Patents

Literature

38results about How to "Reduced reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

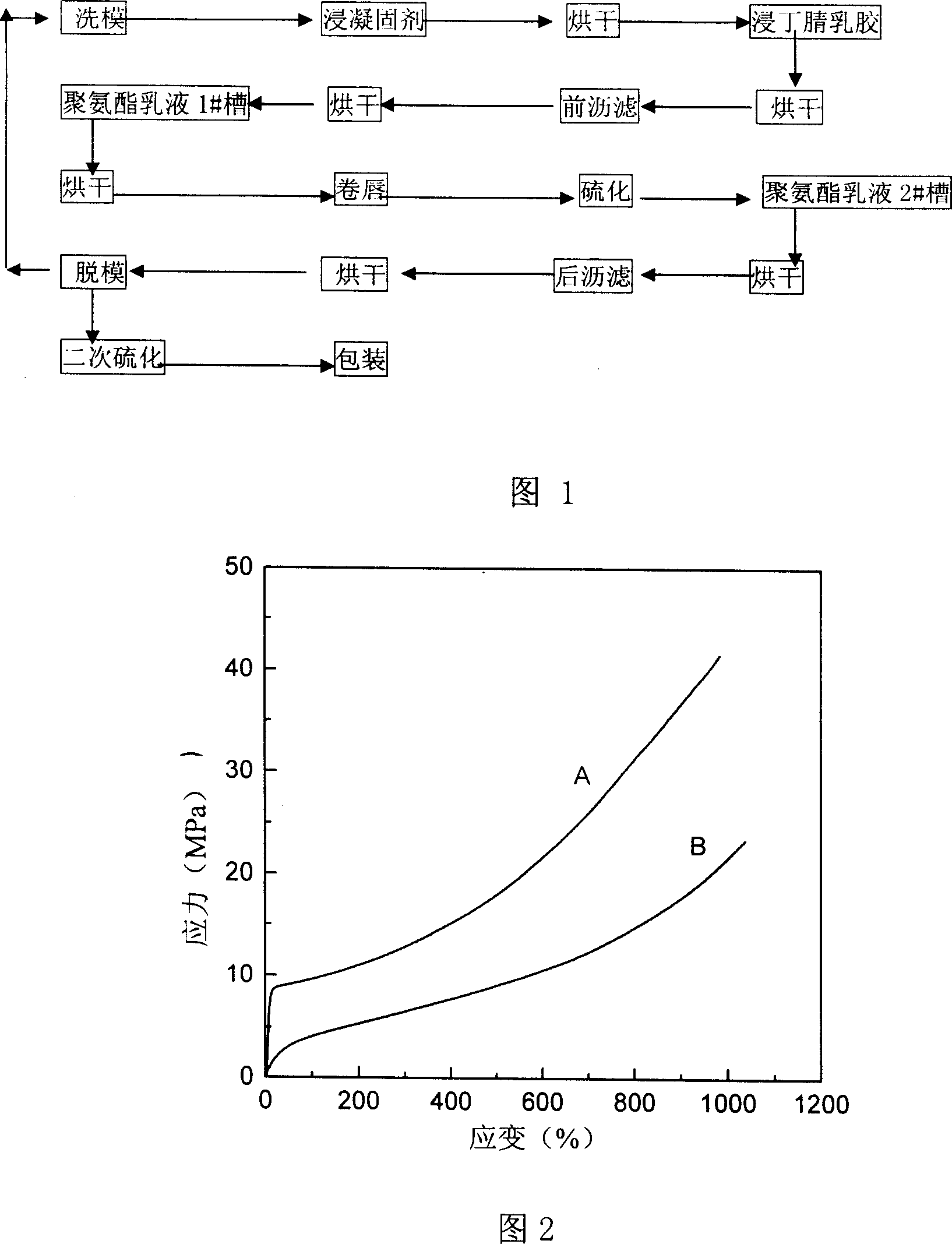

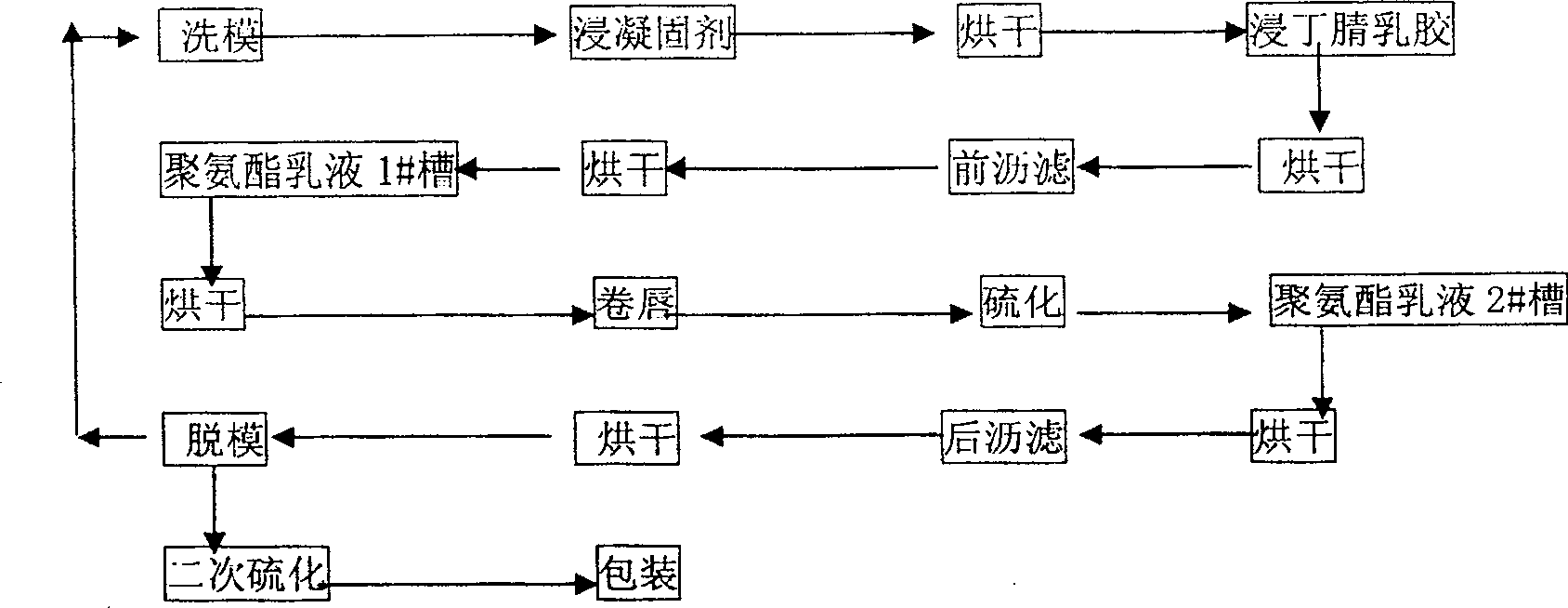

Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane

InactiveCN101003165AGood breathability and moisture permeabilityImprove wearing comfortDiagnosticsGlovesHigh resistanceEmulsion

A process for preparing the expendable composite nitrile rubber-polyurethane glove includes generating a layer of nitrile rubber film on a mould, and dipping it in aquatic polyurethane emulsion. The resultant glove has high resistance to oil and bacterial osmosis, high weatherability, and high air and moisture permeability.

