Patents

Literature

272results about How to "Less solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

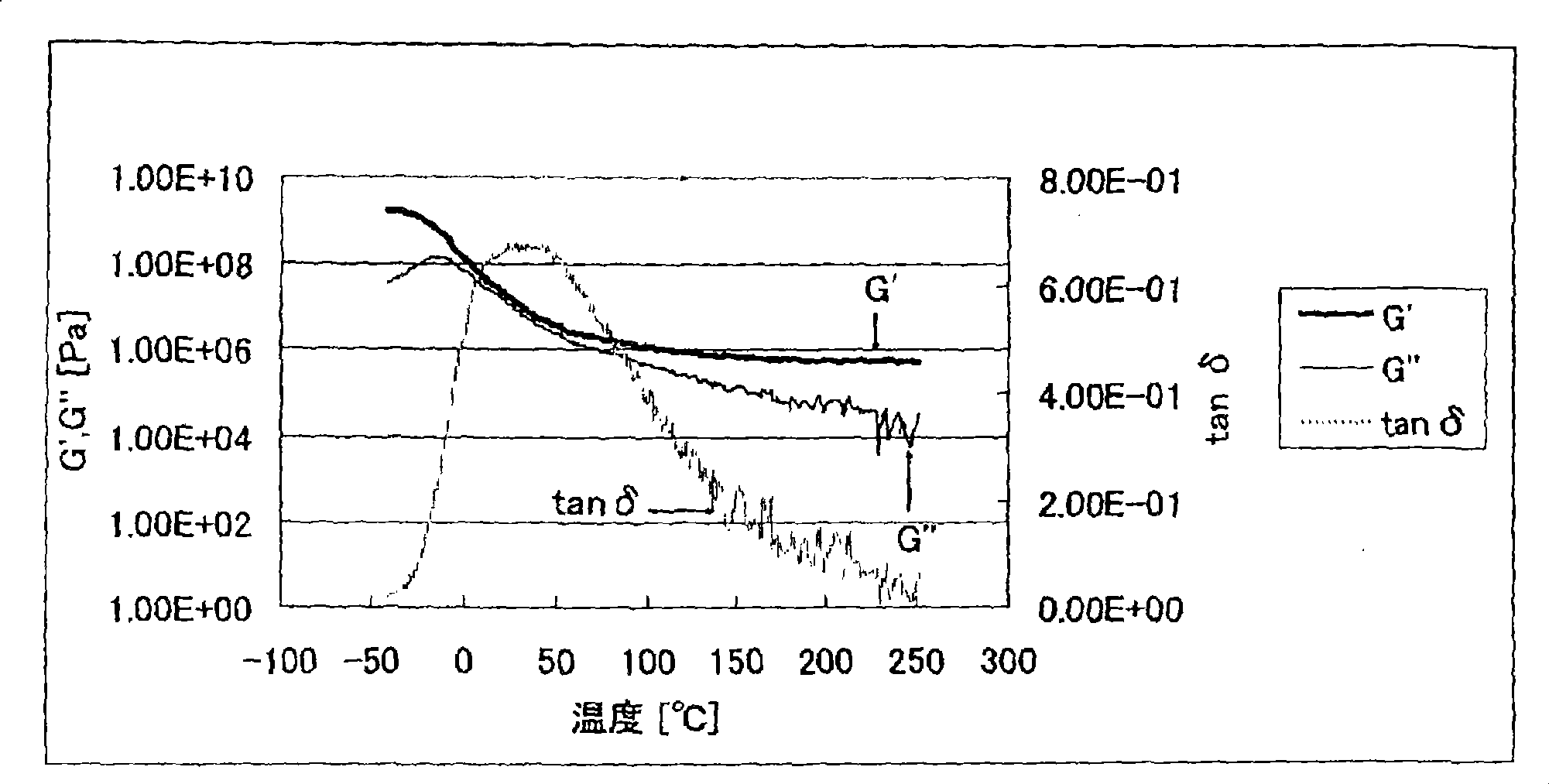

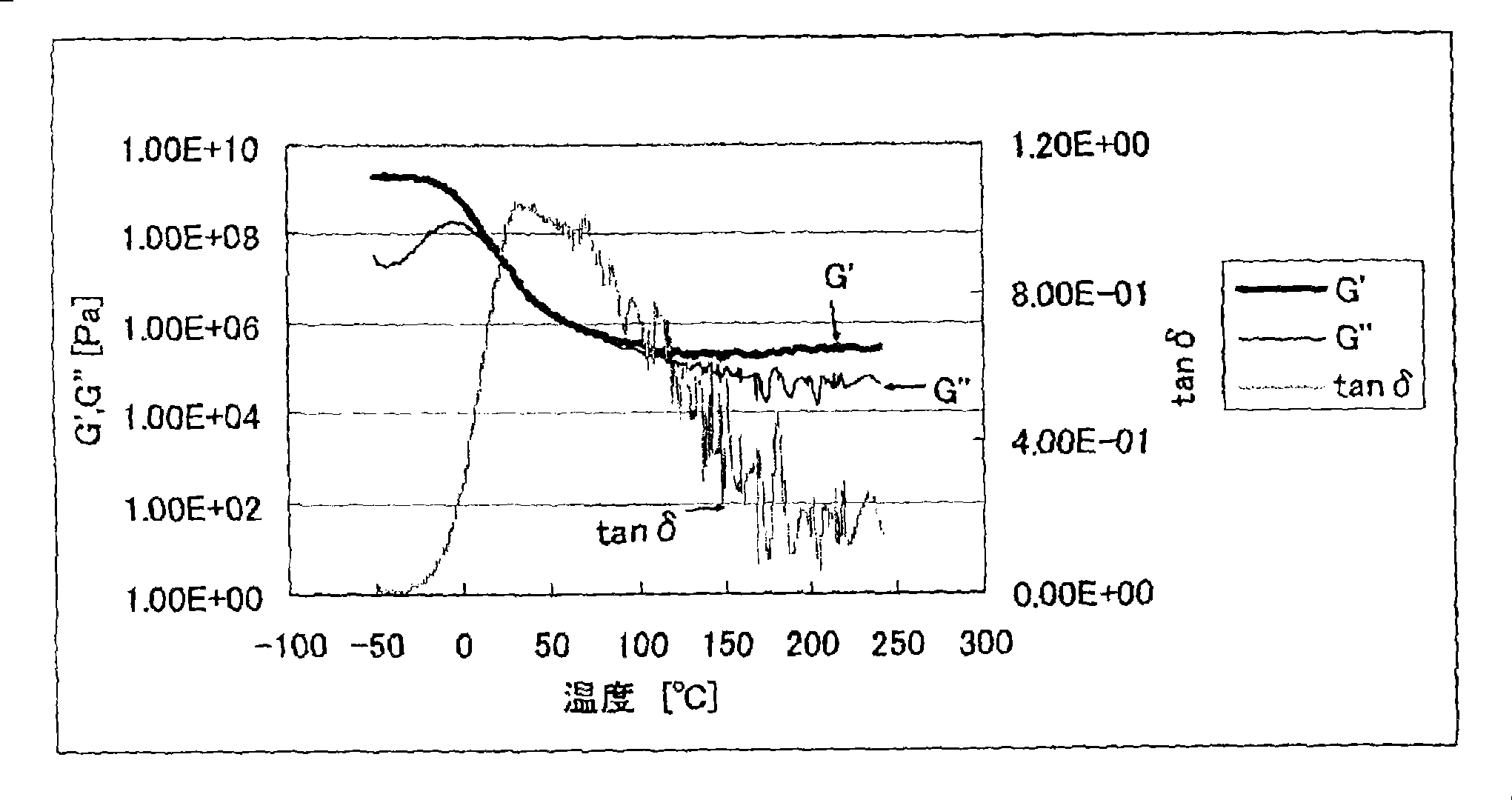

Method for producing aqueous dispersion of thermoplastic resin microparticles and toner for electrophotography

The present invention provides a method for producing an aqueous dispersion of thermoplastic resin microparticles containing considerably less residual solvent remaining in resin particles, and a toner for electrophotography containing considerably less residual solvent. A self-water-dispersible thermoplastic resin is swollen using an organic solvent having a boiling point lower than 100° C., which does not dissolve but can swell the self-water-dispersible thermoplastic resin, to produce a swollen material and the resulting swollen material is dispersed into an aqueous medium in the form of microparticles to produce an initial aqueous dispersion, and then the organic solvent is removed from the initial aqueous dispersion to prepare a dispersion. A toner for electrophotography contains microparticles obtained by separating microparticles of the self-water-dispersible thermoplastic resin from the aqueous dispersion of thermoplastic resin microparticles and drying the microparticles.

Owner:DAINIPPON INK & CHEM INC

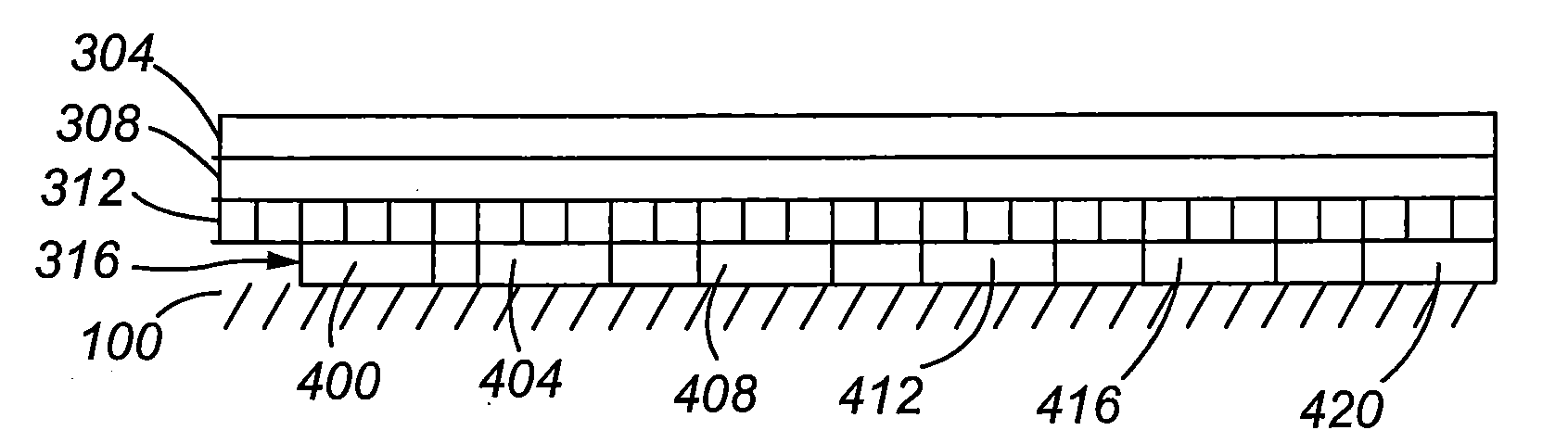

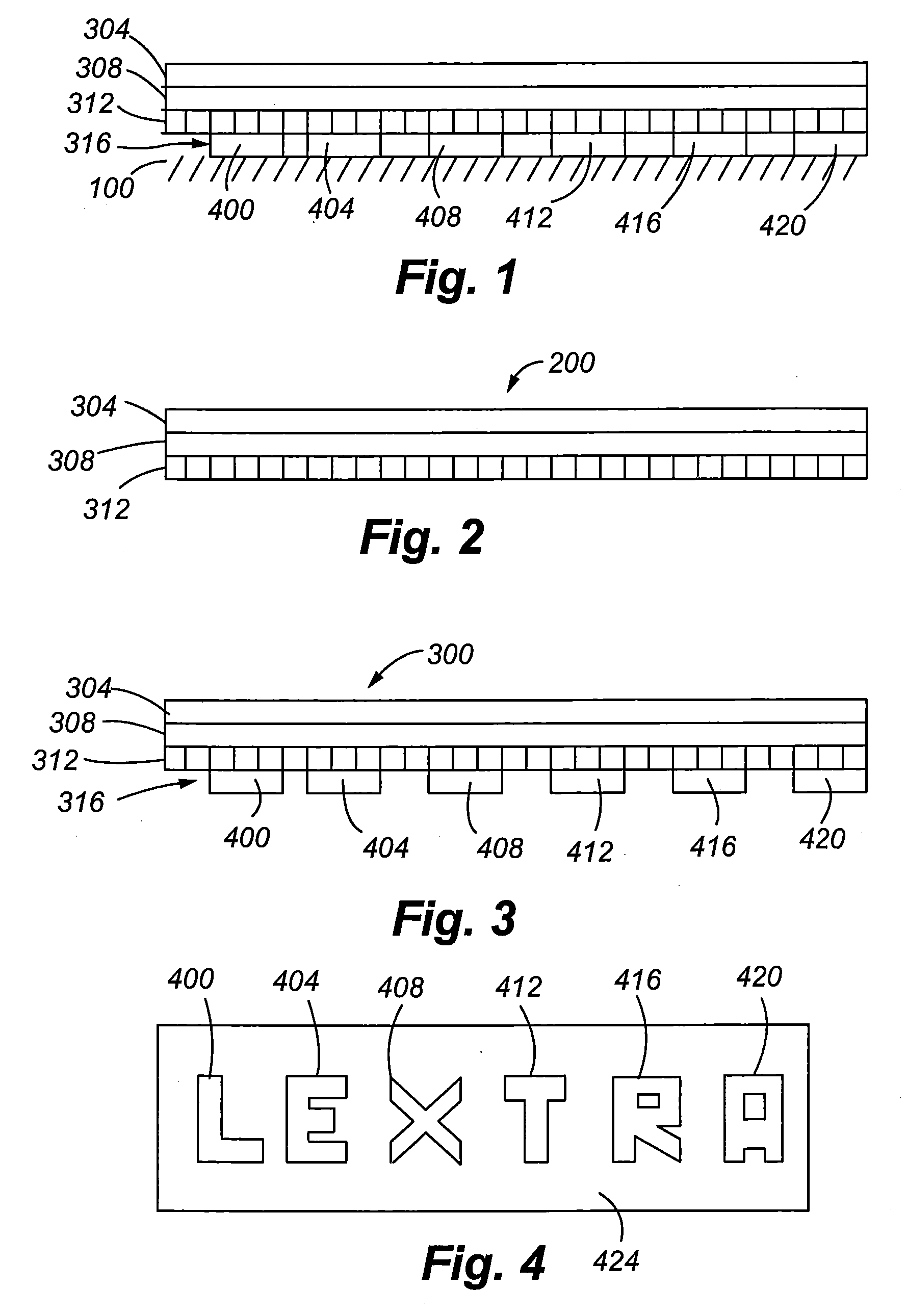

Stimulated lighting devices

InactiveUS20120033403A1Easy to operateEasy to handleLight source combinationsPoint-like light sourceLight equipmentEffect light

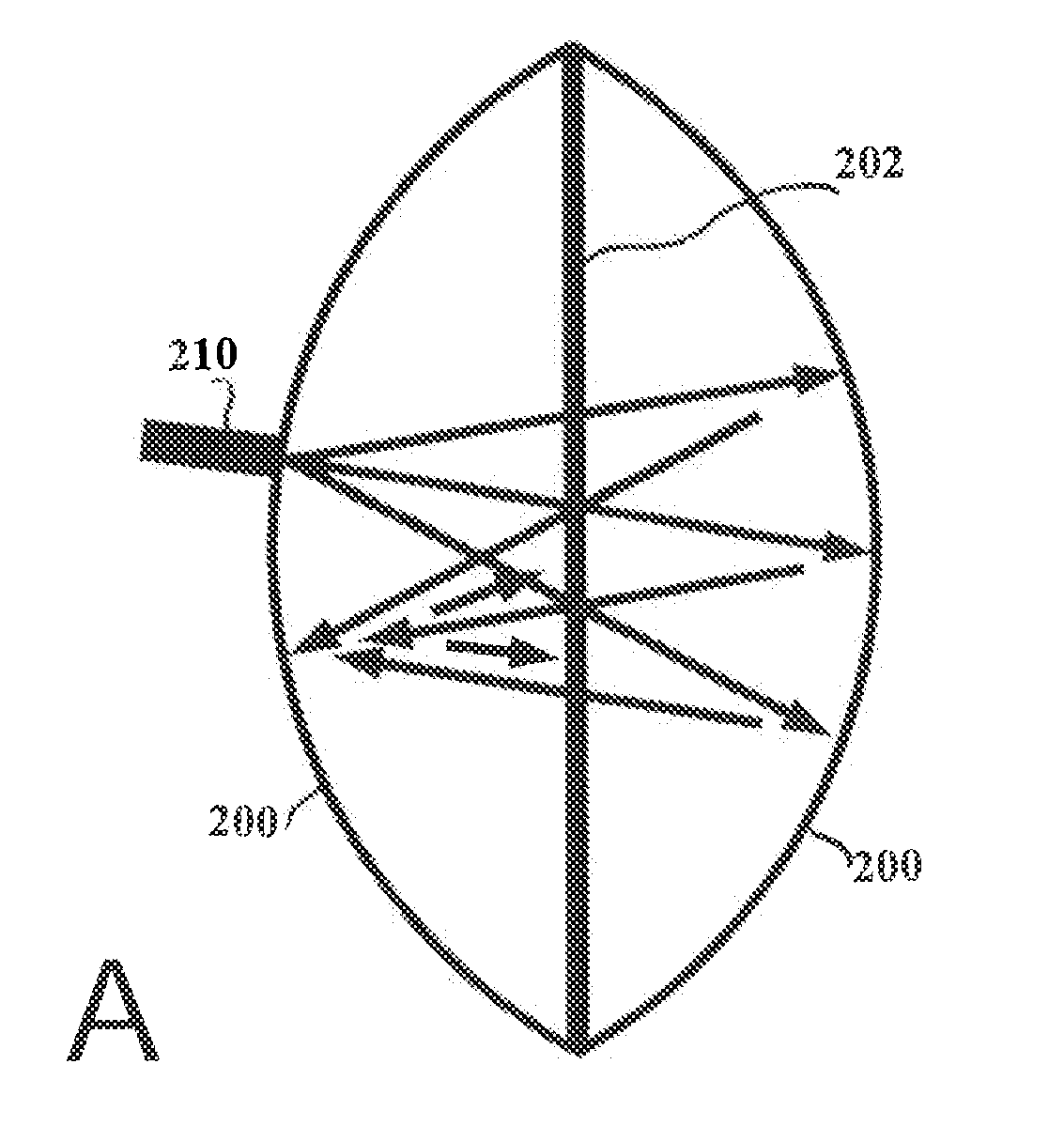

A stimulated lighting device for stimulatable light emission including a luminescent sheet including light stimulatable particles which emit secondary light upon receiving primary light. The lighting device includes a source configured to generate and direct the primary light obliquely onto the luminescent sheet, at least one reflector configured to reflect at least a part of the primary light and a part of the secondary light onto the luminescent sheet and configured to reflect at least a part of scattered primary light and a part of the secondary light from the luminescent sheet toward the light exit, and a light exit configured to emanate light as a combination of the primary light and the secondary light.

