Loom let-off bobbin rack for wearing flat coarse warp woven fabric

A warp machine, flat technology, applied in the field of loom let-off creels, can solve the problems of large area of creels, long operating routes for workers, increased wear and other problems, and achieves reduction of uneven rate of breaking strength, convenient operation, The effect of improving breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

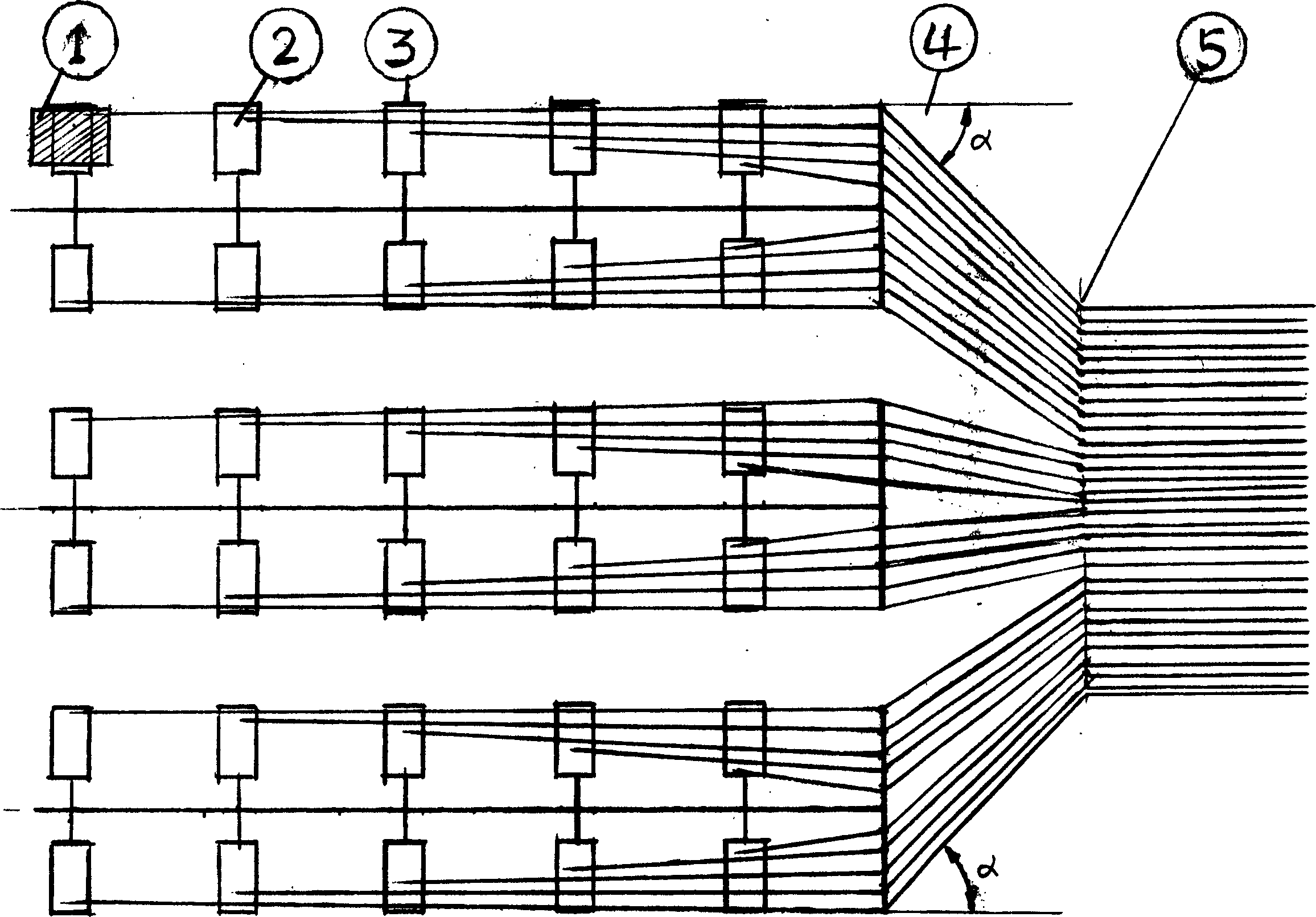

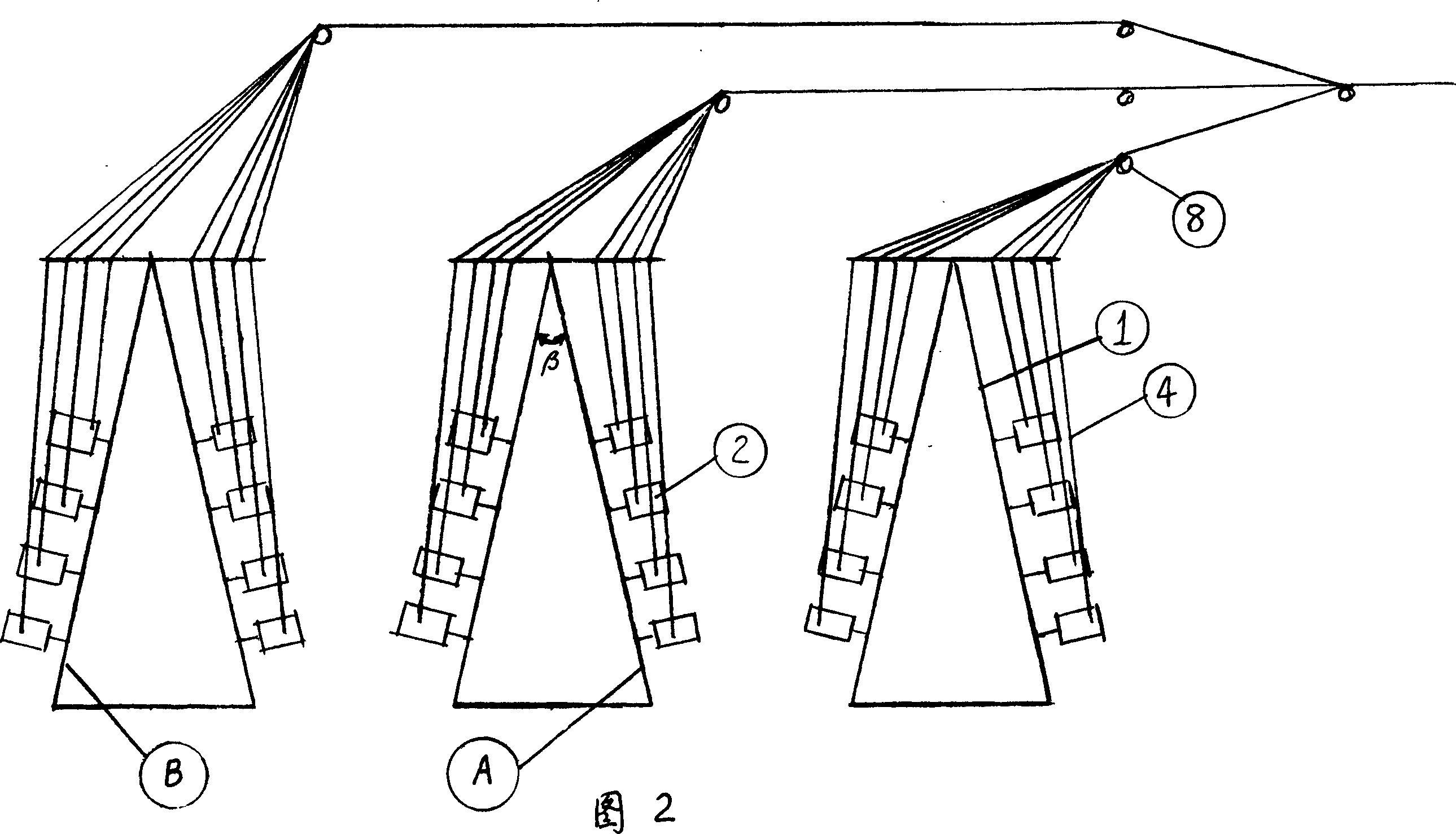

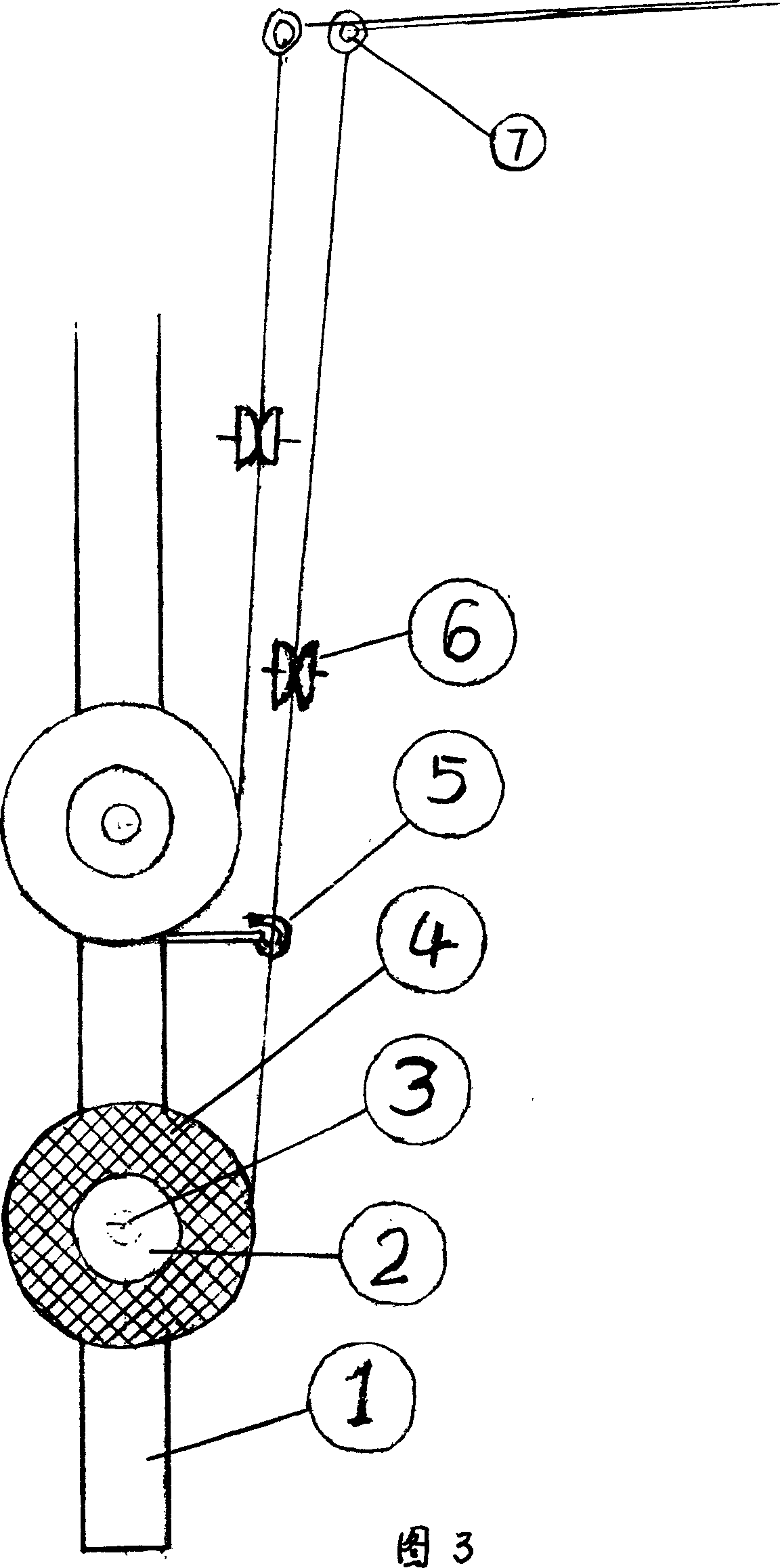

[0014] The material adopted by each component of the present invention is no different from that of the current let-off creel of the loom, and there is no special requirement. The two working faces A and B of base frame 1 are symmetrically installed with bobbin 2, bobbin shaft 3, yarn guide hook 5, tension device 6, and yarn guide porcelain eye 7, and yarn guide rod 8 is installed on the top of base frame 1. The yarn-guiding porcelain eyes on the surface are 20mm lower than the yarn-guiding porcelain eyes on the rear working surface, and the angle between working surfaces A and B is 15°. A total of 63 bobbins with 7 layers and 9 columns are installed on each working surface, and a total of 1 base frame Set 5, the total number of roots is 630. The operating aisle between the base frames 1 is 450mm wide, the distance between the yarn guide hook 5 and the corresponding bobbin rotating shaft 3 is 320mm, and the position of the bobbins on the lower layer is parallel to the right by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com