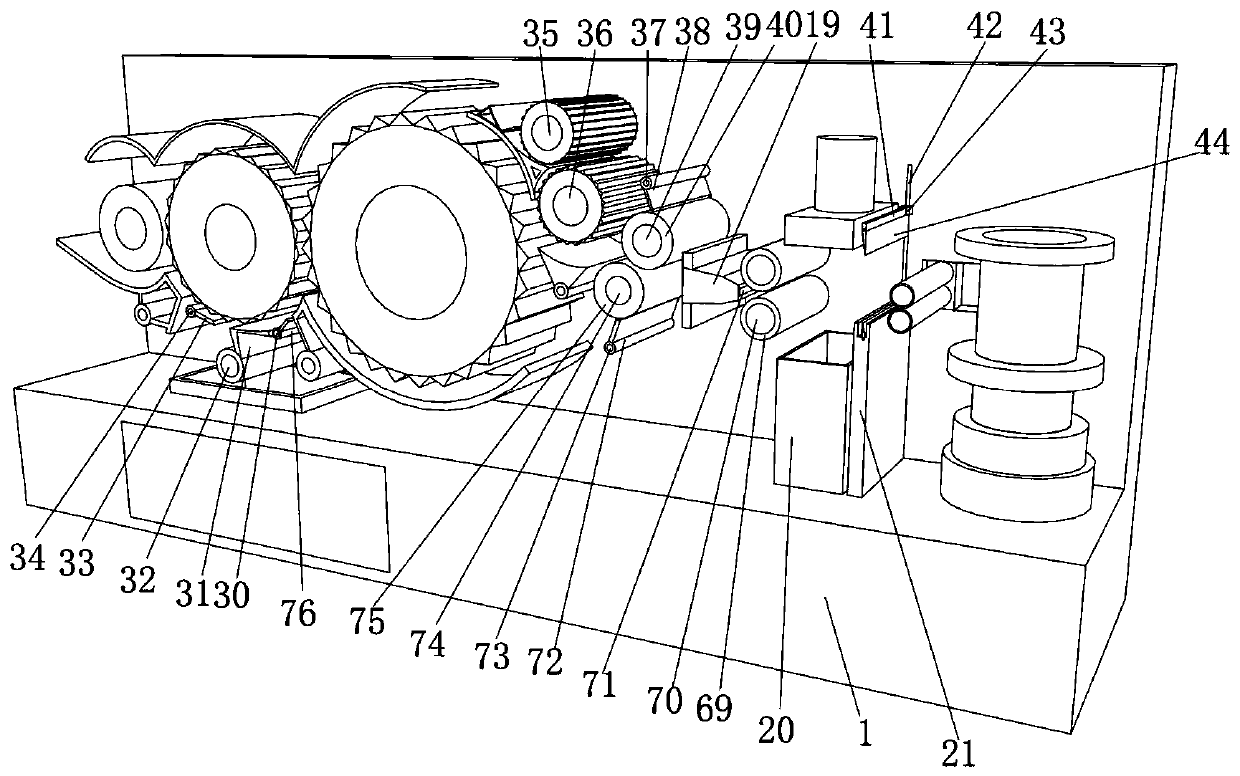

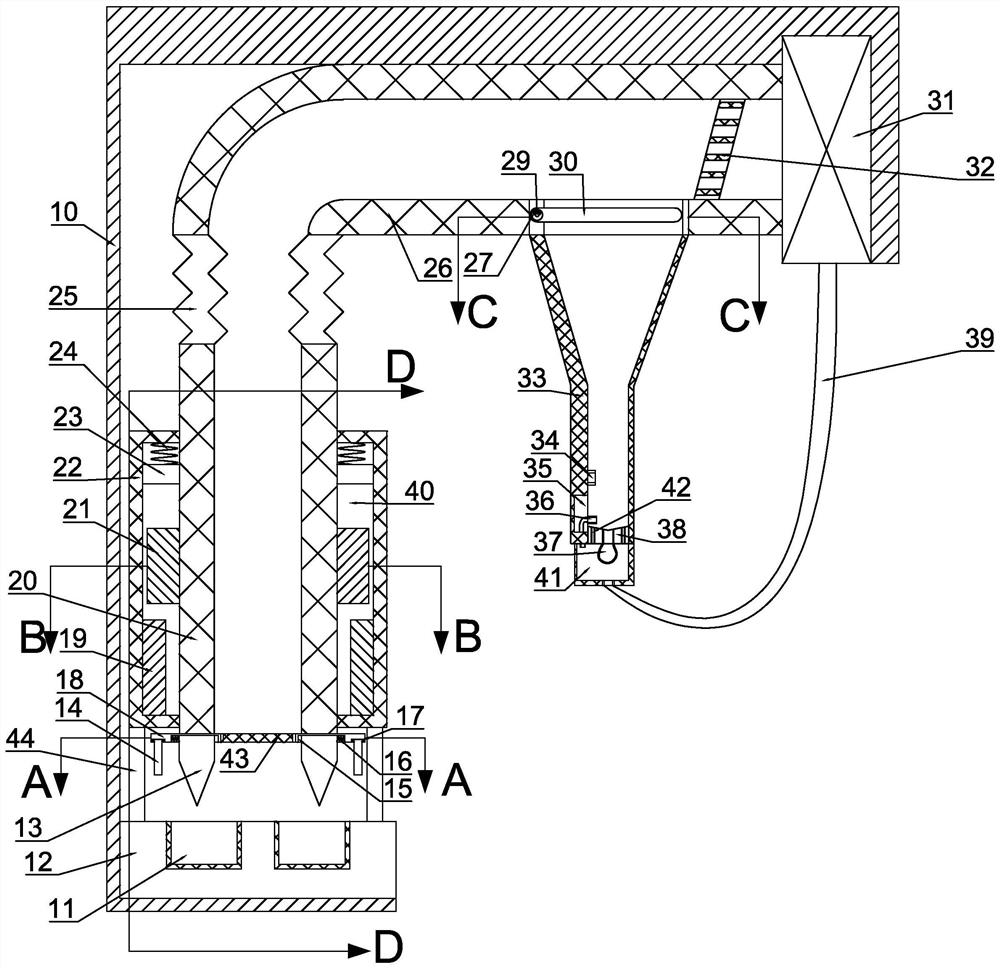

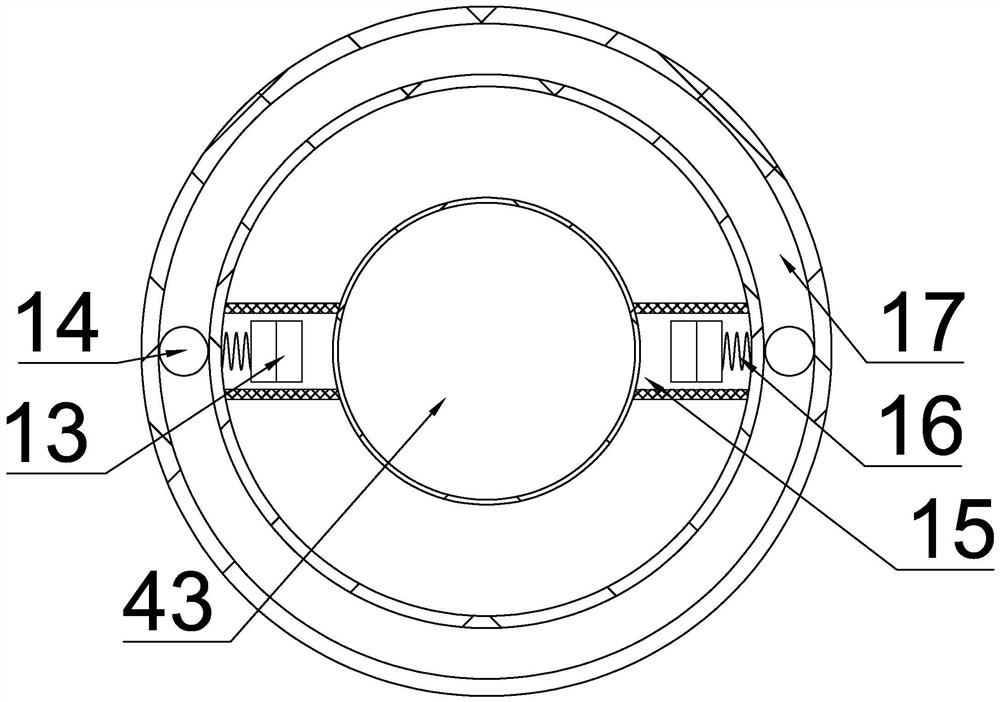

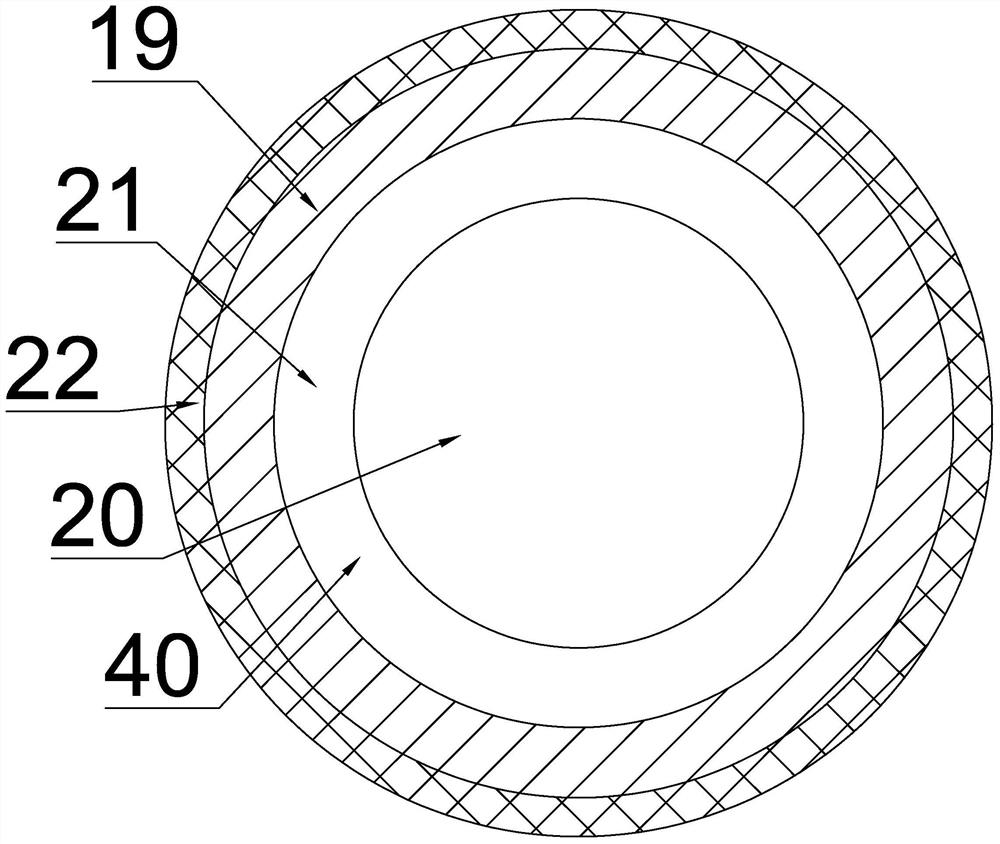

Double-layer synchronous tailoring system for home textile fabric

ActiveCN105905653AEasy to adjustImprove cutting efficiencySevering textilesArticle deliveryEngineeringMechanical engineering

