Elastic cloth clothing cutting and banding equipment capable of avoiding thread ends

A kind of edge banding equipment and elastic technology, which is applied in the cutting of textile materials, fabric edge trimming, fabric surface trimming, etc., can solve the problems of affecting the quality of clothing, poor cutting effect of equipment, unstable cutting and other problems, and achieve good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

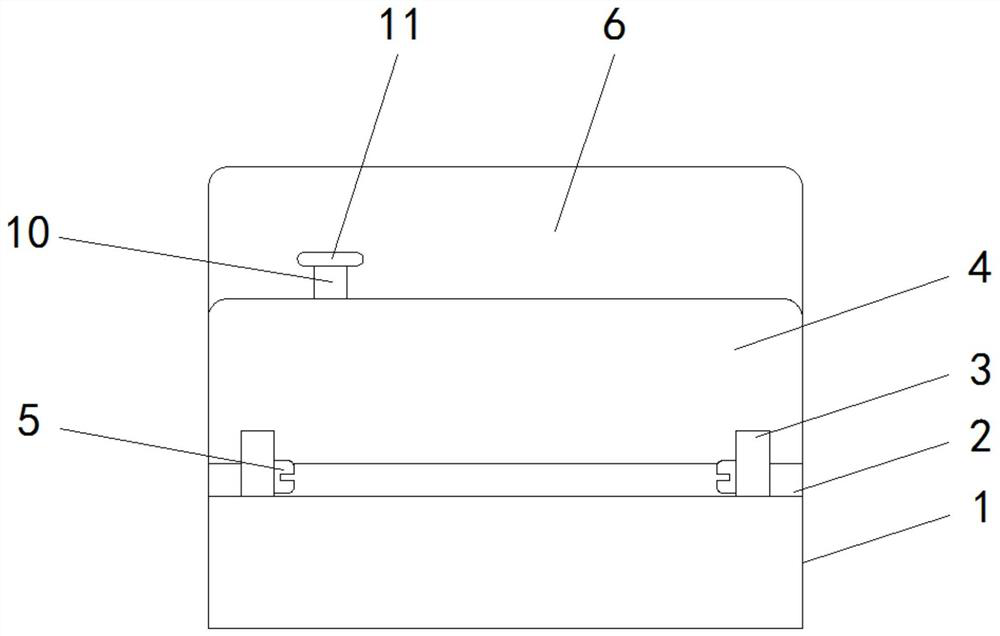

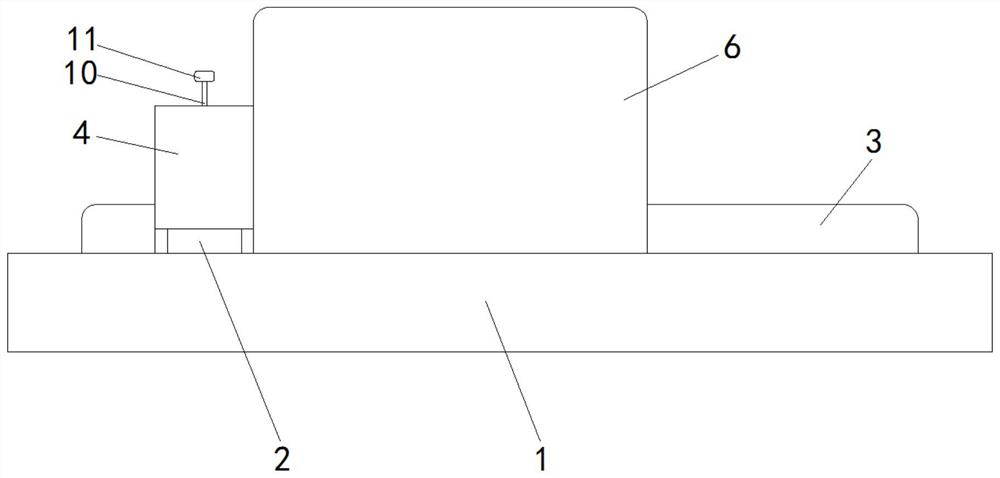

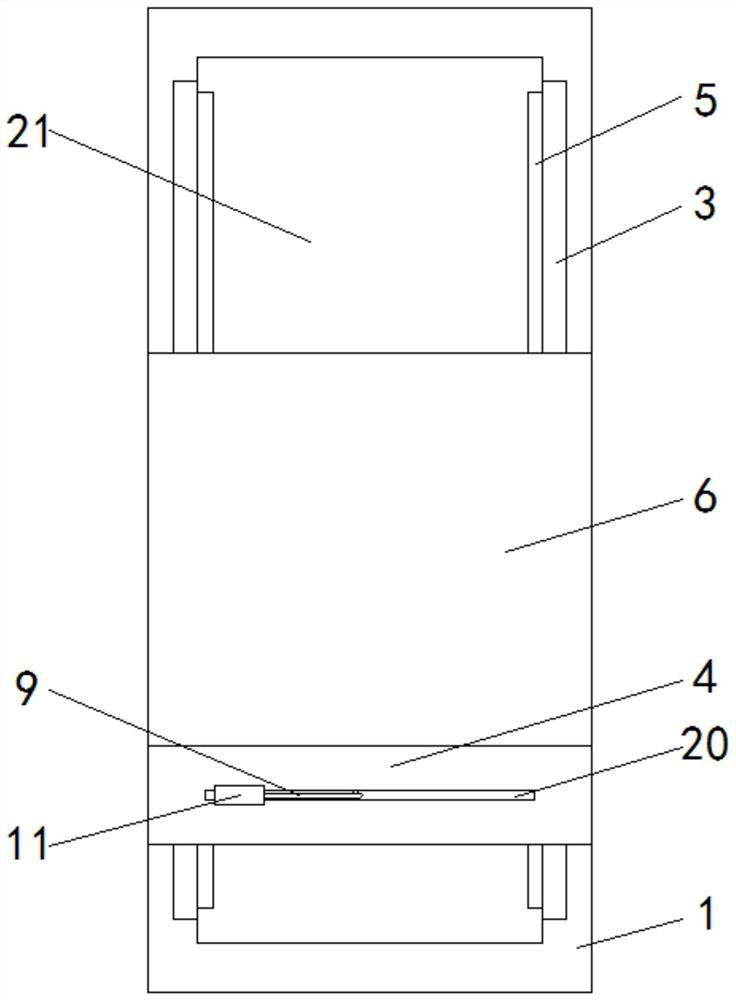

[0026] As attached figure 1 Attached Image 6 Shown:

[0027] The present invention provides an elastic cloth garment cutting edge sealing device for preventing thread ends, which comprises a base 1, a support member 2 is fixedly installed on the upper side of the base 1, a fixed baffle 3, and the fixed baffle 3 penetrates the cutting mechanism 4 and the edge sealing mechanism 6. A clamp 5 is installed on the opposite side of the fixed baffle 3. When the cloth is placed on the equipment, the cloth is clamped by the clamp 5 so that the cloth can be stabilized. The upper side of the support member 2 is fixedly installed with a cutting mechanism 4, An edge banding mechanism 6 is installed on the back side of the cutting mechanism 4, and the lower side of the edge banding mechanism 6 is connected to the base 1. The cutting mechanism 4 is provided with a mounting part 7 inside, and a cutting blade 9 is provided on the mounting part 7. 7 and the cutting blade 9 are movably installed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com