Double layer synchronous cutting system for home textile fabrics

A double-layer, fabric technology, applied in the cutting of textile materials, thin material processing, textiles and papermaking, etc., can solve the problems of uneven fabrics on both sides of the cutting, insufficient cutting of the cutting surface, and uneven lengths of lines, etc. , to achieve the effect of precise cutting size, convenient mechanism adjustment and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

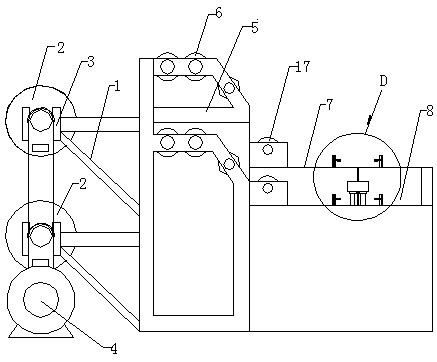

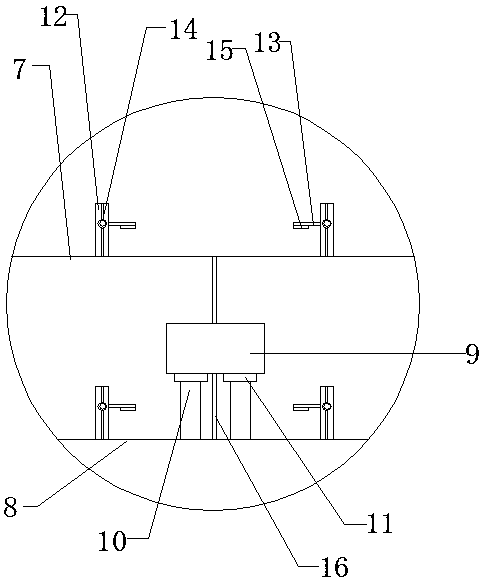

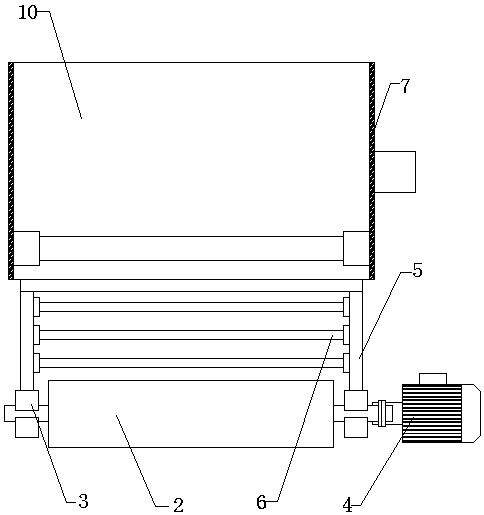

[0020] Refer to attached Figure 1-3 The shown is a double-layer synchronous cutting system for home textile fabrics, which sequentially includes a double-layer feeding device, a double-layer monolithic device, and a double-layer cutting platform from the feed end to the discharge end; the double-layer cutting platform includes an upper cutting platform. Platform 7 and lower cutting platform 8, the feeding end of described upper cutting platform 7 and described lower cutting platform 8 is all provided with at least one horizontal roller 17, is set between described upper cutting platform 7 and described lower cutting platform 8 The electric shear knife 9 that can cut up and down simultaneously; The electric shear kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com