The invention discloses a double-layer synchronous tailoring system for home textile fabric. The double-layer synchronous tailoring system for the home textile fabric sequentially comprises a double-layer feeding device, a double-layer material tidying device and a double-layer tailoring platform from the feeding end to the discharging end. The double-layer tailoring platform comprises an upper tailoring platform and a lower tailoring platform. An electric shear knife capable of conducting up-and-down cutting at the same time is arranged between the upper tailoring platform and the lower tailoring platform. Each of the upper tailoring platform and the lower tailoring platform is provided with a gap adjusting positioning mechanism. Each gap adjusting positioning mechanism comprises an adjusting base and a pressing plate perpendicular to each other. The tailoring system is simple in structure, the tailoring size is accurate, the positioning effect and the pressing effect are good in the tailoring process, the automation degree is high, and labor force is saved. The tailoring efficiency is high and is two times of the existing tailoring efficiency, the tailoring time is greatly saved, and the fabric processing period is shortened.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

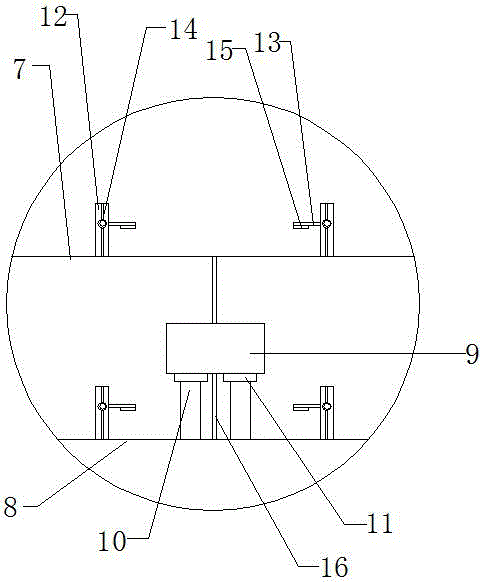

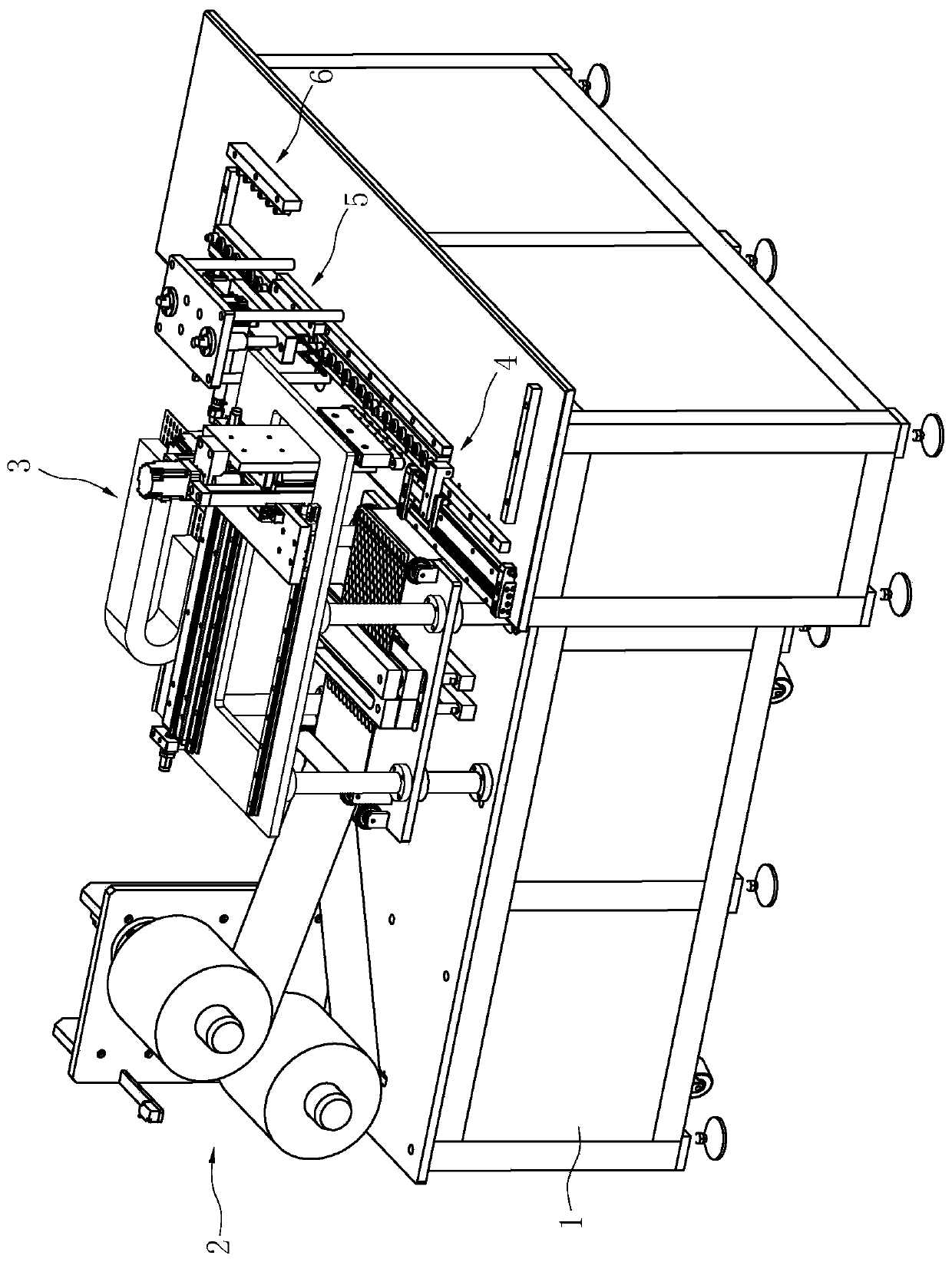

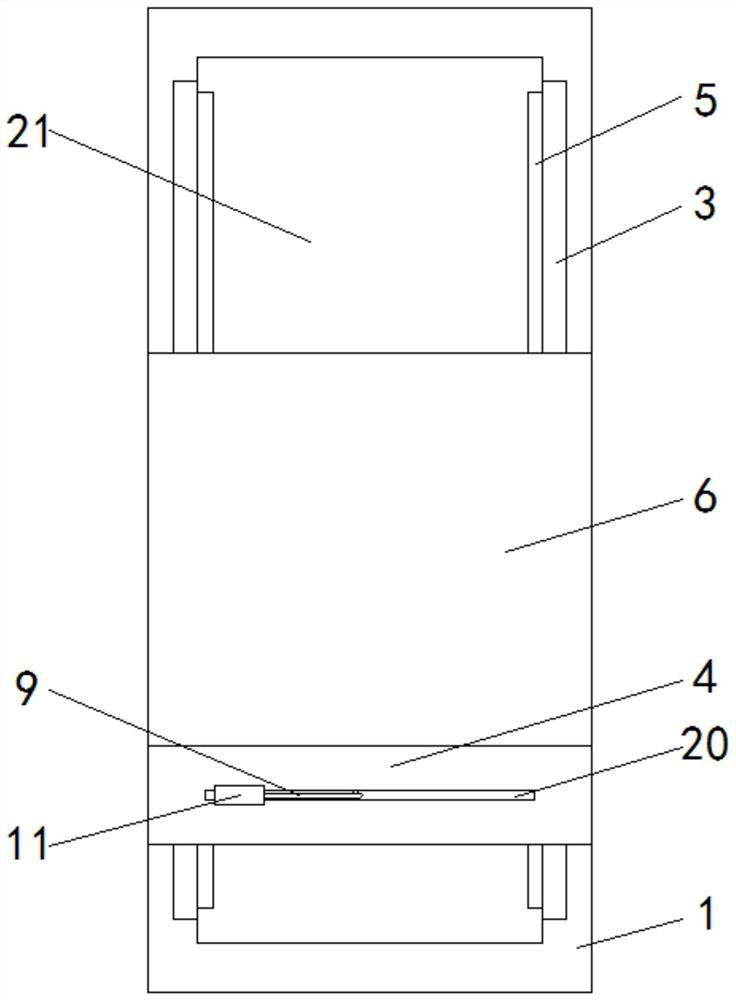

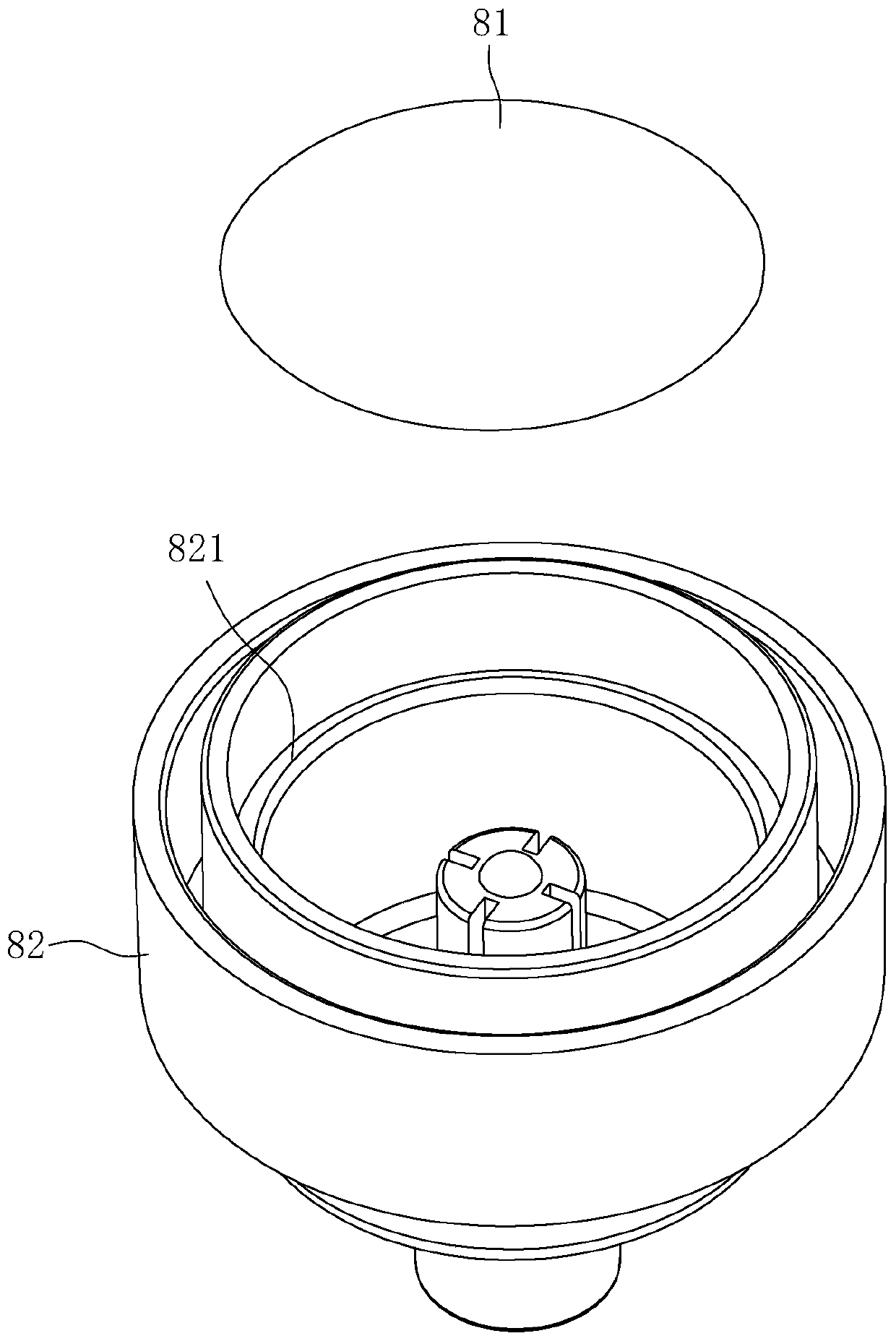