Owner:RES TRIANGLE INST

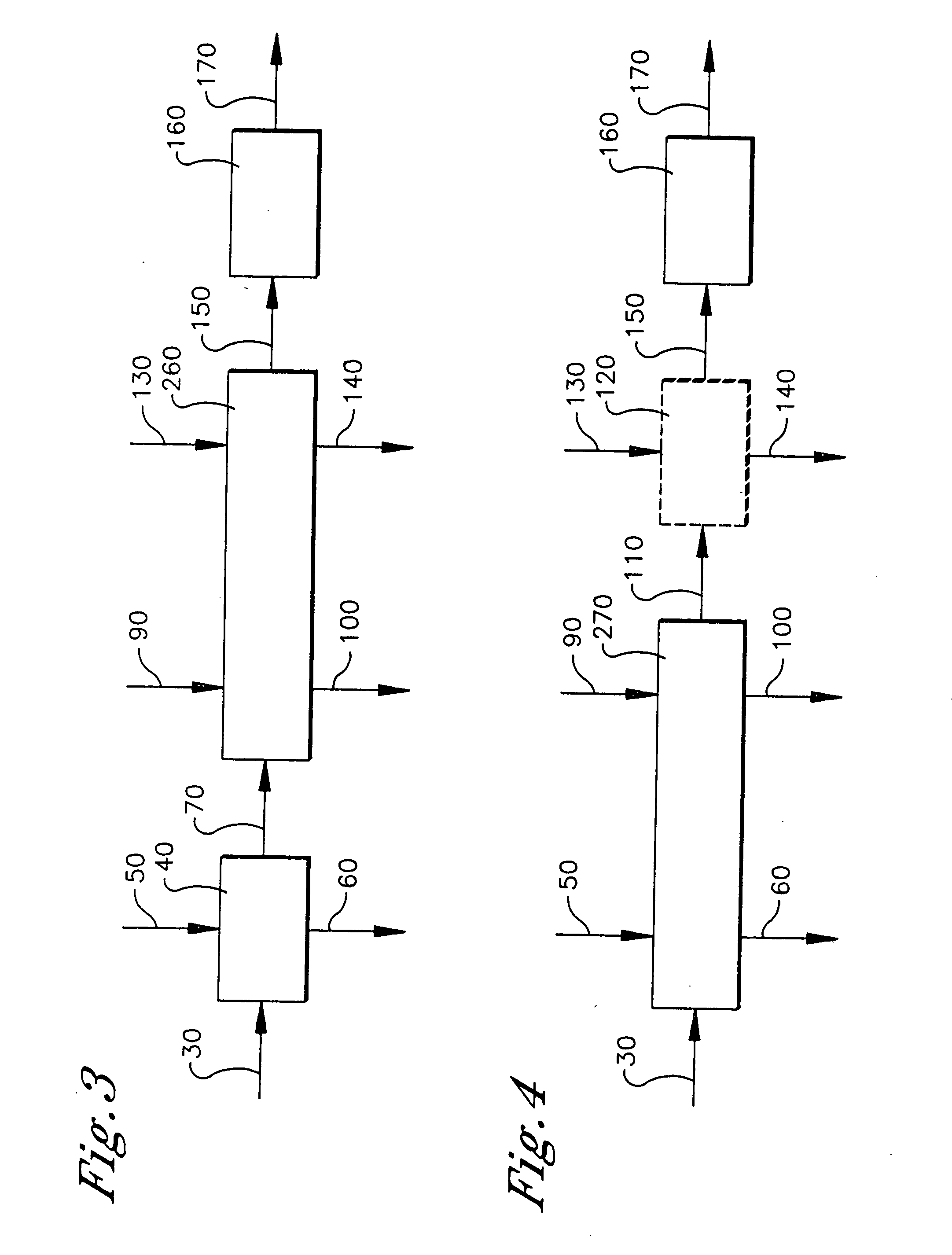

Process for production of a dried carboxylic acid cake suitable for use in polyester production

ActiveUS20050159616A1Less solventOrganic compound preparationCarboxylic preparation by oxidationCarboxylic acidSlurry

The present invention relates to a process by which a dried carboxylic acid cake is obtained from a slurry or cake carboxylic acid product through the use of at least one counter current wash. More specifically, the present invention relates to a process by which a dried terephthalic acid cake suitable as a starting material for polyester or co-polyester production is obtained from a slurry or cake terephthalic acid product through the use of at least one counter current wash.

Owner:GRUPO PETROTEMEX DE C V

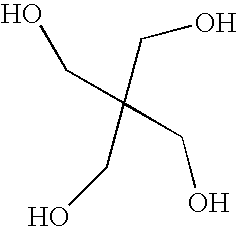

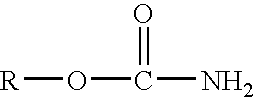

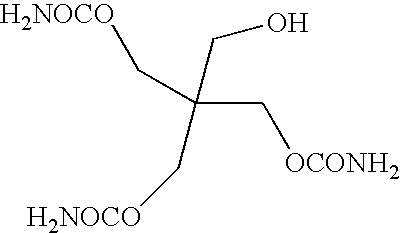

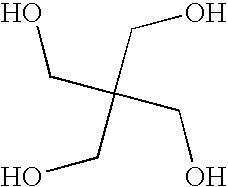

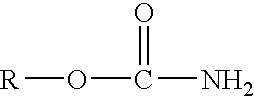

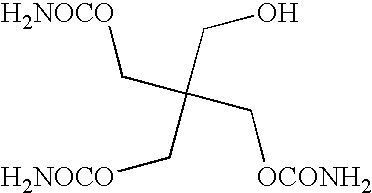

Polyester resin composition for use in a coating composition and method of preparing the same

ActiveUS7045588B2Improved scratch and mar characteristicReduce tensionGlass/slag layered productsYarnSilyleneCarbamate

A polyester polycarbamate resin composition for use in coating compositions to produce films having improved scratch and mar characteristics. The resin composition is the reaction product of a first compound having a plurality of hydroxyl groups with a carbamate compound reactive with the hydroxyl groups of the first compound and added in an amount sufficient to form a carbamated intermediary. The carbamated intermediary has at least one primary carbamate group available for cross-linking and has unreacted hydroxyl groups. Then, a silyl compound having a terminal isocyanate group is reacted with the unreacted hydroxyl groups of the carbamated intermediary. The silyl compound also has silylalkoxy groups available for secondary cross-linking. The present invention is also directed to a method of preparing the resin composition.

Owner:BASF CORP

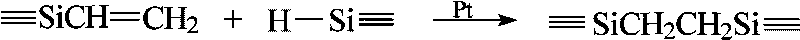

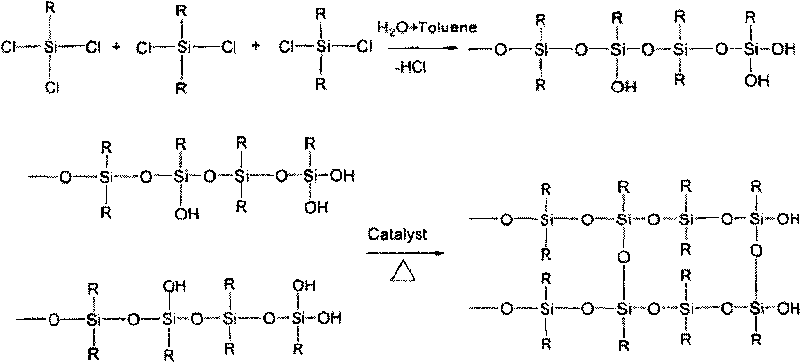

Method for preparing methyl phenyl vinyl silicone resin

The invention discloses a method for preparing a methyl phenyl vinyl silicone resin, which comprises the following steps of: under a condition of a nitrogen atmosphere at the temperature of between 30 and 45 DEG C, dissolving a certain amount of methyl trimethoxy silane, vinyl trimethoxy silane and alkyl dimethoxy silane in ethanol; adjusting the pH of the system to between 2.8 and 3.5; after full reaction, adding the methyl trimethoxy silane, the vinyl trimethoxy silane, the alkyl dimethoxy silane and deionized water into the mixture to perform isothermal reaction for 0.5 to 1 hour at the temperature of between 50 and 60 DEG C; raising the temperature to between 72 and 78 DEG C, performing the isothermal reaction again for 8 to 10 hours, and then dropping an end capping agent and deionized water into the mixture; performing reaction at the temperature of between 72 and 78 DEG C for 6 to 10 hours to obtain a white emulsion; and standing the mixture until complete demixing, separating the mixture to obtain an oily matter at a lower layer, and performing vacuum drying on the oily matter to obtain a product of the methyl phenyl vinyl silicone resin. In the method, the process is simple, the product is easy to separate and purify, the reactions are mild and are easy to control, and the processability is greatly improved.

