Crystalline Agomelatine solvate and preparation method thereof

A technology of agomelatine acetic acid and agomelatine ethylene glycol is applied in the field of agomelatine solvate crystal form and preparation thereof, and can solve the harsh conditions and method of agomelatine crystal form method. Problems such as poor reproducibility and inability to popularize and use, achieve the effects of good reproducibility, low production cost, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

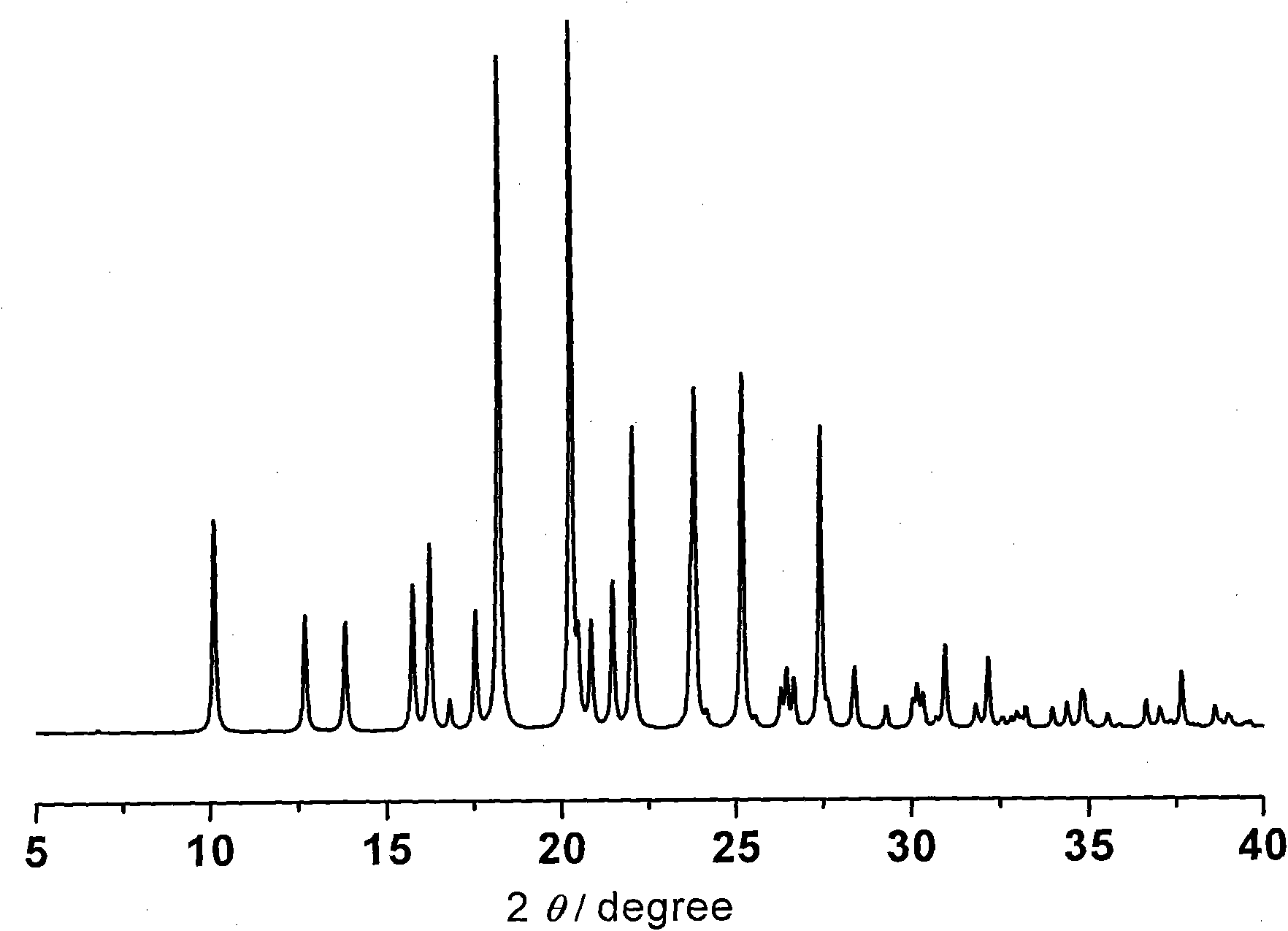

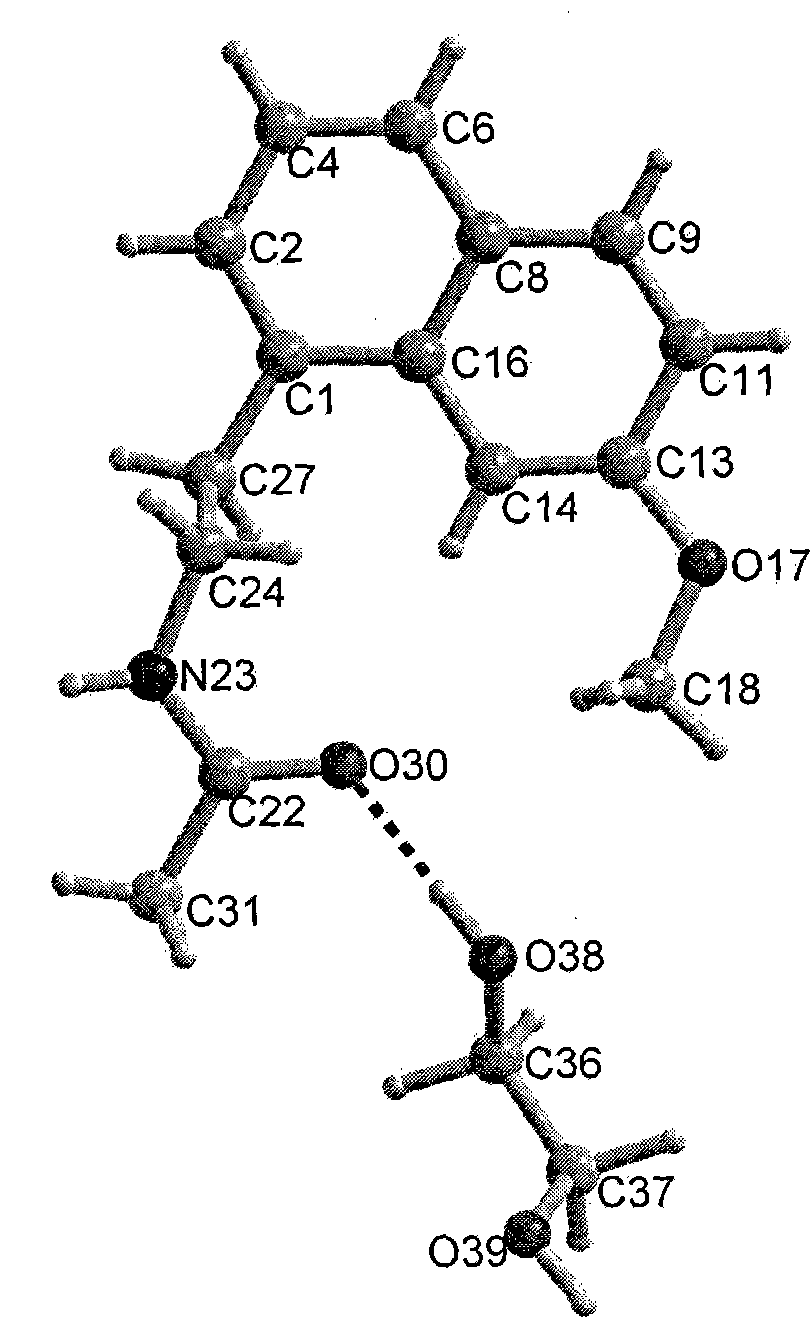

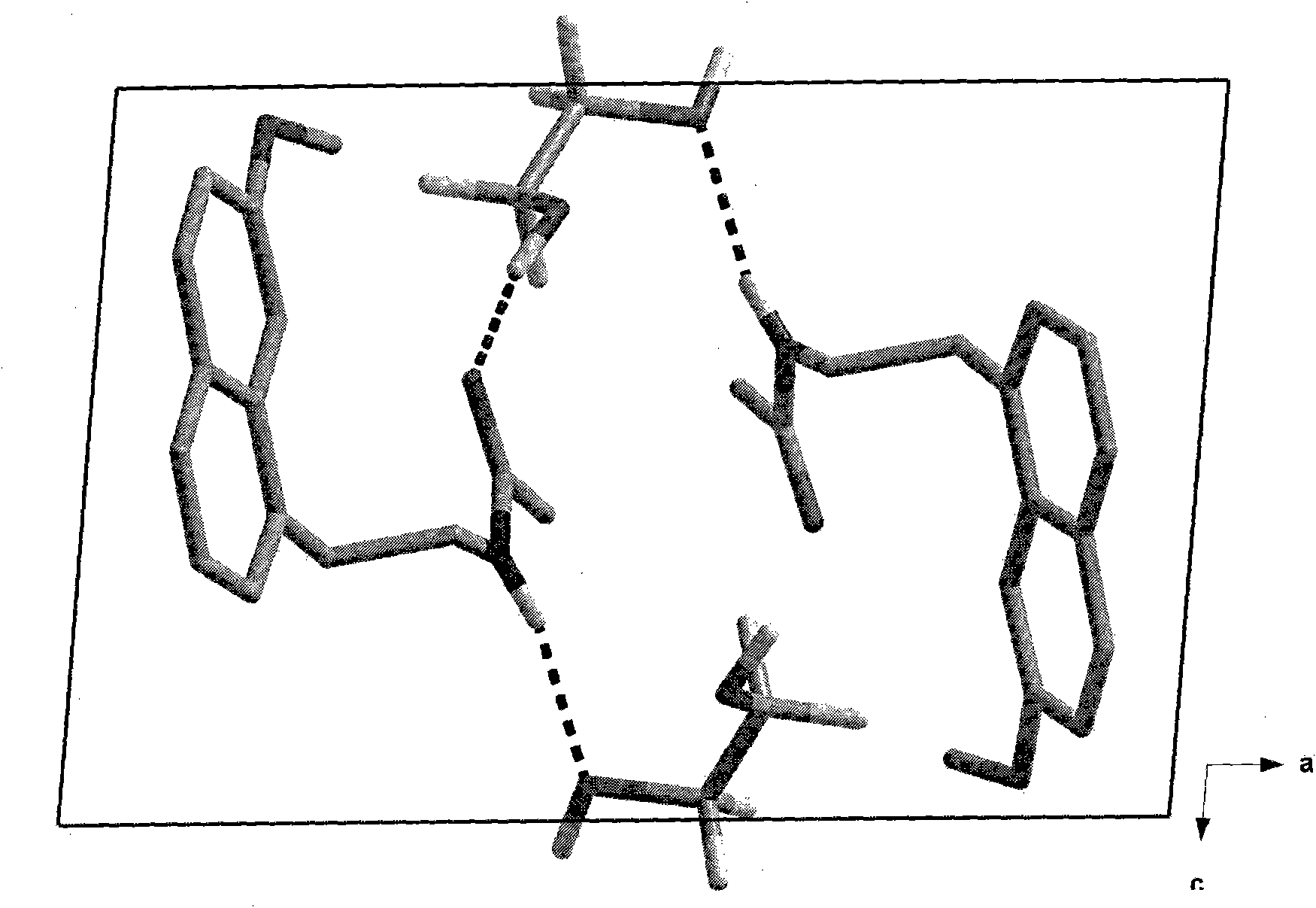

Embodiment 1

[0044] Put 1 g of agomelatine in a test tube, add 0.51 g of ethylene glycol (molar ratio 1:2), seal it, heat it at 100°C to melt it, and after stirring for 2 hours, keep it at 0°C to fully crystallize it to obtain White solid 1.23g. Yield: 98%, melting point: 67.6°C.

Embodiment 2

[0046] Put 2g of agomelatine in a test tube, add 1.53g of ethylene glycol (molar ratio 1:3), seal it, heat it at 110°C to melt, stir for 2h, keep it at 0°C to fully crystallize, and get White solid 2.46g. Yield: 98%, melting point: 67.6°C.

Embodiment 3

[0048] Put 5g of agomelatine in a test tube, add 3.825g of ethylene glycol (molar ratio 1:3), seal it, heat it at 120°C to melt it, and after stirring for 2h, keep it at 0°C to fully crystallize it, and get White solid 6.15g. Yield: 98%, melting point: 67.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com