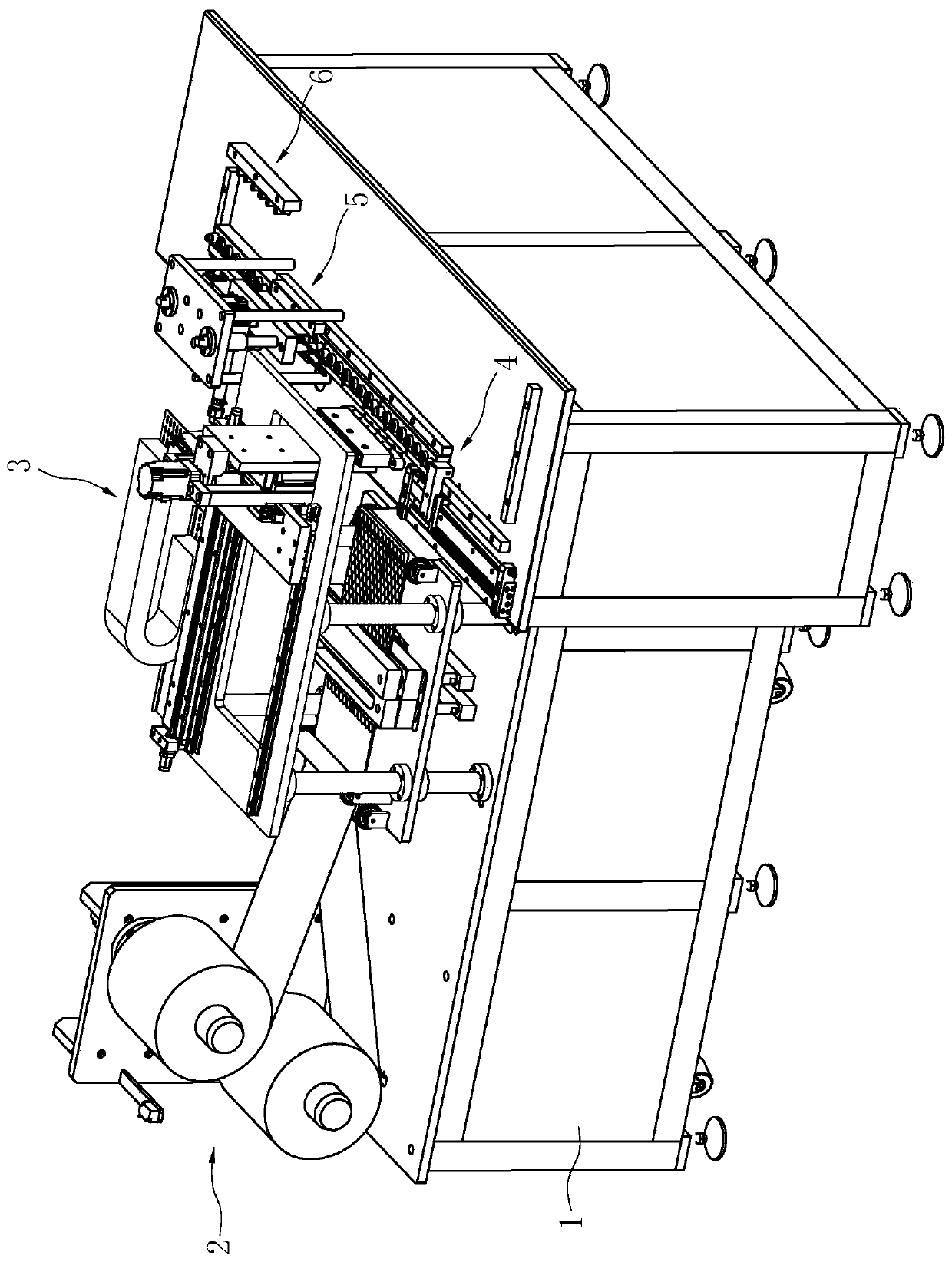

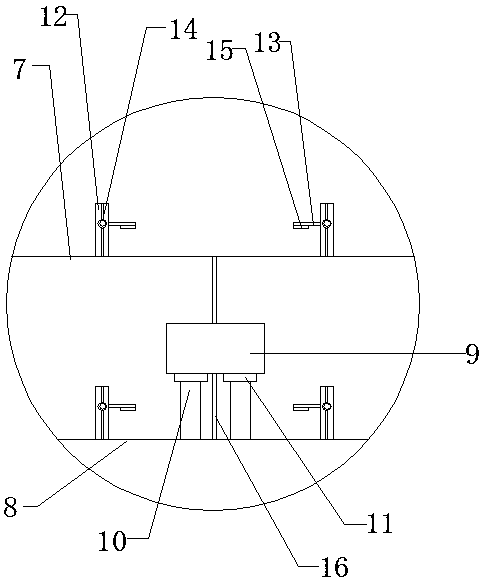

Filter automatic assembling device

ActiveCN111469431ARealize the assemblyImprove assembly accuracyDomestic articlesMetal working apparatusPunchingThin membrane

The invention discloses a filter automatic assembling device. The filter automatic assembling device comprises a rack (1), a filter film loading device (21), a bottom film loading device (22), a dual-layer thin film composite device (23), a dual-layer thin film stepping feeding device (24), a filter film punching pickup device (3), a filter conveying device (4), a filter welding device (5) and a filter discharging device (6), wherein the filter film loading device (21), the bottom film loading device (22), the dual-layer thin film composite device (23), the dual-layer thin film stepping feeding device (24), the filter film punching pickup device (3), the filter conveying device (4), the filter welding device (5) and the filter discharging device (6) are mounted on the rack. Through cooperative work of the above devices, assembling of a filter can be finished. Compared with the prior art, the filter automatic assembling device can automatically assemble the filter, punching, film suction and assembling can be coherent, the automation degree is high, sucked film deviating is prevented, the product assembling precision is high, sucking is carried out while cutting is carried out, andan obtained film is more complete and fit.