Owner:SUZHOU UNIV

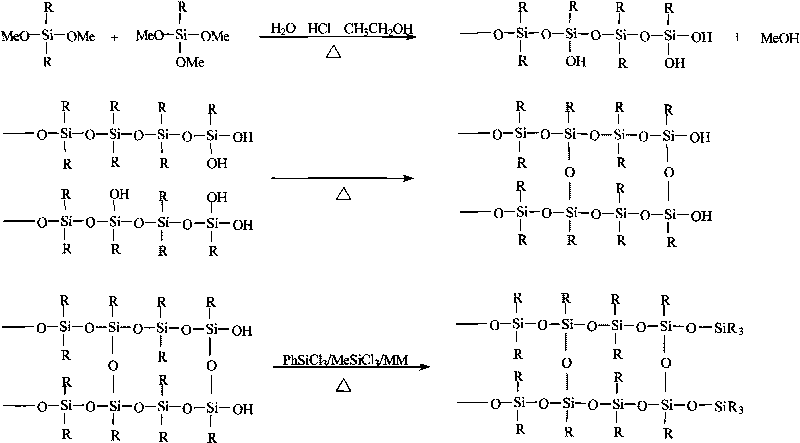

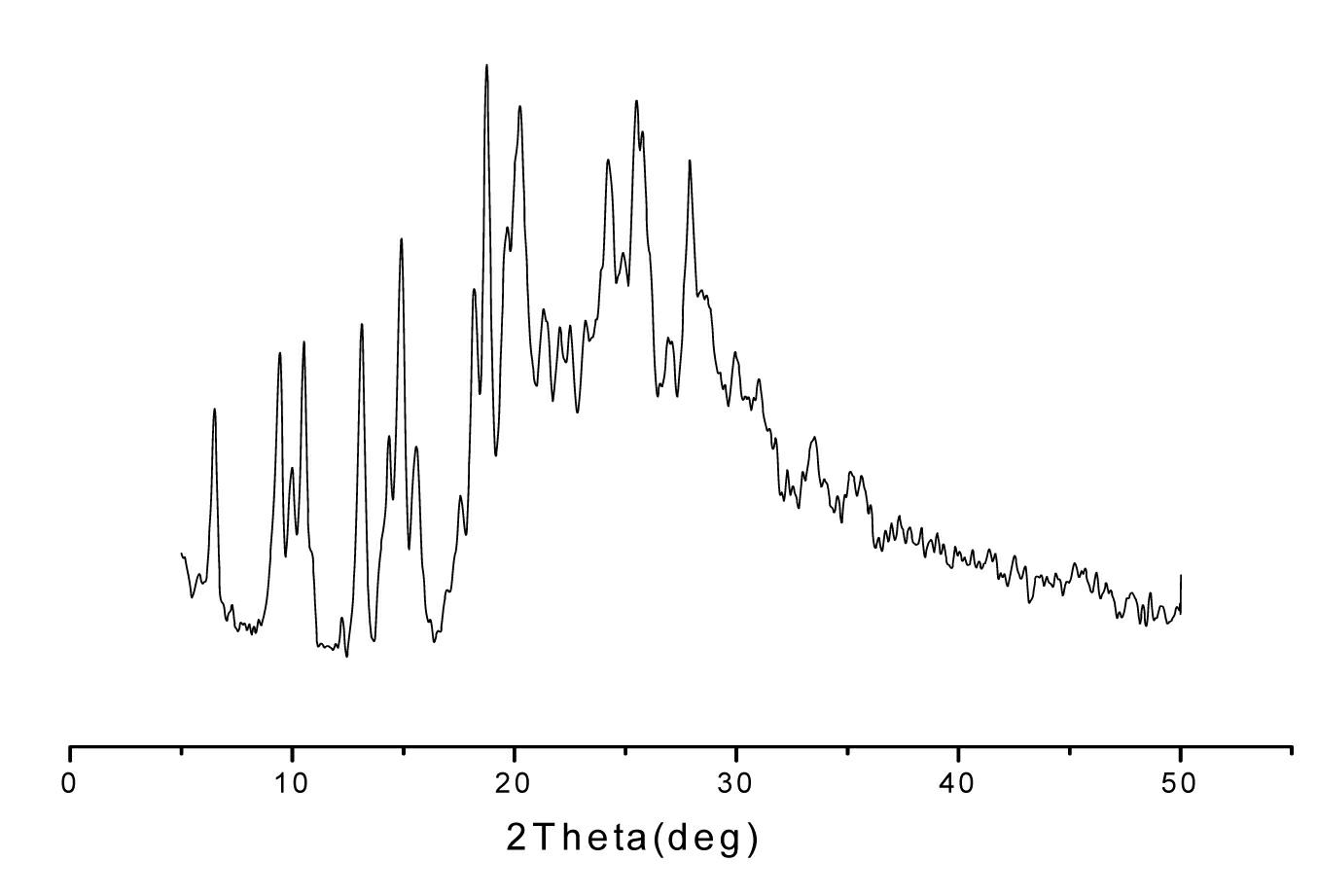

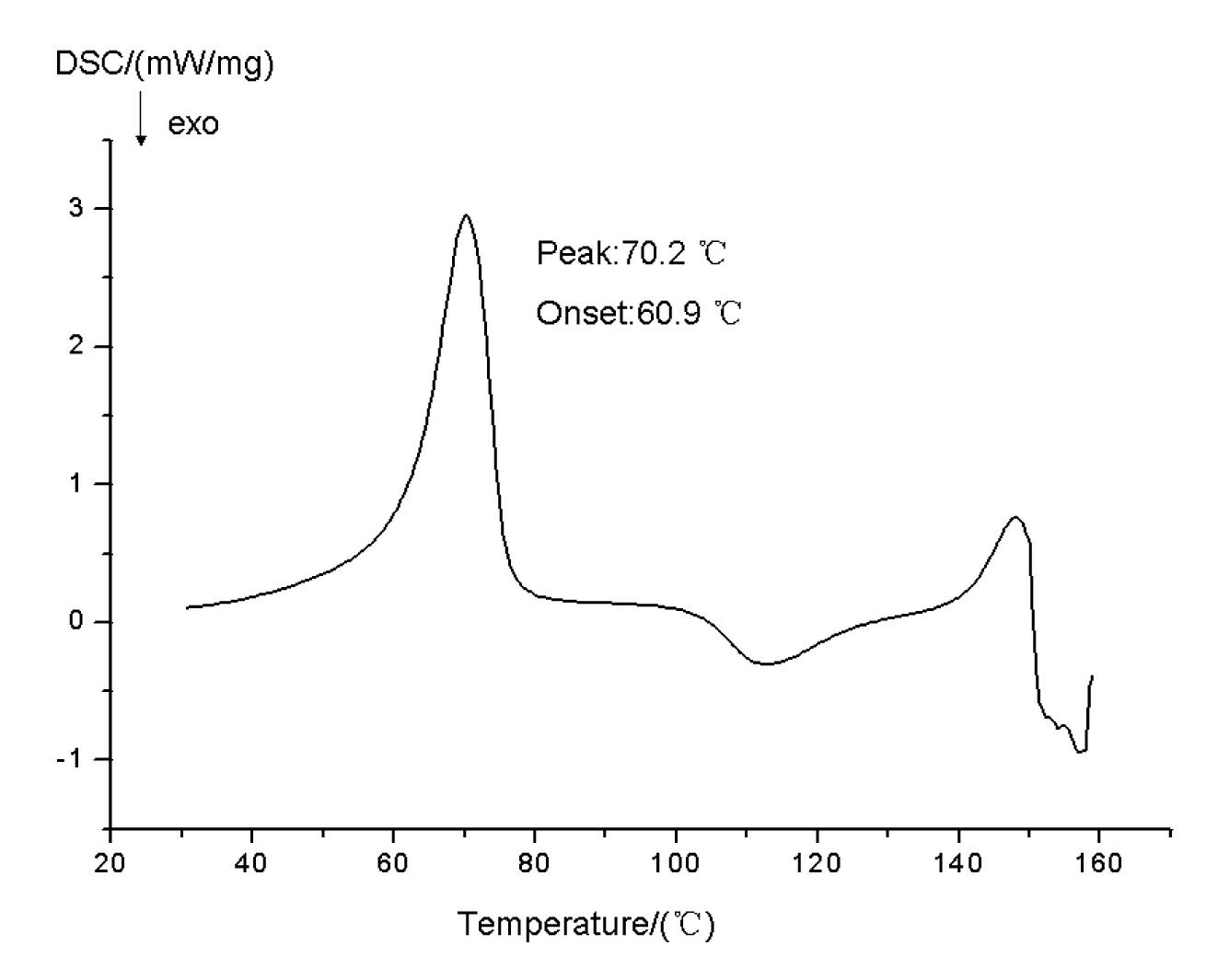

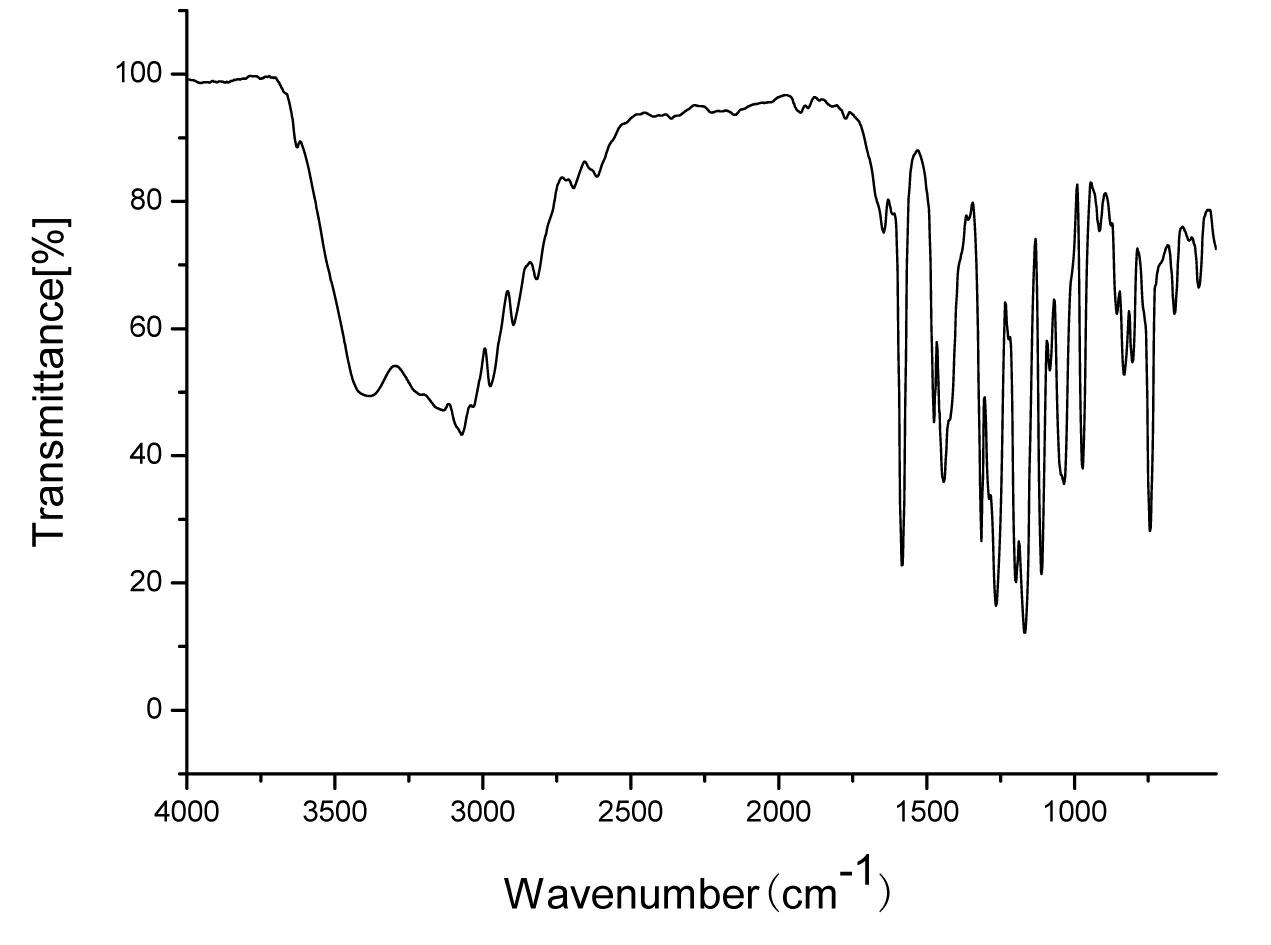

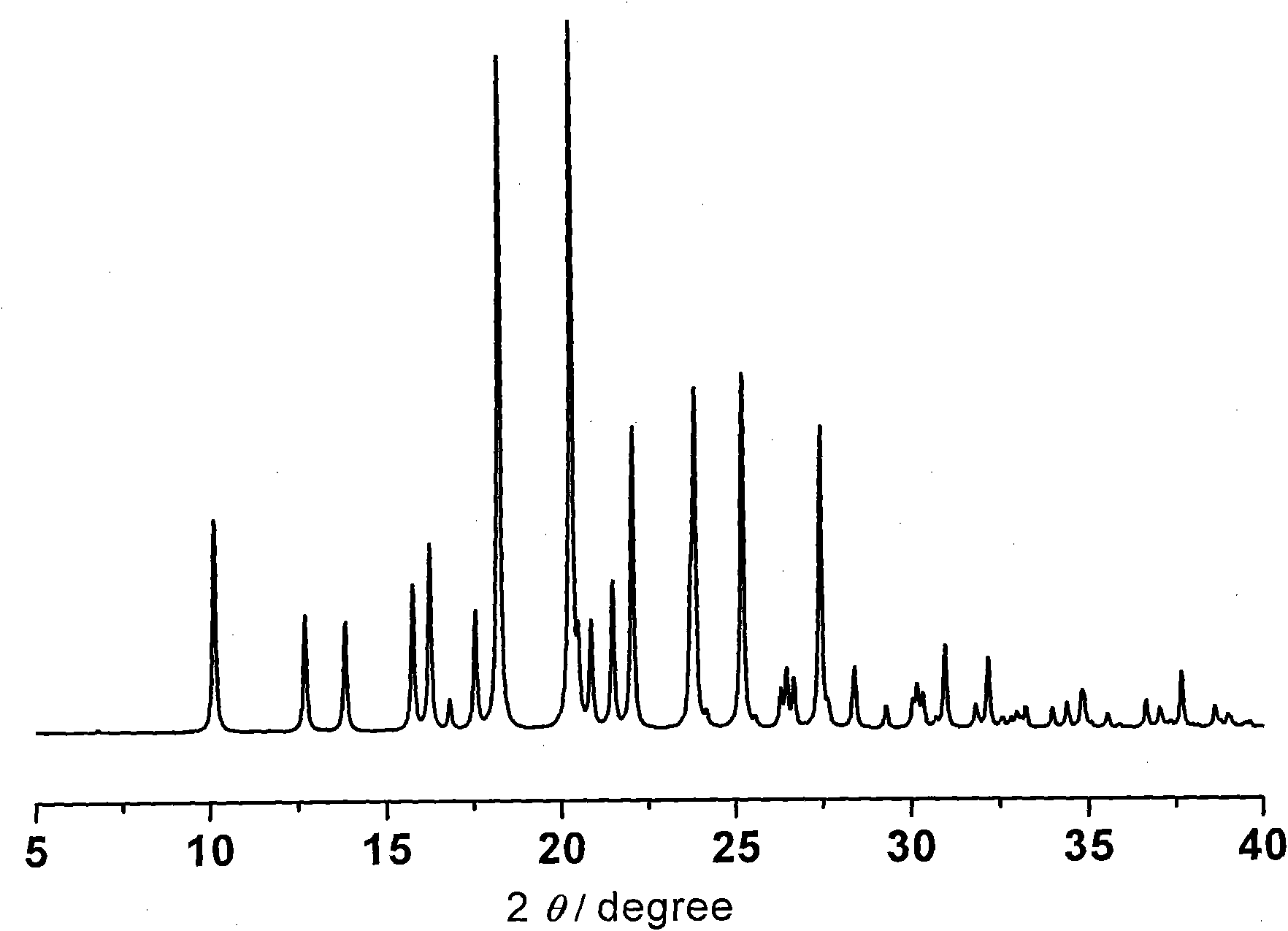

New crystal form of lansoprazole and preparation method and application thereof

InactiveCN102180866AEasy to prepareLess solventAntibacterial agentsOrganic active ingredientsSolventMedicinal chemistry

The invention discloses a new crystal form of lansoprazole and a preparation method and application thereof. The new crystal form of the lansoprazole is easy to prepare. The crystal form of the lansoprazole prepared by the method has high purity and low impurity content; the required amount of a solvent is small, and production cost is low; the preparation method is easy to operate and high in repeatability; reaction conditions are mild, and easy to control; and the target product crystal form can be stably obtained.

Owner:SUN YAT SEN UNIV +1

Ink composition

An ink composition includes a first saccharide and a second saccharide. The first saccharide is a linear saccharide having 4 or more saccharide units and the second saccharide is at least one selected from the group consisting of trehalose, maltotriose, and a cyclic saccharide.

Owner:SEIKO EPSON CORP

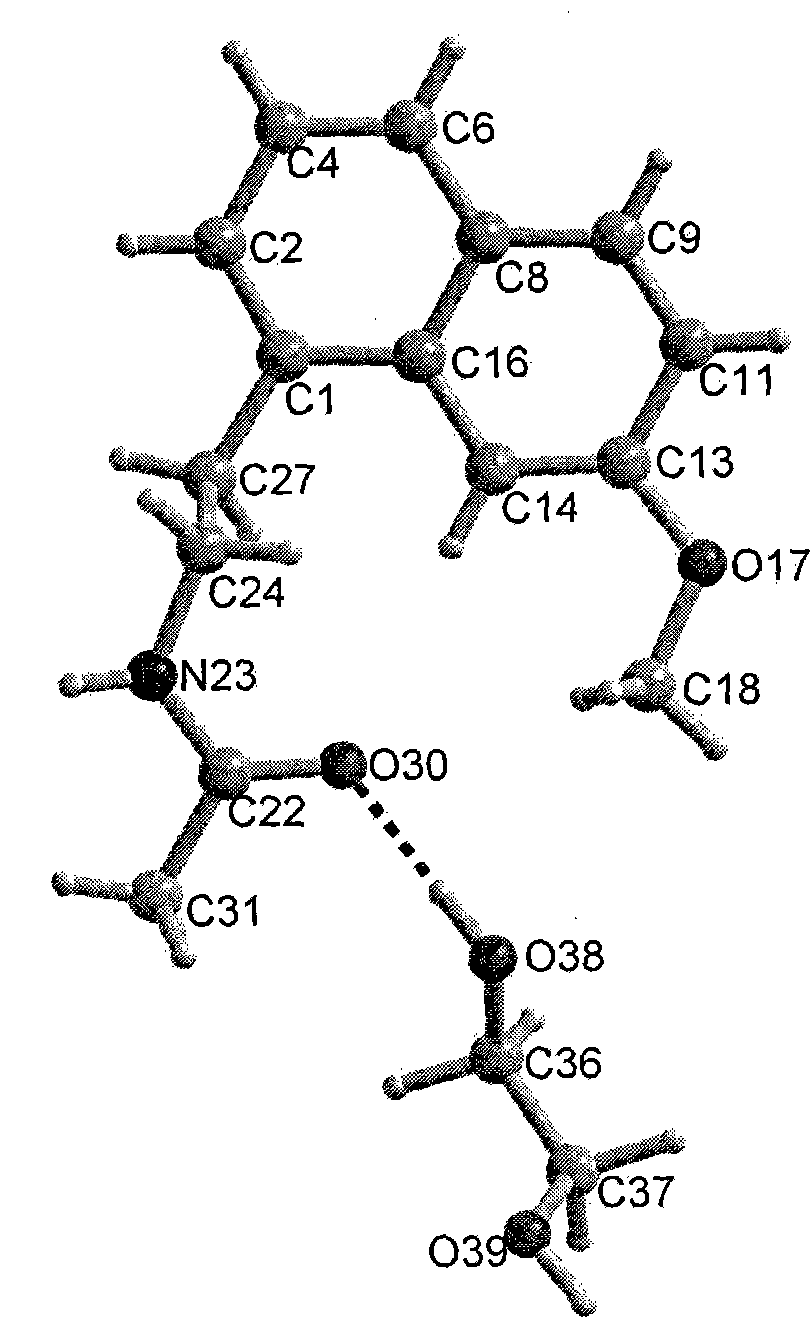

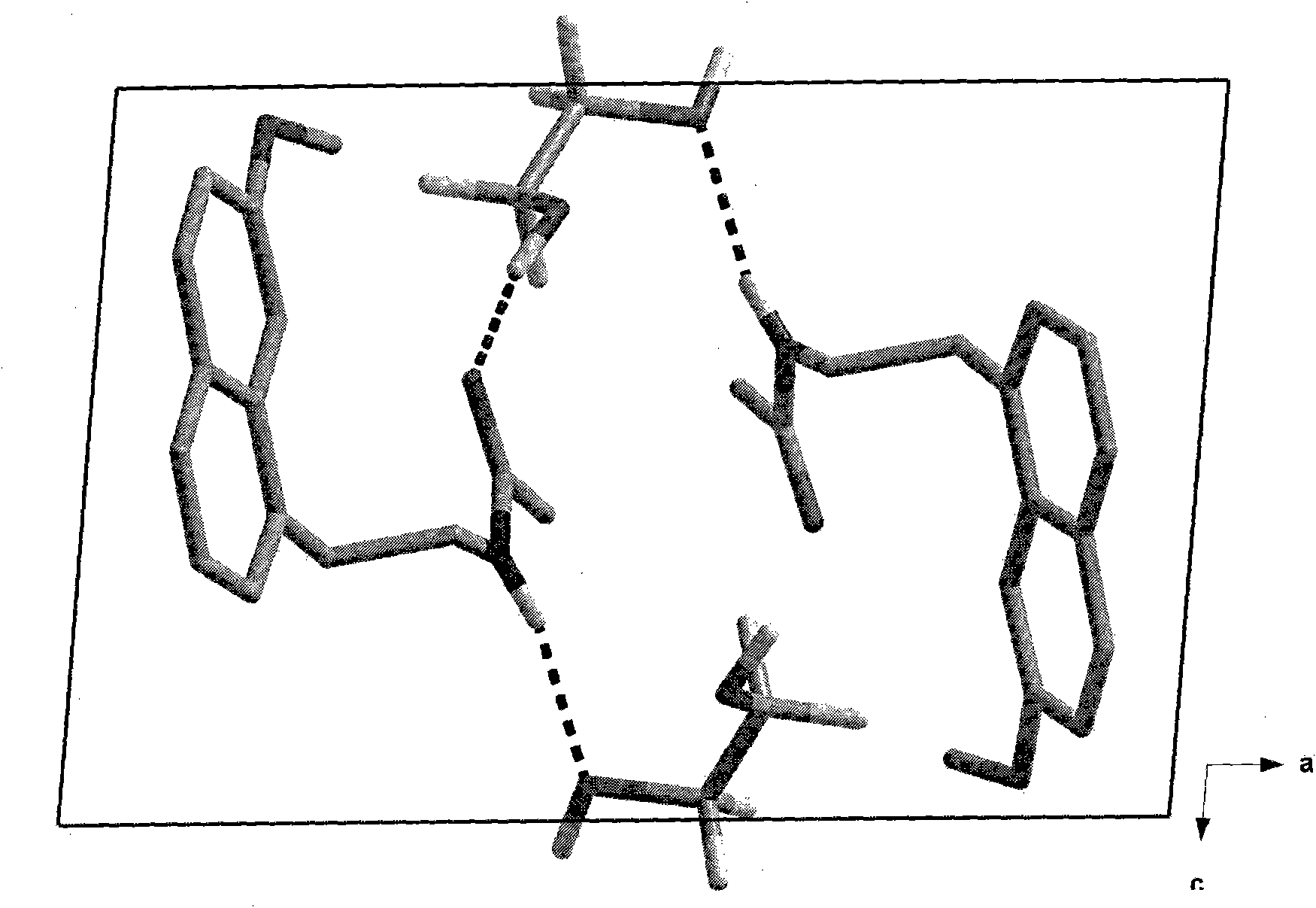

Crystalline Agomelatine solvate and preparation method thereof

InactiveCN101870662ALess solventReduce manufacturing costOrganic compound preparationCarboxylic acid amides preparationAcetic acidSolvent

The invention discloses a crystalline Agomelatine ethylene glycol, acetic acid solvate and a preparation method thereof. The preparation method of the crystalline Agomelatine ethylene glycol solvate comprises the steps of: mixing Agomelatine with ethylene glycol according to the proportion of 1:2-5, heating the mixture to 100 to 130 DEG C, and melting and cooling the heated mixture to result in solids. The preparation method of the crystalline Agomelatine ethylene glycol solvate further comprises the steps of: dissolving Agomelatine in acetic acid to result in solution, and adding the solution into antisolvent, followed by standing still or constantly stirring or evaporating the solvent below 50 DEG C to result in crystal. The crystalline Agomelatine ethylene glycol, acetic acid solvate prepared according to the method has the advantages of: obviously reduced melting point of the solvate, high crystallization purity, good reproducibility, less amount of the solvent used, no need of protection from inert gas, low production cost, simple operation, mild reaction condition and easy control.

