Combing machine with rotary positioning driving device

A technology of positioning drive and combing machine, applied in the field of combing machine, can solve the problems of poor winding effect, disordered winding of sliver, low winding efficiency, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

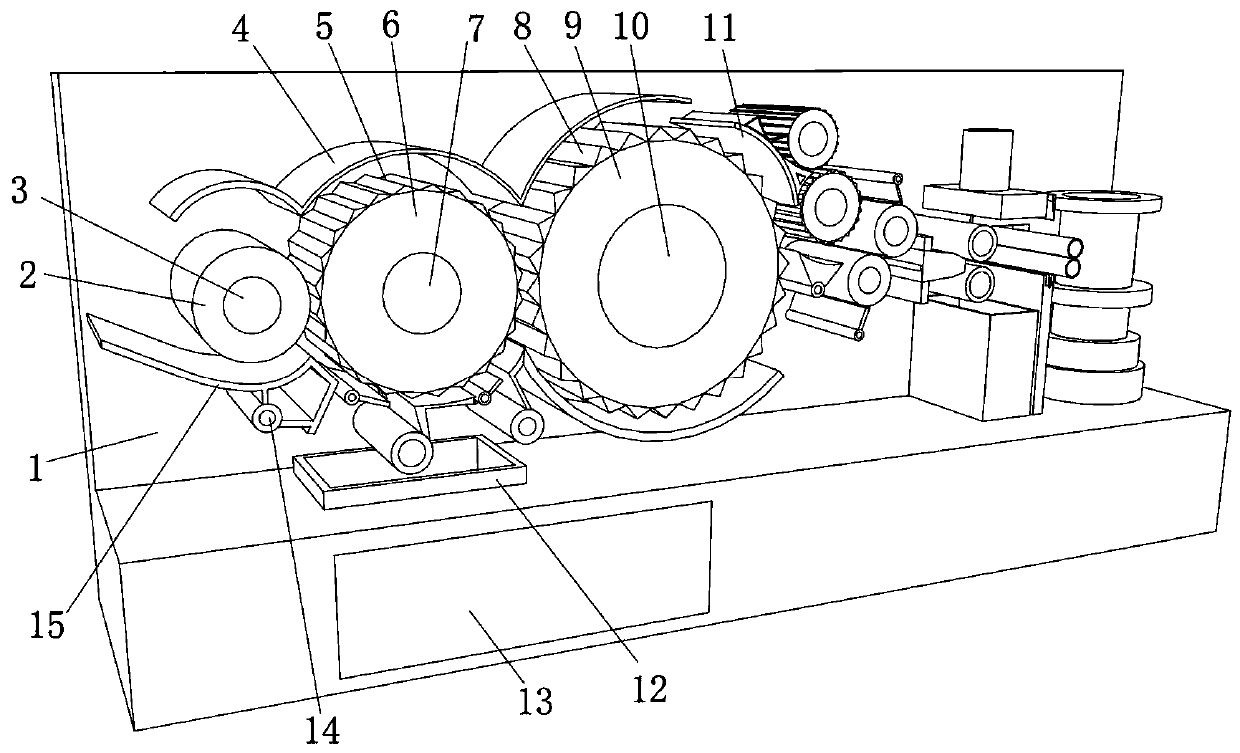

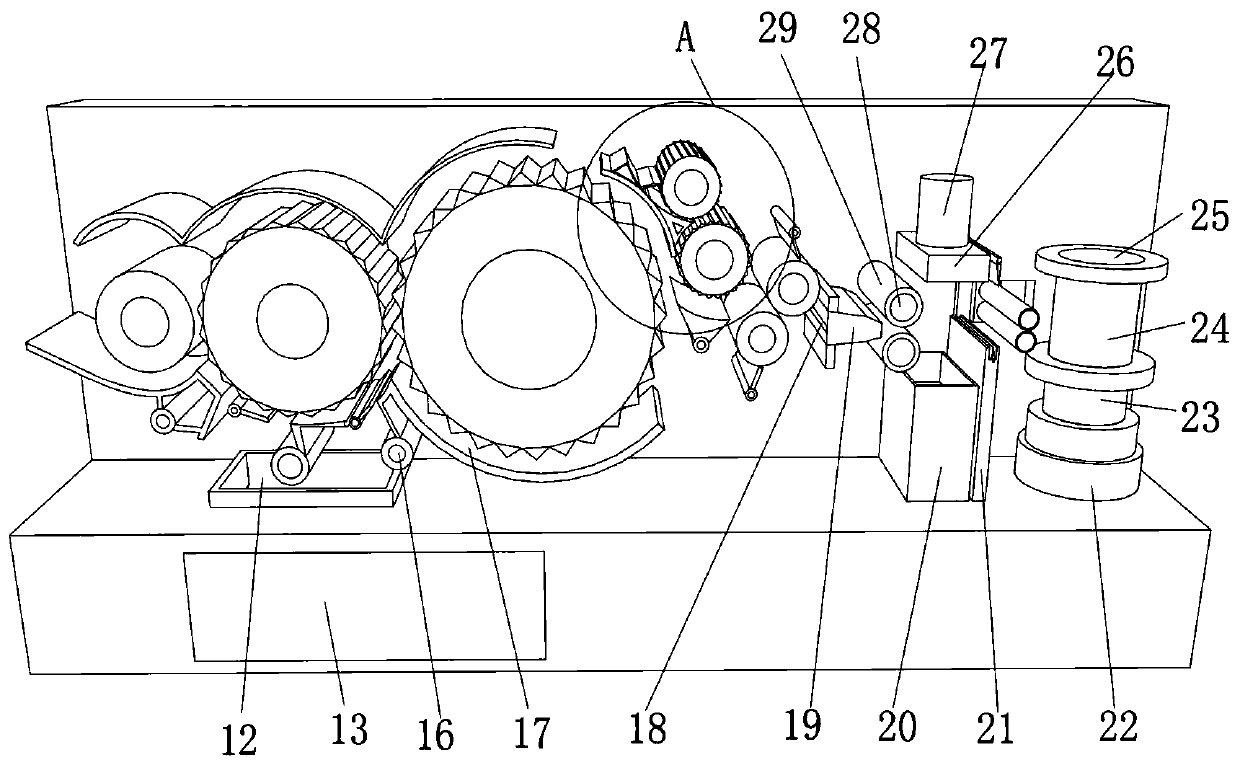

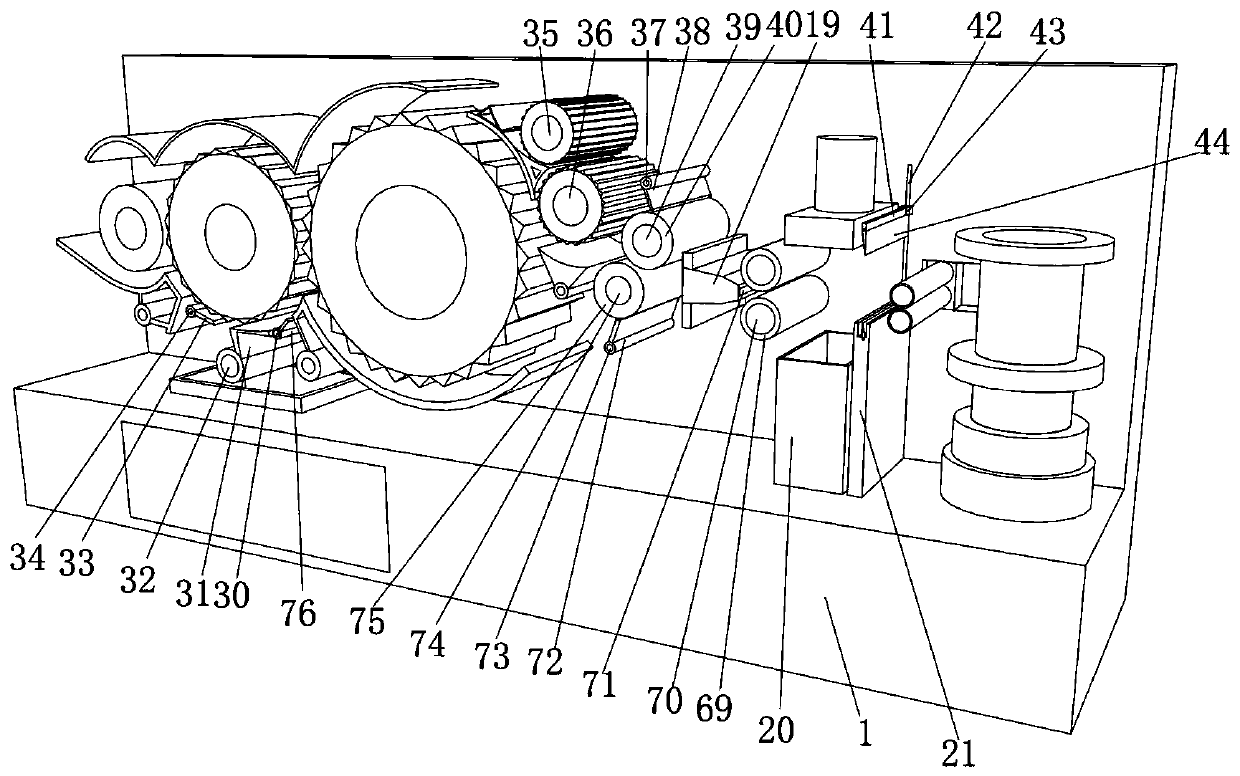

[0035] A combing machine with rotary positioning drive, such as figure 1 , figure 2 and image 3 As shown, it includes a housing 1, the top outer wall of the housing 1 is fixed with a telescopic column 22 by screws, the top outer wall of the telescopic column 22 is fixed with a first drive motor 23, and the output end of the first drive motor 23 is passed through a coupling Connected with a fixed shaft 25, the outer wall of the fixed shaft 25 is fixed with a take-up disk 24 by screws, and the outer wall of one side of the shell 1 is fixed with a bell mouth 19 by screws, and the outer wall of one side of the bell mouth 19 is provided with a cotton inlet 18, and the bell mouth The outer wall of the other side of 19 has a cotton outlet 71, and the inside of the telescopic column 22 is fixed with a pneumatic tappet by screws; The cotton sliver output by 71 is rolled up, and the height adjustment is carried out through the telescopic column 22, which can make the rolling up of t...

Embodiment 2

[0041] A combing machine with rotary positioning drive, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in order to solve the problem of absorbing sundries; this embodiment makes the following improvements on the basis of embodiment 1: a collection chamber 45 is opened at the bottom of the housing 1, and a door 13 is fixed to the outer wall of one side of the collection chamber 45 by screws , the top outer wall of the housing 1 is fixed with a suction pipe 12 by screws, the top inner wall of the collection chamber 45 is fixed with a connecting pipe 47 by screws, the other end of the connecting pipe 47 is fixed with an exhaust fan 48 by screws, and one side of the outer wall of the connecting pipe 47 A filter plate 46 is plugged in, and the top outer wall of the collection chamber 45 is fixed with a third drive motor 49 by screws, and the output end of the third drive motor 49 is connected to a connecting shaft 50 through a coupling, and the peripheral outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com