Owner:TIANJIN GREENCOAT POLYMER MATERIAL TECH CO

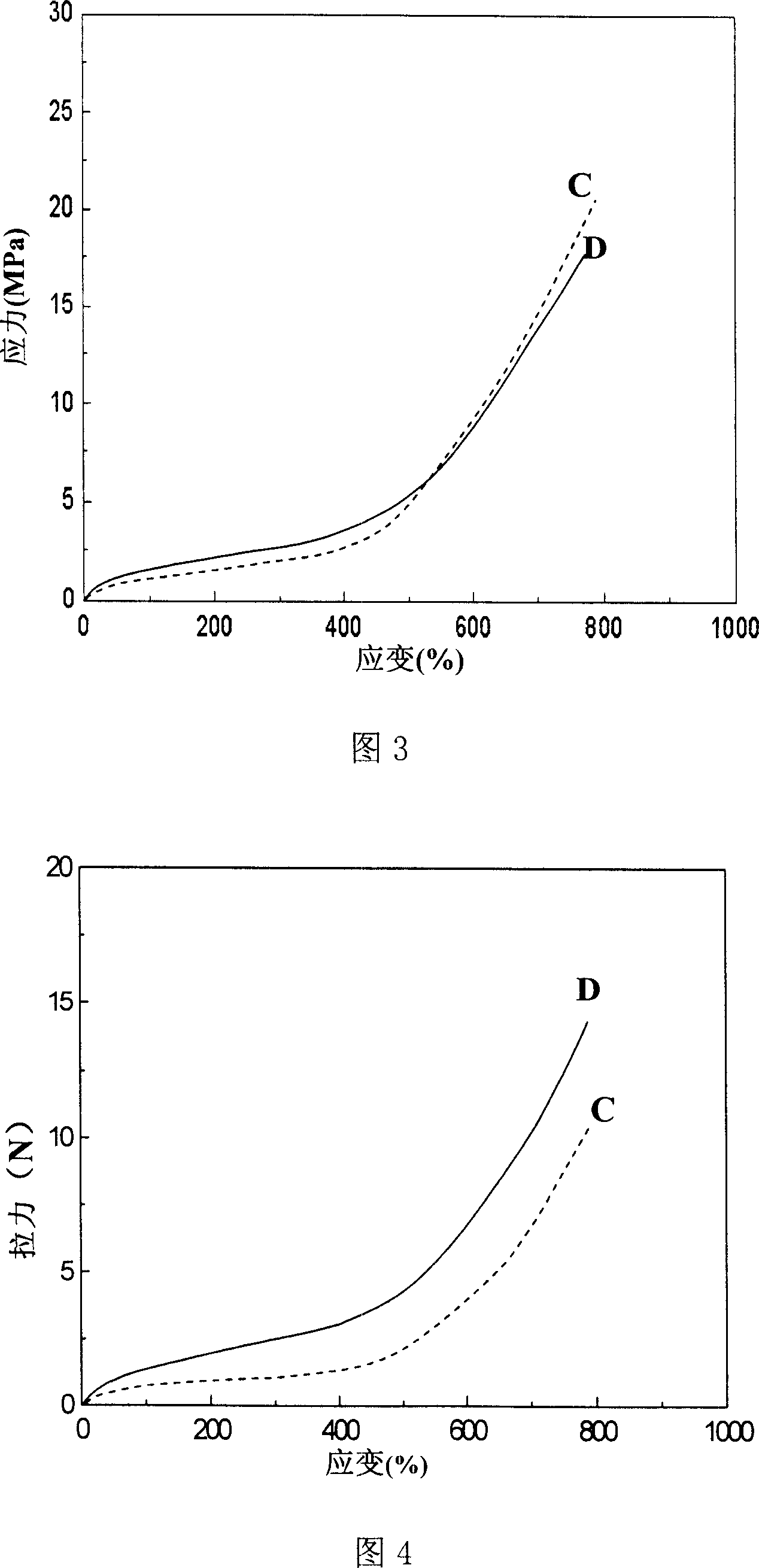

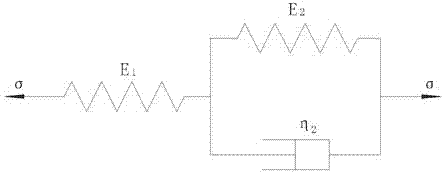

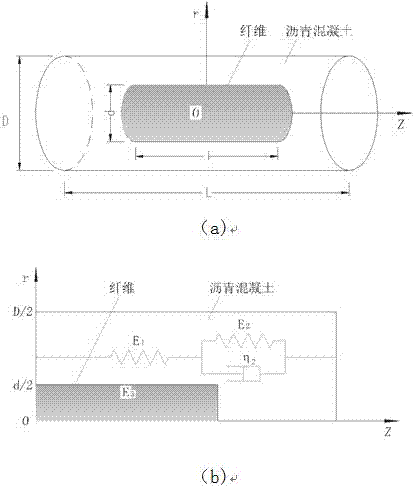

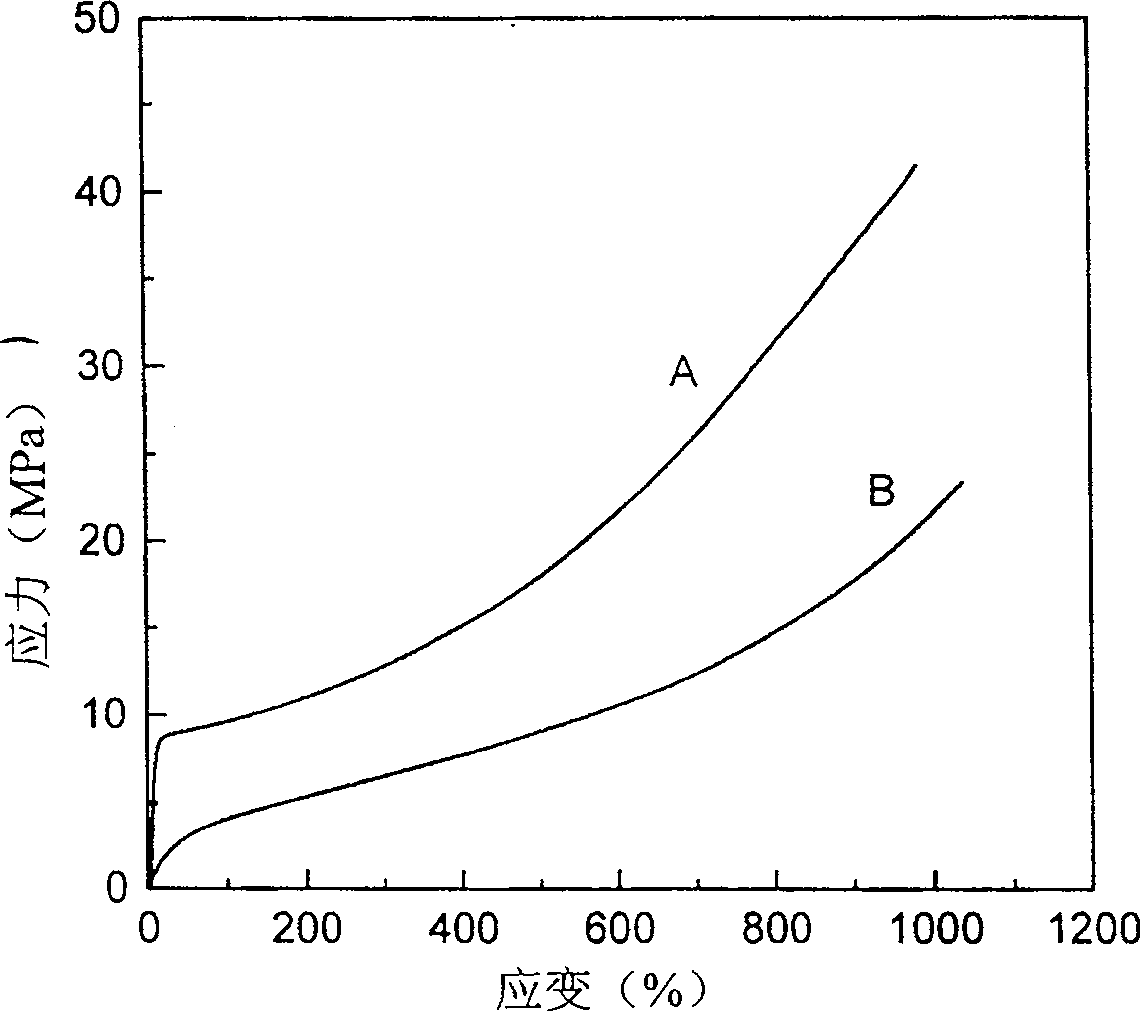

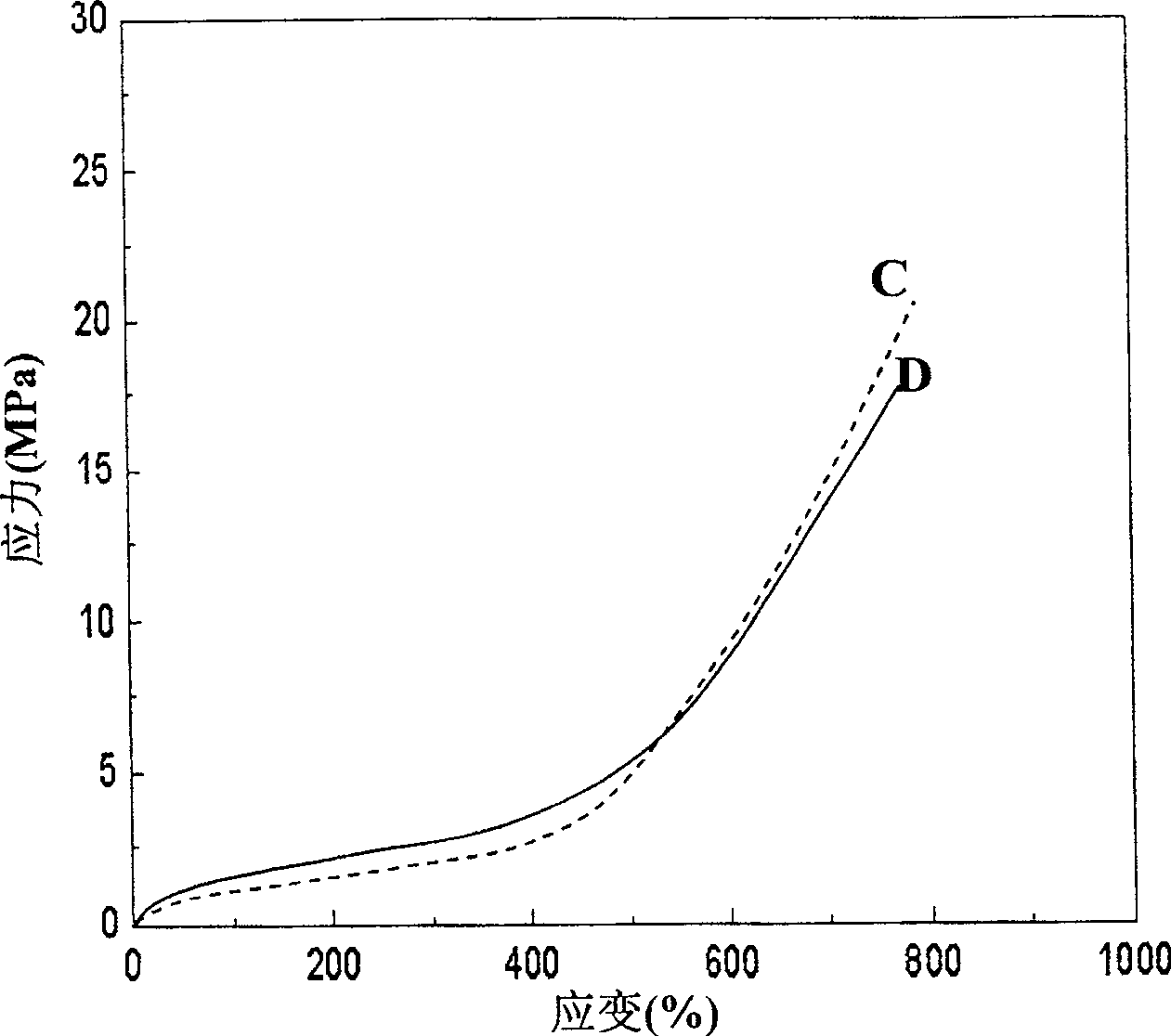

Method for constructing viscoelasticity prediction model for fiber asphalt concrete

InactiveCN107480835AImprove realismImprove road performanceForecastingDesign optimisation/simulationFiberNumerical models

The invention discloses a method for constructing a viscoelasticity prediction model for fiber asphalt concrete. The method comprises the steps of: the construction of the FRA material model, the derivation of the FRA relaxation model and the creep compliance, the analysis of the wheel tracking test, the determination of the SMA-13 viscoelastic characteristic parameter and the verification of the valid values of the model. The method of the invention has the advantages of using the FRA viscoelastic behavior model, which better presents the viscoelastic characteristics of the fiber asphalt concrete, and is effective to improve the practicality of the mesoscopic numerical model for the fiber asphalt concrete.

Owner:NANTONG UNIVERSITY

Magnesium smelting reduction pot and preparation method thereof

InactiveCN101805833APrevent oxidationImprove high temperature resistanceFoundry mouldsFoundry coresPOWDERED CELLULOSEEmulsion

The invention relates to a magnesium smelting reduction pot and a preparation method thereof, which belong to the technical field of metal smelting. The magnesium smelting reduction pot comprises a pot body and an external application coating layer, and is characterized in that: the pot body comprises the following components in percentage by weight: 0.2 to 0.4 percent of C, 1.0 to 2.0 percent of Mn, 0.6 to 2.0 percent of Si, 24.0 to 26.0 percent of Cr, 6.0 to 8.0 percent of Ni, 0.015 to 0.05 percent of Ti, 0.03 to 0.10 percent of Re, and the balance of iron; and the external application coating layer comprises the following components in percentage by weight: 47.9 to 74.1 percent of zircon powder or graphite with the particle size of 200 to 270 meshes, 1.5 to 3.8 percent of bentonite, 1.5 to 2.9 percent of powdered cellulose (carboxymethylcellulose sodium), 0.7 to 2.4 percent of white latex (polyvinyl acetate emulsion), and 22.2 to 43.0 percent of ethanol. All types of the components of the pot body are put into an intermediate frequency furnace and are melted for pouring, and are brushed with a coating according to the component proportion after being cooled. Starting from each process step of preparing the magnesium smelting reduction pot, the components of materials of the reduction pot, a melting process and a centrifugal casting process are optimized and adjusted, and a high-temperature resistant coating is brushed on the surface of the reduction pot to effectively promote the oxidation resistance of the reduction pot at a high temperature, so the service life of the pot body is prolonged.

Owner:BAOTOU BINGKE SILICON MAGNESIUM MATERIAL ENG TECH RES CENT

Lightweight aluminum alloy profile

The invention discloses a lightweight aluminum alloy profile. The lightweight aluminum alloy profile comprises the following components of, in percentage by weight, copper, magnesium, silicon, zinc, lithium, manganese, titanium, vanadium, boron, nickel, chromium, iron, rare earth metals, and and the balance aluminum and inevitable impurities, wherein the rare earth elements are any one or more mixtures of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium. According to the lightweight aluminum alloy profile, the aluminum is taken as a main raw material, various metal materials are added, the manufactured aluminum alloy is light in weight, so that lightweight of the material is achieved; by adding the copper into the aluminum alloy, the mechanical property of the aluminum alloy can be improved, and the machinability of the aluminum alloy becomes better; and by adding the silicon into the aluminum alloy, the fluidity of the aluminum alloy during casting can be improved, best fluidity is obtained from eutectic to hypereutectic, and meanwhile, the tensile strength, the hardness, the machinability and the strength at high temperature of the aluminum alloy can be improved.