Owner:SUN YAT SEN UNIV

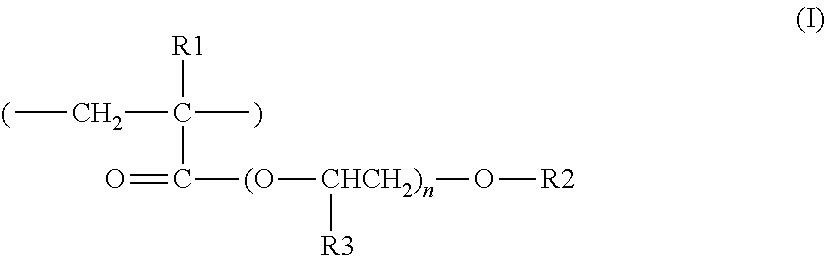

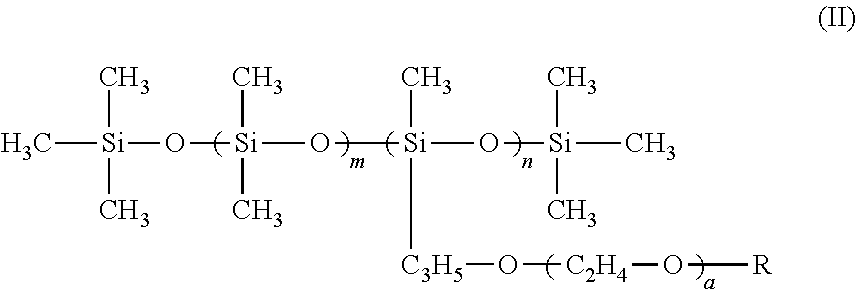

High solid content acrylic varnish, and preparation method and application thereof

The invention discloses a high solid content acrylic varnish which comprises the following raw materials in percentage by mass: 50-60% of hydroxy acrylic resin, 20-30% of polyurethane curing agent, 12.6-18% of organic solvent, 0.1-2% of wetting agent, 0.1-2% of flatting agent and 0.1-1% of antifoaming agent. The high solid content acrylic varnish disclosed by the invention can be applied in bamboo and wood tableware, is combined with a high solid content coating technology and technologies of cross-linked film curing and organic solvent removal and is a new development direction for bamboo and wood coatings and coating materials.

Owner:CARPOLY CHEM GRP

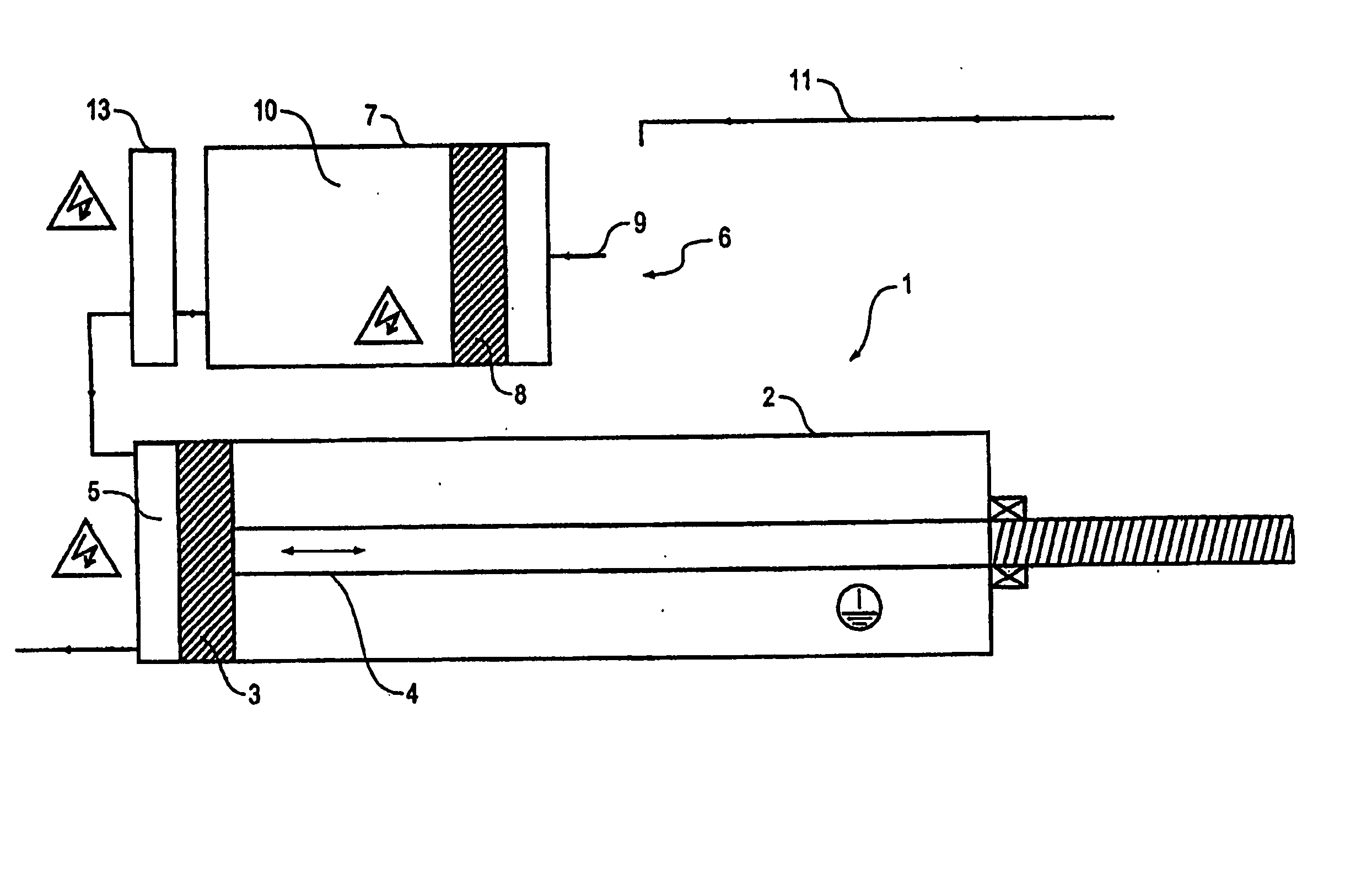

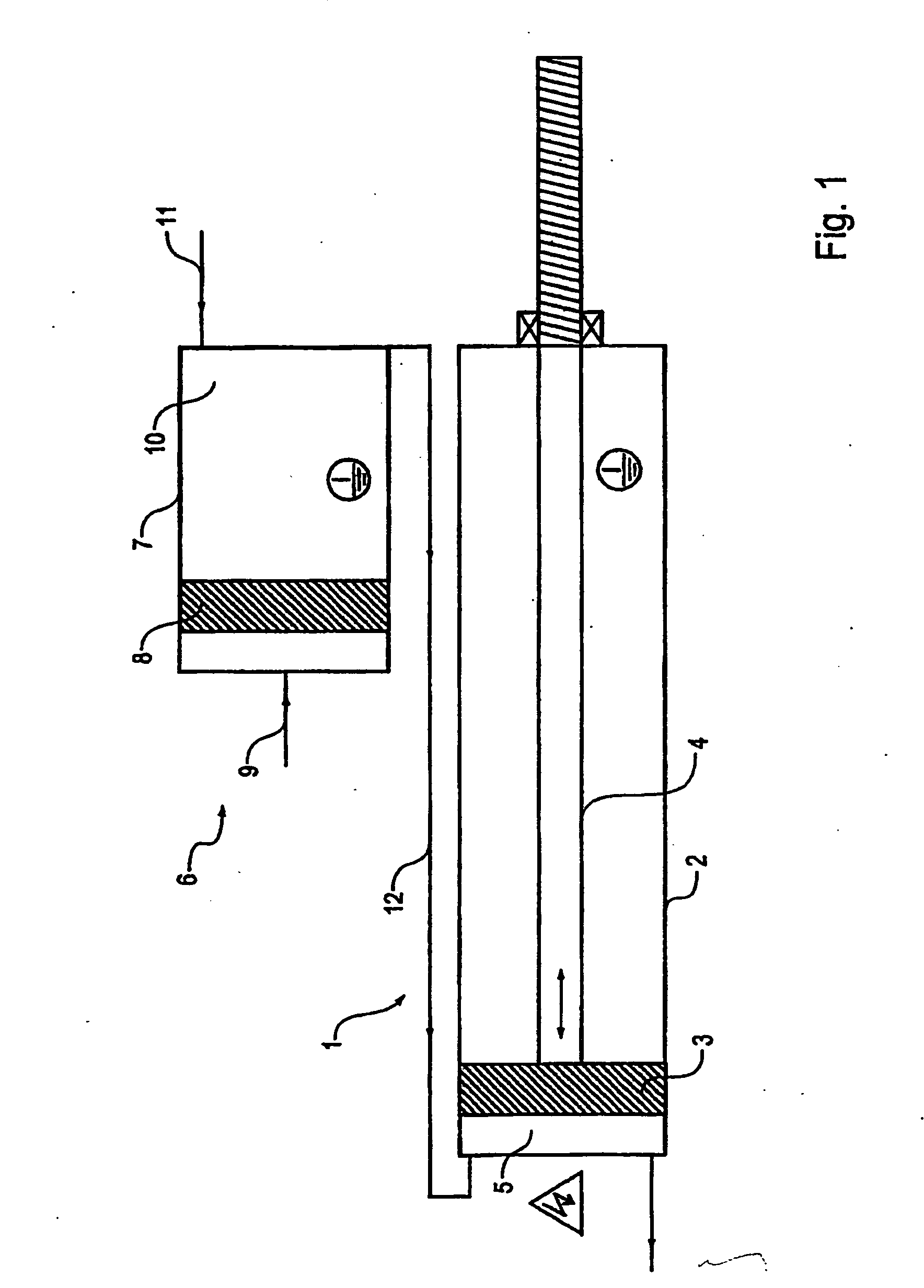

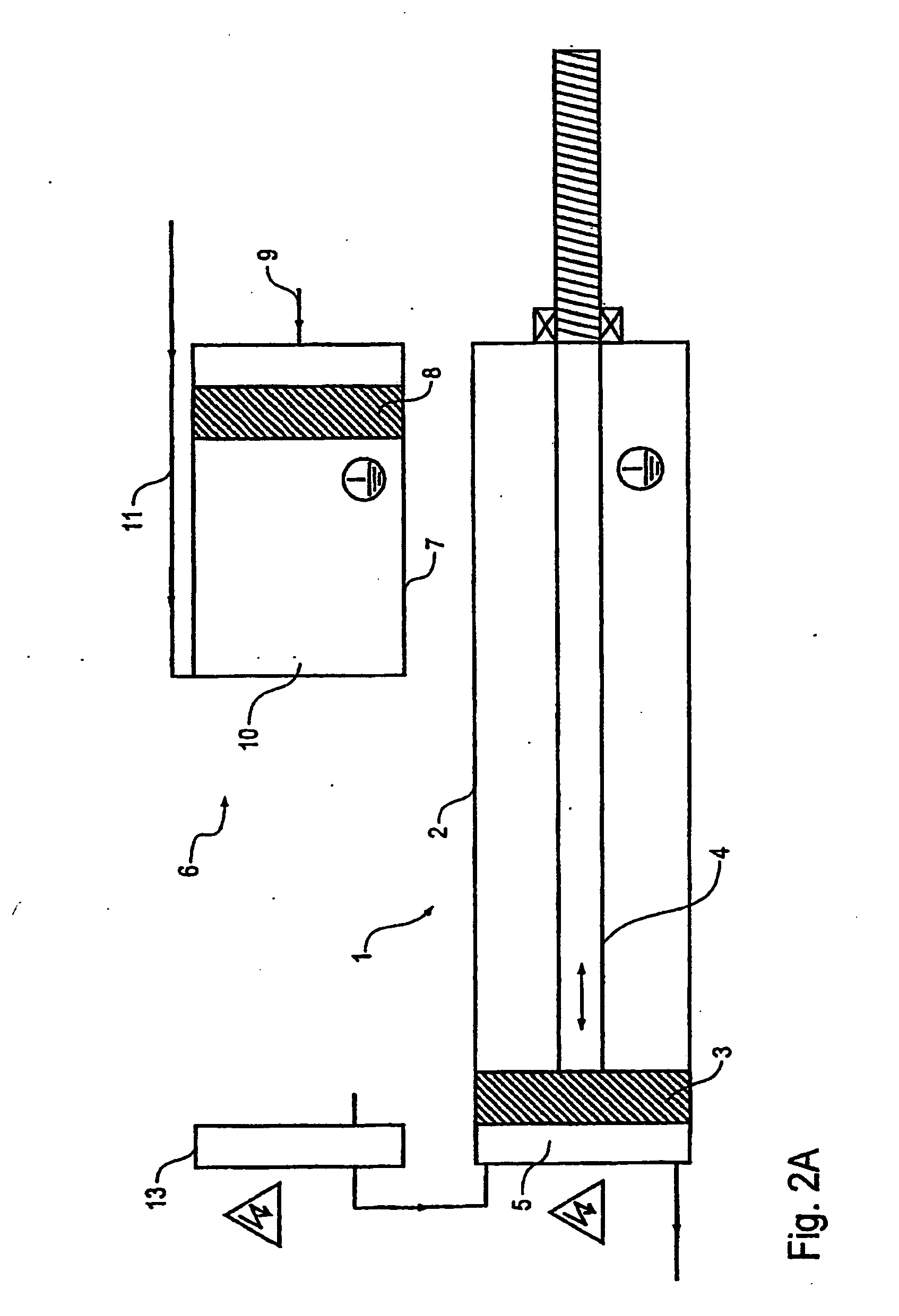

Coating material supply installation and associated operating procedure

ActiveUS20070082143A1Shorten color change timeSmall paint flow quantityBurnersLiquid surface applicatorsEngineeringHigh pressure

A coating means supply device, in particular for a paint facility, having a coating means meter that meters coating means to be applied to application equipment. The coating means supply device includes a coating means reservoir for holding the coating means and for supplying the coating means meter with the coating means. During application of coating material to equipment, the coating means reservoir is at ground potential and is located upstream from the coating means meter, which is at high-voltage potential. The reservoir is connected via an insulating path to the coating means meter. The coating means meter is at ground potential when the coating means reservoir supplies coating means to the coating means meter. Before the coating means meter is returned to a high-voltage potential for continued application of coating material, the insulating path is emptied to again insulate the coating means meter from the coating means reservoir.

Owner:DURR SYST INC

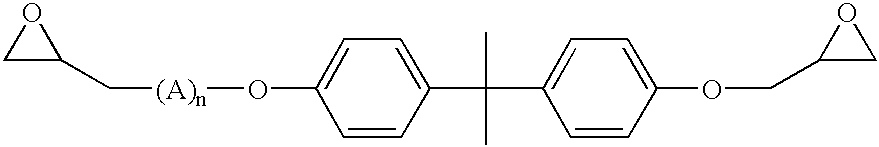

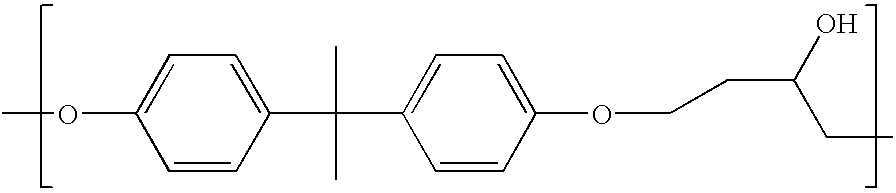

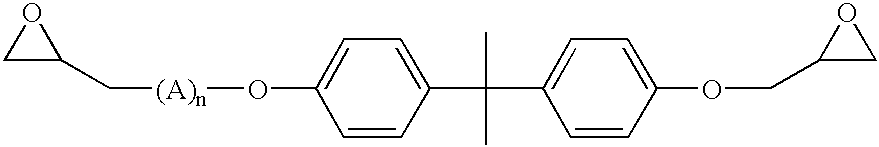

Epoxy dispersions for use in coatings

InactiveUS6989411B2LessImproved coating bath stabilityAnti-corrosive paintsPaints for electrolytic applicationsEpoxyChemistry

Epoxy resins that have one or more functional groups that impart an anionic character to the epoxy resins are prepared. The resulting anionic functionalized epoxy resins may be used to produce high solids, epoxy-based dispersions that are capable of being used as a component of a coating bath which can provide to a coating that may be applied to a surface using a variety of techniques.

