Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane

A technology of nitrile rubber and manufacturing method, which is applied in the direction of gloves, surgical gloves, and other household appliances, etc., can solve the problems of nitrile rubber gloves such as poor air permeability and moisture permeability, easy damage to hand skin, and small market share. The effect of no loss of strength, improvement of wearing comfort, good application and economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

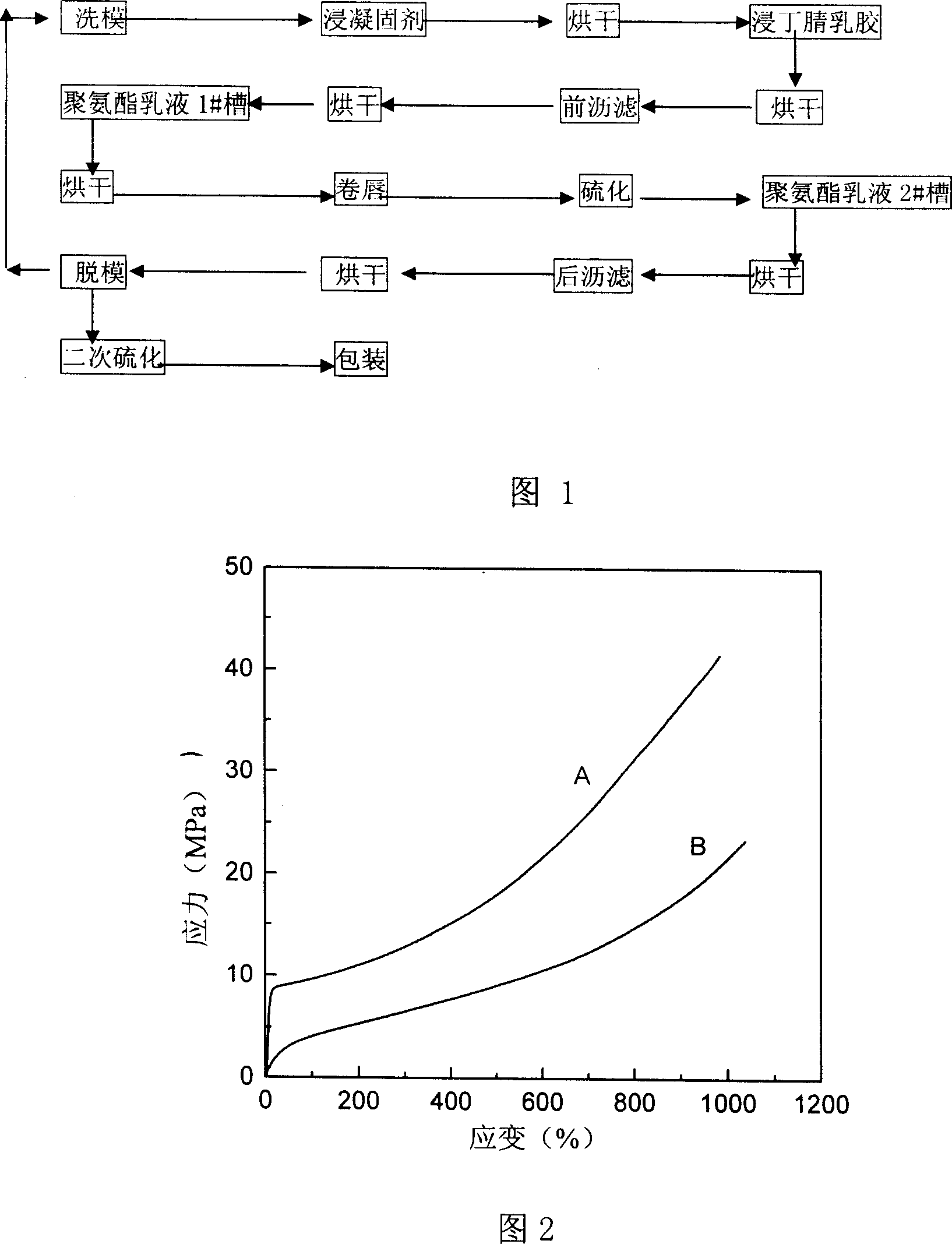

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of dispersion

[0046] Sulfur: 12.9Kg

[0048] Accelerator BZ: 10.32Kg

[0049] Titanium dioxide: 25.8Kg

[0050] Dispersant: 4.13Kg

[0051] Deionized water: 147Kg

[0052] Put the above materials into the ball mill and grind for 48~72 hours, and control the fineness below 10 mesh.

[0053] 2. Preparation of nitrile rubber

[0054] Synthomer6311: 2867Kg

[0055] KOH (5%) solution: 240Kg

[0056] Dispersion liquid: 215.63Kg

[0057] Ammonia water (3% concentration): 258Kg

[0058] Blue pigment SS377-1: 2Kg

[0059] Release agent 56Kg

[0060] Deionized water 1613Kg

[0061] Put the above materials into the rubber mixing tank in order, stir slowly for 24~72 hours, and then put them into the nitrile latex tank of the production line. The nitrile rubber should be slowly circulated in the tank for at least 2-4 hours to eliminate the bubbles in the liquid and start the production line.

[0062] 3. Preparation of coagu...

Embodiment 2

[0090] 1. Preparation of dispersion

[0091] Sulfur: 12.9Kg

[0093] Accelerator BZ: 10.32Kg

[0094] Titanium dioxide: 25.8Kg

[0095] Dispersant: 4.13Kg

[0096] Deionized water: 147Kg

[0097] Put the above materials into the ball mill and grind for 48~72 hours, and control the fineness below 10 mesh.

[0098] 2. Preparation of nitrile rubber

[0099] Synthomer6311: 2867Kg

[0100] KOH (5%) solution: 240Kg

[0101] Dispersion liquid: 215.63Kg

[0102] Ammonia water (3% concentration): 258Kg

[0103] Blue pigment SS377-1: 2Kg

[0104] Release agent 56Kg

[0105] Deionized water 1855Kg

[0106] Put the above materials into the rubber mixing tank in order, stir slowly for 24~72 hours, and then put them into the nitrile latex tank of the production line. The nitrile rubber should be slowly circulated in the tank for at least 2-4 hours to eliminate the bubbles in the liquid and start the production line.

[0107] 3. Preparation of coagu...

Embodiment 3

[0118] 1. Preparation of dispersion

[0119] Sulfur: 12.9Kg

[0121] Accelerator BZ: 10.32Kg

[0122] Titanium dioxide: 25.8Kg

[0123] Dispersant: 4.13Kg

[0124] Deionized water: 147Kg

[0125] Put the above materials into the ball mill and grind for 48~72 hours, and control the fineness below 10 mesh.

[0126] 2. Preparation of nitrile rubber

[0127] Synthomer6311: 2867Kg

[0128] KOH (5%) solution: 240Kg

[0129] Dispersion liquid: 215.63Kg

[0130] Ammonia water (3% concentration): 258Kg

[0131] Blue pigment SS377-1: 2Kg

[0132] Release agent 56Kg

[0133] Deionized water 2100Kg

[0134] Put the above materials into the rubber mixing tank in order, stir slowly for 24~72 hours, and then put them into the nitrile latex tank of the production line. The nitrile rubber should be slowly circulated in the tank for at least 2-4 hours to eliminate the bubbles in the liquid and start the production line.

[0135] 3. Preparation of coagula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com