Owner:安徽鑫铂铝业股份有限公司

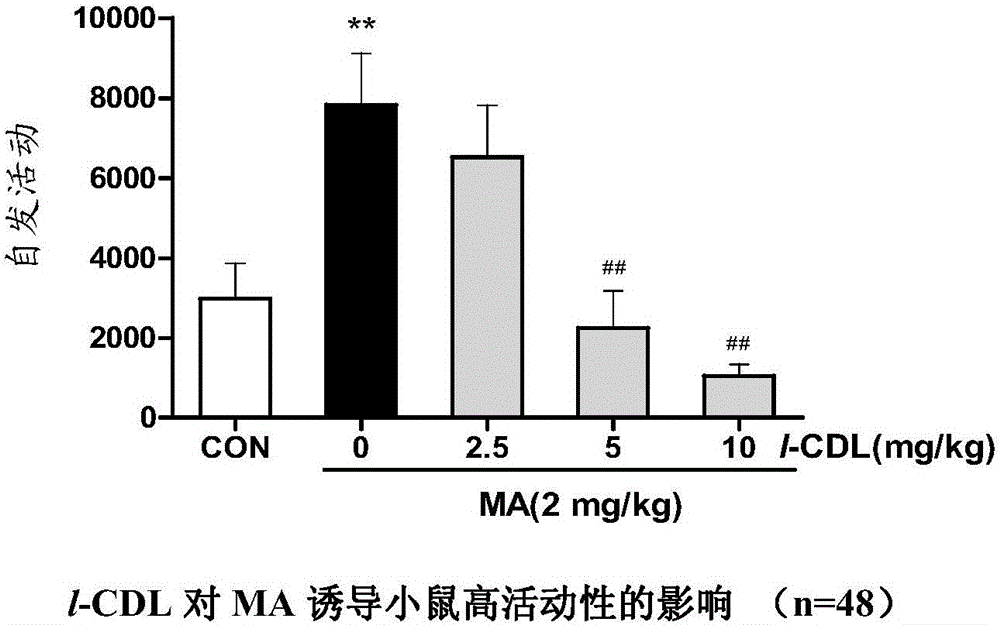

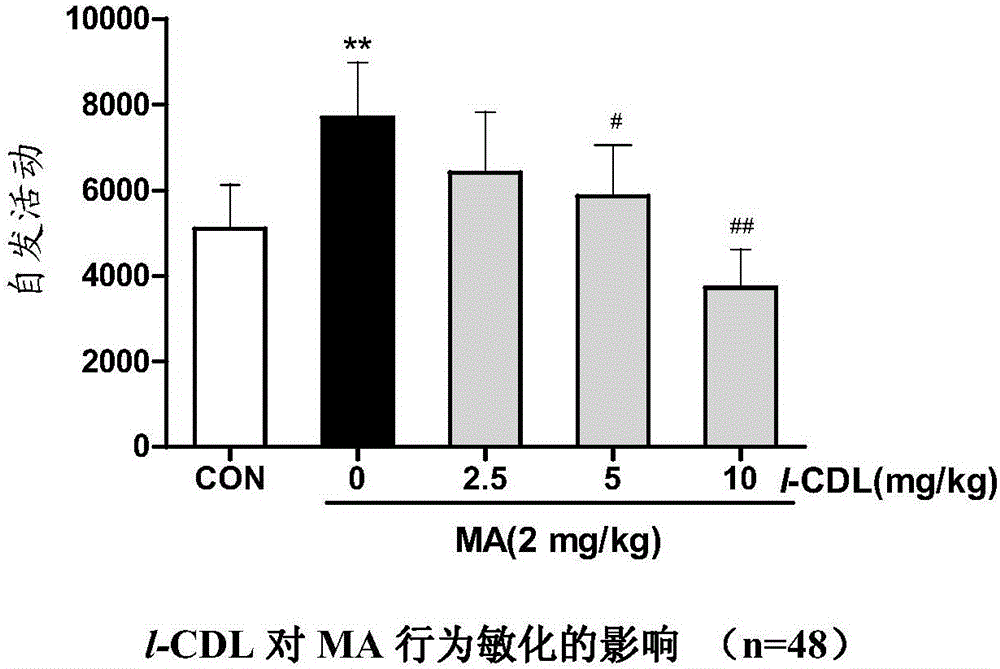

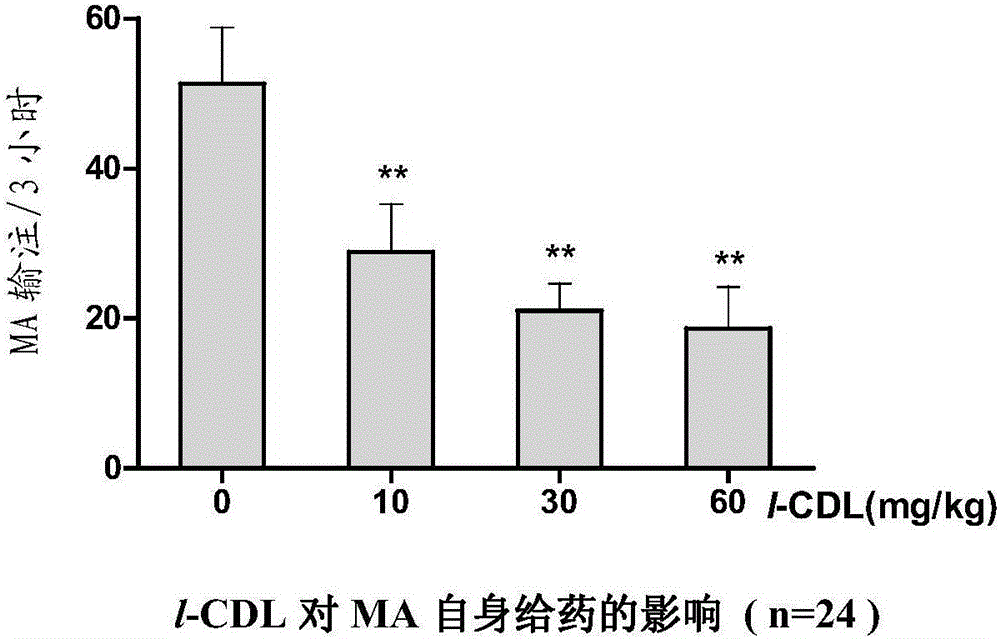

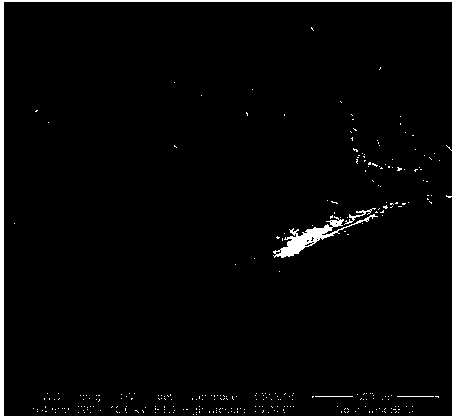

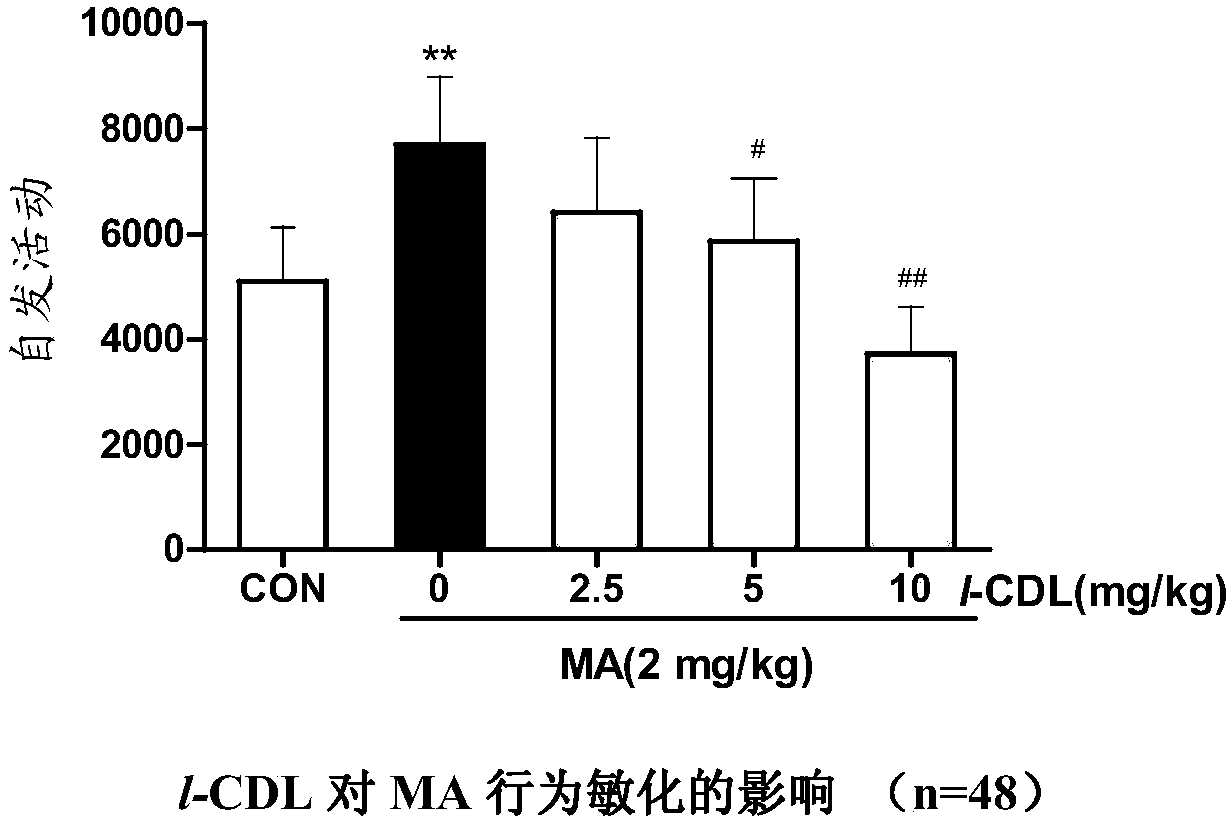

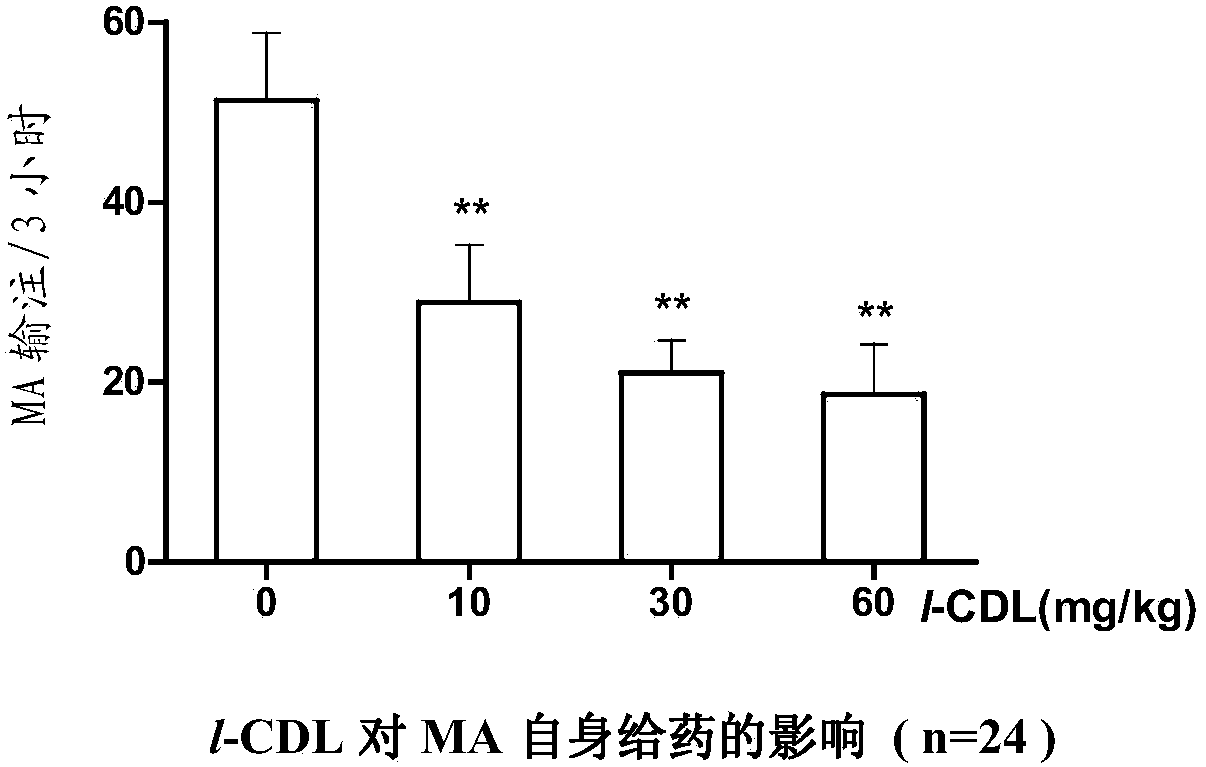

Anti-addiction medical application of L-corydalmine (L-CDL)

ActiveCN106176740AReduced reinforcementIncrease mobilityOrganic active ingredientsNervous disorderDiseaseIsoquinoline

The invention relates to an application of a lead compound namely L-corydalmine (L-CDL) of isoquinoline compounds on treating diseases related with addiction. The diseases comprise drug addiction (heroin, opium, methyl amphetamine, morphine, marihuana, cocaine, and the like), nicotine addiction, and alcohol addiction, and also comprise novel drug addiction (stimulant type novel drugs) and brain damage caused by novel drugs.

Owner:杨征

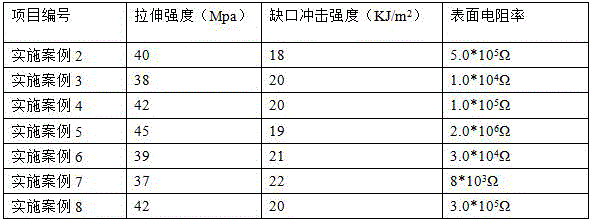

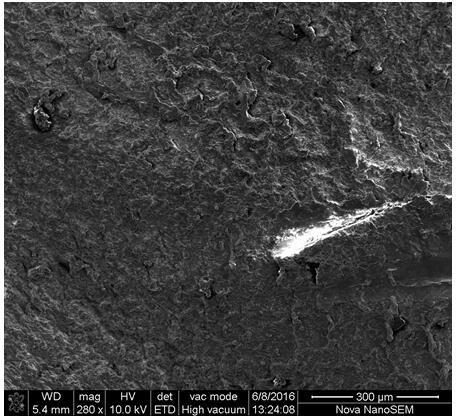

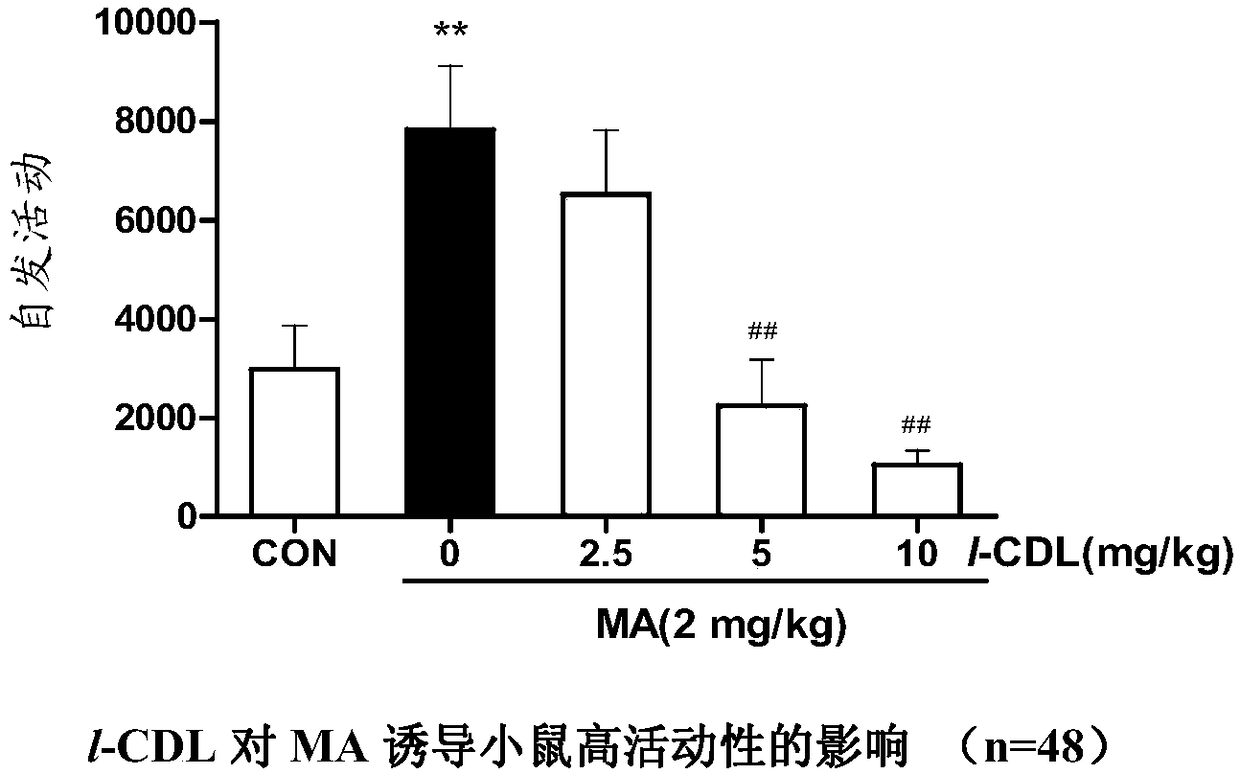

Preparation method of static-conductive PVC (polyvinyl chloride) mining pipe

The invention discloses a preparation method of a static-conductive PVC (polyvinyl chloride) mining pipe. The method comprises the following steps: (1) adding a PVC resin and a two-dimensional-plane-structure nano carbon material into a kneader, and kneading to obtain a PVC / nano carbon master batch; and (2) proportionally adding the PVC resin, conductive carbon black, a compatibilizer, a heat stabilizer, lubricant and processing aids into the PVC / nano carbon master batch, stirring and mixing, and carrying out melting and extrusion forming to obtain the mining pipe finished product. The method can enhance the static conductivity of the PVC mining pipe, and can also enhance the impact resistance, corrosion resistance, heat stability and other properties of the PVC mining pipe.

Owner:DEYANG CARBONENE TECH

Modified 700MPa grade high-strength weathering steel and method for preparing same

InactiveCN101285157AGuaranteed StrengthReduce precipitationMetal rolling arrangementsThin slabAbsorbed energy

The invention discloses an improved 700MPa level high strength weathering steel and a method for manufacturing the same. The improved 700MPa level high strength weathering steel is manufactured with a thin slab casting and rolling process, wherein the main chemical constituents of refined liquid steel are as follows: 0.03 to 0.07 weight percent of C, less than 0.3 weight percent of Si, 1.51 to 2.10 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.008 weight percent of S, 0.2 to 0.4 weight percent of Cu, 0.4 to 0.7 weight percent of Cr, 0.10 to 0.35 weight percent of Ni, 0.08 to 0.14 weight percent of Ti, and less than or equal to 0.008 weight percent of N. The improved 700MPa level high strength weathering steel has yield strength more than or equal to 700MPa, tensile strength more than or equal to 750 MPa, and extensibility more than or equal to 14 percent. The impact absorbing energy Akv of a half size sample (5 x10 x 55mm) at 20 DEG.C below zero is more than or equal to 33J.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane and the use thereof

InactiveCN100513118CGood breathability and moisture permeabilityImprove wearing comfortDiagnosticsGlovesPolymer scienceNitrile rubber

A method for making a disposable acrylonitrile-butadiene-polyurethane composite glove and a use thereof are provided. The method includes below steps: using a continuous line, first forming a substrate film of acrylonitrile-butadiene on a former, then dip-coating the former with water-soluble polyurethane latex to form a polyurethane film on the outer of the substrate film of acrylonitrile-butadiene. The polyurethane accounts for 3-15% of the total weight of the glove.

