Preparation method of ultrahigh molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin man-made filament, spinning solution preparation, wet spinning, etc. structure and other problems, to achieve the effect of reducing the breaking strength and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

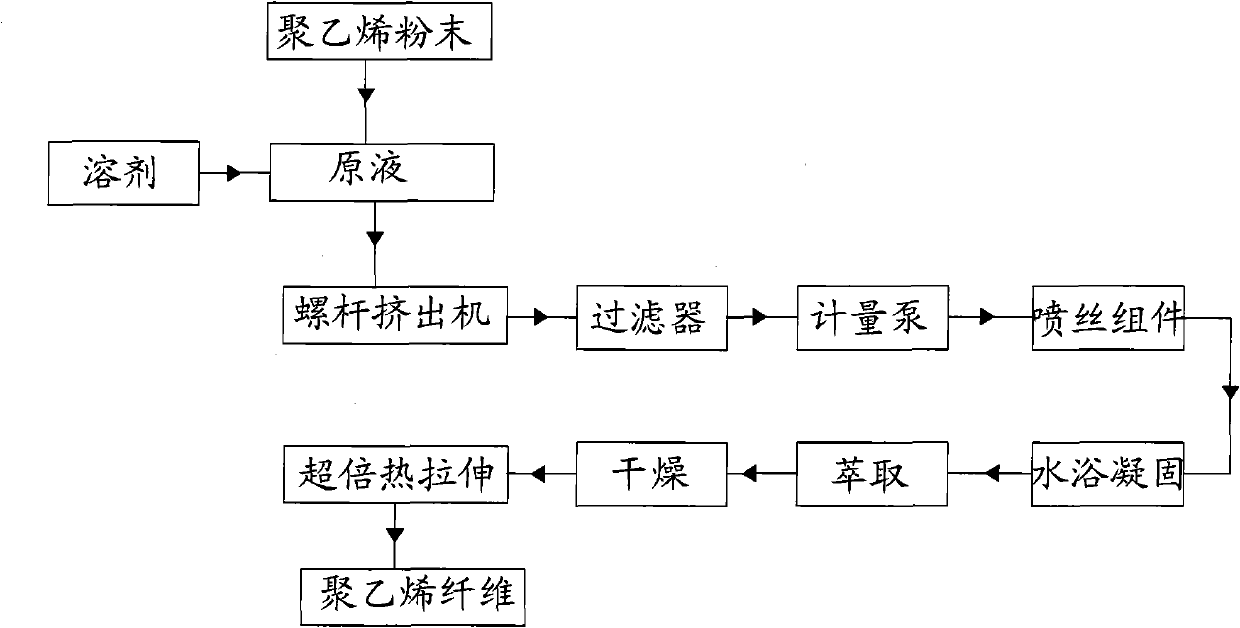

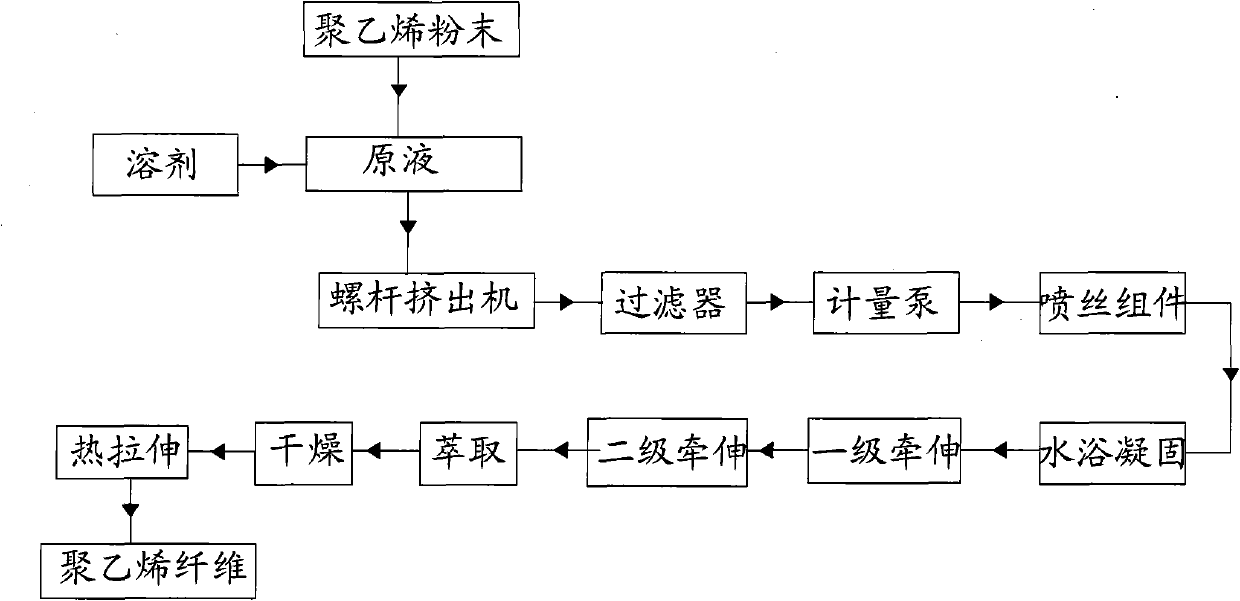

[0012] see figure 1 with figure 2 The main difference between the method of the present invention and the method of the prior art is that the present invention performs primary drawing and secondary drawing in sequence before extraction. Wherein, the multiple of primary drafting can be 2 to 8 times, and the multiple of secondary drafting can be 1.1 to 3 times, and the thermal stretching multiple of the present invention is lower than the prior art, and its range is 30 to 45, Therefore, the obtained fiber of the present invention still maintains its high breaking strength while having a relatively low denier. The present invention will be described in further detail below in conjunction with specific embodiments.

[0013] A preparation method of ultra-high molecular weight polyethylene fibers, comprising the steps of:

[0014] (1), prepare the frozen collagen silk of ultra-high molecular weight polyethylene: ultra-high molecular weight polyethylene (viscosity-average molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com