Owner:威海赛威智能科技有限公司

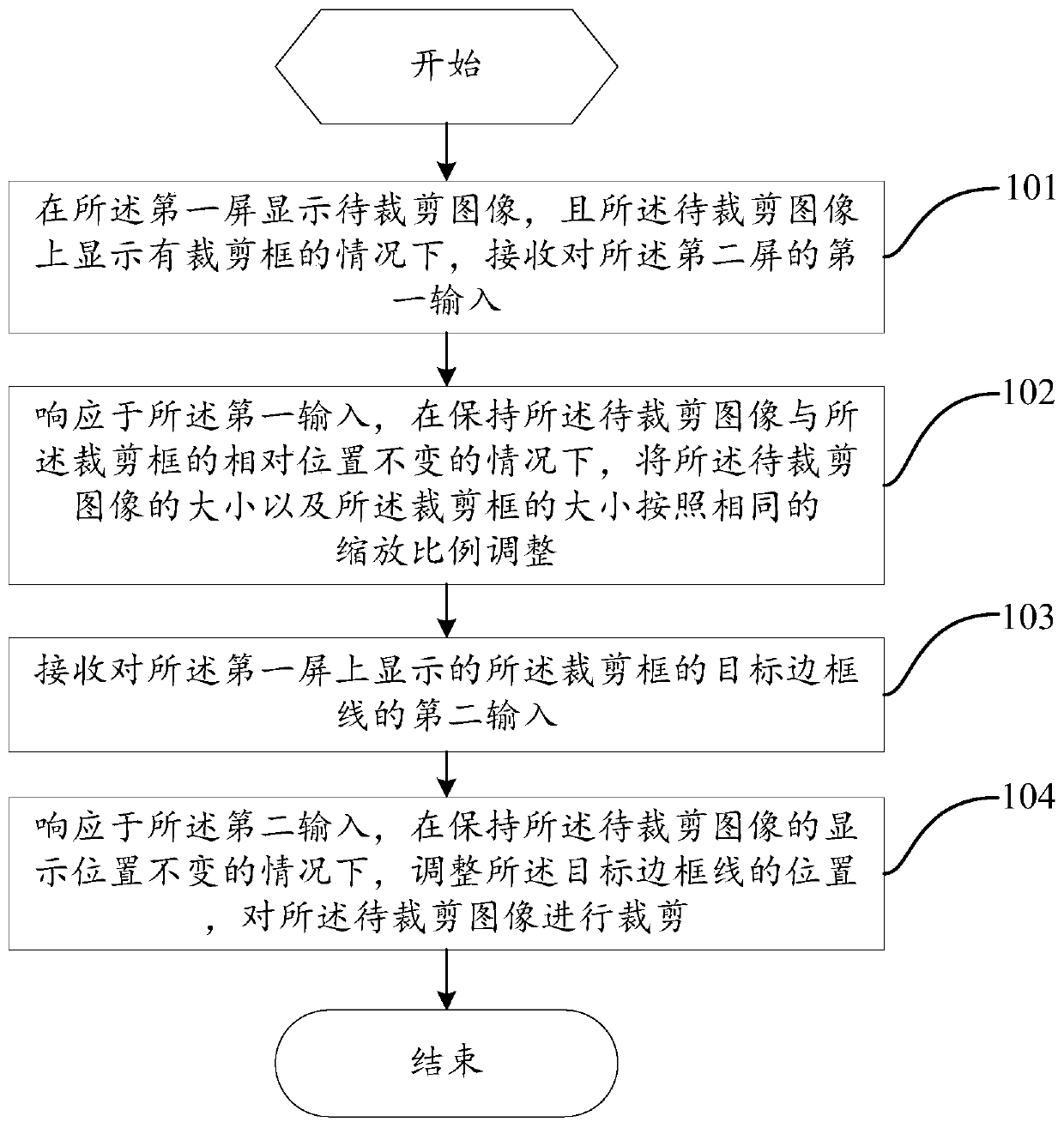

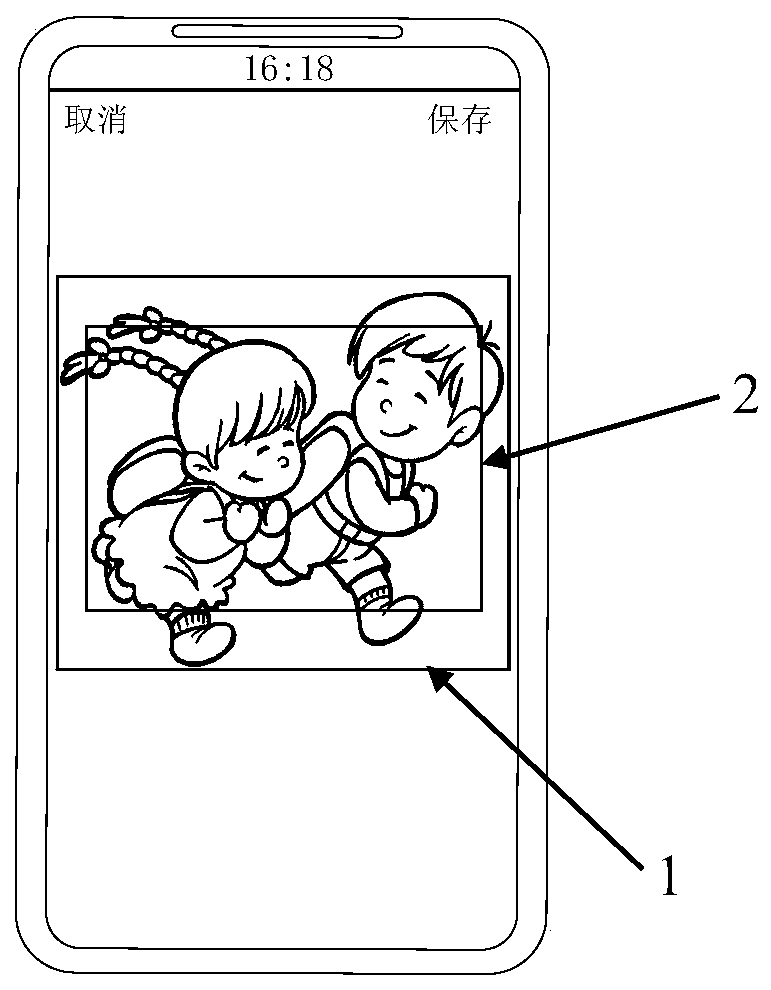

Image cutting method and electronic equipment

ActiveCN111311489ARealize fine cuttingMeet cutting needsImage enhancementImage analysisEngineeringComputer science

The invention provides an image cutting method and electronic equipment. The method comprises the steps of receiving a first input to a second screen under the condition that a to-be-clipped image isdisplayed on a first screen and a clipping frame is displayed on the to-be-clipped image; in response to the first input, adjusting the size of the to-be-clipped image and the size of the clipping frame according to the same zoom ratio under the condition of keeping the relative position of the to-be-clipped image and the clipping frame unchanged; receiving a second input of a target frame line ofa cutting frame displayed on the first screen; and in response to the second input, under the condition of keeping the display position of the to-be-clipped image unchanged, adjusting the position ofthe target frame line, and clipping the to-be-clipped image. According to the invention, a user does not need to repeatedly move the cutting frame up and down and left and right, refined cutting of the image can be realized through simple cutting operation, a better cutting effect can be achieved, the cutting requirement of the user for the image is met, and the experience of the cutting operation of the user is improved.

Owner:VIVO MOBILE COMM CO LTD

Elastic cloth clothing cutting and banding equipment capable of avoiding thread ends

InactiveCN111691174AGood tailoringAvoid damageMechanical cleaningPressure cleaningTemperature treatmentEngineering

The invention provides elastic cloth clothing cutting and banding equipment capable of avoiding thread ends. The elastic cloth clothing cutting and banding equipment comprises a base; a supporting component and fixing baffle plates are fixedly arranged on the upper side of the base; a cutting mechanism is fixedly arranged on the upper side of the supporting component; a banding mechanism is arranged on the rear side of the cutting mechanism; the lower side of the banding mechanism is connected to the base; an assembling component is arranged in the cutting mechanism; and a cutting blade is arranged on the assembling component. According to the elastic cloth clothing cutting and banding equipment capable of avoiding thread ends, a banded cloth is placed on an assembling plate, thread ends which remain during banding and are not processed completely exist on the cloth; kinetic energy is generated by a drafting machine, and the thread ends are absorbed through opening holes in the assembling plate; then heat is generated by a heating pipe, so that the absorbed thread ends are removed through high-temperature treatment; meanwhile, heat is separated from the cloth through a heat insulation plate, so that the cloth is prevented from being damaged; and the effect of removing the thread ends through high temperature of the equipment is reached.

Owner:潘燚

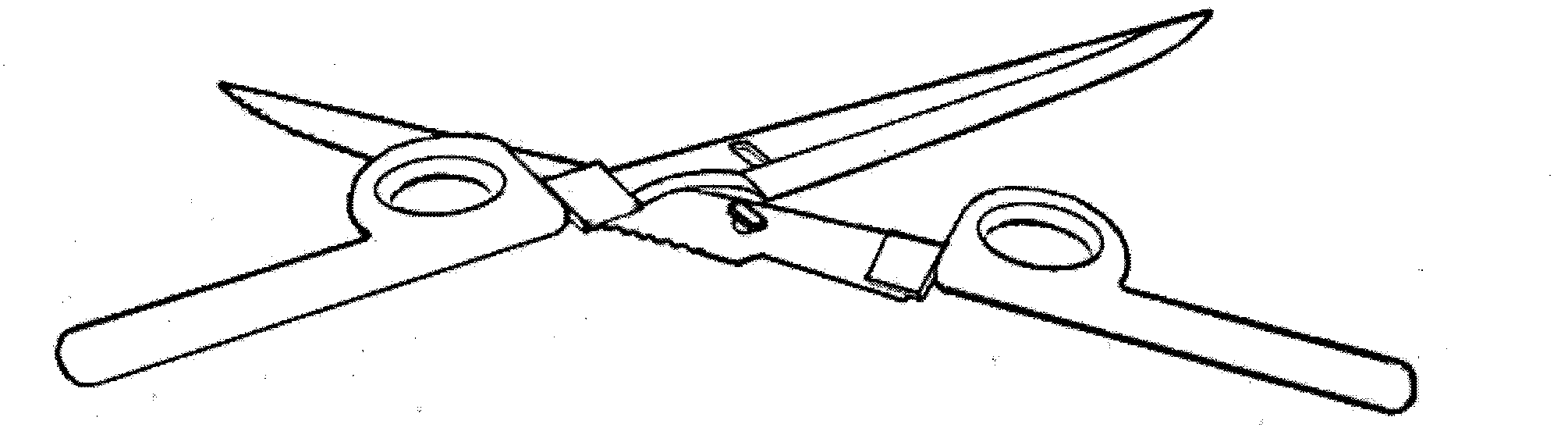

Multifunctional scissors

InactiveCN103770133ASimple structurePracticalMetal working apparatusKnife bladesBiomedical engineering

Owner:陈勇军

Tailoring device for clothing manufacture

InactiveCN111235859AReduce labor intensityGood tailoringSevering textilesElectric machineryEngineering

The invention discloses a tailoring device for clothing manufacture, and belongs to the technical field of clothing manufacture. The tailoring device comprises a working table, supporting legs, a first compressing device, a second compressing device and a cutting device, wherein the first compressing device and the second compressing device are mounted on the working table; a strip-shaped cut is formed in the working table, and the first compressing device and the second compressing device are located on both sides of the cut; the cutting device comprises a lead screw assembly, a driving device and a cutting knife mounted at the output end of the driving device; the lead screw assembly is mounted below the working table, and the lead screw assembly comprises a lead screw shaft, a mountingbase, a lead screw slide block and a motor, wherein the output end of the motor is connected with the lead screw shaft; the lead screw shaft is connected with the bottom wall of the working table through the mounting base; the lead screw slide block is movably arranged on the lead screw shaft and matched with the lead screw shaft; the driving device is mounted on the lead screw slide block; the cutting knife extends out of the cut from the side below the cut; and the lead screw shaft is parallel to the cut. The tailoring device has the advantages of small labor intensity and better tailoring effect.

Owner:繁昌县纺东服饰有限公司

Garment production cutting device

InactiveCN106041319BHigh position stabilityImprove finenessLaser beam welding apparatusEngineeringLaser

The invention discloses a garment producing and cutting device. The garment producing and cutting device comprises two side plates. A raw material roller, front pressing rollers, rear pressing rollers and a scrap roller with rotation power are sequentially arranged between the side plates. Supporting bases are arranged in the positions, between the front pressing rollers and the rear pressing rollers, of the side plates. A guide rod is arranged on the supporting bases of one side plate, and a sliding base is arranged on the guide rod. A lead screw is arranged on the supporting bases of the other side plate, one end of the lead screw is connected with an output shaft of a motor, and the other end of the lead screw is matched with the supporting bases through bearings. A nut is arranged on the lead screw in a matched mode. The lead screw is parallel to the guide rod. A sliding sleeve is arranged between the nut and the sliding base. A metal sliding block is arranged on the sliding sleeve in a matched mode. A plurality of electromagnets are arranged in the sliding sleeve in sequence. A chuck is mounted on the metal sliding block. A laser is mounted on the chuck. A metal liner plate is arranged on the lower portion of the laser. The lead screw and the nut are adopted as a travelling structure in the X-axis direction, the fineness is high, deformation is not caused by long-time using, the height position of the laser is stable, and the multiple electromagnets are adopted in the Y-axis direction.

