Preparation of ornithine aspartate for injection

A technology for ornithine aspartate and injection, which is applied in the field of pharmaceutical preparation technology, and can solve the problems of large eluent volume, high alcohol consumption, and long process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 20kg of L-ornithine hydrochloride, add 50L of water for injection, stir while adding, then add 2kg of NaOH, stir to dissolve completely, heat to 60°C, and continue stirring for about 1 hour;

[0031] Weigh 16 kg of L-aspartic acid, add it to the above solution in portions, and stir while adding to dissolve completely, until the pH of the strip reaches 7.0-7.5, and continue to stir at about 60°C for 3 hours;

[0032]Under a sterile environment in the production control area, weigh 90 g of activated carbon powder, add it to the above-mentioned raw material reaction solution, continue heating and stirring (60 ° C) for 30 min, and filter it with a microporous membrane with a pore size of 0.22 μm while it is hot, and the filtrate is set aside;

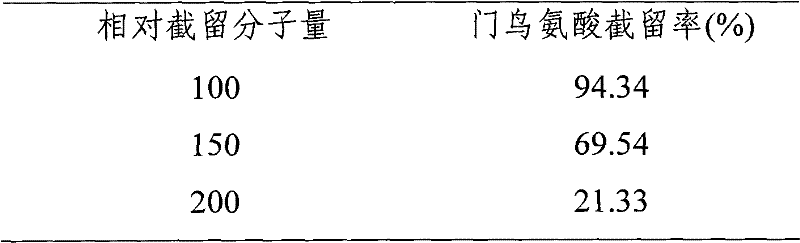

[0033] In a sterile environment in the production control area, prepare a nanofiltration machine with a nanofiltration membrane pore size of 100 Daltons; start the machine, adjust the pump flow rate, and maintain the membrane inl...

Embodiment 2

[0036] Take 20kg of L-ornithine hydrochloride, add 50L of water for injection, stir while adding, then add 3kg of NaOH, stir to dissolve completely, heat to 60°C, and continue stirring for about 1 hour;

[0037] Weigh 24 kg of L-aspartic acid, add it to the above solution in portions, and stir while adding to dissolve completely, until the pH of the strip reaches 7.0-7.5, and continue to react at about 60°C for 2 hours;

[0038] Under a sterile environment in the production control area, weigh 450 g of activated carbon powder, add it to the above-mentioned raw material reaction solution, continue heating and stirring (60 ° C) for 30 min, and filter it while hot with a microporous membrane with a pore size of 0.22 μm, and the filtrate is set aside;

[0039] In a sterile environment in the production control area, prepare a nanofiltration machine with a nanofiltration membrane pore size of 200 Daltons; start the machine, adjust the pump flow rate, and maintain the membrane inlet ...

Embodiment 3

[0042] Take 20kg of L-ornithine hydrochloride, add 50L of water for injection, stir while adding, then add 5kg of NaOH, stir to completely dissolve, heat to 60°C, and continue stirring for about 1 hour;

[0043] Weigh 24 kg of L-aspartic acid, add it to the above solution in portions, and stir while adding to dissolve completely, until the pH of the strip reaches 7.0-7.5, and continue to react at about 60°C for 2 hours;

[0044] Under the aseptic environment of the production control area, weigh 800g of activated carbon powder, add it to the above-mentioned raw material reaction solution, continue heating and stirring (60°C) for 30min, filter it with a microporous membrane with a pore size of 0.22μm while it is hot, and use the filtrate for later use;

[0045] In a sterile environment in the production control area, prepare a nanofiltration machine with a nanofiltration membrane pore size of 150 Daltons; start the machine, adjust the pump flow rate, and maintain the membrane in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com