Owner:HENKEL KGAA

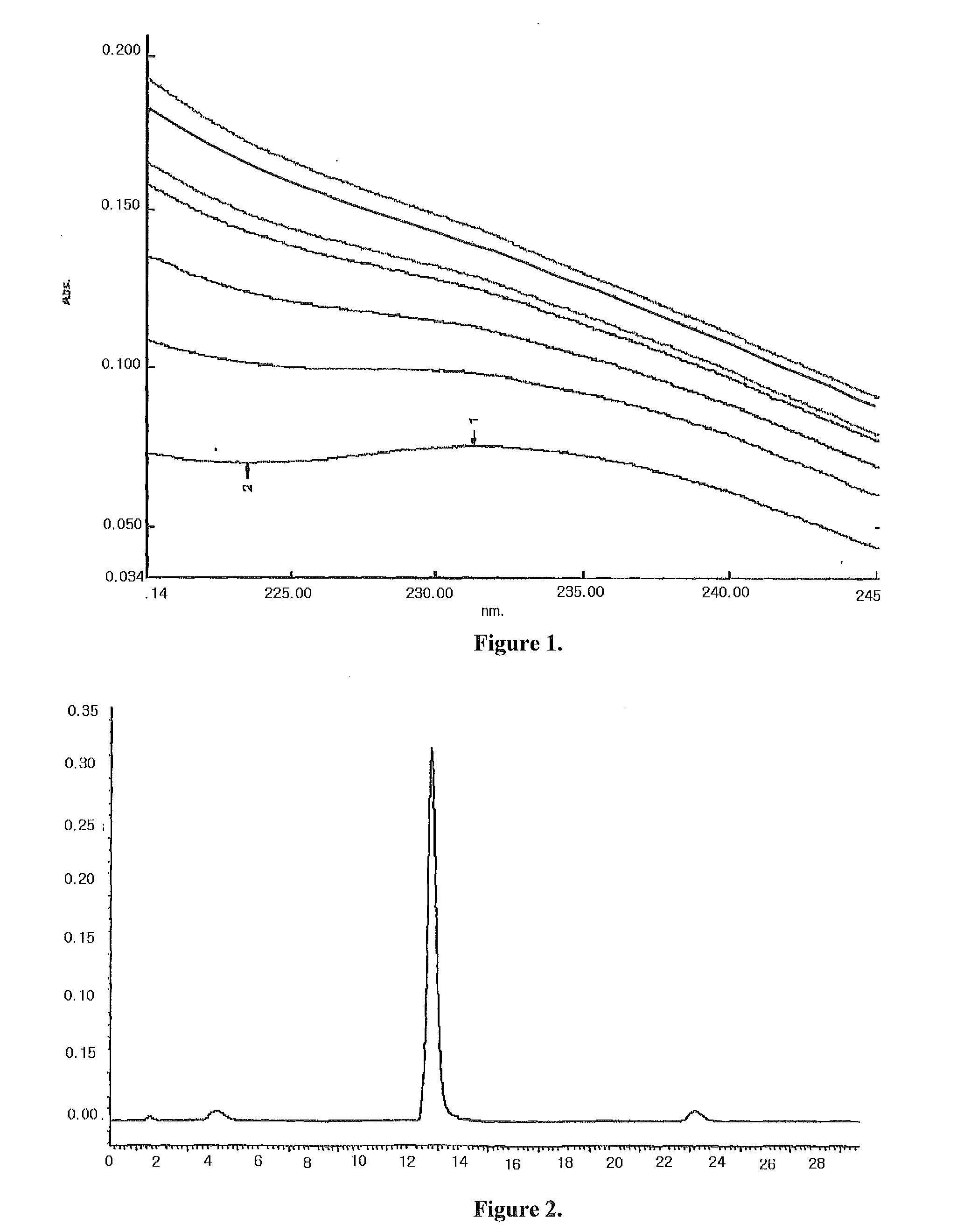

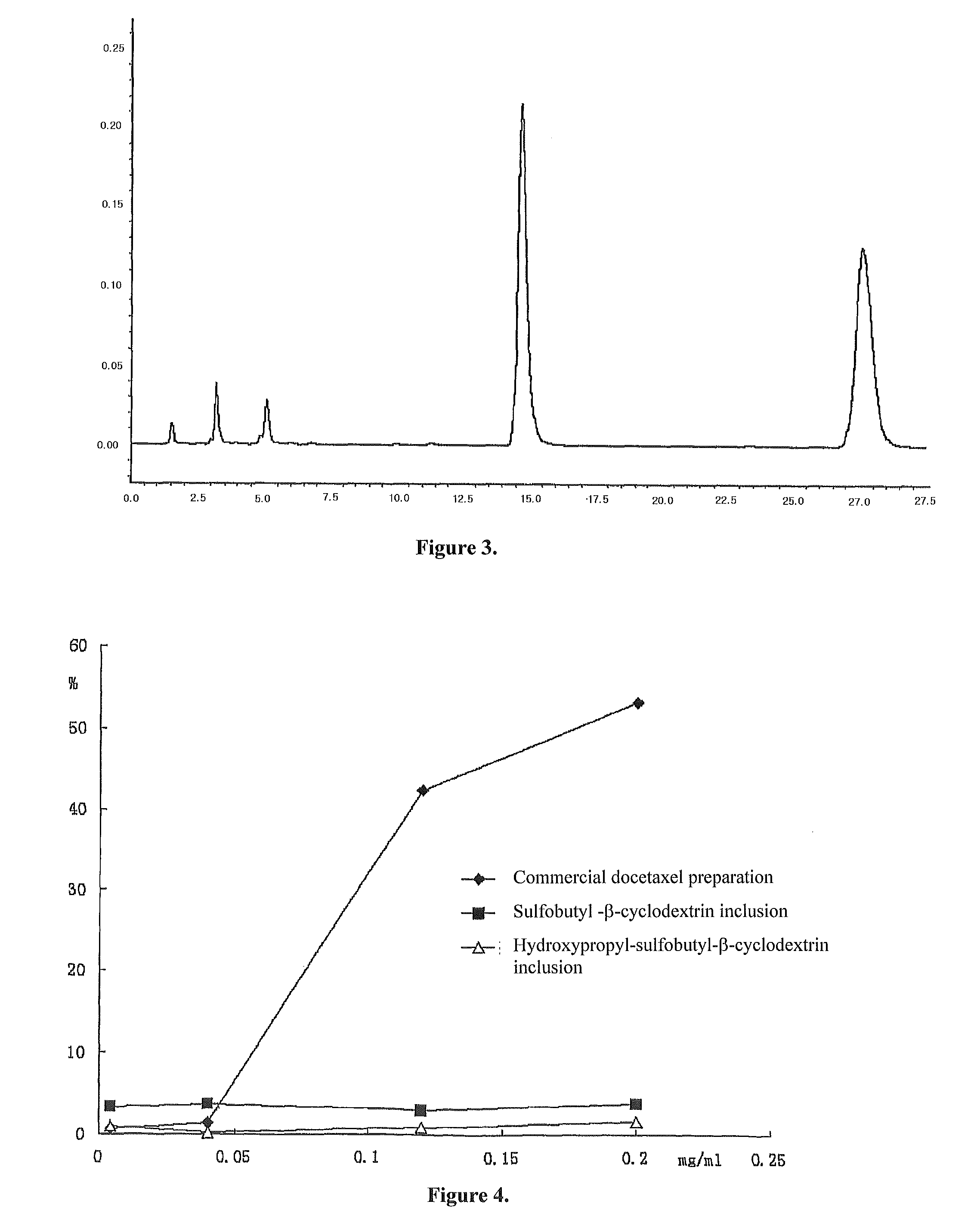

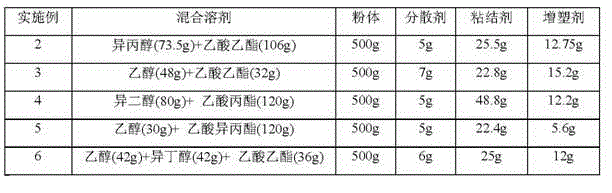

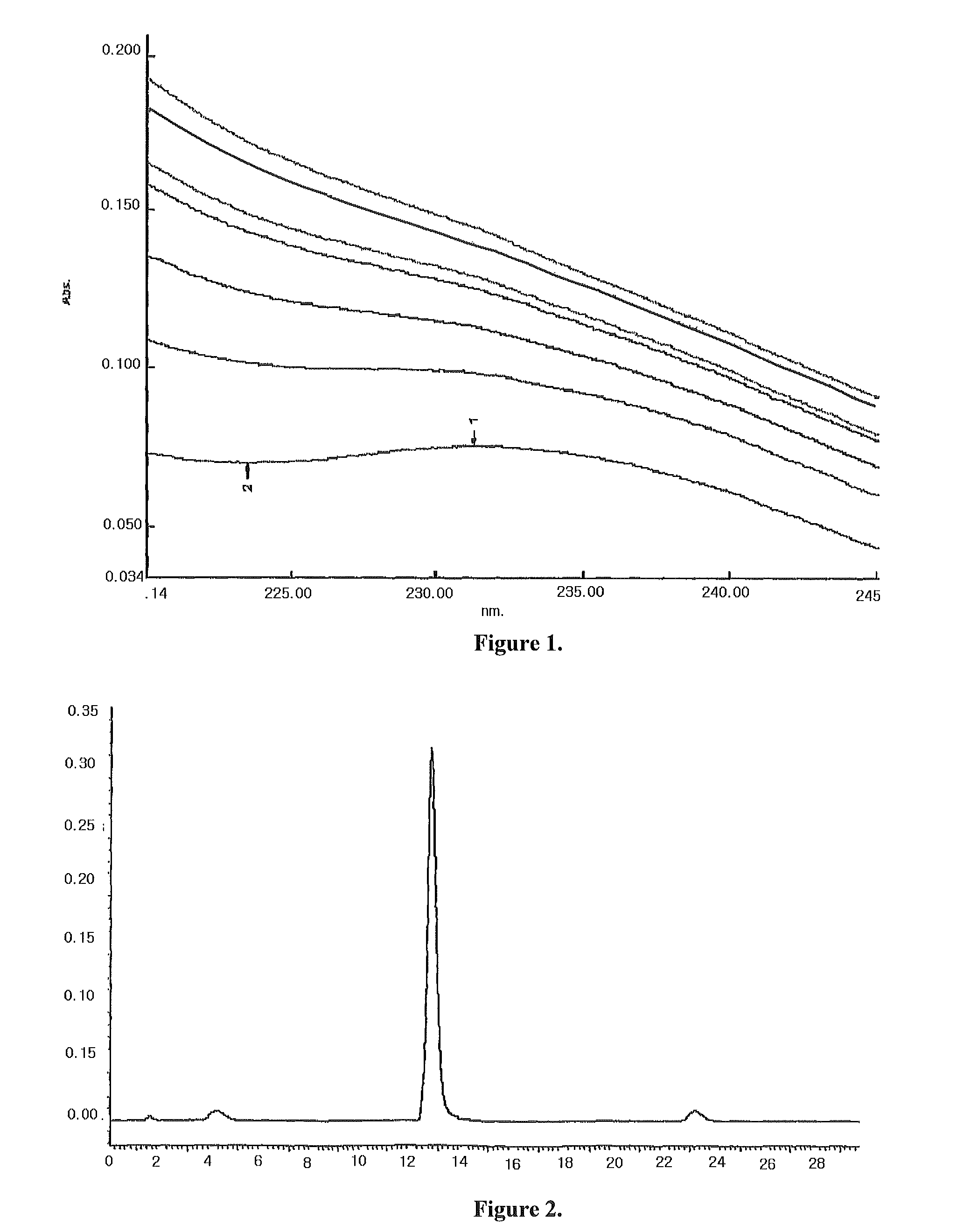

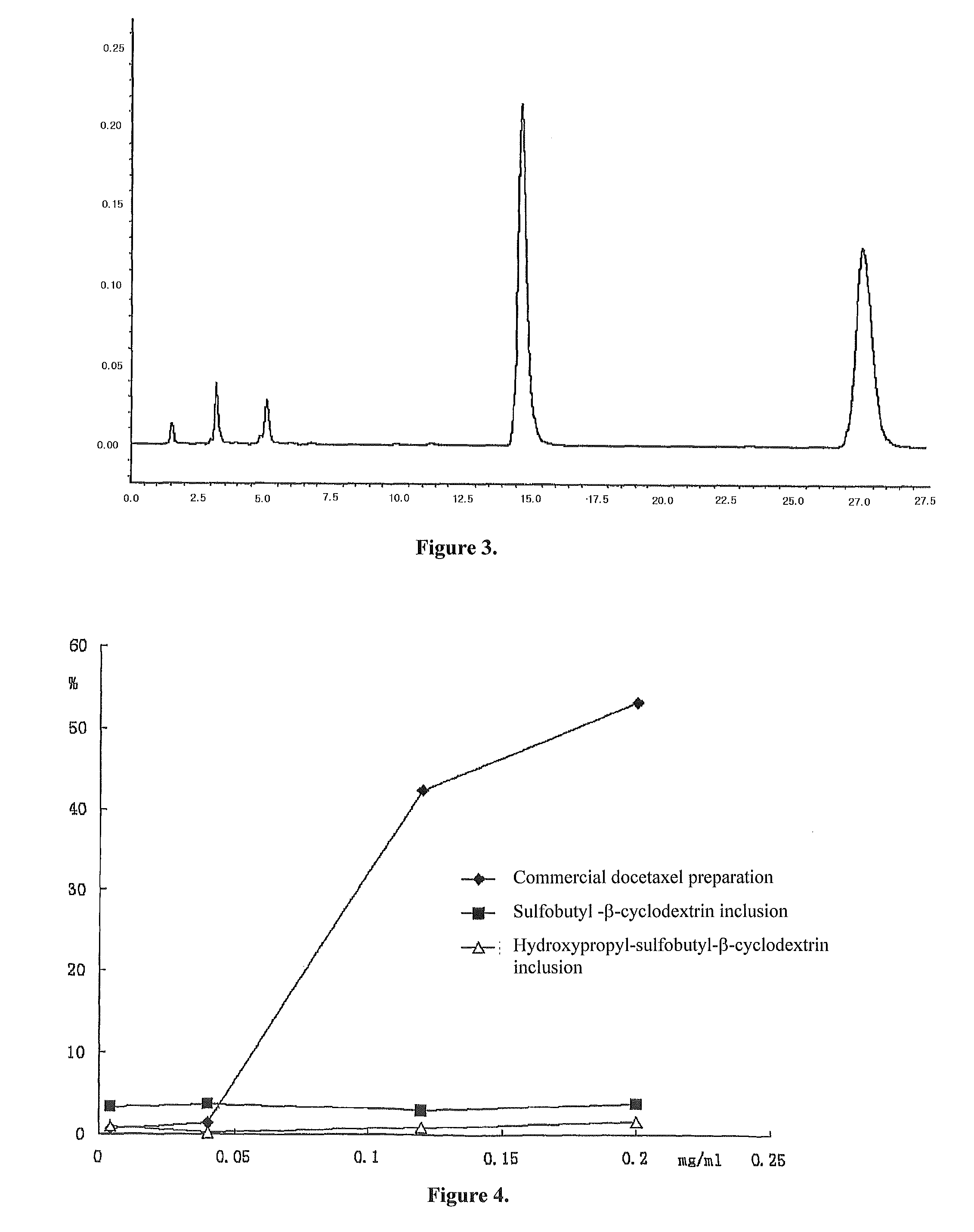

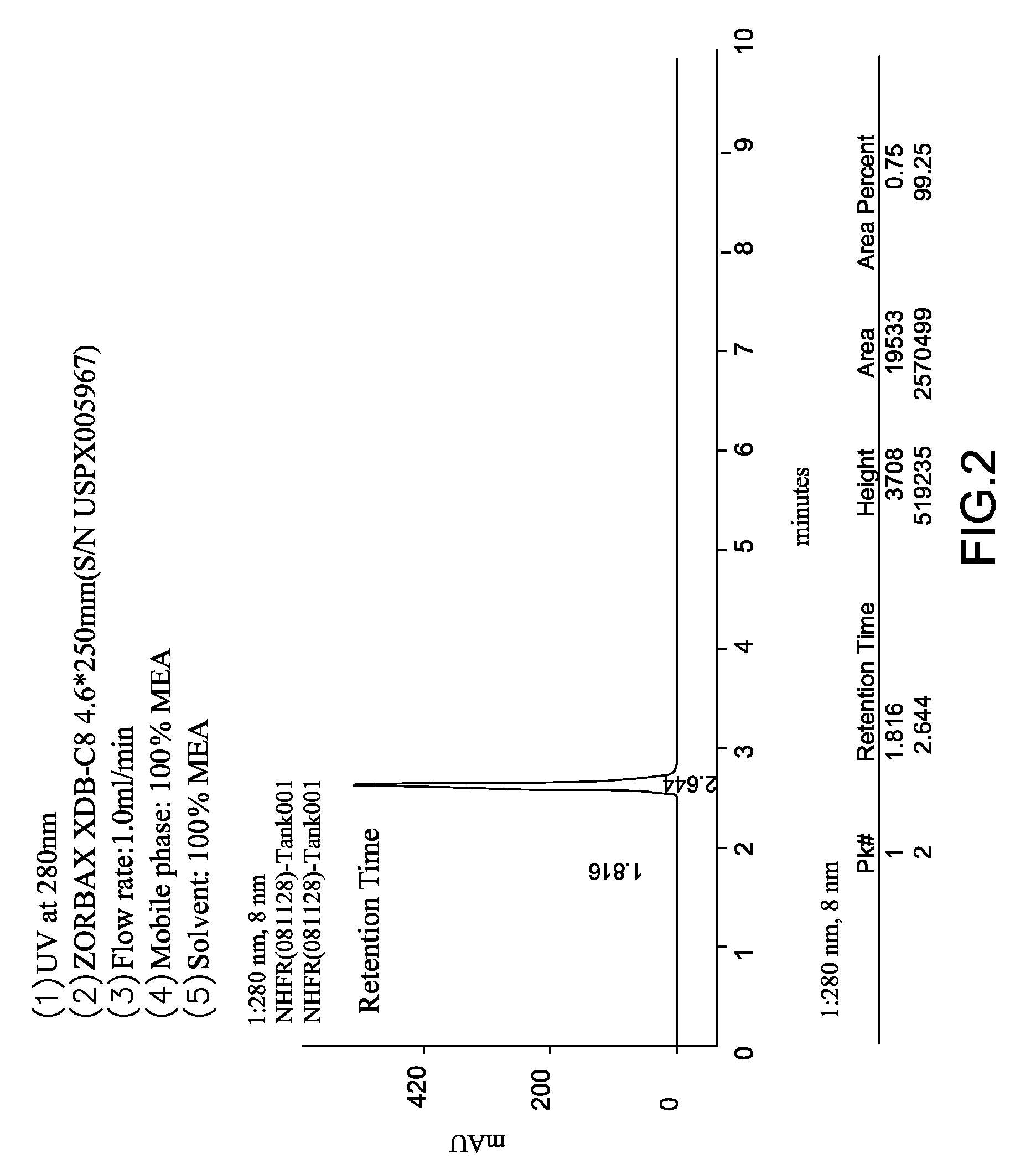

Pharmaceutical composition containing docetaxel-cyclodextrin inclusion complex and its preparing process

InactiveUS20100048685A1Improve solubilityClear long timeBiocideOrganic active ingredientsDocetaxelChemistry

A docetaxel inclusion complex having improved water-solubility (up to 15 mg / ml) and stability (stability constant Ka=2056M−1-13051M−1), comprises docetaxel and hydroxypropyl-beta-cyclodextrin and / or sulfobutyl-beta-cyclodextrin in a ratio of 1:10-150. The method includes steps as follows: docetaxel dissolved in ethanol is added into water solution of cyclodextrin via stirring, until docetaxel is completely dissolved; said solution is filtered in 0.2-04 μm microporous membrane then ethanol is removed through reduced pressure to obtain the inclusion complex in a liquid form; or ethanol, followed by water is removed through reduced pressure, then dried to obtain the inclusion complex in a solid form.