Owner:WENZHOU POLYTECHNIC

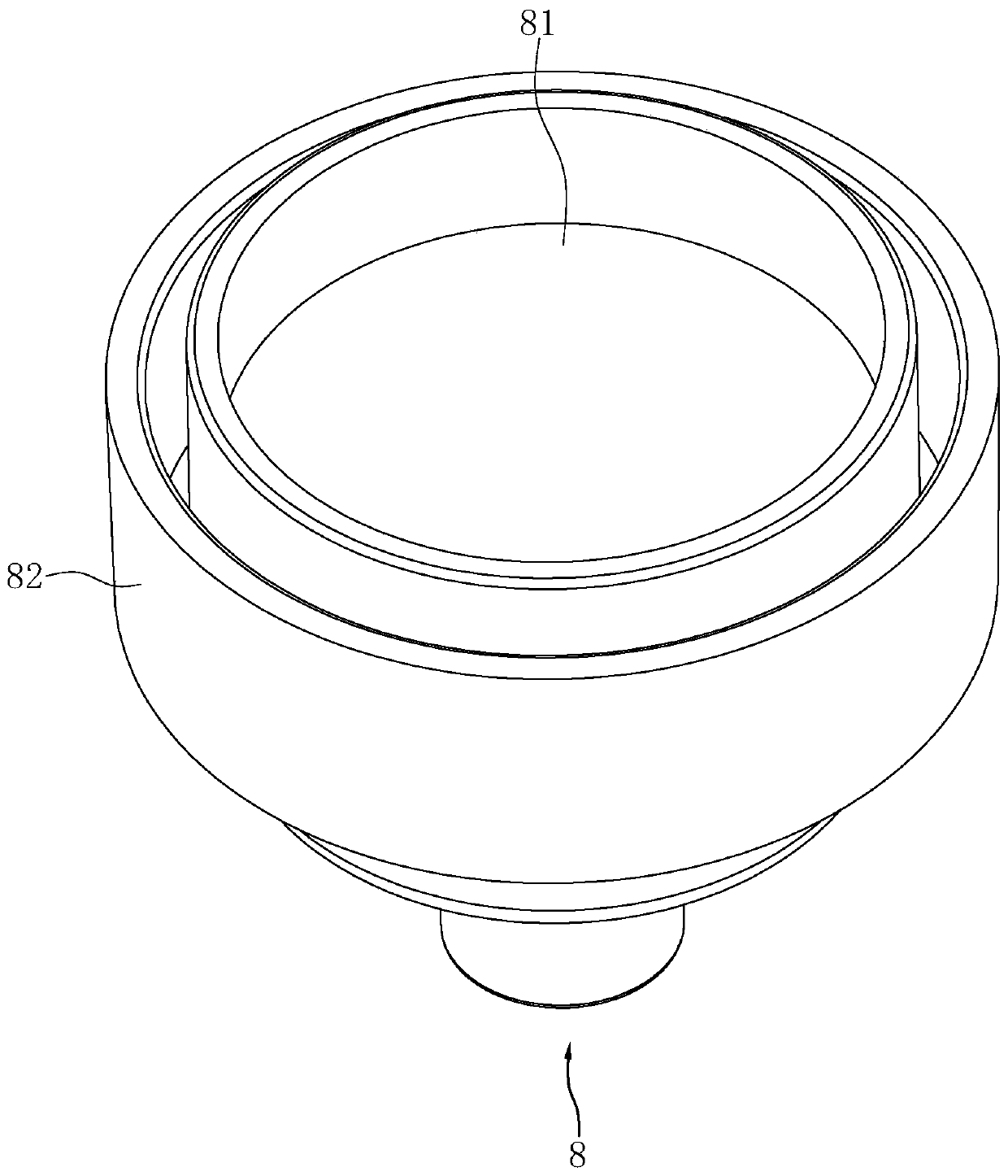

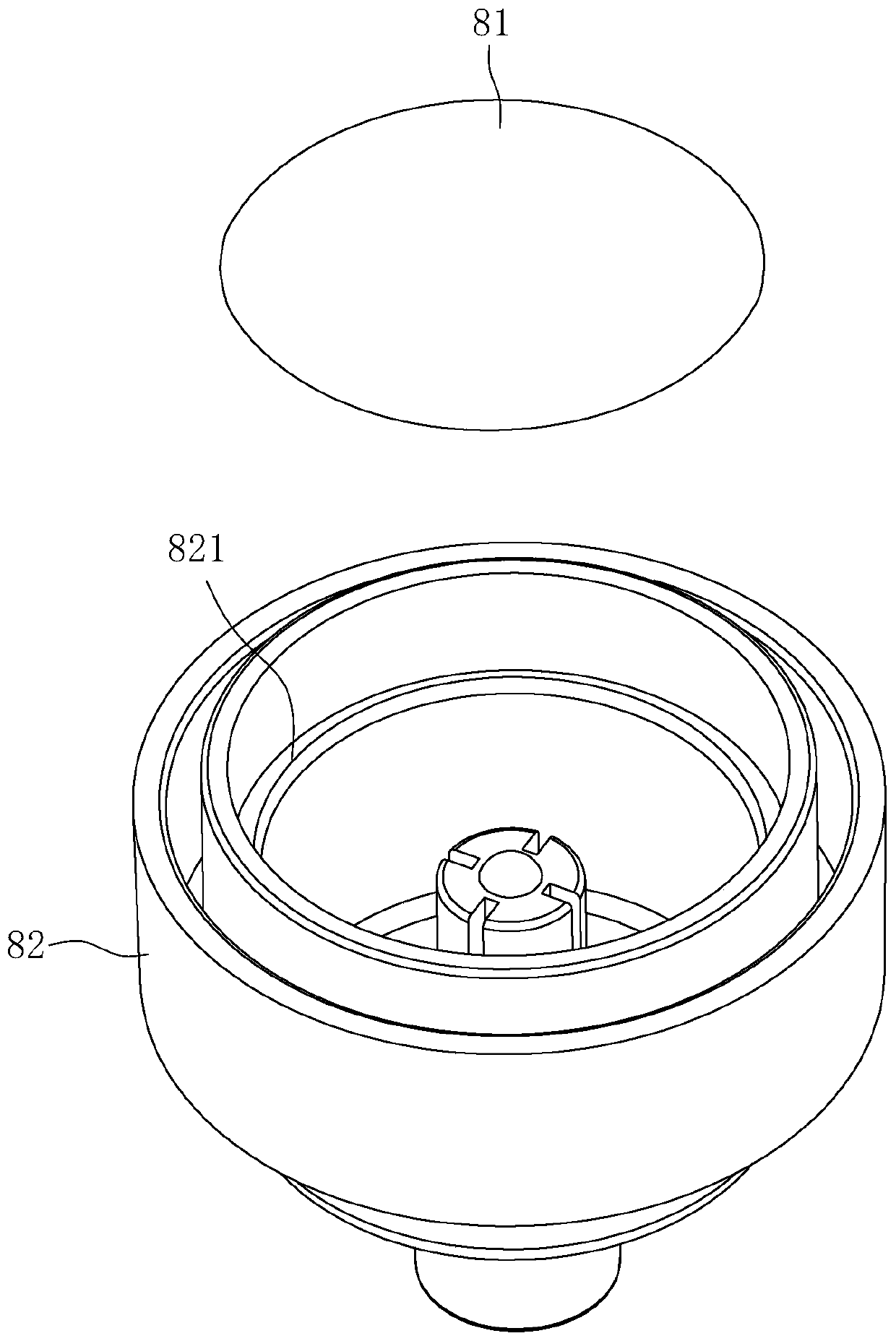

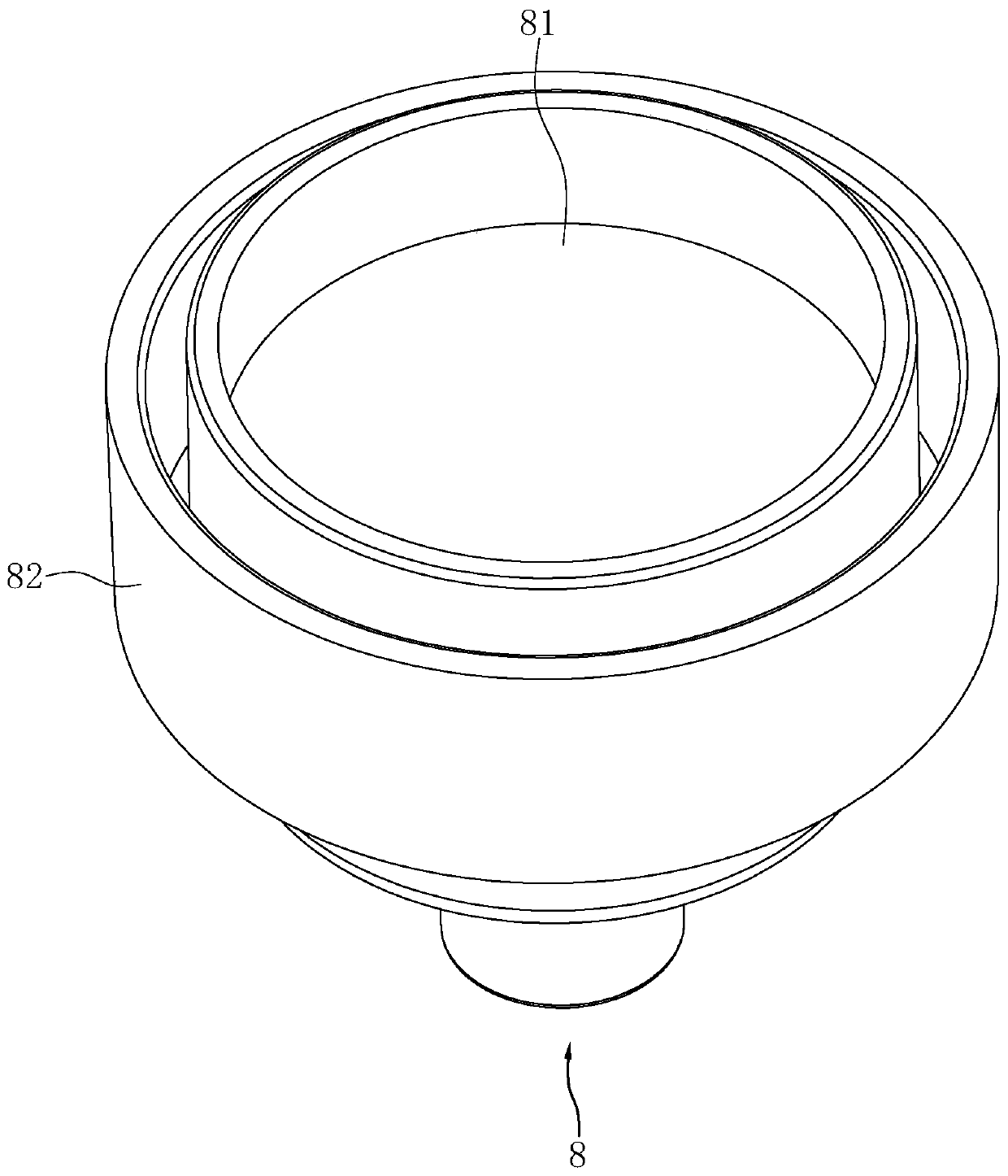

Automatic assembling method of filter

ActiveCN111495072ARealize the assemblyImprove assembly accuracyDispersed particle filtrationStationary filtering element filtersBi layerThin membrane

The invention discloses an automatic assembling method of a filter. The automatic assembling method comprises the following steps: S1, a filter membrane (71) and a bottom membrane (72) are supplied toa double-layer membrane feeding station; S2, the filter membrane (71) and the bottom membrane (72) are laminated into a double-layer membrane (7); S3, the double-layer membrane (7) is conveyed to a filtering membrane punching station; S4, the double-layer membrane (7) is punched to form a filter membrane slice (81); S5, the filter membrane slice (81) is moved into a filter base (82); s6, the filter membrane slices (81) are welded on the filter base (82) to form a filter (8); and S7, the filter (8) is taken out. Compared with the prior art, the automatic assembling method of the filter has theadvantages that the filter can be automatically assembled, punched, filmed and assembled in one step, the automation degree is high, the attached membrane is prevented from deviating, the product assembling precision is high, and the obtained membrane is more complete and smooth by performing attaching while punching.

