Preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips

A polyester chip, anti-aging technology, applied in the direction of single-component polyester artificial filament, etc., to achieve good anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

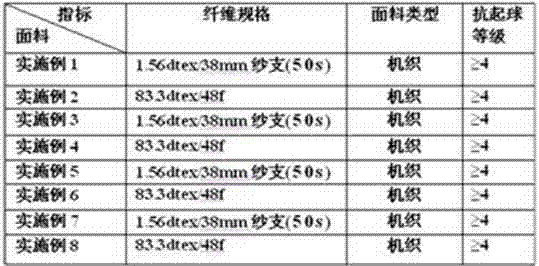

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing an anti-pilling, anti-aging, normal-pressure cationic dyeable polyester chip, which includes the following steps:

[0031] (1) One-time esterification reaction process: Take 18kg of purified terephthalic acid (PTA) and 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, stir evenly, start to heat up and pressurize to 0.3Mpa , carry out esterification, the esterification temperature is controlled at 255 ~ 260 ° C, until the esterification water is completed, return to normal pressure, and end the reaction.

[0032] (2) Transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C for 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, the transesterification reaction is carried out, so that the unreacted SIPM can complete the transester...

Embodiment 2

[0036] This embodiment provides a method for preparing an anti-pilling, anti-aging, normal-pressure cationic dyeable polyester chip, which includes the following steps:

[0037] (1) One-time esterification reaction process: take 18kg of purified terephthalic acid (PTA), 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, stir evenly, start to heat up and pressurize to 0.3Mpa , carry out esterification, the esterification temperature is controlled at 255-260 °C, until the esterification water is completed, return to normal pressure, and end the reaction.

[0038] (2) Transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C for 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, the transesterification reaction is carried out, so that the unreacted SIPM can complete the transesterificat...

Embodiment 3

[0042] This embodiment provides a method for preparing an anti-pilling, anti-aging, normal-pressure cationic dyeable polyester chip, which includes the following steps:

[0043] (1) One-time esterification reaction process: take 18kg of purified terephthalic acid (PTA), 7.05kg of ethylene glycol (EG), add 70 liters of polyester experimental equipment, stir evenly, start to heat up and pressurize to 0.3Mpa , carry out esterification, the esterification temperature is controlled at 255-260 °C, until the esterification water is completed, return to normal pressure, and end the reaction.

[0044] (2) Transesterification reaction process: After the primary esterification is completed, add ethylene glycol to cool down and depolymerize, control the temperature at 220-245°C for 0.4-1.0 hours, then add 1400g of three-monomer solution, stir evenly, and heat up to At 255°C, the transesterification reaction is carried out, so that the unreacted SIPM can complete the transesterificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com