Owner:ZHAO WILLIAM DR +1

Ceramic casting slurry and preparation method thereof

The invention relates to a ceramic casting slurry and a preparation method thereof. The ceramic casting slurry is characterized by comprising a ceramic powder, a mixed solvent of alcohol and ester, a binder, a plasticizer and a dispersing agent; and the ceramic powder accounts for 65-75wt%, and a weight ratio of the ceramic powder to the mixed solvent is 5:2-4:1. The ceramic casting slurry provided by the invention has high solid content; and the mixed solvent of alcohol and ester has low cost, good environment compatibility, and low poison to the human body.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

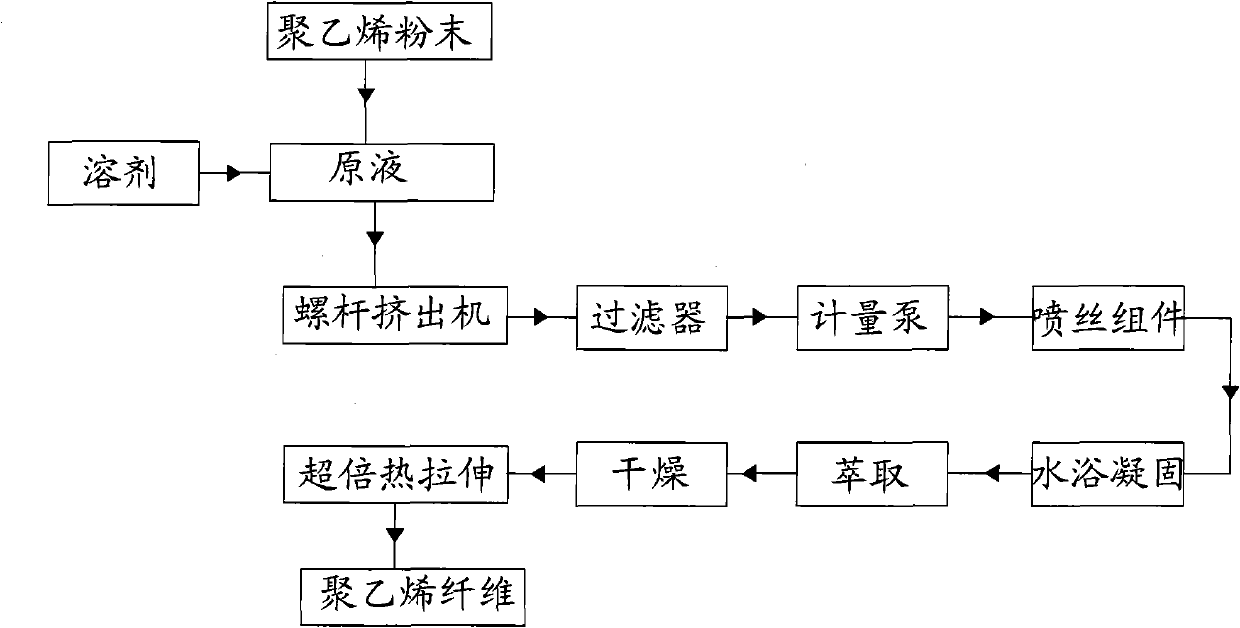

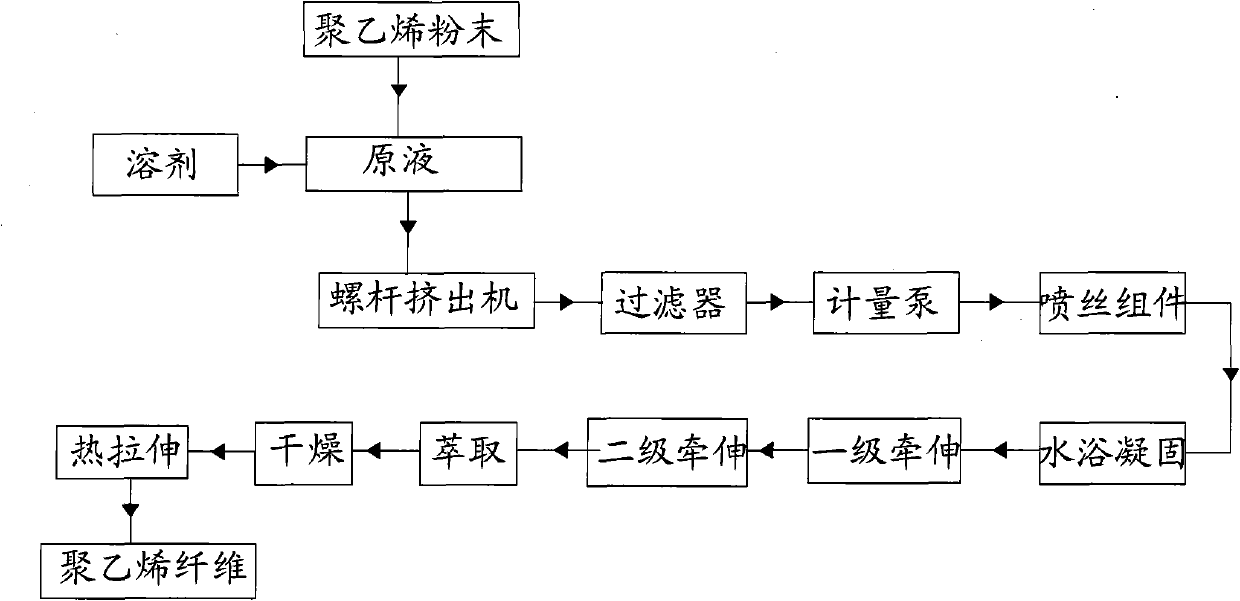

Preparation method of ultrahigh molecular weight polyethylene fiber

ActiveCN101768786AReduced breaking strengthReduce dosageWet spinning methodsMonocomponent polyolefin artificial filamentUltra-high-molecular-weight polyethyleneFiber

The invention relates to a method of preparing ultrahigh molecular weight polyethylene fiber through gel spinning method. The method comprises the following steps: (1) preparing gel protofilament of ultrahigh molecular weight polyethylene; and (2) processing the gel protofilament through extracting, drying and hot drawing to obtain the ultrahigh molecular weight polyethylene fiber. The method is characterized in that the method also comprises the step of pre-drawing the gel protofilament obtained in the step (1) before the step (2), wherein the pre-drawing time is 2.2-24 times and the total hot drawing time in the step (2) is 30-45 times. The method of the invention can be used to obtain ultrahigh molecular weight polyethylene fiber product with low size and high breaking strength and the production cost is low.

Owner:CHANGSHU SUPERFIBER

Synthetic process for cyclic organosilanes

A process for preparing a cyclic organosilane using a solvent that promotes ring-closure reactions between an organosilane compound and a dihalo organic compound is disclosed. The ring-closure reactions may form a 4-, 5- or 6-member cyclic organosilane. The process involves a mixture including a dihalo organic compound, an organosilane having at least two functional groups, a solvent and magnesium (Mg). The two functional groups in the organosilane may include halogen, alkoxy or a combination thereof. In the presence of Mg, a Grignard intermediate is formed from the dihalo organic compound in the mixture. The solvent favors intra-molecular or self-coupling reactions of the Grignard intermediate. The intra-molecular or self-coupling reaction promotes ring-closure reaction of the Grignard intermediate to form the cyclic organosilane.

Owner:STARFIRE SYST

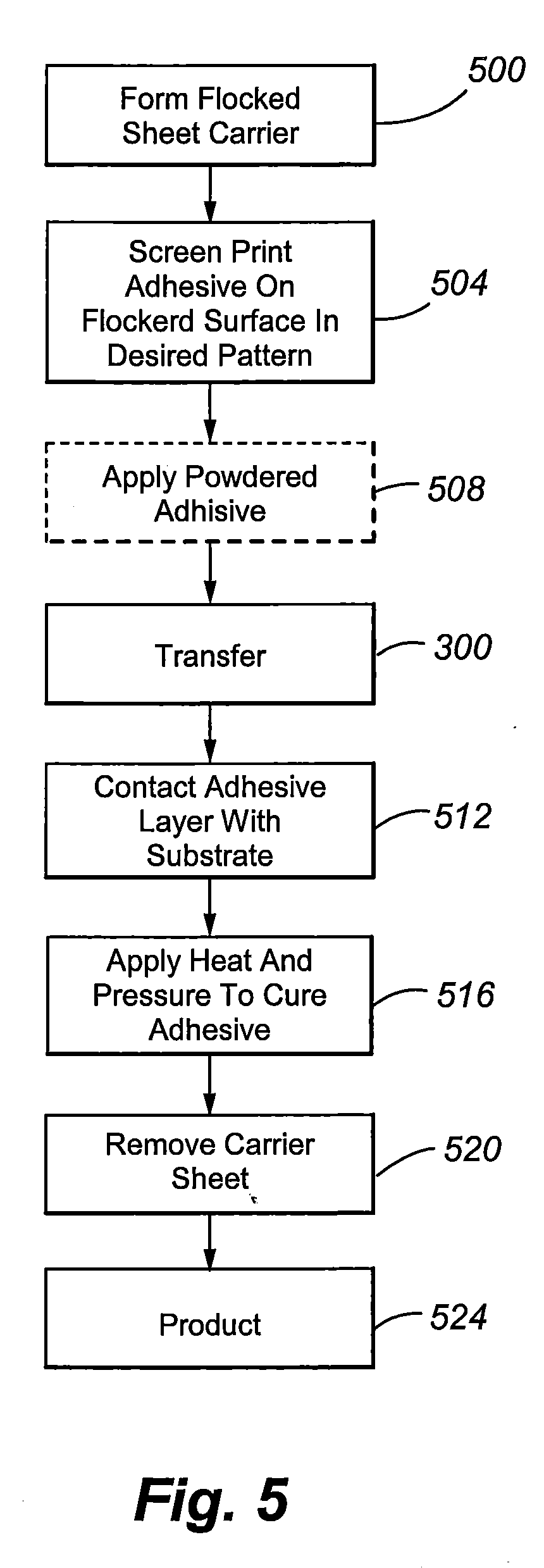

Flocked slurried thermosetting adhesive article

InactiveUS20100068447A1Good chemical resistanceRelease lessPattern printingCoatingsEngineeringSlurry

Owner:HIGH VOLTAGE GRAPHICS

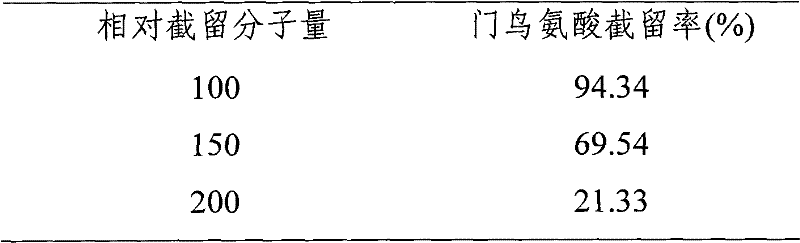

Preparation of ornithine aspartate for injection

InactiveCN102475697AAchieve desalinationShorten the timeOrganic active ingredientsPowder deliveryDesalinationOrnithine aspartate

The invention relates to a preparation process of ornithine aspartate for injection. According to the preparation process, a one-step operation of concentration, desalination and purification is carried out on the obtained reacted raw material liquid. The process used in the invention, which has the advantages of simplicity, short production period, and low energy consumption, is very suitable for the industrialized production of ornithine aspartate injections.

Owner:BEIJING KAWIN TECH SHARE HLDG +1

Pharmaceutical composition containing docetaxel-cyclodextrin inclusion complex and its preparing process

InactiveUS8481511B2Improve solubilityMaintain longBiocideOrganic active ingredientsDocetaxel-PNPDocetaxel

A docetaxel inclusion complex having improved water-solubility (up to 15 mg / ml) and stability (stability constant Ka=2056M−1-13051M−1), comprises docetaxel and hydroxypropyl-beta-cyclodextrin and / or sulfobutyl-beta-cyclodextrin in a ratio of 1:10-150. The method includes steps as follows: docetaxel dissolved in ethanol is added into water solution of cyclodextrin via stirring, until docetaxel is completely dissolved; said solution is filtered in 0.2-04 μm microporous membrane then ethanol is removed through reduced pressure to obtain the inclusion complex in a liquid form; or ethanol, followed by water is removed through reduced pressure, then dried to obtain the inclusion complex in a solid form.

Owner:ZHAO WILLIAM DR +1

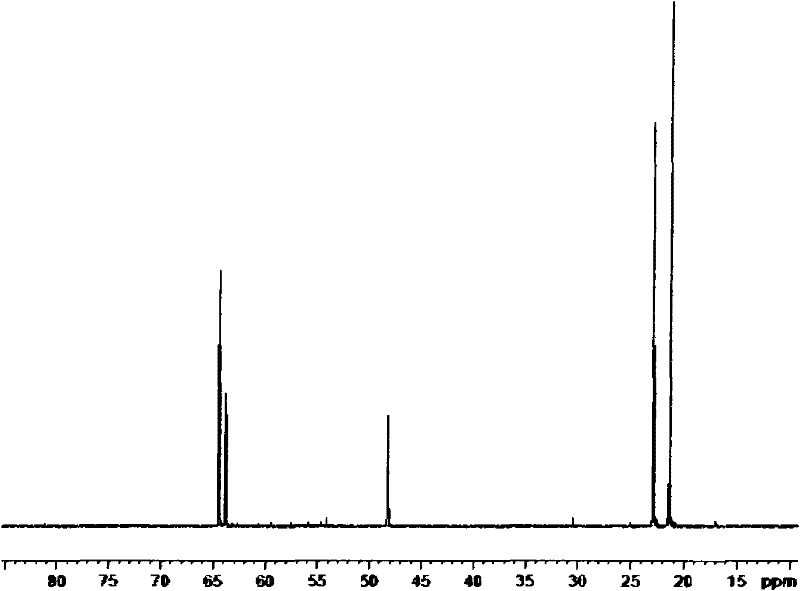

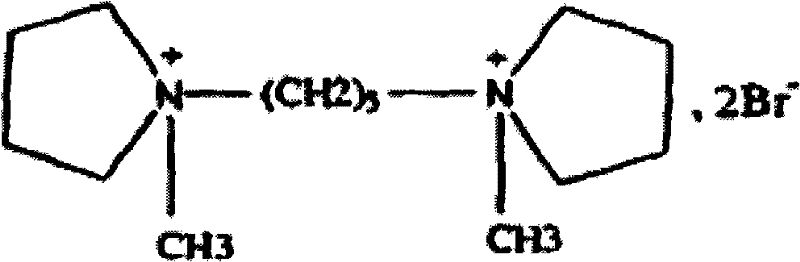

Synthetic method of biquaternary ammonium salt

ActiveCN102453000AQuick responsePrevent aggregation tendencyOrganic chemistryHigh concentrationSolvent

The invention discloses a synthetic method of biquaternary ammonium salt. In the method, ultrasonic waves are introduced into a reaction system in a dispersing manner, and a biquaternary ammonium pentane-1,5 (methylpyrrolidinium) dibromide can be synthesized under the high temperature and high concentration. In the method, the quantity of the used solvent is fewer, the particles of the biquaternary ammonium salt which is generated by the reaction are smaller, so that the following washing, filtering, recrystallization and other operations are very facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