Owner:威海赛威智能科技有限公司 +1

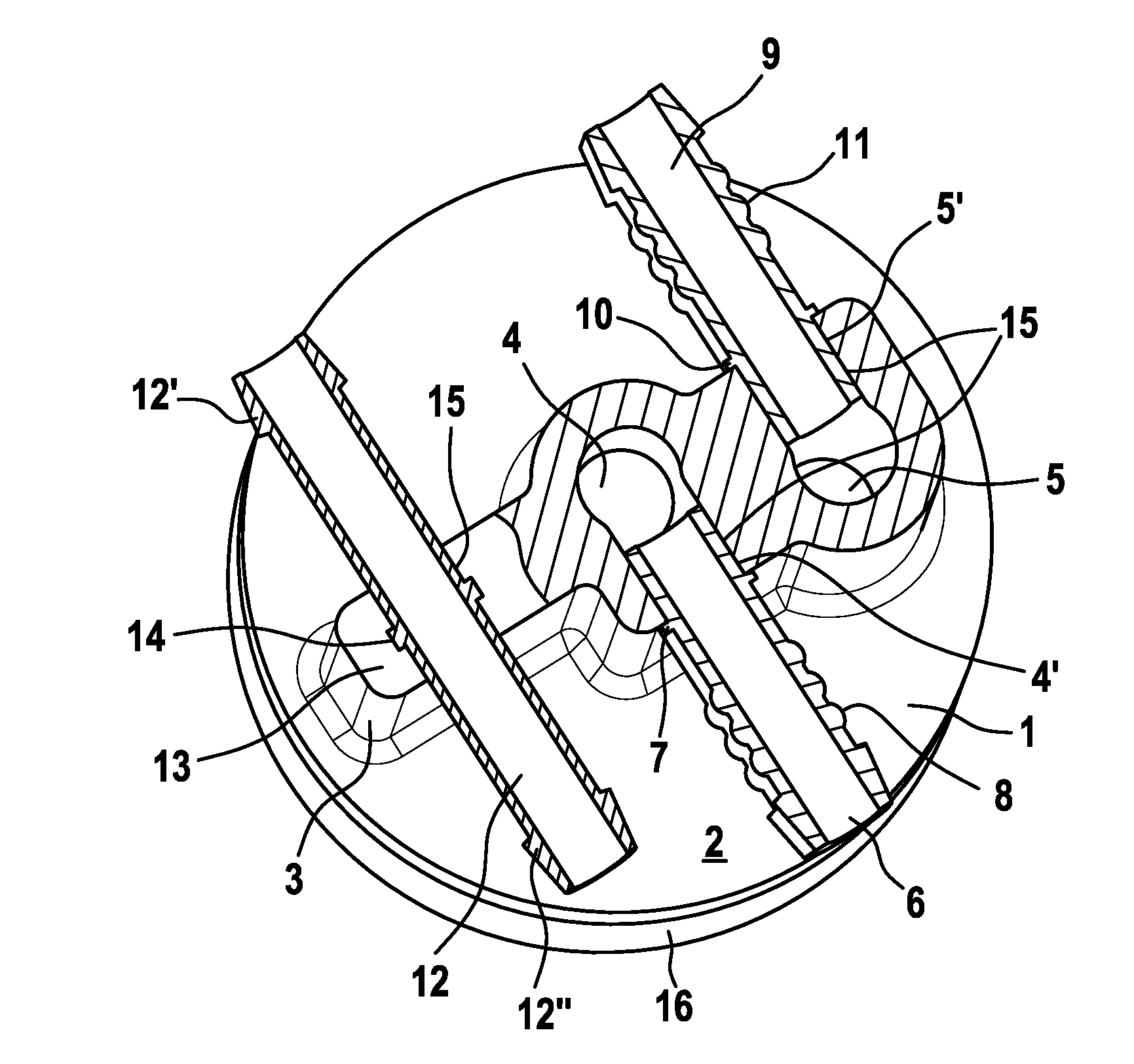

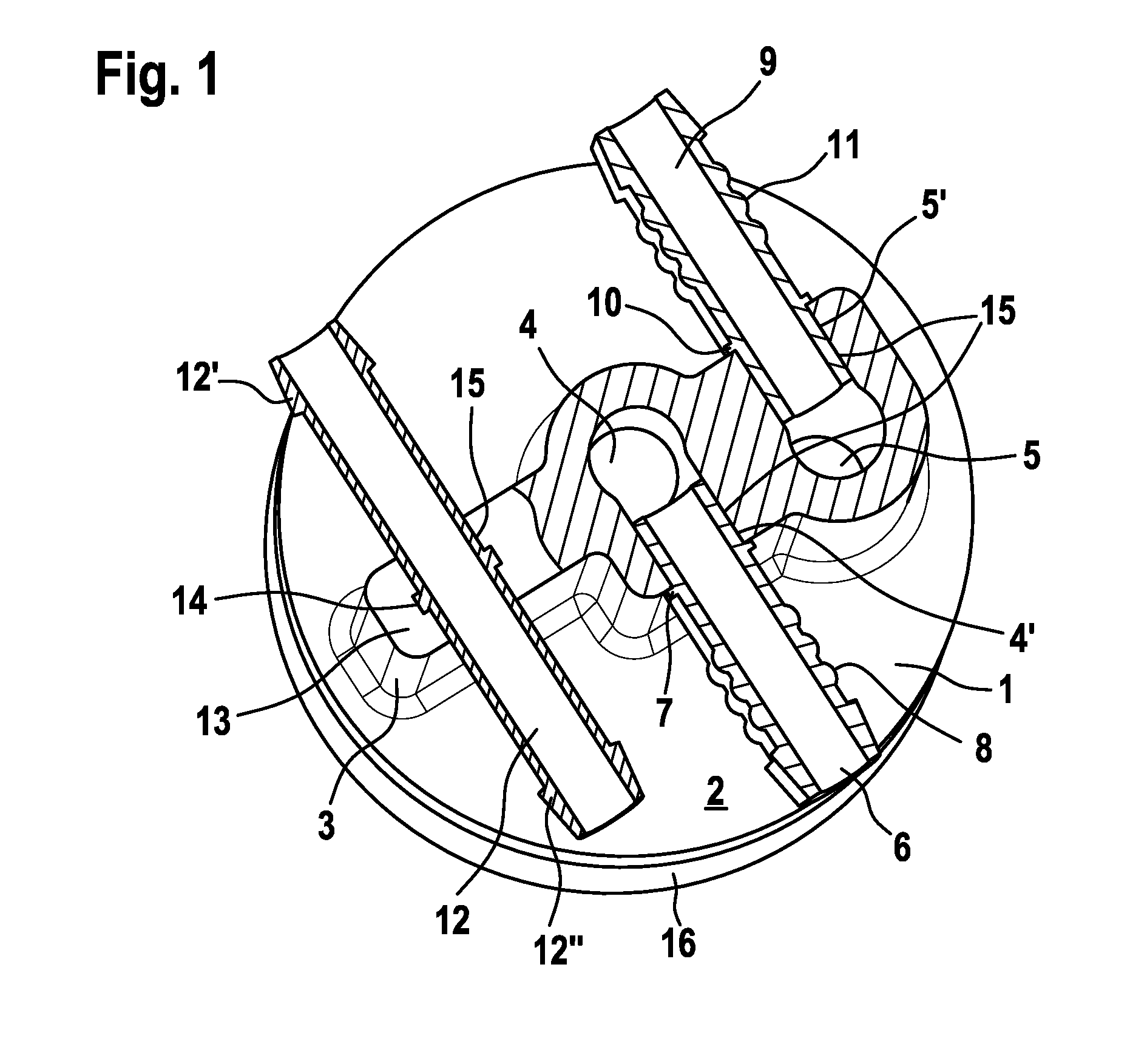

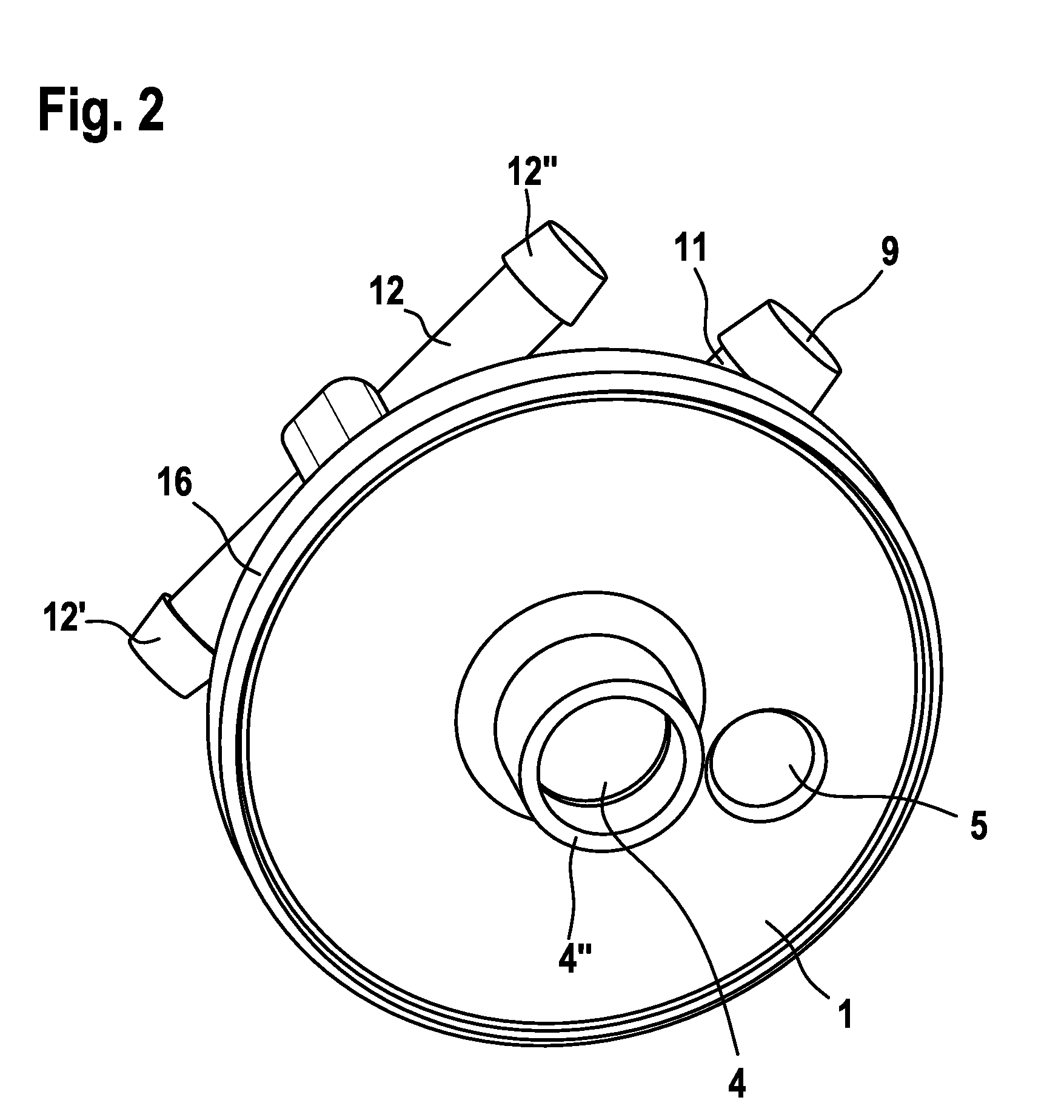

Liquid Filter

A liquid filter intended for use as a fuel filter is composed of a housing produced from aluminium by an extrusion process and of a cover (1) formed as an aluminium casting. The cover (1) is provided with connecting bores (4′, 5′) in which pipe elements (6, 9) which are intended for delivering and discharging fuel are held by means of an adhesive bond. This results in a cover which can be produced more cost-effectively than the prior art and which can further be used as a casting which can be employed in modular fashion, this casting allowing different variations for the connections of the pipe elements.