Owner:TIANJIN GREENCOAT POLYMER MATERIAL TECH CO

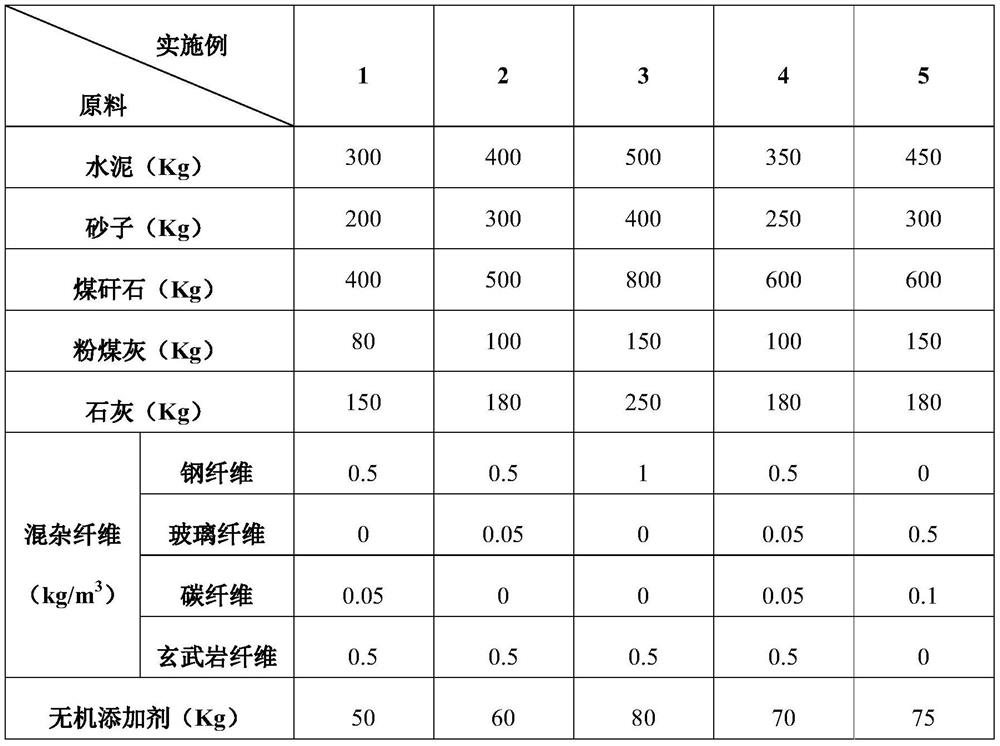

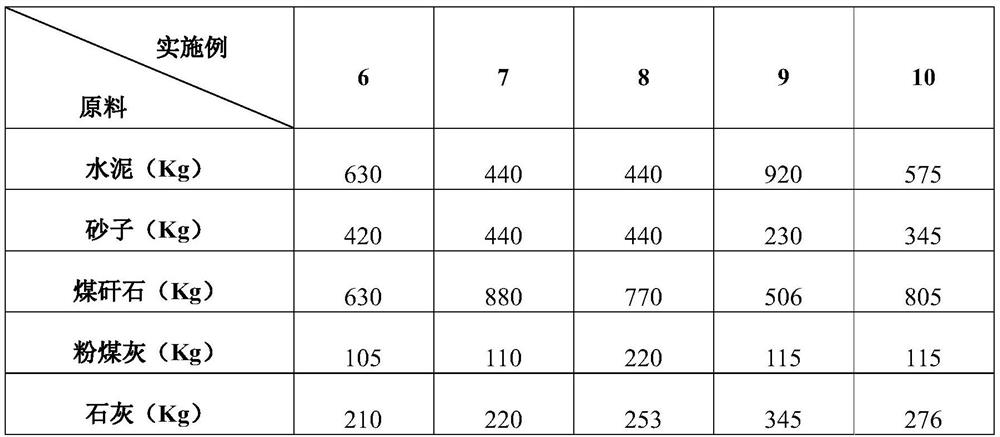

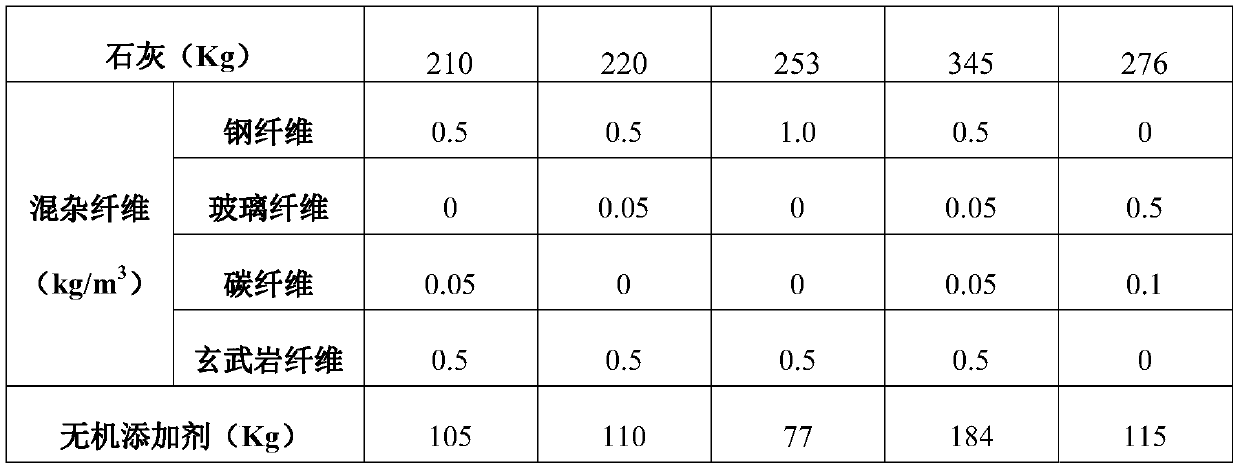

Waste coal mine filler based on coal gangue

InactiveCN112897964AImprove fire resistanceReduce intensitySolid waste managementMaterial fill-upBasalt fiberMaterials science

Owner:陕西拉发纪新材料科技有限公司 +1

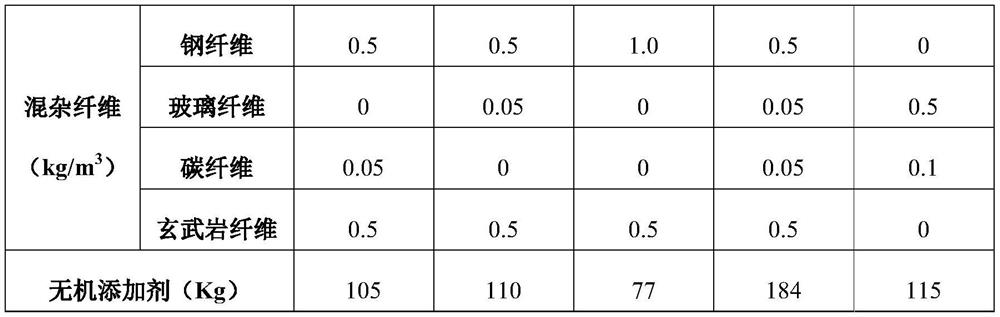

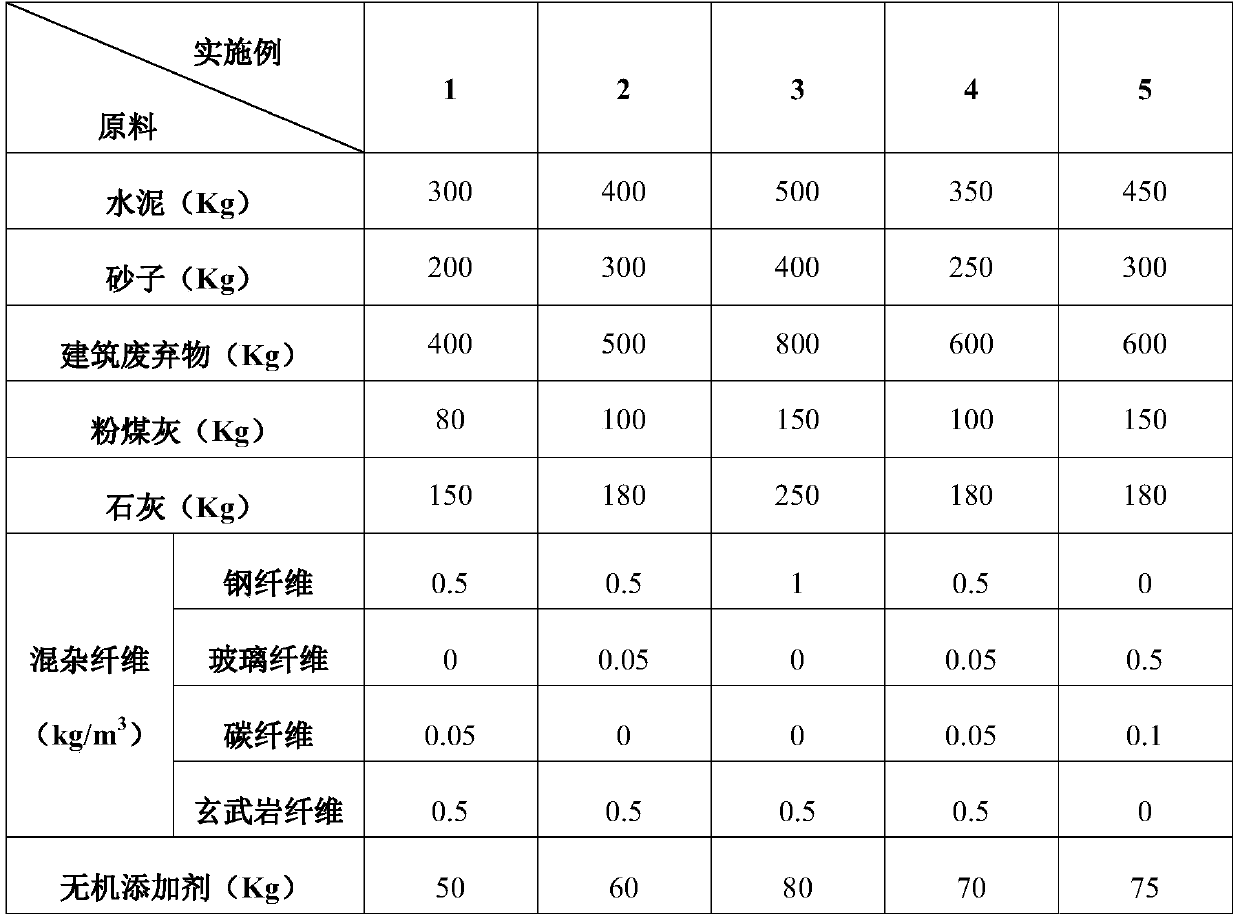

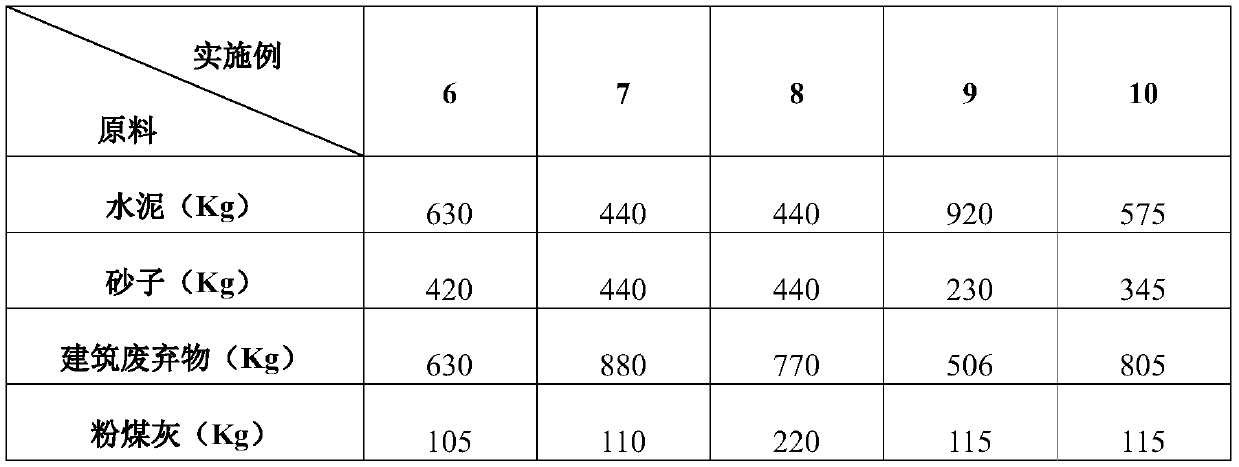

Waste coal mine filler based on construction waste

InactiveCN111592323AImprove corrosion resistanceMeet support needsSolid waste managementGlass fiberMining engineering

Owner:陕西拉发纪新材料科技有限公司 +1

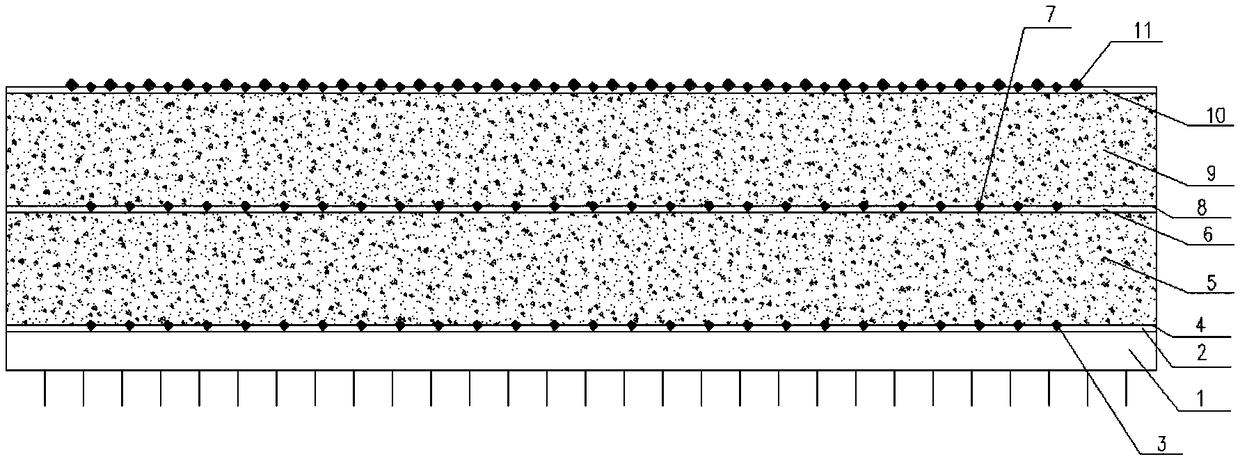

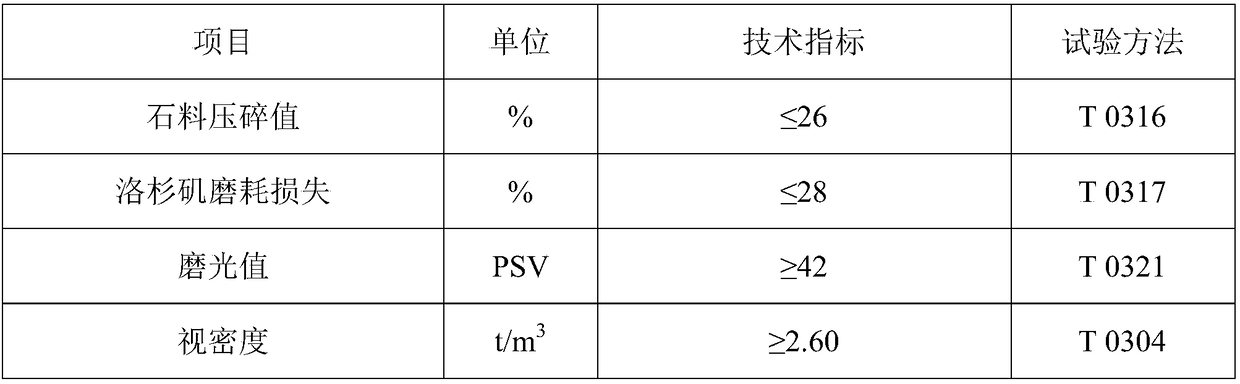

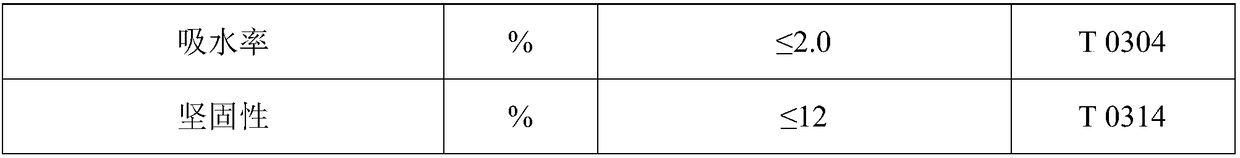

Pavement structure for orthotropic steel bridge deck plate reinforcing and construction method

PendingCN109457610AEasy constructionEasy to useBridge structural detailsBridge erection/assemblyFatigue damageSurface layer

The invention discloses a pavement structure for orthotropic steel bridge deck plate reinforcing and a construction method. The pavement structure comprises a resin-asphalt waterproof anti-sliding binding layer, a first resin-asphalt binder layer, a resin-asphalt concrete lower surface layer, a resin-asphalt waterproof binding layer, a second resin-asphalt binder layer, a resin-asphalt concrete upper surface layer and a resin-asphalt anti-sliding cover surface layer which are sequentially paved on a surface layer of a steel bridge deck plate from bottom to top. The pavement structure is constructed at the normal temperature, and the using performance of old bridge deck pavement can be guaranteed; by improving the bridge deck pavement rigidity, fatigue damage of a vehicle load to the steelbridge deck plate is reduced, and the service life of the orthotropic steel bridge deck plate is prolonged.

