Sliding clutch method and device of downhole measuring and adjusting instrument

A technology of measuring and adjusting instrument and clutch shaft, which is used in earth-moving drilling, wellbore/well components, production fluid, etc. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

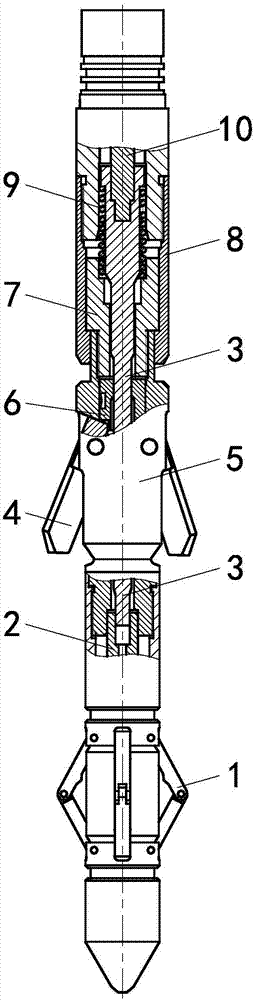

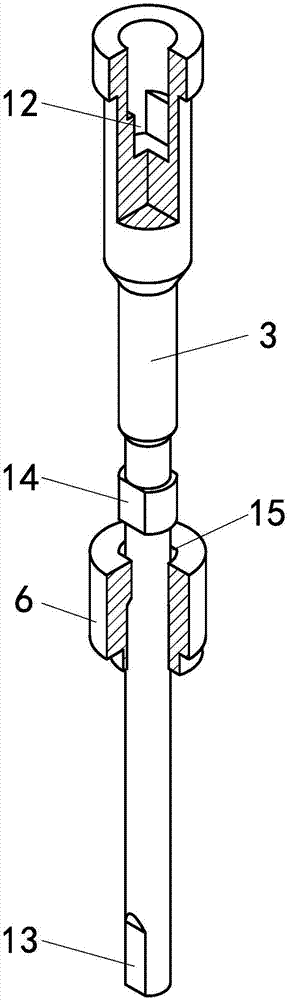

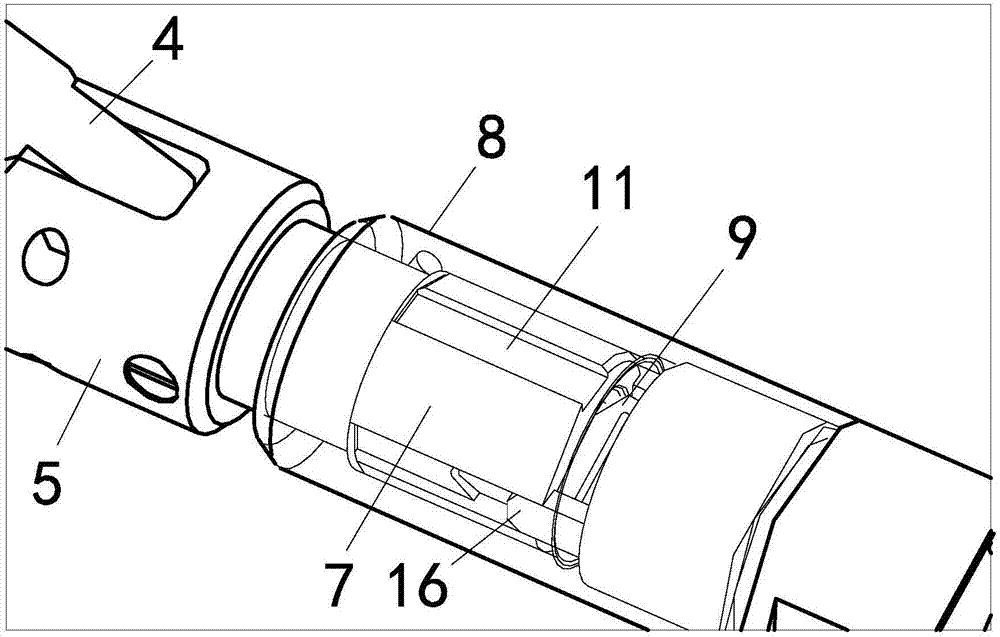

[0020] The device used in this example is Figure 1-3 As shown, the adjustment shaft 2 is connected with the adjustment arm 1, and when the adjustment shaft 2 rotates, the adjustment arm 1 rotates. The adjustment shaft 2 upper end is processed with a flat hole, the clutch shaft 3 lower end is processed with a flat shaft, and the flat shaft at the clutch shaft 3 lower end can slide in the flat hole of the adjustment shaft 2, and the clutch shaft 3 rotates and the adjustment shaft 2 rotates. High point and low point are processed on the cam 6, and when the cam 6 rotates, the positioning arm 4 can be retracted. A flat hole is processed in the middle of the cam 6, and a flat shaft is processed in the middle of the clutch shaft 3 to cooperate with the flat hole of the cam 6. The flat shaft is separated, at this time the clutch shaft 3 rotates and the cam 6 does not rotate, but the adjustment arm 1 can rotate; when the cam 6 moves to the lower limit position, the flat hole on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com