Owner:A KAYSER AUTOMOTIVE SYST

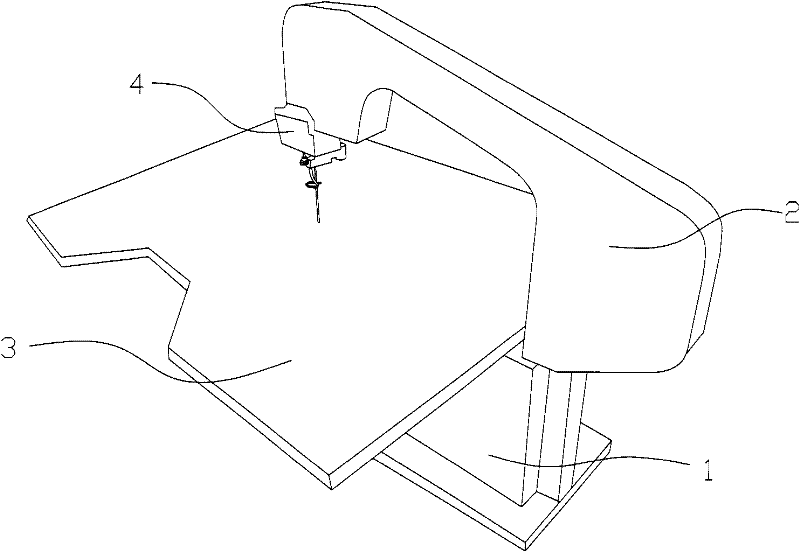

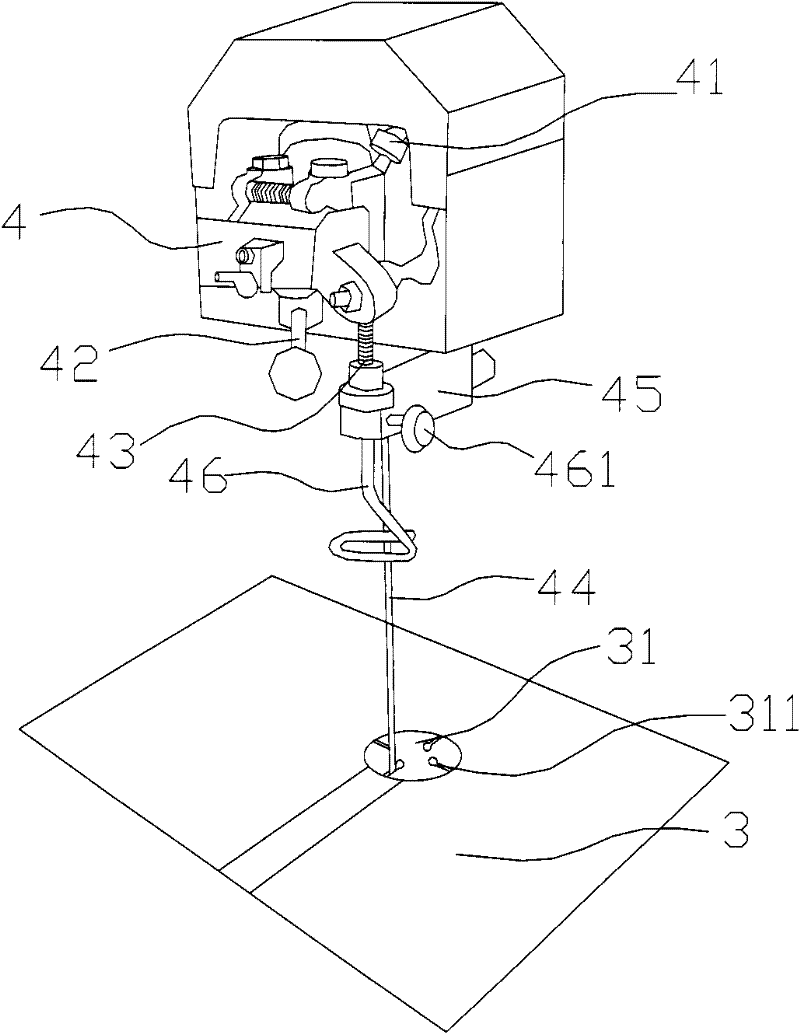

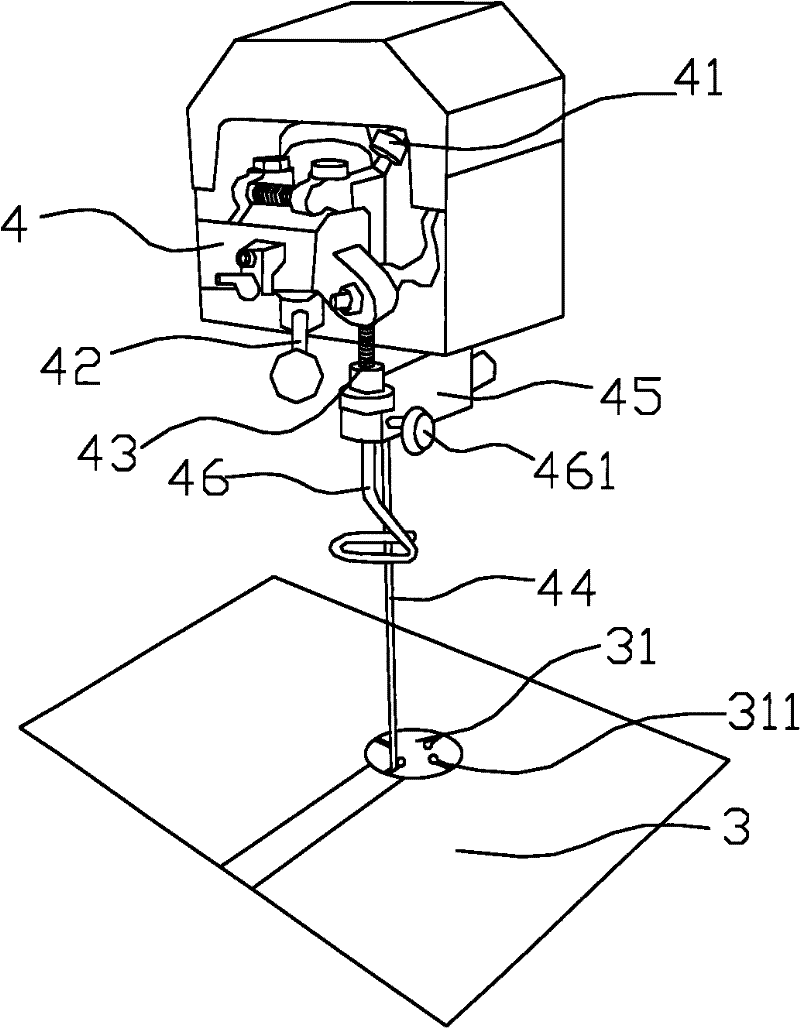

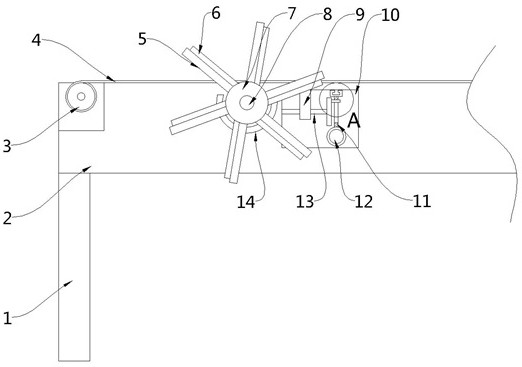

Cloth cutting device

InactiveCN102454101AMeet the needs of developmentSimple structureSevering textilesProduction rateEngineering

The invention discloses a cloth cutting device used in the clothes field. The cloth cutting device comprises a body, a supporting arm, a workbench and a head of the cloth cutting device. The supporting arm is fixedly arranged on the body; the workbench is fixedly arranged on the body; the head of the cloth cutting device is fixedly arranged on one end of the supporting arm; the middle part of the workbench is provided with a disc; the disc is provided with four strip-shaped through holes; the head of the cloth cutting device is fixedly connected with an air cylinder and comprises a control handle, an adjusting screw rod and a cutter; the control handle is arranged on one side of the head of the cloth cutting device; the adjusting screw rod is arranged at the bottom of the head of the cloth cutting device; and the cutter is fixedly arranged on the head of the cloth cutting device. In the invention, because the cutter is arranged on the head of the cloth cutting device, the workbench is provided with strip-shaped through holes, and the cutter is arranged in the strip-shaped through holes, the cloth cutting device can be used for cutting. The cloth cutting device disclosed by the invention has a simple structure, is practical and convenient to use, can be used for rapidly cutting a plurality of layers of cloth with good effect, improves the production rate, is in line with the needs of the development of the clothes industry very much and has very positive significance.

Owner:SUZHOU MARLLIN FOR GARMENT & TEXTILES

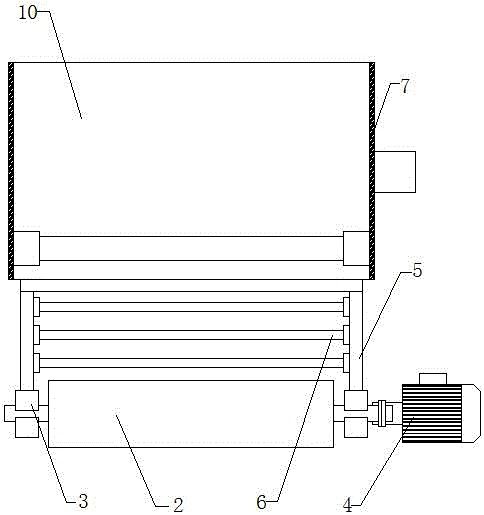

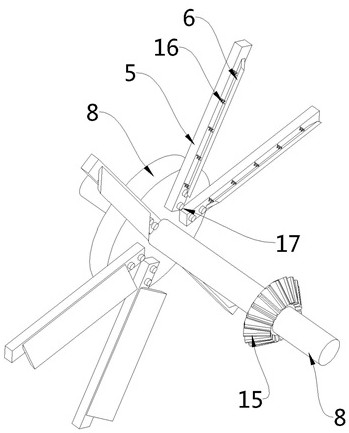

Combing machine with rotary positioning driving device

InactiveCN111549403ARoll up orderlyCurl is not messySevering textilesCombing machinesCouplingEngineering

The invention discloses a combing machine with a rotary positioning driving device, and relates to the technical field of sliver processing. The combing machine with the rotary positioning driving device is used for solving the problem of incapability of automatically winding up slivers. Specifically, a shell is included, and a telescopic column is fixed to the outer wall of the top of the shell by screws. A first drive motor is fixed to the outer wall of the top of the telescopic column by screws. The output end of the first drive motor is connected with a fixed shaft through a coupling, a winding disc is fixed to the outer wall of the periphery of the fixed shaft by the screws, a bell mouth is fixed to the outer wall of one side of the shell by the screws, a cotton inlet is formed in theouter wall of one side of the bell mouth, a cotton outlet is formed in the outer wall of the other side of the bell mouth, and a pneumatic tappet is fixed into the telescopic column by the screws. According to the combing machine with the rotary positioning driving device, the first drive motor drives the winding disc to rotate so as to wind the slivers output from the cotton outlet in the bell mouth, and the height is adjusted through the telescopic column to enable the slivers to be wound more orderly. The slivers can be wound without being messy and effect is good without manual winding.

