Clamp for clamping material head of mould

A clamping and fixture technology, which is applied in the field of notebook computer parts processing, can solve the problems of poor fixing effect of the clamping head, inability to clean the clamping head, insufficient functionality, etc., and achieve good clamping effect, complete functions, and clean good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

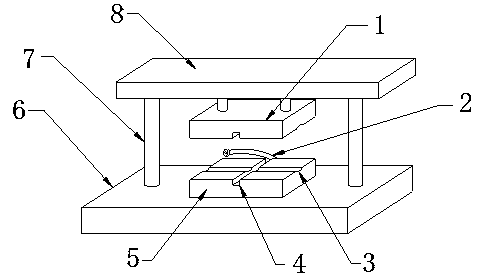

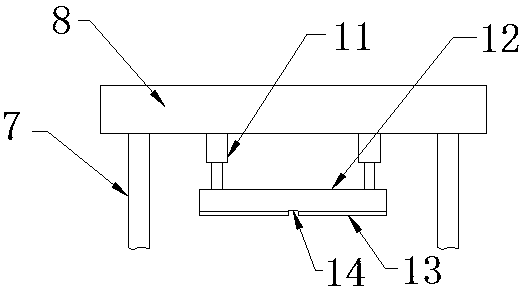

[0024] Specific implementation method: when in use, the operator first places the clamping head in the arc-shaped groove-3 and the square groove-4, and then the operator operates the electric telescopic rod 12, which drives the upper fixed plate 11 to move downward, The upper fixed plate 11 moves downward to drive the arc groove 2 13 and the square groove 2 14 to move downward. When the upper fixed plate 11 and the lower fixed plate 5 are closely attached, the operator stops running the electric telescopic rod 12, and then the arc groove 13, arc-shaped groove 2 13, square groove 1 4 and square groove 2 14 fix the clamping head, thereby realizing the fast fixing function of the clamping head, which is convenient for operators to operate.

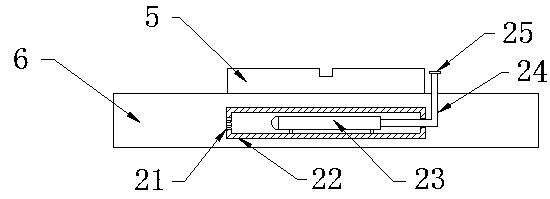

[0025] When the clamping head needs to be cleaned, the operator runs the air pump 23, and the air pump 23 transports the external air to the shell 22 through the air inlet 21, and then transports the air in the shell 22 to the universal joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com