Owner:中南安全环境技术研究院股份有限公司 +1

Impact-resistant flexible protective material as well as preparation method and application thereof

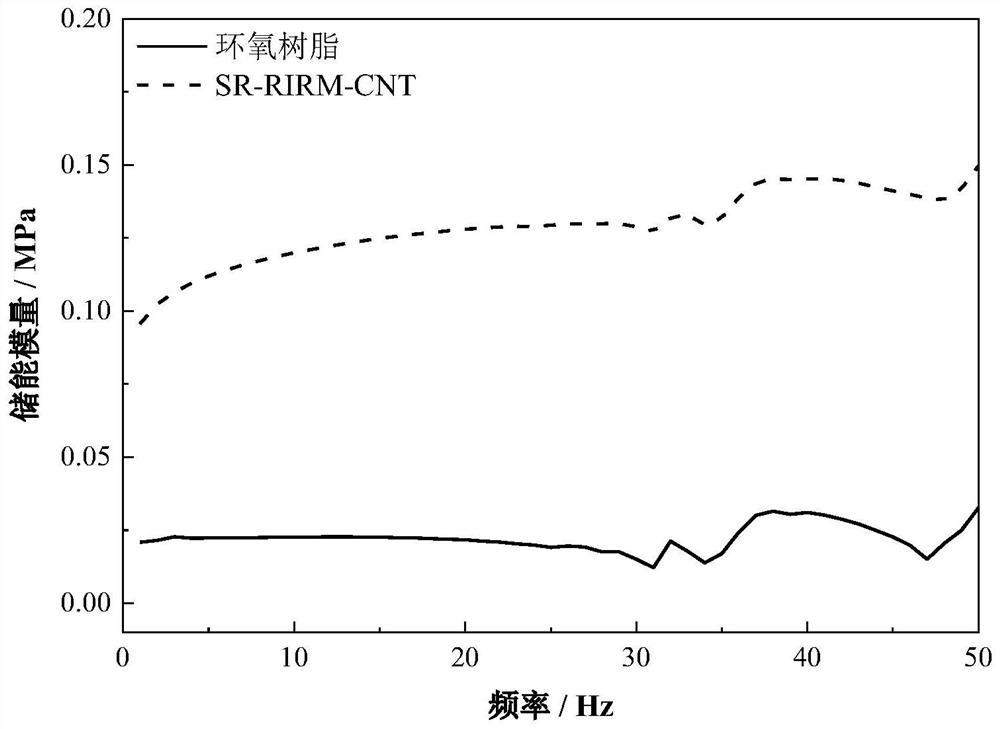

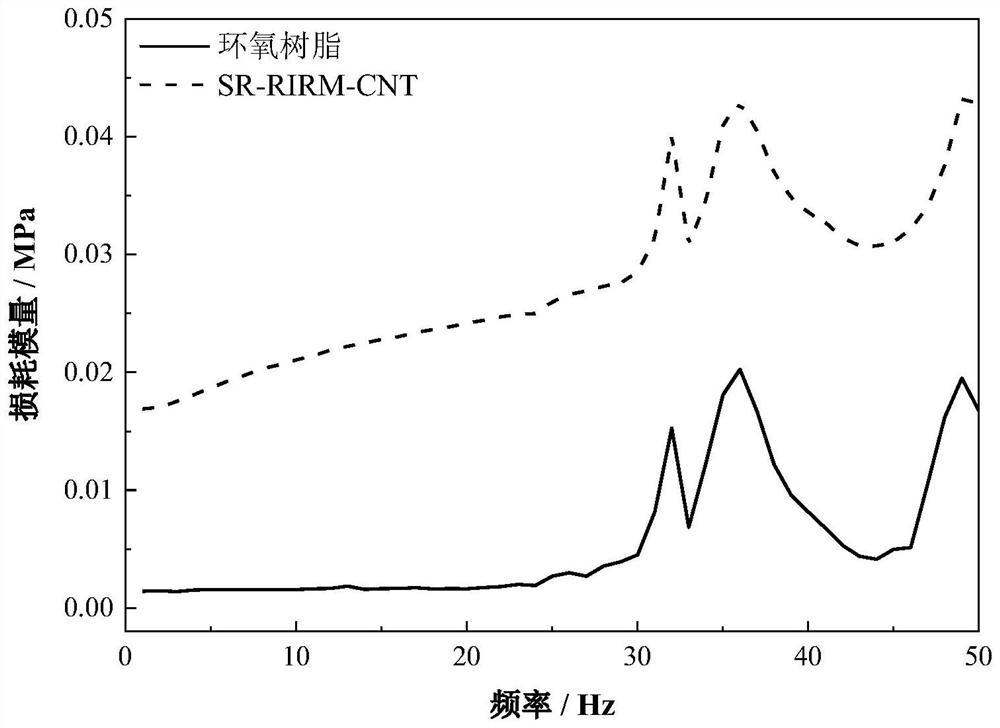

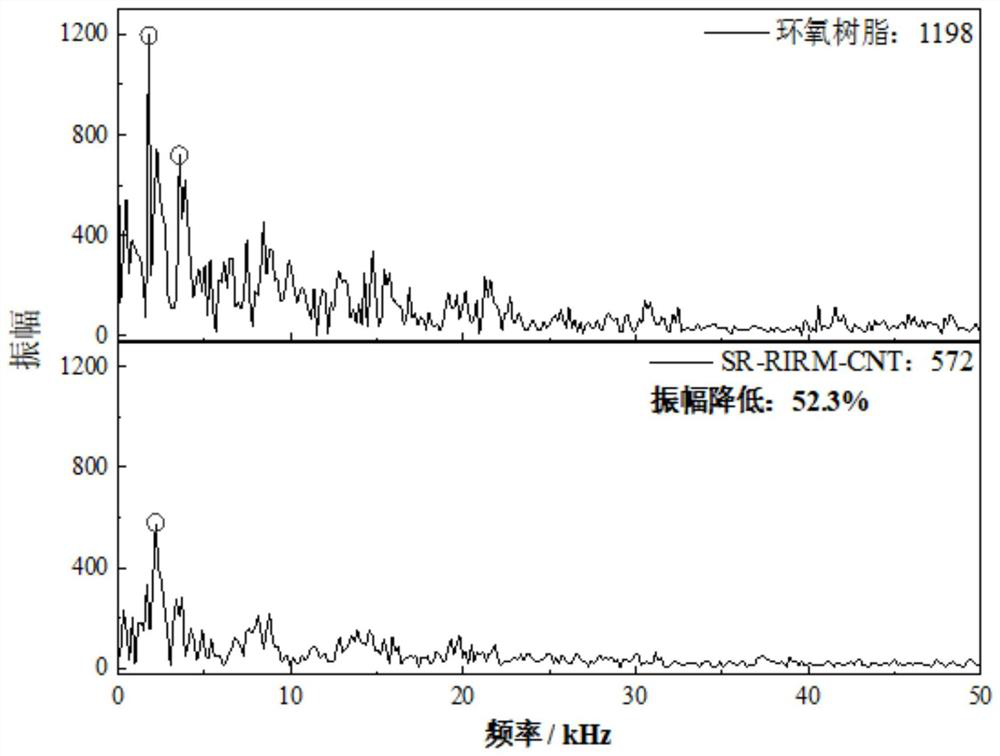

PendingCN113292858AExcellent storage modulusExcellent lossAmmunition fuzesCarbon nanotubeSilicon rubber

The invention discloses a flexible protective material with remarkable impact resistance and vibration suppression performance and a preparation method thereof. The protective material is an SR-RIRM-CNT material, wherein SR is silicone rubber, RIRM is a repairable impact reinforcing material, CNT is a carbon nanotube, and the flexible protective material is formed by compounding the three materials. The SR-RIRM-CNT composite material disclosed by the invention not only has excellent impact resistance and vibration suppression performance, but also has good flexibility. Compared with a traditional impact-resistant vibration suppression material, the SR-RIRM-CNT composite material has more excellent dynamic mechanical properties under the impact load, and the suppression effect on the high-speed impact vibration load is more remarkable.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

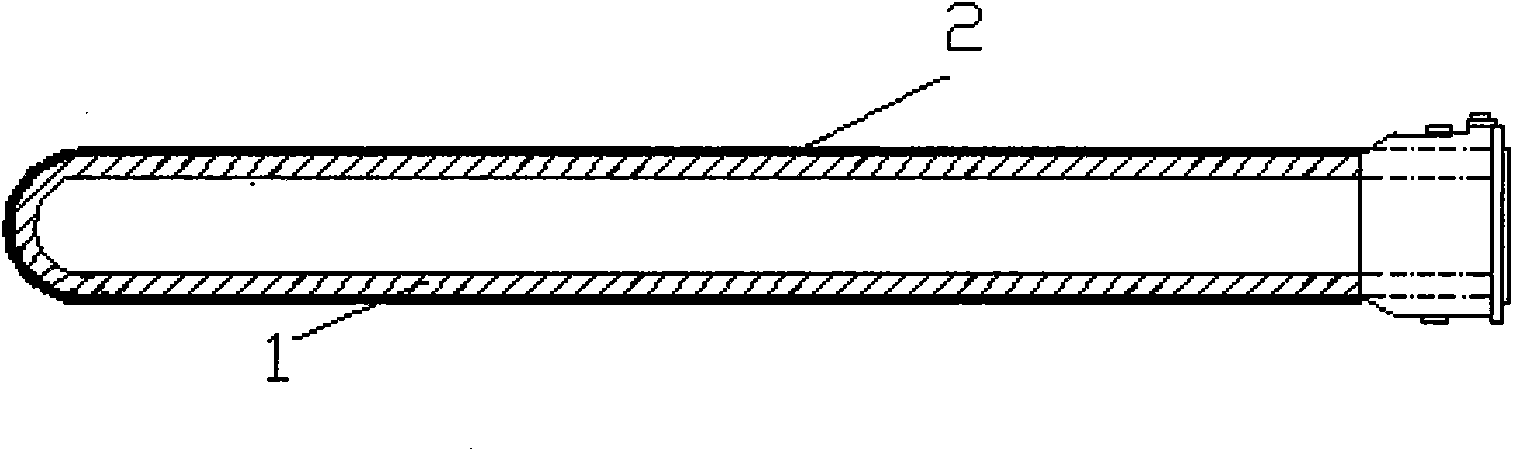

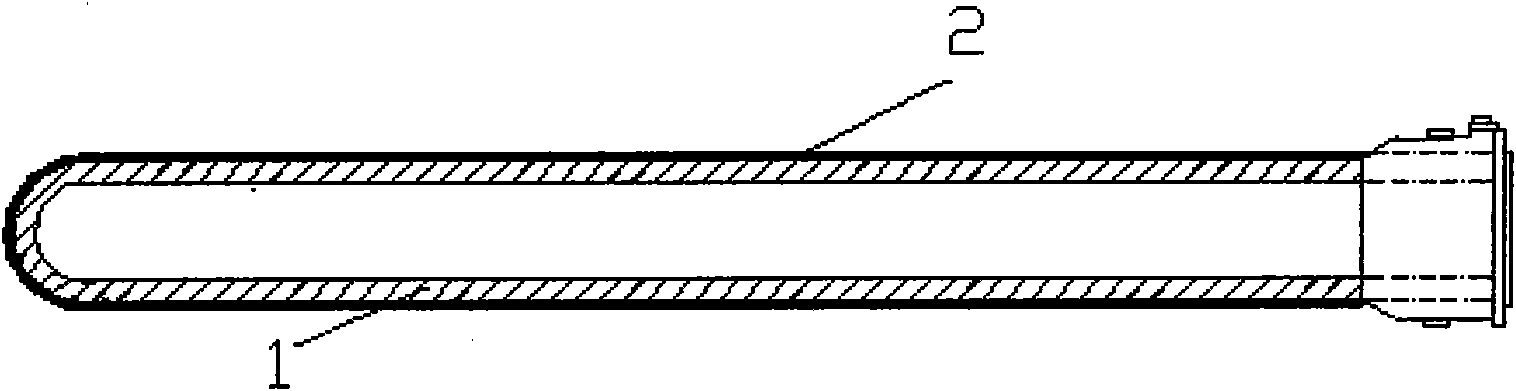

Novel efficient magnesium smelting reduction tank and manufacturing method thereof

The invention belongs to the technical field of metal smelting, and particularly relates to a novel efficient magnesium smelting reduction tank and a manufacturing method thereof. The novel efficient magnesium smelting reduction tank comprises a tank body, a top head and a cooling water jacket, the tank body is formed by centrifugal casting, one end of the tank body is in welded connection with the top head, the other end of the tank body is welded with the cooling water jacket in a riveting mode, the tank body and the top head comprise, by weight, 0.03-0.07% of C, 20-27% of Cr, 8-12% of Ni, 2-3% of Al, 1-2% of Si, 0-0.03% of Re, 0-0.03% of S, 0-0.03% of P, and the balance Fe. By the adoption of the reasonable manufacturing process, chrome, nickel, tungsten, manganese and other beneficial elements are added, the contents of harmful elements like carbon, sulfur and phosphorus are controlled, a novel Fe-Cr-Ni-Al dual-phase heat resisting alloy is researched, the heat resisting temperature of the alloy is improved to 1200-1280 DEG C, the superior castability and weldability are obtained, the good mechanical performance and high-temperature oxidation resistance performance are obtained at high temperature, and the service life is more than twice that of similar products.

Owner:蚌埠市圣光化工有限公司

Anti-microbial superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe and preparation method thereof

InactiveCN105837990AImprove heat resistanceImprove aging resistanceBuilding insulationsCerium nitratePolyvinyl chloride

The invention discloses an anti-microbial superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe. The water pipe is prepared from, by weight, 29-30 parts of superfine fully-vulcanized powdered rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nano-wires, 3-3.2 parts of cerium nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulphate, 2.3-2.5 parts of graphene oxide, 0.8-1 part of nano-cuprous oxide, 0.8-1 part of asphalt, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 60-70 parts of ethyl alcohol and 15-16 parts of ammonium hydroxide. According to the water pipe, graphene oxide and nano-cuprous oxide are mixed and stirred for 20-30 min at 2-2.5 MPa, so that the surface of graphene oxide is loaded with nano-cuprous oxide, and a good anti-microbial effect is achieved; then, asphalt is added, so that the cohesiveness of graphene oxide, nano-cuprous oxide and PVC is improved.

