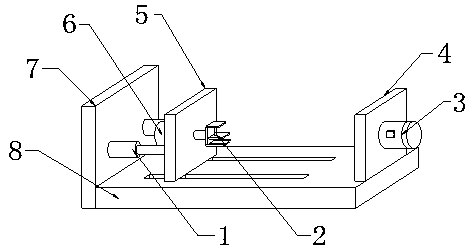

Conductive cloth winding auxiliary device

A technology of conductive cloth and auxiliary equipment, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of large use limitations, limited processing range, cumbersome fixing steps, etc., and achieve high processing efficiency and improved Stable and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

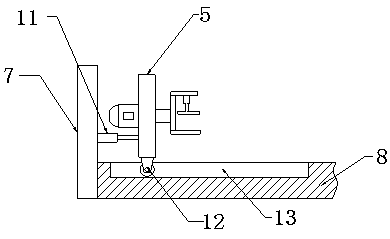

[0023] Specific implementation method: when in use, the operator adjusts the position of the vertical plate 5 according to the length of the wire harness, the operator runs the electric lift cylinder 11, and the electric lift cylinder 11 drives the vertical plate 5 to move to the right, and the vertical plate 5 moves to drive The guide pulley 12 moves in the guide groove 13, and then the vertical plate one 5 moves to the right on the base 8. When the vertical plate one 5 moves to the designated position, the operator stops moving the electric lifting cylinder 11, thereby realizing the vertical lift. The adjustment function of the distance between the first plate 5 and the second vertical plate 4 is convenient for processing wire harnesses of different lengths and specifications.

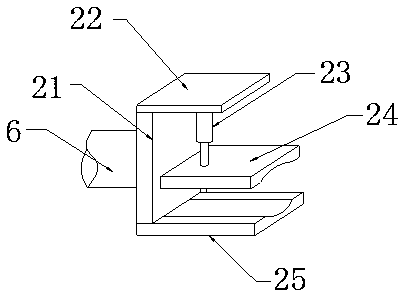

[0024] Then the operator places the left end of the wiring harness in the arc-shaped groove on the lower fixing plate 25, and then the operator operates the electric push rod 23, and the electric push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com