Synthetic method of biquaternary ammonium salt

A synthesis method and a technology for diquaternary ammonium salts are applied in the field of preparation of diquaternary ammonium salts, which can solve the problems of slow reaction speed, increase the difficulty of recycling, and use a large amount of solvent, so as to accelerate the reaction speed, reduce the preparation time, prevent the The effect of agglomeration trends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

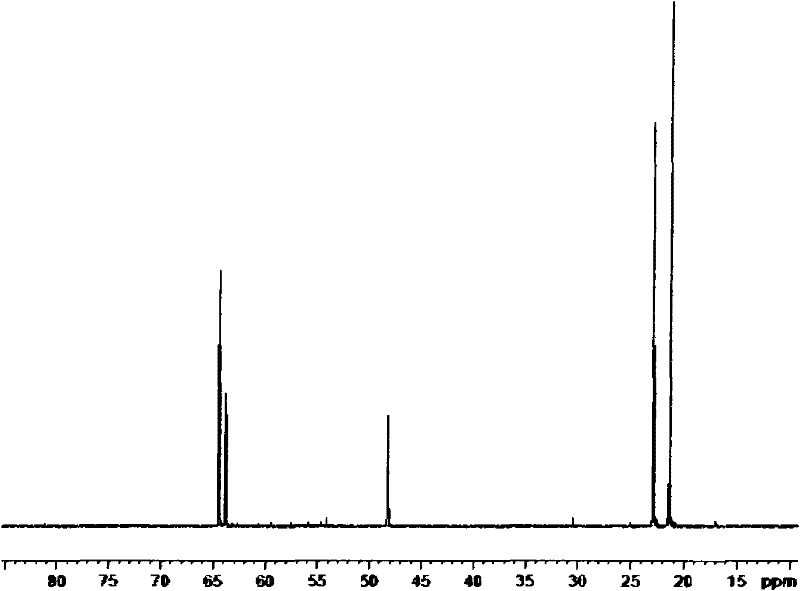

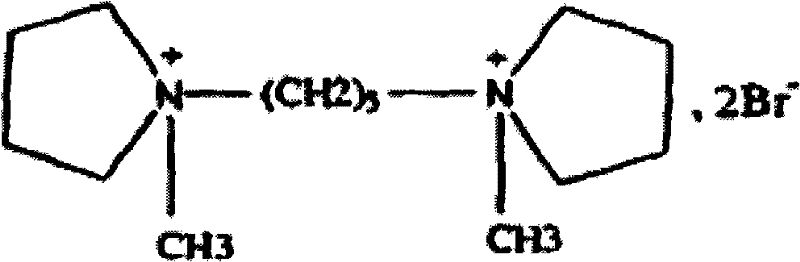

[0017] Mix 40mL, 30mL, and 70.5mL of N-methylpyrrolidine, 1,5-dibromopentane, and acetone in a three-necked flask with a reflux device, then place the three-necked flask in a 50kHz ultrasonic dispersion water bath, and start the ultrasonic wave Disperser, the mixture was vigorously stirred at 35°C for 8 hours until a suspension containing a large number of small particles was formed. The suspension was frozen at -10°C, a large amount of powder solids were precipitated, and then the solids were separated by filtration. Put the solid matter into ether at 25°C, stir continuously and add ether according to the degree of dissolution until the solid matter is completely dissolved in ether. Afterwards, the above solution was frozen at -10°C, a large amount of powdery solids were precipitated, and then the solids were separated by filtration. The above steps of washing, recrystallization and separation were repeated 3 times to finally obtain a beige solid powder, which was confirmed ...

Embodiment 2

[0019] Mix 60mL, 27.7mL, and 55mL of N-methylpyrrolidine, 1,5-dibromopentane, and acetone in a three-necked flask with reflux, and then place the three-necked flask in a 70kHz ultrasonic dispersion water bath to start ultrasonic dispersion The mixture was stirred vigorously at 40°C for 3 hours until a suspension containing a large number of small particles was formed. The suspension was frozen at -10°C, a large amount of powder solids were precipitated, and then the solids were separated by filtration. Put the solid matter into ether at 25°C, stir continuously and add ether according to the solubility until the solid matter is completely dissolved in ether. Afterwards, the above solution was frozen at -10°C, and a large amount of powder solids were precipitated, and then the solids were separated by filtration. The above steps of washing, recrystallization and separation were repeated 3 times to finally obtain a beige solid powder, which was confirmed to be the diquaternary a...

Embodiment 3

[0021] Mix 40mL, 24mL, and 35.5mL of N-methylpyrrolidine, 1,5-dibromopentane, and ethanol in a three-necked flask with reflux, then place the three-necked flask in a 100kHz ultrasonic dispersion water bath, and start ultrasonic dispersion The mixture was stirred vigorously at 50°C for 2 hours until a suspension containing a large number of small particles was formed. The suspension was frozen at -5°C, a large amount of powder solids were precipitated, and then the solids were separated by filtration. Put the solid matter into acetone at 25°C, stir continuously and supplement acetone according to the solubility until the solid matter is completely dissolved in acetone. Afterwards, the above solution was frozen at -5°C, and a large amount of powder solids were precipitated, and then the solids were separated by filtration. The above steps of washing, recrystallization and separation were repeated 3 times to finally obtain a beige solid powder, which was confirmed to be the diqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com