Owner:蚌埠市燕南塑料制品厂

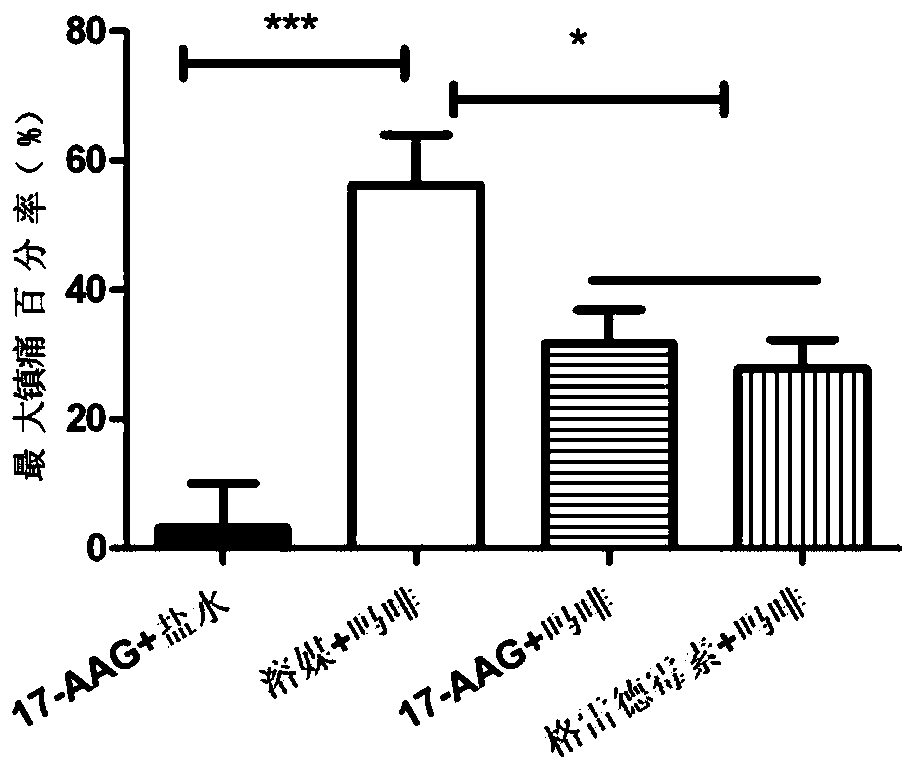

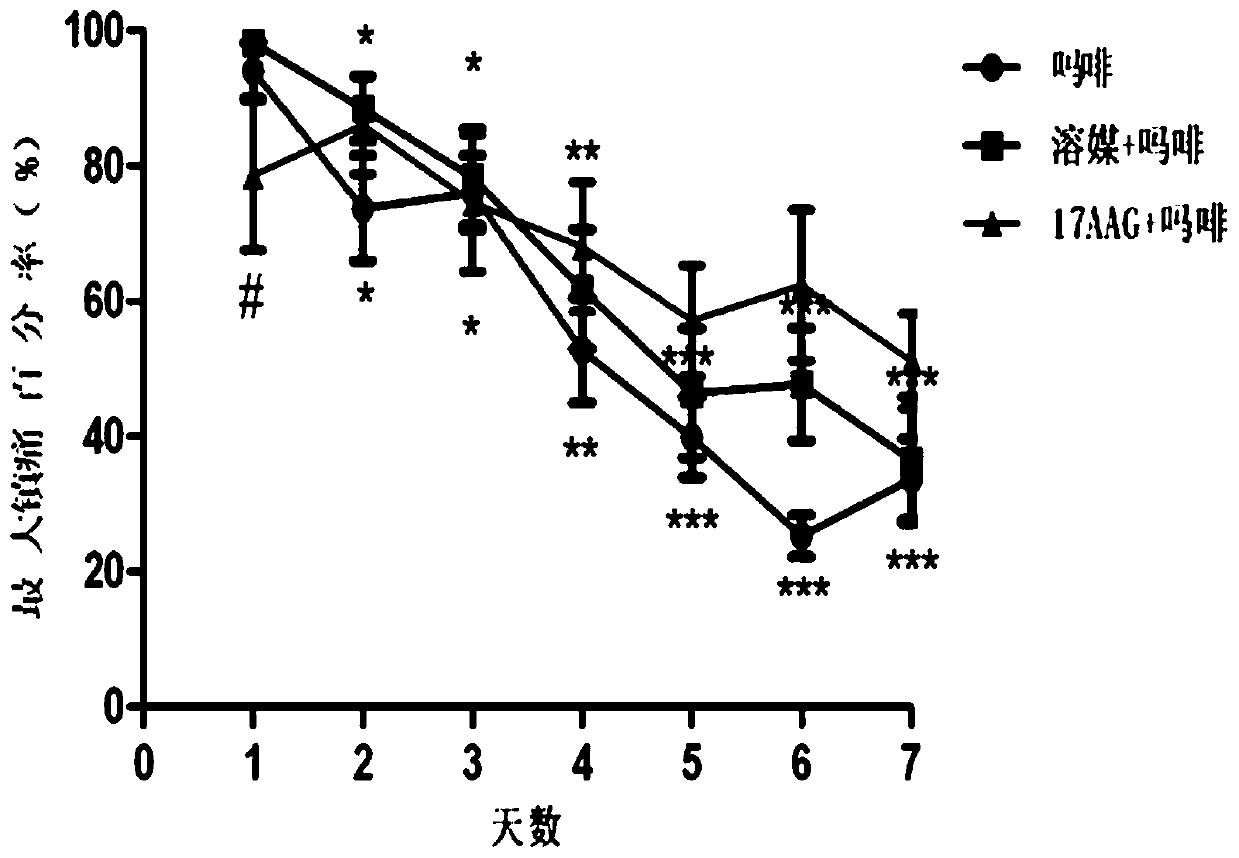

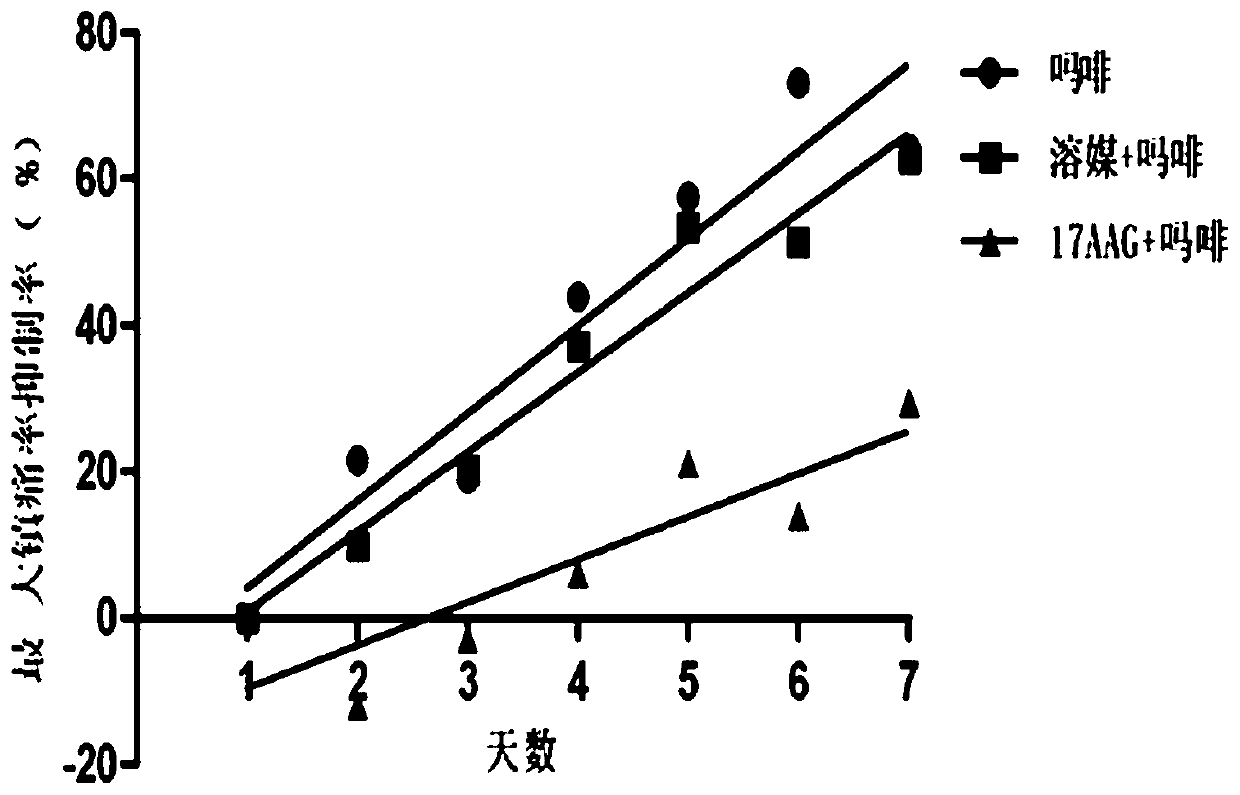

Preparation for inhibiting adverse reactions of opioid analgesic drugs and application of preparation

ActiveCN110917190AReduce Opioid DependenceLow cost of treatmentAntipyreticAnalgesicsPethidine hydrochlorideMorphine Sulfate Sustained-Release Tablet

The invention relates to a preparation for inhibiting adverse reaction of opioid analgesic drugs and application of the preparation. The preparation contains one or more of 17-N-allylamino-17-demethoxygeldanamycin or / and homologs thereof, and the opioid analgesic drug comprises one or a combination of more of a morphine hydrochloride tablet, a morphine sulfate sustained-release tablet, a codeine phosphate tablet, a morphine hydrochloride injection, a piperidine hydrochloride injection and a fentanyl injection. By the adoption of the technical scheme, 17-AAG can obviously inhibit the symptom ofprecipitation withdrawal reaction along with chronic administration of morphine, body tolerance and mental dependence of morphine can be obviously inhibited, 17-AAG and homologs thereof and opioid analgesic drugs are reasonably used. Meanwhile, the compound has dual effects of resisting tumors and inhibiting the tolerance and dependence of opioid analgesic drugs, so that the use of other drugs can be reduced.

Owner:ACADEMY OF MILITARY MEDICAL SCI

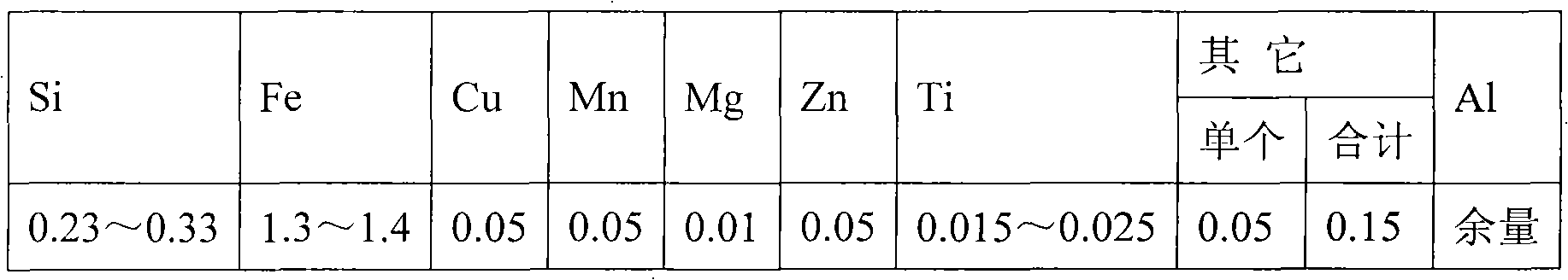

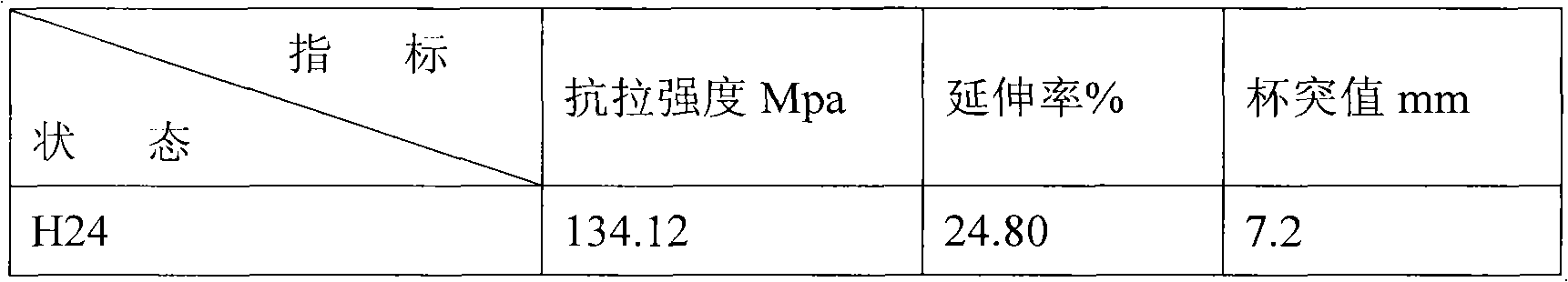

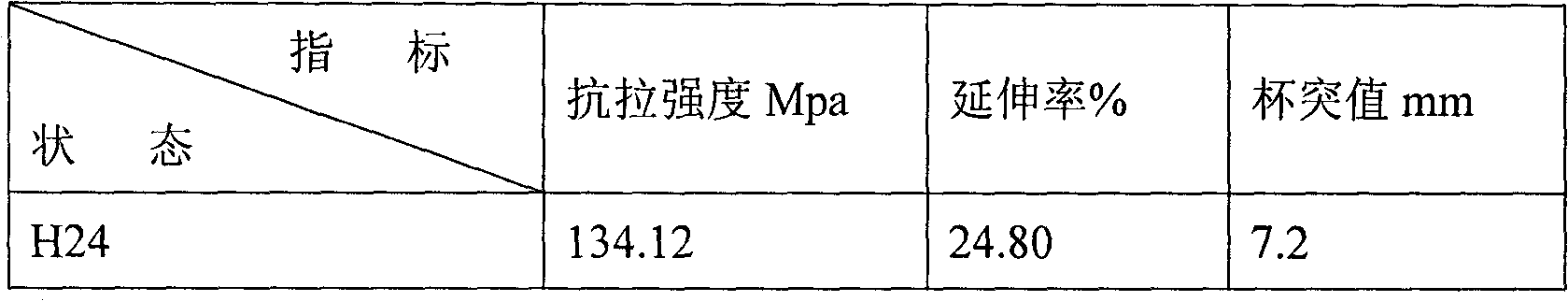

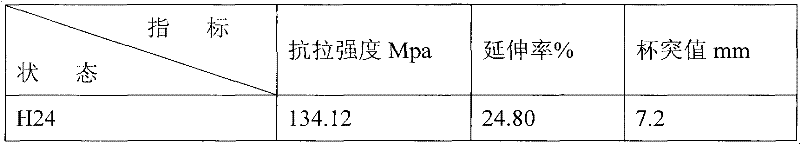

Universal aluminium alloy air-conditioner foil and manufacturing method thereof

InactiveCN101818287AMeet performance requirementsTo achieve a unified technical effectRoll mill control devicesMetal rolling arrangementsPunchingAluminium alloy

The invention discloses a universal aluminium alloy air-conditioner foil and a manufacturing method thereof. The universal type means to the punching processing technology suitable for various punches. The universal aluminium alloy air-conditioner foil is characterized in that as for the alloying elements distributed in Al base, the weight ratio of Fe to Si is controlled to be 4-6:1, so that the aluminium alloy air-conditioner foil tends to Fe causing 45-degree earing and tends to Si causing 0 or 90-degree earing combined action in the punching process so as to improve the evenness of earing direction.

Owner:江阴博威合金材料有限公司

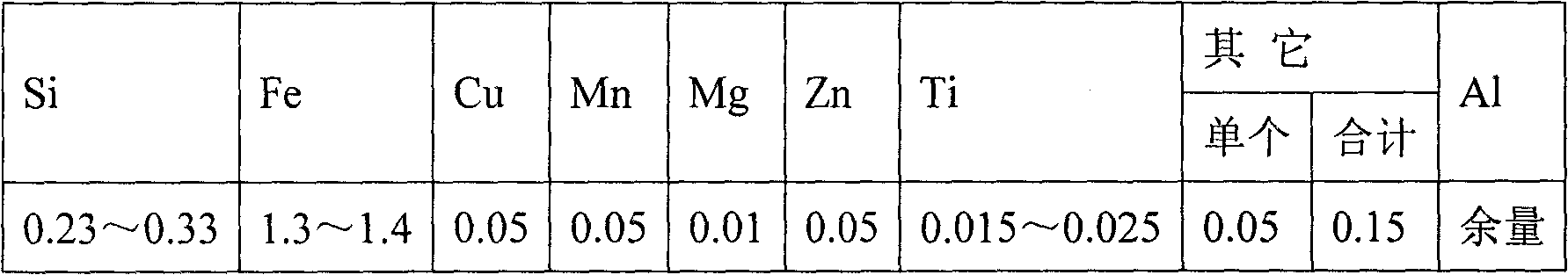

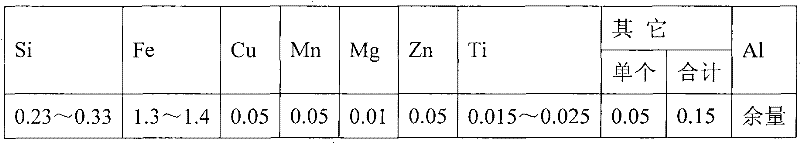

Full applicability air conditioning foil and manufacturing method thereof

InactiveCN101818288ATo achieve a unified technical effectMeet performance requirementsGranularityAir conditioning

The invention relates to a full applicability air conditioning foil and manufacturing method thereof. Al base only comprises Fe, Si and Ti three alloying elements, and the weight ratio of the three alloying elements is controlled to be that Fe: Si: Ti is equal to 60-80: 15-16: 1; the weight ratio causes aluminium alloy air conditioning foil is subject to combined action of Fe leading to 45 degrees of earing and Si leading to 0 or 90 degrees of earing in stamping process, so as to improve uniformity in earing direction, Ti therein realizes grain refining function, so that the grain size of air conditioning foil is less than or equal to one class, and plasticity of air conditioning foil is improved. The air conditioning foil can meet the performance requirement of various special punches used by the current air conditioner factories to stamping material, avoids the condition restriction that different special punch requirements of different suppliers are corresponding to different air conditioning foil materials and achieves the technical effect of unionization of air conditioning foil material.