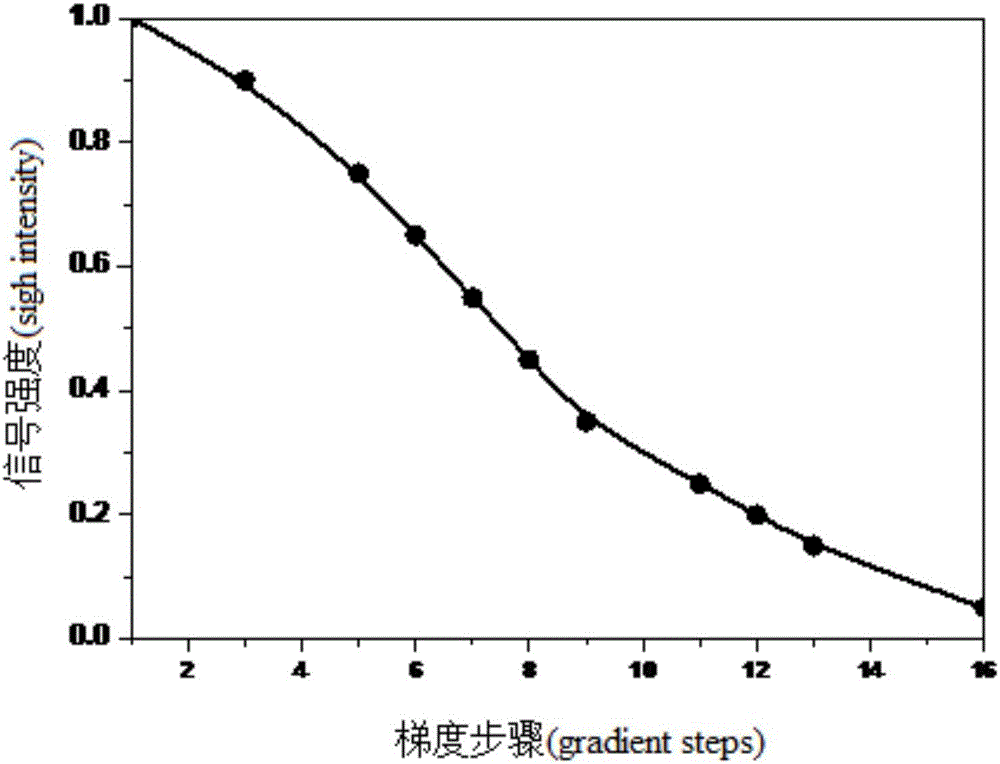

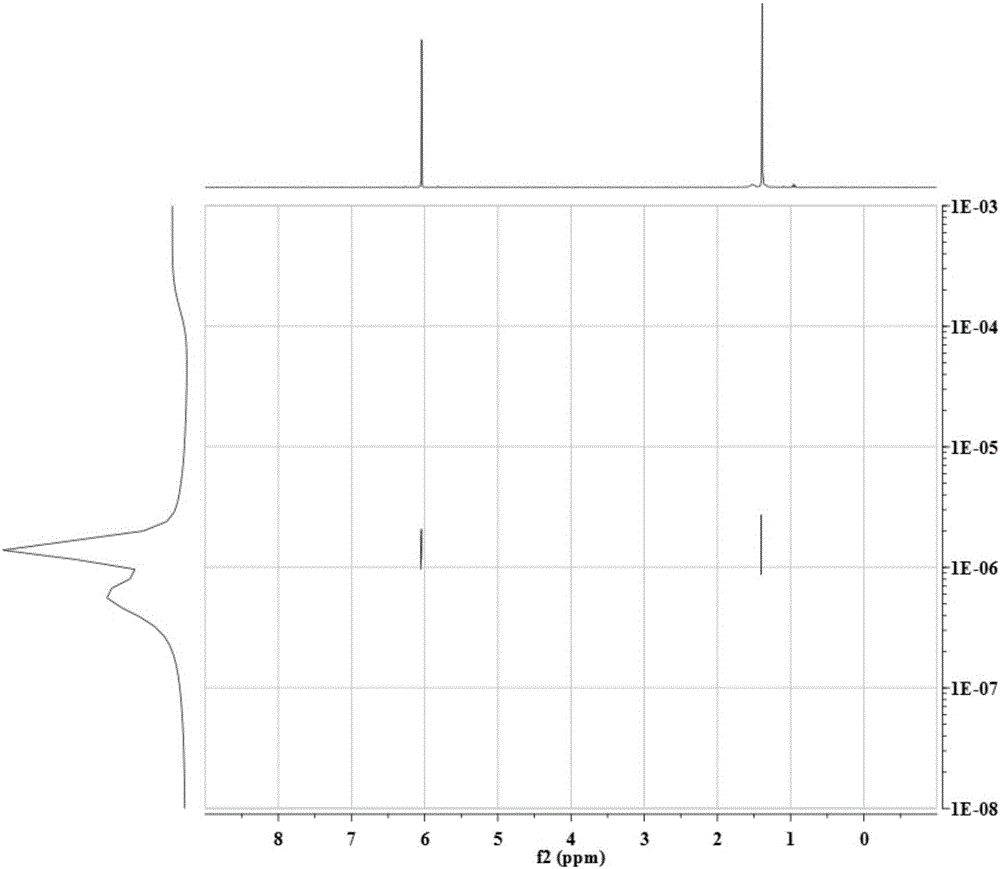

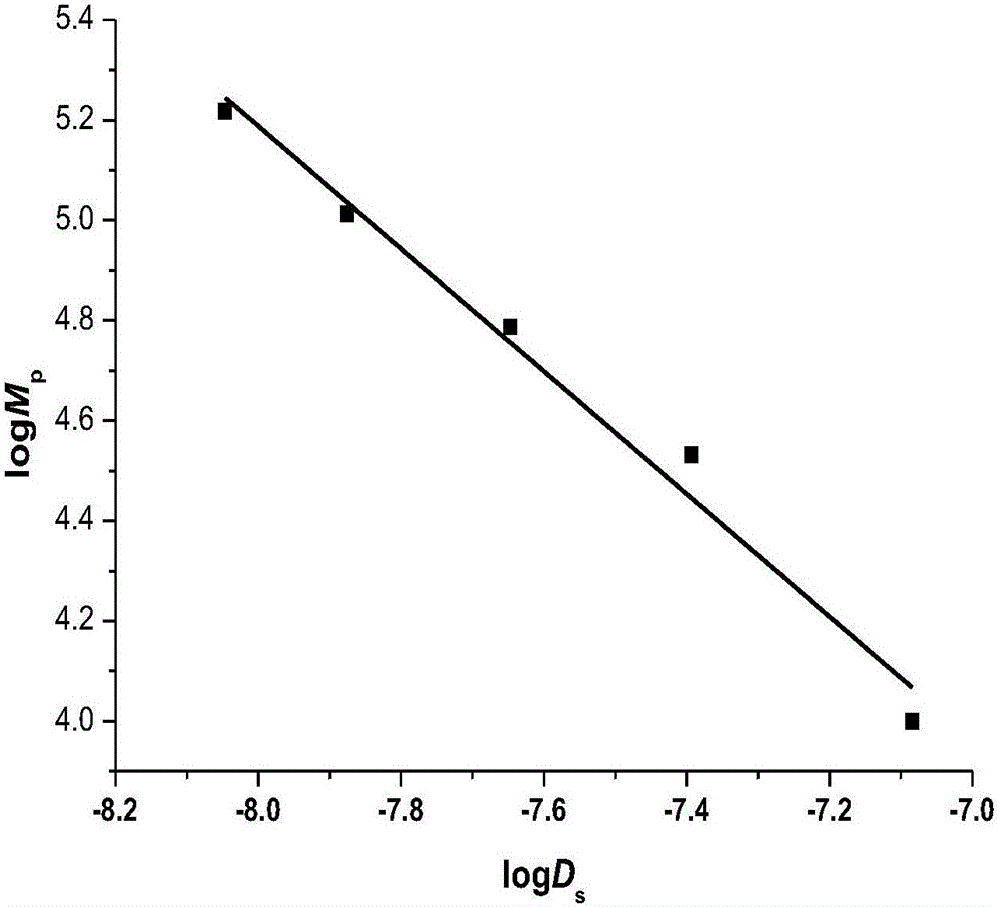

Characterization method for polymer molecular weight

ActiveCN106198594AEasy to operateSmall amount of sample and solventAnalysis using nuclear magnetic resonanceDiffusion analysisSolventNMR - Nuclear magnetic resonance

The invention provides a characterization method for polymer molecular weight. The method comprises the following steps: performing a two-dimensional molecular diffusion experiment in a nuclear magnetic resonance technology (namely, two-dimensional diffusion-ordered spectroscopy (2D DOSY)) on a polymer solution with a known molecular weight to obtain a diffusion coefficient, and establishing a standard curve of the polymer molecular weight and the diffusion coefficient; performing a two-dimensional molecular diffusion experiment on a to-be-measured polymer solution with an unknown molecular weight to obtain a diffusion coefficient, and calculating the molecular weight of a to-be-measured polymer and distribution thereof according to the standard curve of the molecular weight of the type of polymer and the diffusion coefficient, wherein the concentration of the to-be-measured polymer solution is controlled at 0.2-1.5mg / mL and the experimental temperature is controlled at 90-150 DEG C according to the molecular size. The method is easy to operate, the needed sample size and solvent amount are very small, the characterization cost is low, and a test result is accurate; moreover, two or more different types of polymers with approximate molecular weights in polymers can be distinguished while the polymer molecular weight and the molecular weight distribution are characterized.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Surface coated lithium ion battery cathode material and preparation method thereof

The invention discloses a surface coated lithium ion battery cathode material. The surface coated lithium ion battery cathode material is formed by coating the surface of a cathode active material with a coating agent, wherein the cathode active material comprises one of lithium cobalt oxide, lithium manganate and nickel lithium cobalt oxide or a mixture of more than one of the lithium cobalt oxide, lithium manganate and nickel lithium cobalt oxide; the coating agent is prepared by reacting an agent A with an agent B; the agent A is a saturated solution of acid or a saturated solution of alkali or water; and the agent B is a saline solution which can be hydrolyzed to precipitate when meeting the agent A. The invention has the main characteristics that: the addition of the solution is controlled by utilizing the adsorption of the surface of the particles on the solution, and the adsorbed water on the surfaces of solid particles accounts for the vast majority of the solution in a uniformly mixed solid-liquid system; and moreover, proper conditions are provided to ensure that a hydrolysis reaction is carried out in adsorption layers on the surfaces of the particles, a coating generated in the adsorbed water layers uniformly covers the surfaces of the particles, and an effect of uniformly coating is achieved.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

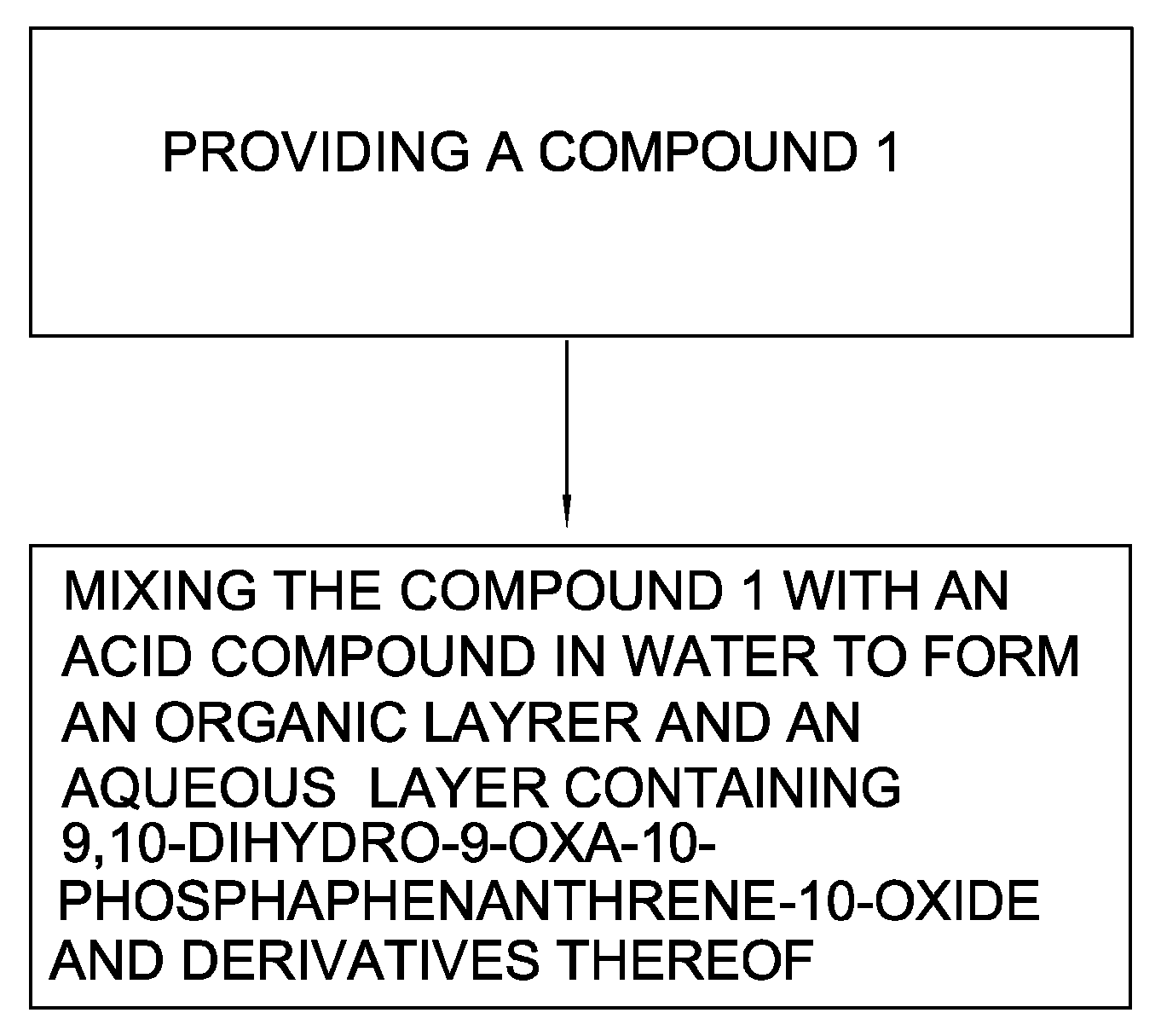

Method for synthesizing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and derivatives thereof

ActiveUS20110034717A1Improve yieldReduce environmental impactPhosphorus organic compoundsCost savingsSide reaction

A method for synthesizing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or its derivatives has a step of introducing 6-chloro-6H-dibenz[c,e][1,2]oxaphosphorin or its derivative, an acid compound and water into a reacting chamber to form an organic layer having 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or its derivative and an aqueous layer. Because the acid compound is from an external source and has a catalyzing effect, employing the method can prevent side reaction from occurring and increase yield of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or its derivative. Furthermore, the method is a one-pot operation of hydrolysis, dehydration and cyclization, so the method does not require purification of intermediates. Therefore, the method is time-and cost-saving and requires less organic solvent, resulting in less pollution to the environment.

Owner:UFC CORP

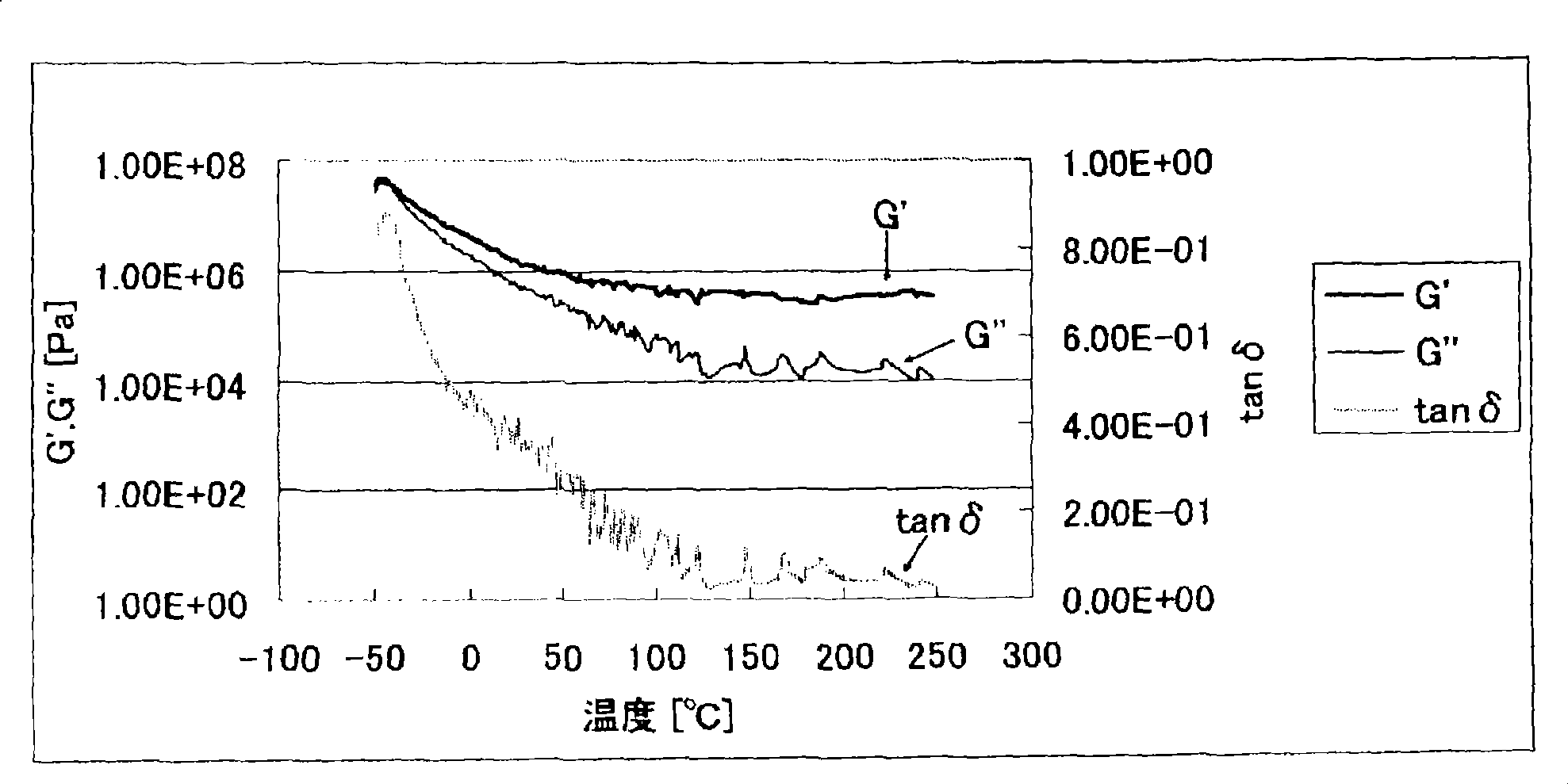

Thermosetting polyimide resin composition and cured product thereof

Owner:MITSUBISHI GAS CHEM CO INC

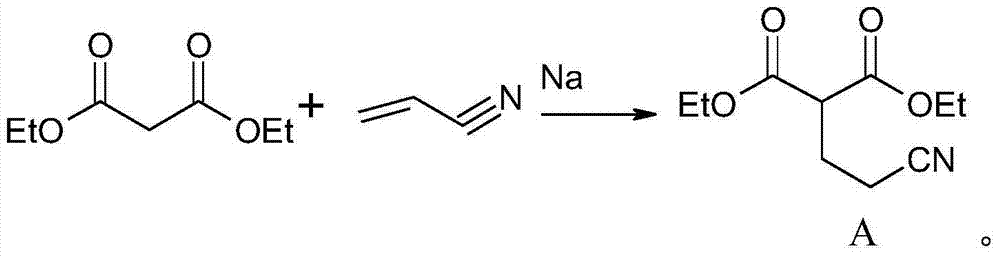

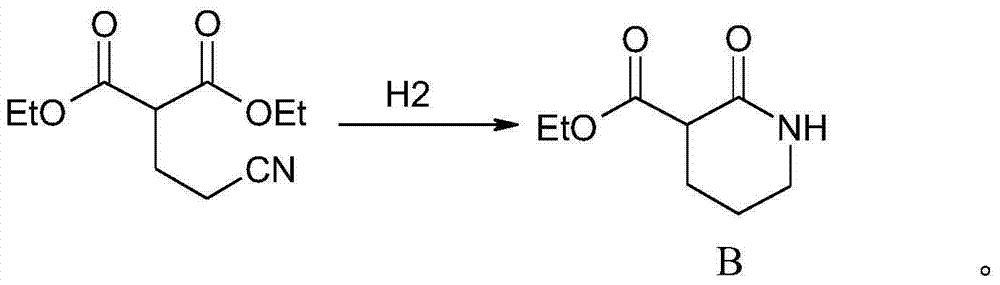

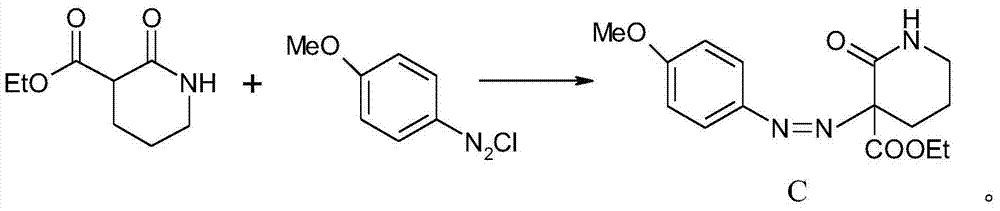

Synthesis method of melatonin

The invention belongs to the field of chemical synthesis of medicines and specifically relates to a synthesis method of melatonin. The method comprises the following steps: performing addition, ammonolysis of ester, coupling, rearrangement, hydrolysis of amide, decarboxylation, acylation and the like from diethyl malonate and acrylonitrile to obtain melatonin. According to the synthesis method provided by the invention, the starting raw materials are easy to obtain, the reaction in each step is relatively mild, a used solvent is small in amount and can be recovered and applied mechanically, an intermediate can directly enter the next-step reaction without refining and drying, and thus the synthesis method is suitable for industrial production.

