A processing device with a cutting mechanism for high-strength non-woven fabrics

A processing device and high-strength technology, applied in the cutting, transportation and packaging of textile materials, textiles and papermaking, etc., can solve the problems of scattered placement of side materials, accumulation of side materials, and affecting the normal cutting of non-woven fabrics, etc. Achieve good cutting effect and improve winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

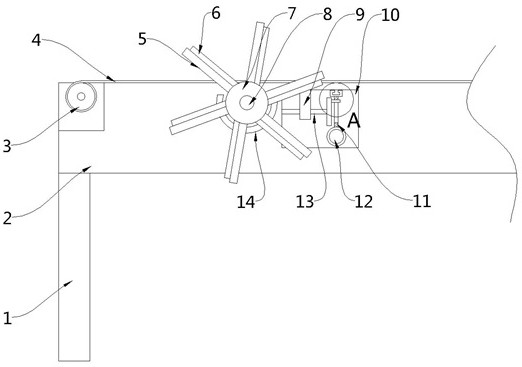

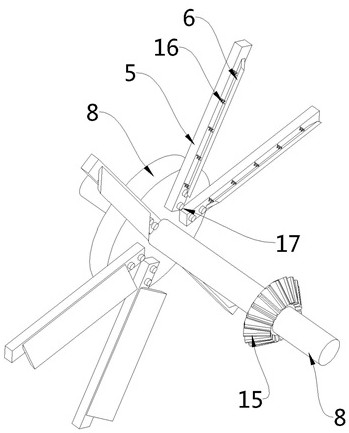

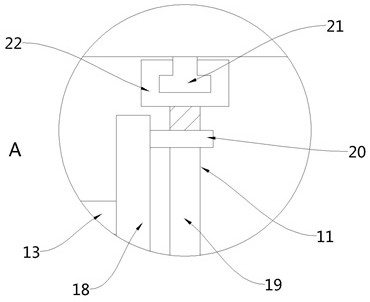

[0024] see Figure 1-3 , this embodiment provides a processing device with a cutting mechanism for high-strength non-woven fabrics, including a support table 2, a number of legs 1 are fixedly arranged at the bottom of the support table 2, and a support table 2 is provided on the upper side. The winding assembly 3 for winding the non-woven fabric 4 is provided with a cutting assembly on the front and rear sides of the support table 2. Specifically, the cutting assembly includes a running wheel 7 and a rotating shaft 8 vertically passing through the running wheel 7. The side of the runner 7 facing the support platform 2 is fixedly provided with several support rods 5 distributed along the diameter direction, and each group of the support rods 5 is provided with a blade 6 on the side away from the runner 7, and the blades 6. The blade portion is attached to the side wall of the support platform 2, and the front and rear sides of the support platform 2 are provided with chambers 1...

Embodiment 2

[0035] see figure 1 , a processing device with a cutting mechanism for high-strength non-woven fabrics. Compared with Embodiment 1 in this embodiment, the side of the blade 6 away from the support rod 5 is embedded with a first magnet (not shown) A second magnet 14 repelling the first magnet is also embedded on the front and rear sides of the support table 2 .

[0036] When the support rod 5 drives the blade 6 to rotate to the side of the support table 2, the blade 6 is driven to rotate in the direction of the support rod 5 through the repulsive effect between the second magnet 14 and the first magnet, so that the blade portion of the blade 6 is detached from the support platform 2, to prevent the edge of the blade 6 from contacting the side wall of the support platform 2, causing wear of the blade 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com