Owner:江阴博威合金材料有限公司

Antistatic superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe and preparation method thereof

The invention discloses an antistatic superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe. The water pipe is prepared from raw materials in parts by weight as follows: 29-30 parts of superfine fully-vulcanized powdered rubber, 68-70 parts of PVC SG-3, 2-2.3 parts of zinc oxide nanowires, 3-3.2 parts of cerium nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 parts of ammonium persulfate, 1.6-1.8 parts of barium sulfate, 1.3-1.5 parts of nano indium, 0.7-0.9 parts of nanocarbon sol, 2.6-2.8 parts of dodecafluoroheptylpropyltrimethoxysilane, 60-70 parts of ethanol and 15-16 parts of ammonia water. Barium sulfate and nanocarbon sol are mixed and ground uniformly, nano indium is added, nanocarbon sol is bonded on the surface of barium sulfate, the surface is covered with nano indium, the bonding property of barium sulfate is improved, the antistatic property and the wear resistance of the water pipe are improved through combined use of barium sulfate, nano indium and nanocarbon sol, and the silence effect is also improved.

Owner:蚌埠市燕南塑料制品厂

Universal aluminium alloy air-conditioner foil and manufacturing method thereof

InactiveCN101818287BMeet performance requirementsTo achieve a unified technical effectRoll mill control devicesMetal rolling arrangementsPunchingAluminium alloy

Owner:江阴博威合金材料有限公司

Anti-aging superfine fully vulcanizated powdered rubber polyvinyl chloride composite water pipe and preparing method thereof

InactiveCN105837987AImprove heat resistanceImprove aging resistanceLithium chloridePolyvinyl chloride

The invention discloses an anti-aging superfine fully vulcanizated powdered rubber polyvinyl chloride composite water pipe. The composite water pipe is prepared from, by weight, 29-30 parts of superfine fully vulcanizated powdered rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nanowire, 3-3.2 parts of cerous nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulfate, 2-3 parts of expanded graphite, 0.8-1 part of maleic anhydride, 0.8-1 part of lithium chloride sol, 0.5-0.6 part of nano-crystalline cellulose, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 60-70 parts of ethyl alcohol and 15-16 parts of ammonium hydroxide. By mixing expanded graphite, maleic anhydride and lithium chloride sol, the elasticity of expanded graphite is improved. By adding nano-crystalline cellulose, cohesiveness between expanded graphite and PVC is improved. Modified expanded graphite has high thermal conductivity, and the strength, tenacity and aging resistance of the water pipe are improved.

Owner:蚌埠市燕南塑料制品厂

Mute superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe and preparation method thereof

The invention discloses a mute superfine fully-vulcanized powdered rubber and polyvinyl chloride composite water pipe. The water pipe is prepared from, by weight, 29-30 parts of superfine fully-vulcanized powdered rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nano-wires, 3-3.2 parts of cerium nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulphate, 2-2.3 parts of wood shavings, 10-12 parts of a 9-10% nitric acid solution, 10-12 parts of a urea saturated solution, 2-2.5 parts of glycerin monostearate, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 60-70 parts of ethyl alcohol and 15-16 parts of ammonium hydroxide. According to the water pipe, wood shavings are swollen and filled with glycerin monostearate, so that the compatibility of wood shavings and PVC is improved, and the toughness and mute effect of the water pipe are improved.

Owner:蚌埠市燕南塑料制品厂

Anti-corrosion superfine fully-vulcanized powdered rubber-polyvinyl chloride composite water pipe and preparation method thereof

The invention discloses an anti-corrosion superfine fully-vulcanized powdered rubber-polyvinyl chloride composite water pipe. The composite water pipe is prepared from, by weight, 29-30 parts of superfine fully-vulcanized powdered rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nanowires, 3-3.2 parts of cerous nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulfate, 1.2-1.5 parts of LCP microspheres, 0.8-0.9 part of trichloropropylphosphate, 0.8-1 part of nano-iron oxide, 1.3-1.5 parts of bamboo charcoal micropowder, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 60-70 parts of ethyl alcohol and 15-16 parts of ammonia water. Accordingly, nano-iron oxide is uniformly dispersed in PVC by mixing nano-iron oxide with the bamboo charcoal micropowder, so that the corrosion resistance of the water pipe is improved, and by adding trichloropropylphosphate, the cohesiveness and the flame retardance of the bamboo charcoal micropowder and PVC are improved.

Owner:蚌埠市燕南塑料制品厂

A kind of preparation method of static electricity conducting PVC mine pipe

The invention discloses a preparation method of a static-conductive PVC (polyvinyl chloride) mining pipe. The method comprises the following steps: (1) adding a PVC resin and a two-dimensional-plane-structure nano carbon material into a kneader, and kneading to obtain a PVC / nano carbon master batch; and (2) proportionally adding the PVC resin, conductive carbon black, a compatibilizer, a heat stabilizer, lubricant and processing aids into the PVC / nano carbon master batch, stirring and mixing, and carrying out melting and extrusion forming to obtain the mining pipe finished product. The method can enhance the static conductivity of the PVC mining pipe, and can also enhance the impact resistance, corrosion resistance, heat stability and other properties of the PVC mining pipe.

Owner:DEYANG CARBONENE TECH

Anti-addiction Medicinal Application of Violet Damamine

ActiveCN106176740BReduced reinforcementIncrease mobilityOrganic active ingredientsNervous disorderDiseaseIsoquinoline

The invention relates to an application of a lead compound namely L-corydalmine (L-CDL) of isoquinoline compounds on treating diseases related with addiction. The diseases comprise drug addiction (heroin, opium, methyl amphetamine, morphine, marihuana, cocaine, and the like), nicotine addiction, and alcohol addiction, and also comprise novel drug addiction (stimulant type novel drugs) and brain damage caused by novel drugs.

Owner:杨征

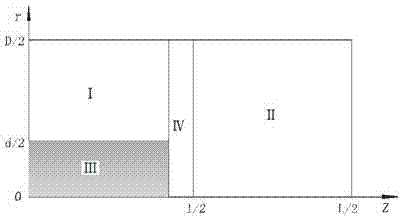

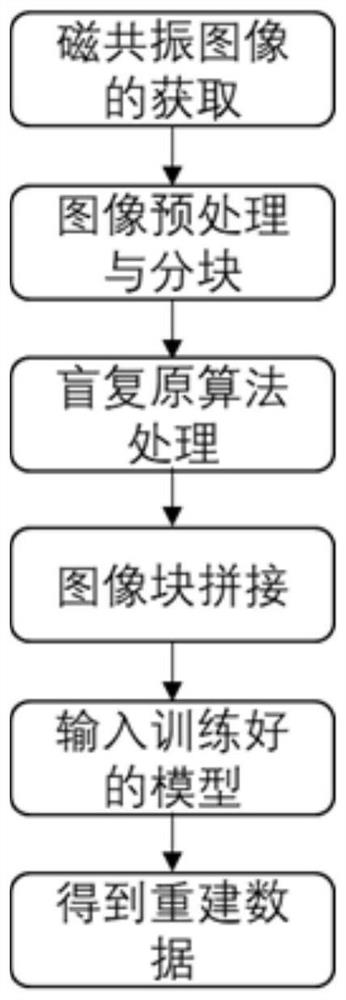

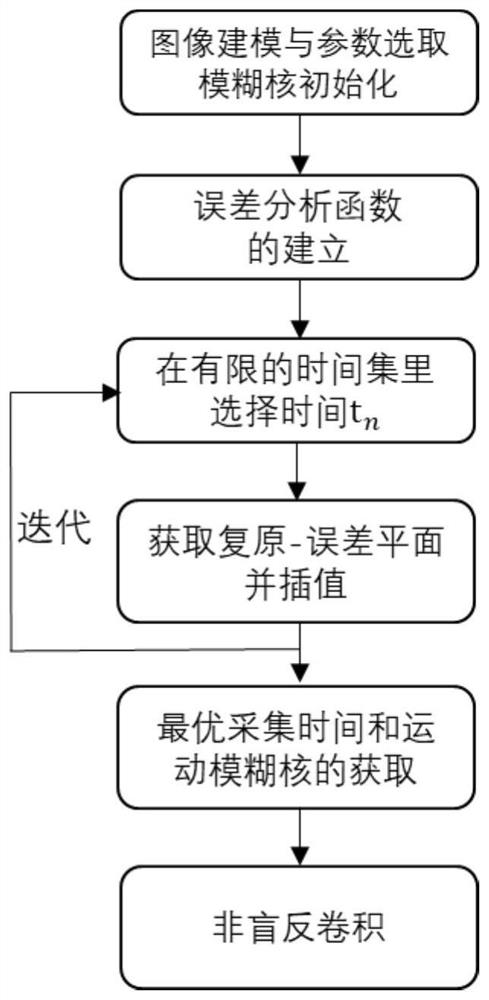

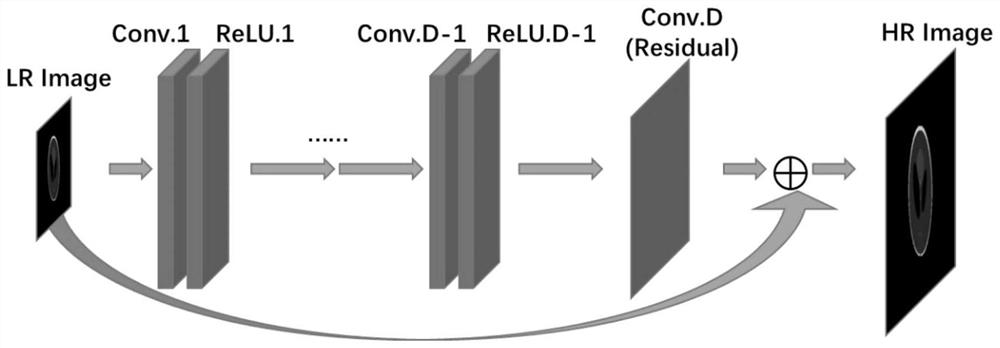

Image reconstruction method and device and electronic equipment

The invention provides an image reconstruction method and device and electronic equipment, and the method comprises the steps: carrying out the partitioning of an obtained magnetic resonance image; processing the image subjected to block processing by adopting a blind restoration algorithm to obtain a plurality of restored image blocks; the plurality of image blocks are spliced; and inputting the spliced image into a pre-trained reconstruction model to obtain a reconstructed image. Block prediction and blind restoration are carried out on the images, finally splicing is carried out, reconstruction is carried out on the input pre-trained reconstruction model, the blind restoration can carry out motion blur restoration and high-resolution prediction by utilizing the estimation of a blur kernel, random trajectory prediction is carried out on motion artifacts of the medical images with spatial shift variation properties, and the motion artifacts of the medical images with spatial shift variation properties can be predicted. The artifact enhancement of the motion blur in the resolution reconstruction process is prevented, and the purpose of reducing the motion artifact and generating an enhancement effect is achieved.

Owner:上海电气控股集团有限公司智惠医疗装备分公司

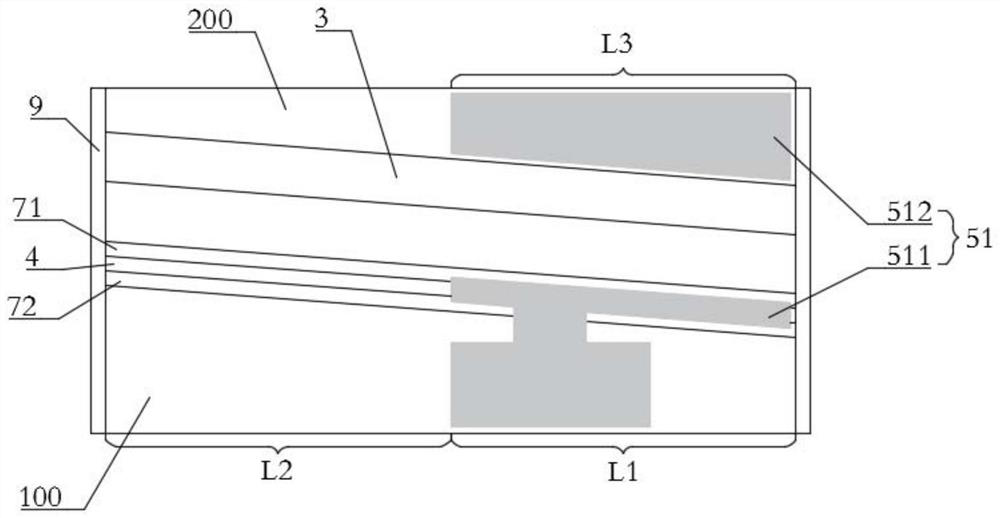

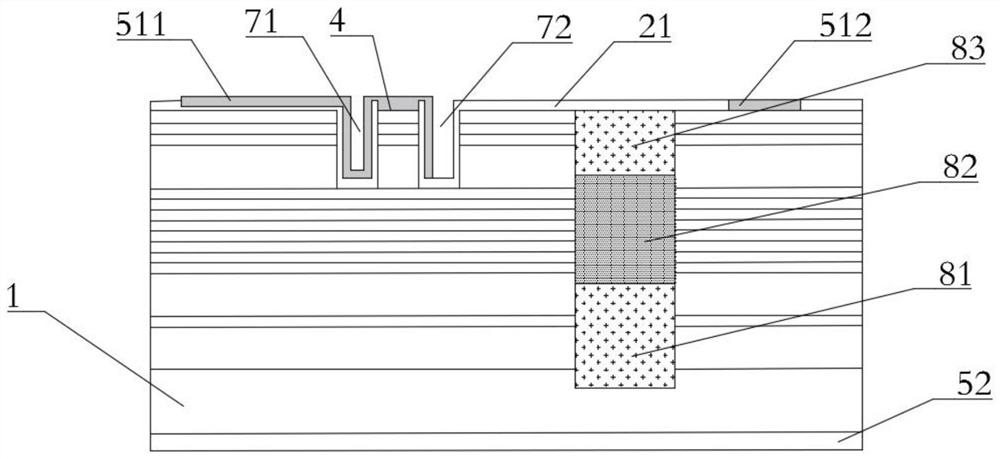

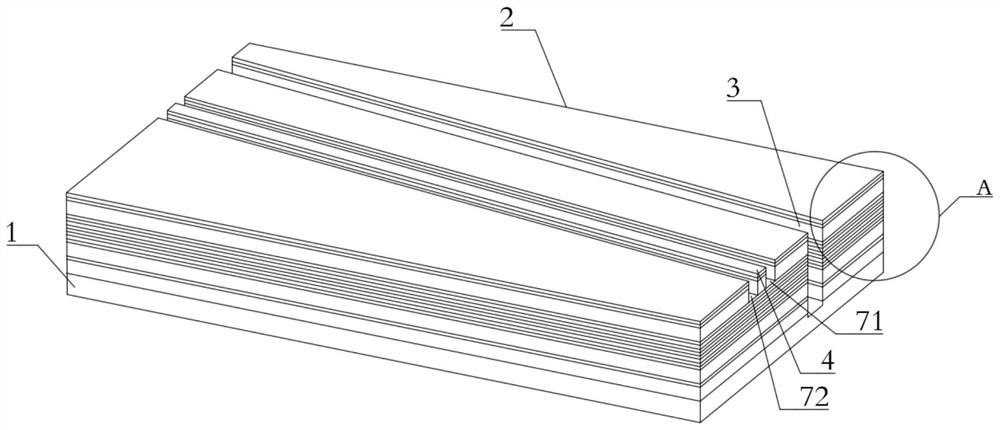

Super-radiation light-emitting diode chip integrated with lateral detector and preparation method of super-radiation light-emitting diode chip