Owner:湖北金赛药业有限公司

Method for preparing polyimide aerogel through direct vacuum drying

The invention provides a method for directly vacuum drying and preparing polyimide airgel. The invention adopts the low boiling point solvent to replace the traditional high boiling point solvent, which can be effectively removed in the preparation of the polyimide airgel, and the replaced solvent can be used repeatedly. In addition, a solvent with a high freezing point is used to replace a solvent with a low boiling point. During the vacuum drying process, the solvent is directly sublimated from the solid phase to the gas phase, which avoids the gas-liquid interface and eliminates the capillary tension. The obtained product maintains the pore structure without collapsing. Compared with supercritical drying or freeze-drying process, this method has the advantages of simple operation, high efficiency and low energy consumption, and can be prepared on a large scale, and the obtained polyimide airgel has excellent performance, especially excellent heat insulation performance, and can be used as Insulation material is used.

Owner:成都正威新材料研发有限公司 +1

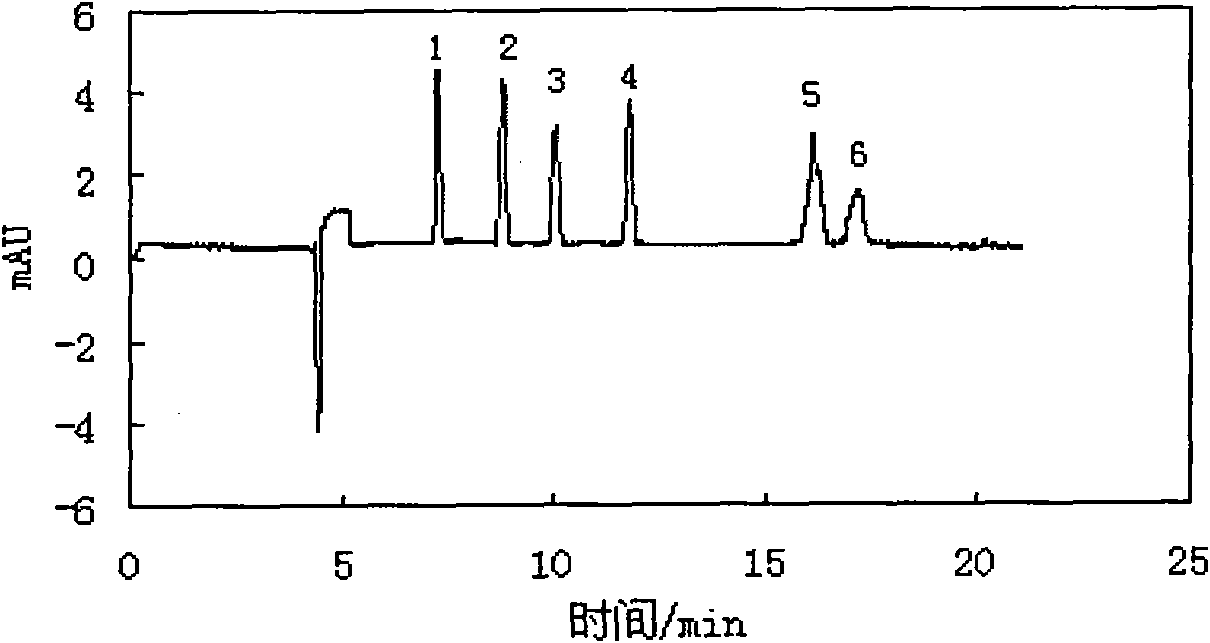

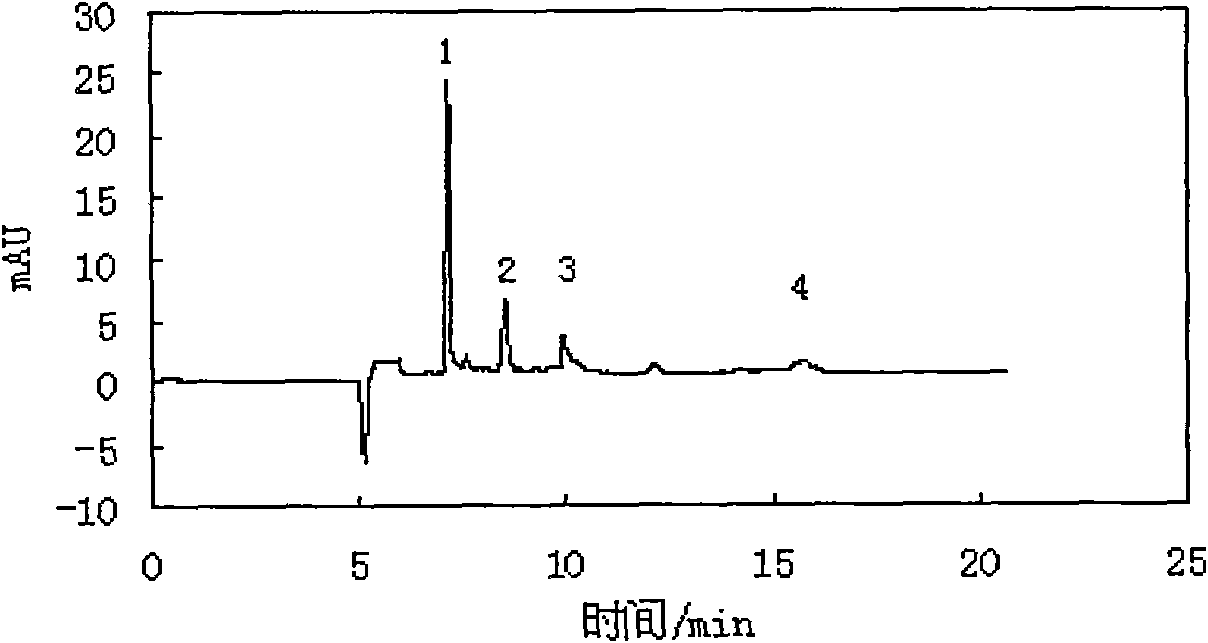

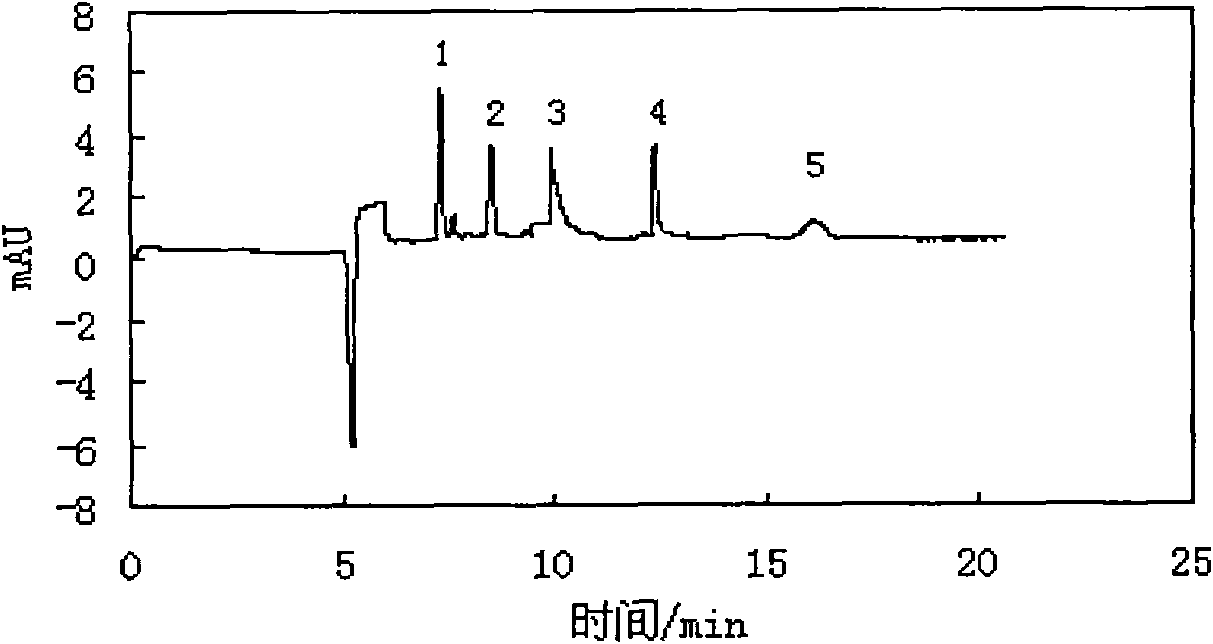

Capillary electrophoresis method for detecting stilbene glucoside and anthraquinone component in polygonum multiflorum

InactiveCN101658559AGood for healthSimple methodComponent separationDigestive systemOrganic solventElectrophoresis

The invention belongs to the technical field of analysis and detection, and discloses a capillary electrophoresis method for simultaneously separating and detecting stilbene glucoside and anthraquinone component in polygonum multiflorum. The method adopts micellar electrokinetic capillary chromatography to analyze and detect polygonum multiflorum extracting solution to obtain the electrophoresis pattern of stilbene glucoside, emodin, aloeemodin, rhein, chrysophanol or physcion; according to a correction curvilinear equation, the concentration of stilbene glucoside, emodin, aloeemodin, rhein, chrysophanol or physcion is calculated. The invention can simultaneously analyze and detect the stilbene glucoside and anthraquinone component in polygonum multiflorum and is simple, quick and efficient; adopted buffer liquid is mainly aqueous solution, does not need a great quantity of organic solvent and has small pollution and environment protection; a small amount of needed solvent and sample is needed, and analysis cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting and separating total alkaloids in prickly ash

The invention discloses a method for extracting and separating the total alkaloids of shiny leaf pricklyash root; the method comprises the following steps: the shiny leaf pricklyash root is crushed, extracted for 1 time to 5 times with acid water-alcohol as a solvent and filtered; the filtrates are combined and decompressed, have the solution removed so that no alcoholic odor exists and are set stewing and delaminated; the supernatant fluid is fetched, and the sediment is repeatedly dissolved by acid water and filtered to obtain a filtrate which is combined with the supernatant fluid, adsorbed by a macroporous resin column and washed by an organic solvent, and then the solvent is recovered to obtain a crude alkaloid product. The method of the invention increases the extraction ratio to more than 93 percent by adding acid for extraction, and macroporous resin is used for separating alkaloids, simple and easy operated, achieving a yield rate about 93 percent.

Owner:GUANGXI MEDICAL UNIVERSITY

Coating composition using a polyester resin composition for forming a paint film on a substrate

ActiveUS20050182232A1Easy to scratchImproved mar characteristicGlass/slag layered productsYarnCross-linkCarbamate

A coating composition for producing films having improved scratch and mar characteristics. The coating composition incorporates a polyester polycarbamate resin composition, a first cross-linking agent, and a cross-linkable resin to form the film. The resin composition is the reaction product of a first compound having a plurality of hydroxyl groups with a carbamate compound reactive with the hydroxyl groups of the first compound and added in an amount sufficient to form a carbamated intermediary. The carbamated intermediary has at least one primary carbamate group available for cross-linking and has unreacted hydroxyl groups. Then, a silyl compound having a terminal isocyanate group is reacted with the unreacted hydroxyl groups of the carbamated intermediary. The silyl compound also has silylalkoxy groups available for secondary cross-linking. The first cross-linking agent and the cross-linkable resin react with the primary carbamate groups and the silylalkoxy groups, respectively, to produce the film having improved scratch and mar characteristics.

Owner:BASF CORP

Preparation method of cladding material of lithium ion battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a preparation method of a cladding material of a lithium ion battery. The preparation method comprises the following steps: stirring a core layer material in a stirring tank; making a cladding layer material into a solution, sol, gel or an emulsion; placing the cladding layer material into an atomizing machine, spraying the cladding layer material onto the surface of the core layer material, and continuously stirring the material; and drying, calcining and crushing the material to obtain the cladding material of the lithium ion battery. Compared with a solid-solid mixing way of the prior art, the mixing way provided by the invention ensures more uniformity in cladding; compared with a liquid-liquid mixing way and a conventional solid-liquid mixing way, the mixing way provided by the invention has the advantages that only the solvent in the sprayed solution is consumed, so that the application amount of the solvent is greatly reduced, and the energy consumption of the subsequent drying process can be reduced.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

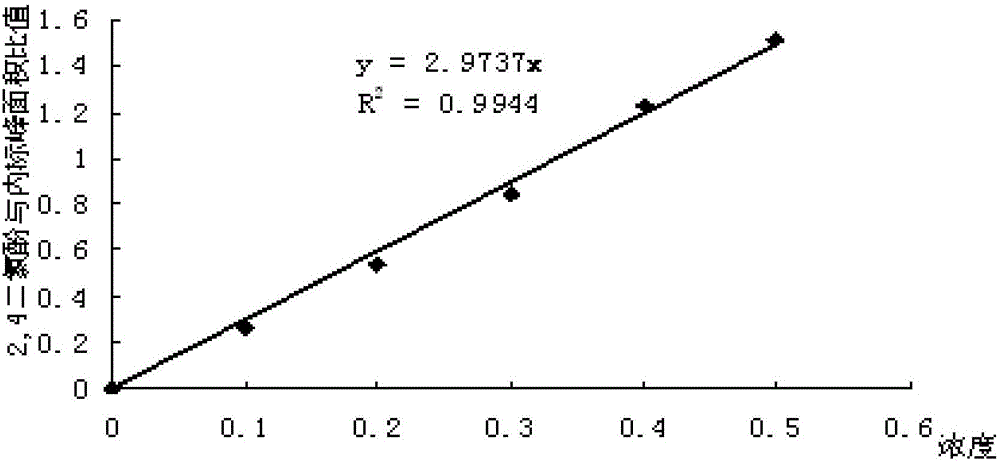

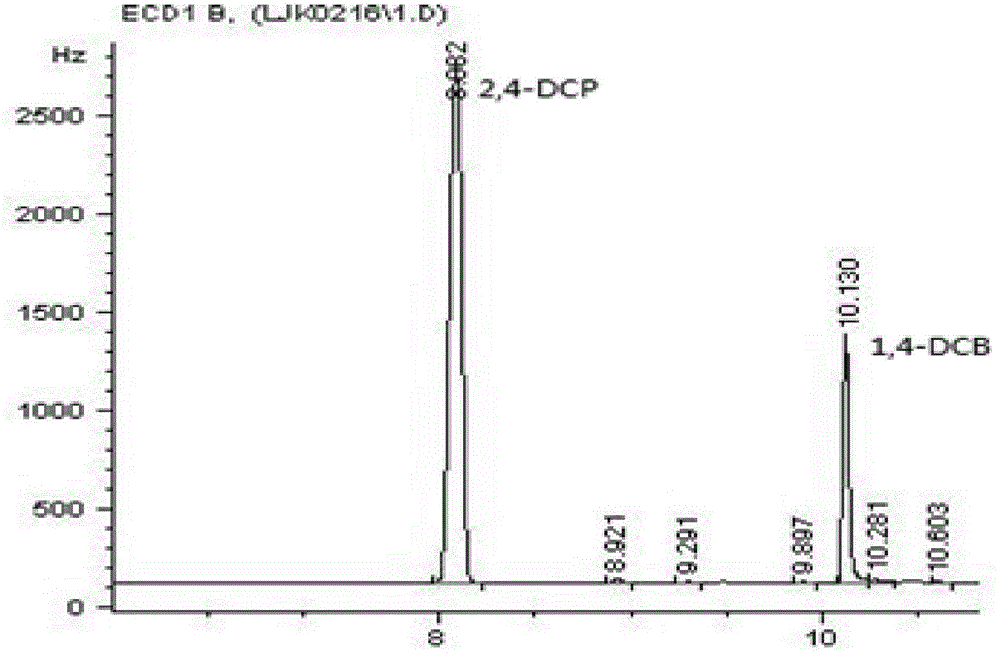

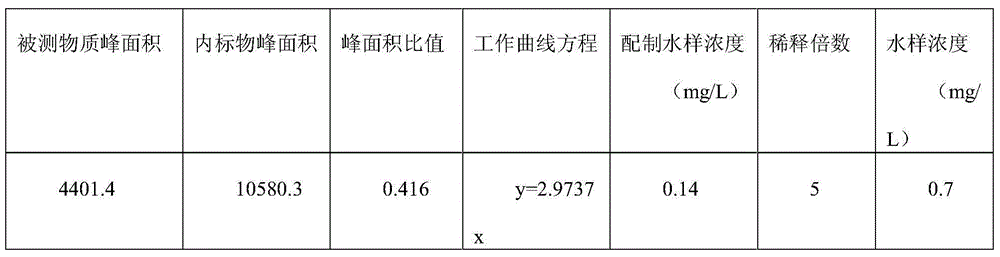

Method for quantitatively detecting 2, 4-dichlorophenol in water

ActiveCN103604883ALess solventLess interfering substancesComponent separationEnvironmental resistanceGas phase

The invention relates to a method for quantitatively detecting 2, 4-dichlorophenol in water, belonging to the field of analysis and detection of a compound. The invention provides a method for detecting 2, 4-dichlorophen in water through a head space solid phase microextraction-gas chromatography. The extracting head of the solid phase microextraction has the effect of gathering volatilizing components and can detect trace 2, 4-dichlorophen in water. The method can be used as a standard method for detecting the concentration of 2, 4-dichlorophen in water, the pretreatment is simple and rapid, and only needs heating and extracting for 30 minutes, no solvent is needed, the method is safe and environment-friendly, the dosage of the sample is less, the method has good linear adding standard recovery, and the detection sensitivity can reach 6.54mu g / L.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com