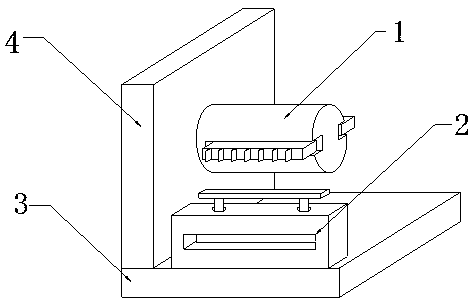

Adhesive tape shaping device

A tape and support plate technology, applied in the directions of sending objects, thin material handling, transportation and packaging, can solve the problems of inability to achieve rapid tape cutting, poor cutting effect, and large use limitations, to increase the scope of application, cutting Good effect and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

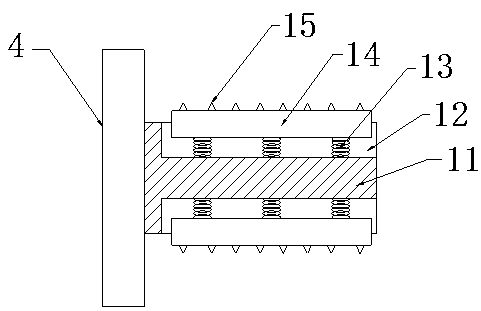

[0023] Specific implementation method: when in use, the operator squeezes the splint 14, the splint 14 moves in the groove 12, the splint 14 moves and squeezes the spring one 13, and the spring one 13 undergoes elastic deformation, and then the operator puts the tape on the bearing shaft 11 Then the operator releases the splint 14, and the spring 13 moves the splint 14 to the initial position under the action of the rebound force, and at the same time, the splint 14 makes the latch 15 closely fit the tape, and then the latch 15 fixes the tape on the bearing shaft 11, thereby realizing the fast fixing function of adhesive tapes of different specifications, increasing the scope of application of the device.

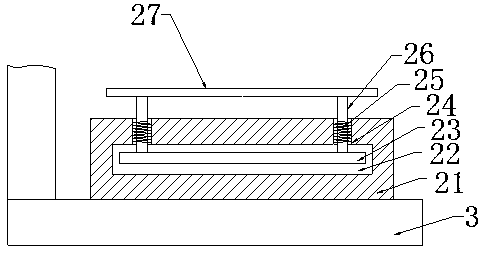

[0024] The operator passes the adhesive tape through the opening 22 on the bracket 21. When the adhesive tape needs to be cut, the operator presses the push handle 27 downward, and the push plate drives the pressure rod 26 to move downward in the guide hole 24, and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com