PendingCN114203838ALow emissivitySuppress light feedbackFinal product manufactureSemiconductor devicesLight detectionWaveguide

The invention discloses a super-radiation light-emitting diode chip integrated with a lateral detector and a preparation method, the super-radiation light-emitting diode chip comprises a substrate and an epitaxial wafer formed on the substrate, and an isolation groove penetrating through the epitaxial wafer downwards is formed in the upper surface of the epitaxial wafer. A ridge waveguide arranged in parallel with the isolation groove is formed on one side, corresponding to the isolation groove, of the upper surface of the epitaxial wafer, and an active area and a passive absorption area are sequentially formed on the side in the length direction of the ridge waveguide. A lateral detection area is formed on the other side, corresponding to the isolation groove, of the epitaxial wafer and at the position opposite to the active area, the ripple coefficient of the super-radiation light-emitting diode can be effectively improved, and the influence of introduction of a passive absorption area on the light detection capacity of a lateral detector is reduced.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP +2

High-antifouling ultrafine-fully-vulcanized-powder-rubber and polyvinyl-chloride composite water pipe and preparing method thereof

InactiveCN105924831AImprove heat resistanceImprove aging resistanceRigid pipesPolyvinyl chlorideNanoporous carbon

The invention discloses a high-antifouling ultrafine-fully-vulcanized-powder-rubber and polyvinyl-chloride composite water pipe. The high-antifouling ultrafine-fully-vulcanized-powder-rubber and polyvinyl-chloride composite water pipe is prepared from, by weight, 29-30 parts of ultrafine fully-vulcanized powder rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nanowires, 3-3.2 parts of cerous nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulfate, 1.5-1.8 parts of nanosilicon dioxide, 1.3-1.5 parts of nano-porous carbon, 1.5-1.6 parts of aluminum isopropoxide, 6-7 parts of isopropyl alcohol, 2.6-2.8 parts of dodecafluoroheptyl-propyl-trimethoxysilane, 60-70 parts of ethyl alcohol and 15-16 parts of ammonium hydroxide. According to the high-antifouling ultrafine-fully-vulcanized-powder-rubber and polyvinyl-chloride composite water pipe, the nano-porous carbon is modified through the nanosilicon dioxide and the aluminum isopropoxide, the nano-porous carbon is good in adsorption performance, the nanosilicon dioxide and the aluminum isopropoxide are adsorbed to the surface and the interior of the nano-porous carbon, and therefore the antifouling performance, the heat resistance and the aging resistance of the water pipe are improved.

Owner:蚌埠市燕南塑料制品厂

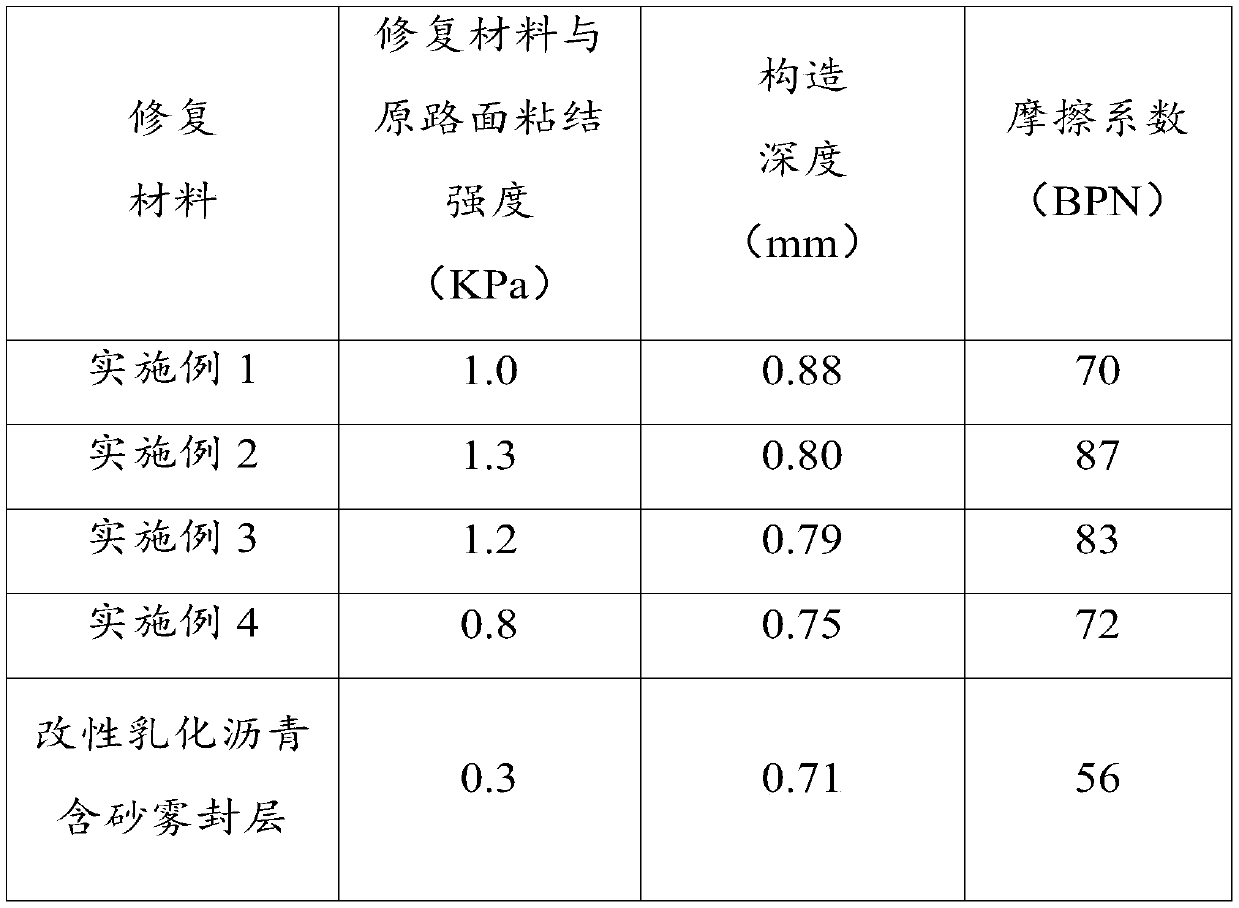

A kind of rapid repair material of millimeter-scale pavement anti-skid surface layer and pavement anti-skid rapid repair method

ActiveCN106348651BGood skid resistance recovery effectImprove flatnessIn situ pavingsEmulsionSurface layer

A millimeter-level pavement antiskid surface rapid repair material and a pavement antiskid rapid repair method are provided; the material is made from, by weight, 6-10 parts of a cementing material and 7-9 parts of wear-resistant aggregate, wherein the cementing material contains 70-85% by weight of waterborne polyurethane emulsion. The repair material has high adhesion with an original pavement under repair, and has the properties such as waterproofness, ultraviolet resistance, and the ability to inhibit aging and bulking of the original pavement; by transferring the cementing material and wear-resistant aggregate in the above material synchronously to a pavement under repair, a millimeter-level ultrathin antiskid surface layer is formed; the method is simple to perform, can provide a shortened construction period, has good repair effect for a pavement, and enables traffic to be normalized within a short time.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Wear-resistant ultrafine-fully-vulcanized-powdered-rubber polyvinyl-chloride composite water pipe and preparation method thereof

The invention discloses a wear-resistant ultrafine-fully-vulcanized-powdered-rubber polyvinyl-chloride composite water pipe. The water pipe is prepared from the following raw materials in parts by weight: 29-30 parts of ultrafine fully-vulcanized powdered rubber, 68-70 parts of PVCSG-3, 2-2.3 parts of zinc oxide nano-wires, 3-3.2 parts of cerium nitrate, 70-80 parts of deionized water, 1.6-1.8 parts of butyl acrylate, 0.2-0.3 part of ammonium persulfate, 0.7-0.9 part of dimolybdenum sulfide, 1.1-1.3 parts of molybdenum trioxide, 1.3-1.5 parts of nano silicon carbide, 0.1-0.2 part of titanate coupling agent, 2.6-2.8 parts of dodecafluoroheptylpropyl trimethoxysilane, 60-70 parts of ethanol and 15-16 parts of ammonia water. According to the water pipe, by using the nano silicon carbide, the dimolybdenum sulfide and the molybdenum trioxide, the dimolybdenum sulfide has good lubricity and fluidity and is used for promoting the homogeneous dispersion of the nano silicon carbide and the molybdenum trioxide in the water pipe, so that the wear resistance of the water pipe is improved.

Owner:蚌埠市燕南塑料制品厂

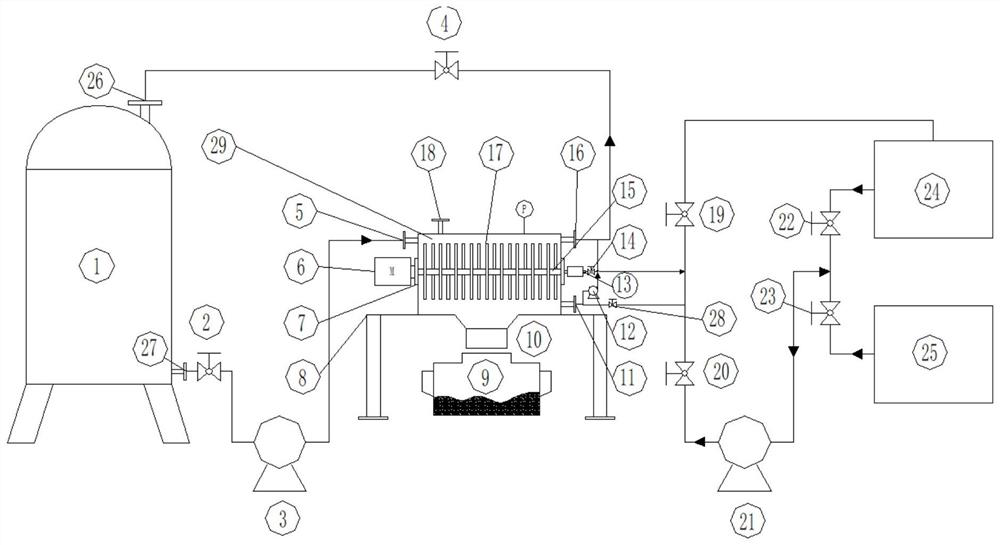

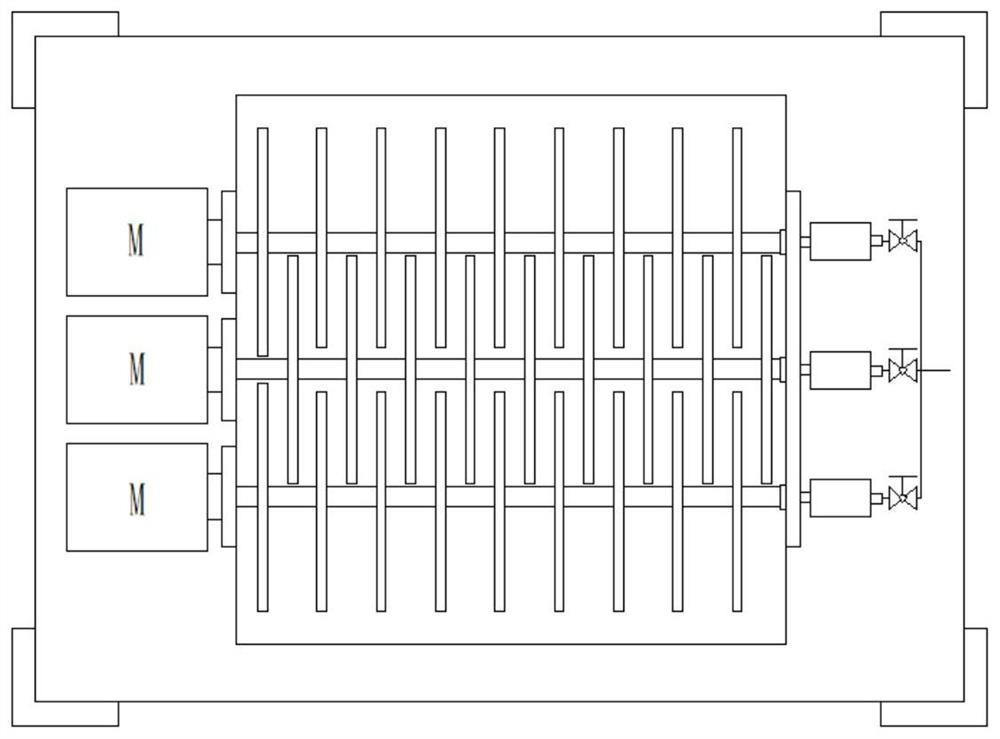

Multi-axis rotating dynamic membrane filtering device with high safety performance and application of multi-axis rotating dynamic membrane filtering device

PendingCN114768532AIncrease membrane fluxAchieve strengthSemi-permeable membranesProcess engineeringRotational axis

The invention relates to a multi-shaft rotating dynamic membrane filtering device with high safety performance and application thereof. The device comprises a transverse multi-shaft rotating dynamic membrane filtering machine, a raw material tank, a cleaning pump, a circulating pump, a filtrate collecting tank, a cleaning liquid tank and a filter residue collecting tank, a plurality of rotating shafts are transversely arranged side by side in the transverse multi-shaft rotating dynamic membrane filter, a plurality of disc-shaped filtering membranes are arranged on each rotating shaft, the disc-shaped filtering membranes of the adjacent rotating shafts are mutually staggered, and each rotating shaft is connected with an independent rotating motor; a feed port, a circulating liquid outlet and a liquid discharge port of the transverse multi-shaft rotating dynamic membrane filter are respectively connected with a discharge port of the raw material tank, a circulating liquid inlet and an outlet of the cleaning pump, meanwhile, the circulating liquid outlet is connected with the liquid discharge port through the circulating pump, and the liquid discharge port is connected with the circulating liquid inlet of the raw material tank; the filtrate outlet is respectively connected with the cleaning pump and the filtrate collecting tank, the residue discharge port is connected with the filter residue collecting tank, and the cleaning liquid tank is connected with the cleaning pump.

Owner:上海化工院环境工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com