Owner:刘美红

Waste clothes metal button recovery processing system

ActiveCN113005756AFit to sizeEasy to recycleSolid waste disposalSevering textilesMechanical engineeringWaste management

The invention belongs to the related field of clothes, and relates to a waste clothes metal button recovery processing system. The waste clothes metal button recovery processing system comprises a shell; a placing table is fixedly arranged on the lower side wall of the shell; an annular cutting ring groove is fixedly formed in the upper side wall of the placing table; supporting rods which are symmetrical left and right are fixedly arranged on the upper side wall of the placing table; electromagnetic sliding grooves are fixedly formed in the upper side walls of the supporting rods; and working cavities are formed in the electromagnetic sliding grooves. The waste clothes metal button recovery processing system is suitable for recycling metal buttons on waste clothes, cloth at the button fixing positions is cut off firstly, then recycling is conducted through negative pressure, the recycled buttons and the cloth related to the buttons are burnt, ash adhering to the buttons after burning is removed, the recycling efficiency of the metal buttons is effectively improved, overall operation is simple, and the waste clothes metal button recovery processing system is suitable for various metal buttons.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Adhesive tape shaping device

InactiveCN109956359ARealize fast fix functionRealize quick crop functionArticle deliveryAdhesive beltEngineering

The invention provides an adhesive tape shaping device. The adhesive tape shaping device comprises a carrying shaft, a groove, first springs, a clamping plate, clamping teeth, a through opening, a cutter, guide holes, second springs, pressure levers and a push handle. The carrying shaft is installed at the middle position of the right surface of a vertical plate. The groove is formed in the annular side face of the carrying shaft. The first springs are fixed into the groove. The clamping plate is fixed to the rear ends of the first springs. The clamping teeth are arranged on the rear surface of the clamping plate. By the aid of the design, adhesive tape of different specifications can be fixed quickly, the through opening is formed in the middle position of the support, the cutter is fixedto the lower end of the pressure lever, the guide holes are formed in the upper surface of the inside of a through hole, the second springs are arranged in the corresponding guide holes, the lower ends of the springs are connected with the guide holes, the pressure lever is assembled into the guide hole, and the push handle is fixed to the upper end of the pressure lever. Through the design, theadhesive tape can be cut quickly, and operation by operators is facilitated. The adhesive tape shaping device is reasonable in structure, wide in range of application, excellent in cutting effect andhigh in reliability.

Owner:重庆市勇焜电子科技有限公司

A processing device with a cutting mechanism for high-strength non-woven fabrics

ActiveCN112374225BImprove the winding effectWind evenlyFilament handlingSevering textilesStructural engineeringNonwoven fabric

Owner:同高纺织化纤(深圳)有限公司

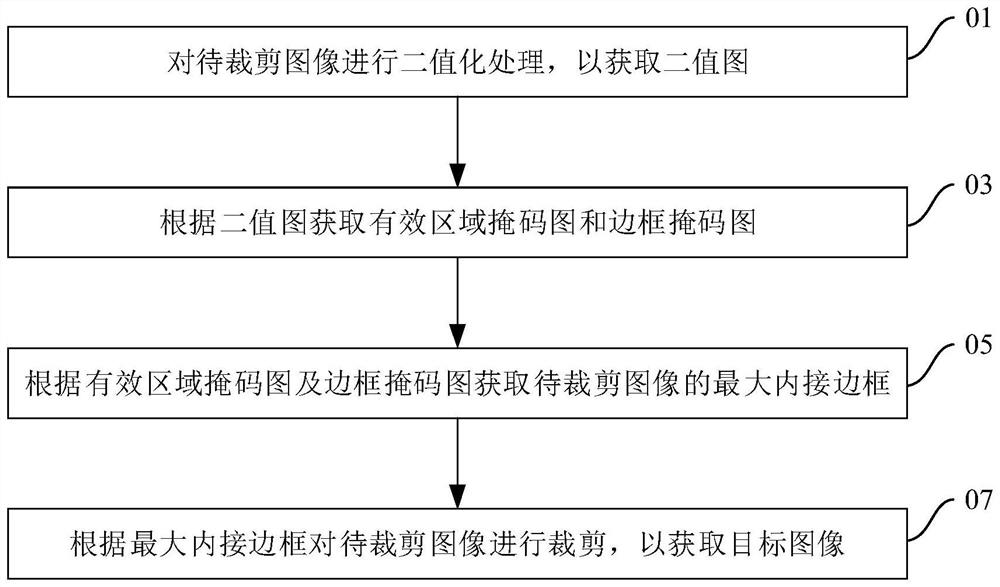

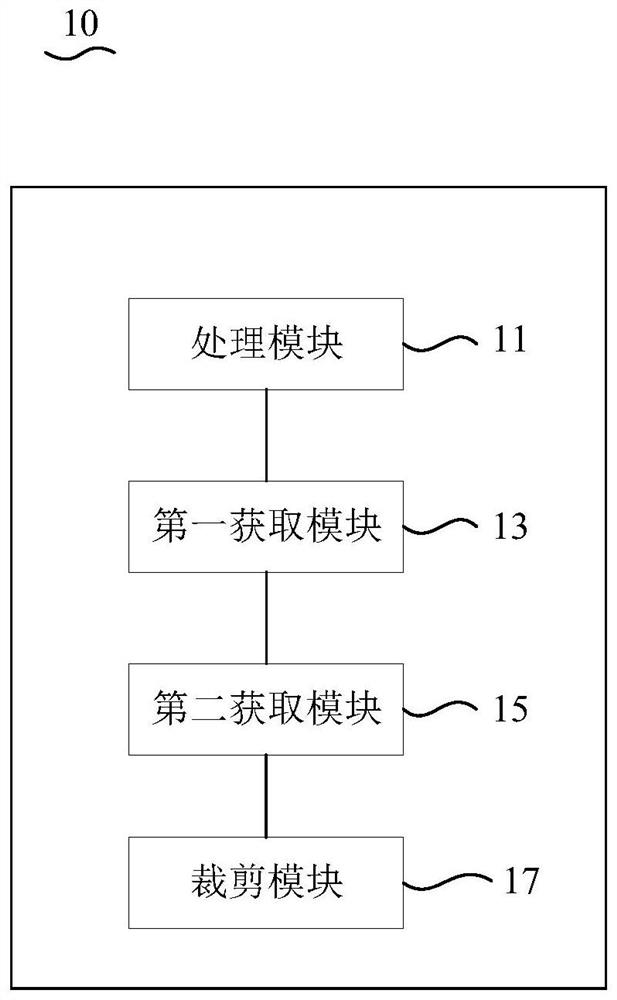

Image cutting method and device, terminal and readable storage medium

PendingCN114549551AImprove cutting efficiencyGood tailoringImage enhancementImage analysisComputer graphics (images)Computer vision

The invention provides an image cutting method and device, a terminal and a readable storage medium. The cutting method comprises the following steps: carrying out binarization processing on a to-be-cut image to obtain a binary image; and obtaining an effective area mask image and a frame mask image according to the binary image. And obtaining the maximum inscribed frame of the to-be-cut image according to the effective area mask pattern and the frame mask pattern. And cutting the to-be-cut image according to the maximum inscribed frame to obtain a target image. According to the clipping method and device, the terminal and the readable storage medium, the effective area mask image and the frame mask image are obtained according to the binary image, the maximum inscribed frame of the to-be-clipped image can be obtained by combining the effective area mask image and the frame mask image, and the to-be-clipped image is clipped by using the maximum inscribed frame, so that the clipping efficiency is improved. Compared with a manual cutting mode, the cutting efficiency is greatly improved, the target image can contain an effective area as large as possible in the to-be-cut image, and the cutting effect is better.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of preparation method of polypyrrole/silver nanocomposite material

ActiveCN104599862BImprove conductivityAct as an inducerHybrid capacitor electrodesHybrid/EDL manufacturePolypyrrolePyrrole

The invention relates to a preparation method of a polypyrrole / silver nanocomposite material, comprising mixing a pyrrole monomer and a silver nitrate solution to form a system, adding a trisodium citrate aqueous solution drop by drop in a stirring state, and continuing to stir for 10-30min after the dropwise addition , then add the ferric chloride aqueous solution dropwise and react for 4-12h. After the reaction, the reaction solution is suction filtered, and the obtained filter cake is washed with ethanol and deionized water for 2-3 times, and then dried to obtain the shape It is spherical or quasi-spherical polypyrrole / silver nanocomposite particles, with a particle diameter of 100-250nm, a pore diameter of 3-15nm, and a pore volume of 0.283-0.356cm3 / g. The preparation method does not need expensive equipment and instruments, the preparation method is simple, the requirement for the reaction environment is low, and the production cost is low. The polypyrrole / silver nano-composite material prepared by it is used as a supercapacitor electrode material, and has excellent specific capacitance performance and thermal stability performance.

Owner:SHANGHAI INST OF TECH

Heat sink clip and method for forming the same

InactiveUS9016353B2Good tailoringImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

Owner:MING YANG HSIEH

Double layer synchronous cutting system for home textile fabrics

ActiveCN105905653BEasy to adjustImprove cutting efficiencySevering textilesArticle deliveryEngineeringAutomation

The invention discloses a double-layer synchronous tailoring system for home textile fabric. The double-layer synchronous tailoring system for the home textile fabric sequentially comprises a double-layer feeding device, a double-layer material tidying device and a double-layer tailoring platform from the feeding end to the discharging end. The double-layer tailoring platform comprises an upper tailoring platform and a lower tailoring platform. An electric shear knife capable of conducting up-and-down cutting at the same time is arranged between the upper tailoring platform and the lower tailoring platform. Each of the upper tailoring platform and the lower tailoring platform is provided with a gap adjusting positioning mechanism. Each gap adjusting positioning mechanism comprises an adjusting base and a pressing plate perpendicular to each other. The tailoring system is simple in structure, the tailoring size is accurate, the positioning effect and the pressing effect are good in the tailoring process, the automation degree is high, and labor force is saved. The tailoring efficiency is high and is two times of the existing tailoring efficiency, the tailoring time is greatly saved, and the fabric processing period is shortened.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com