Multi-axis rotating dynamic membrane filtering device with high safety performance and application of multi-axis rotating dynamic membrane filtering device

A technology of safety performance and filtration device, which is applied in the field of multi-axis rotating dynamic membrane filtration device, can solve the problems of secondary pollution of membrane surface, limited turbulence effect, reduced membrane permeability and service life, etc., and achieves high membrane flux. , maintain permeability and achieve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

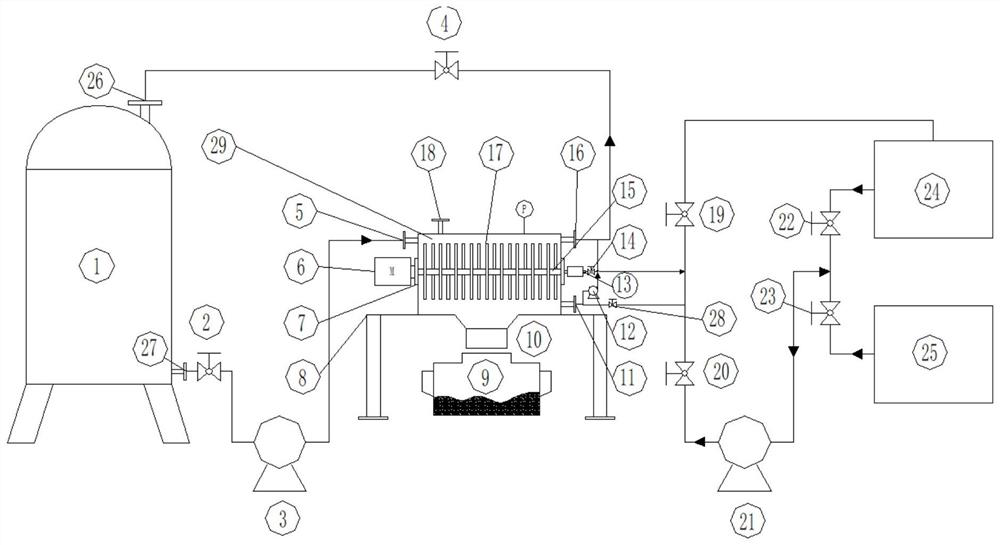

[0082] refer to figure 1 As shown in the figure, a multi-axis rotary dynamic membrane filtration device with high safety performance includes a horizontal multi-axis rotary dynamic membrane filter, a raw material tank 1, a feed pump 3, a cleaning pump 21, a filtrate storage tank 24, a cleaning liquid tank 25, filter residue collection tank 9,

[0083] The transverse multi-axis rotating dynamic membrane filter includes a plurality of rotating shafts 15 arranged inside, each rotating shaft is mounted with a plurality of disc-shaped filter membranes 17, and a plurality of rotating motors 6 are arranged outside the transverse multi-axis rotating dynamic membrane filter. , vibration detection module 7, micro-circulation pump 12, rack 8, feed port 5, circulating liquid outlet 16, vent port 18, flow meter 13, filtrate switch valve 14, liquid discharge port 11 and slag discharge port 10, raw material tank It includes a discharge port 27 and a circulating liquid inlet 26,

[0084] Th...

Embodiment 2

[0099] This embodiment uses a device similar to that in Embodiment 1, but the mode used is terminal filtration, that is, the filter equipment and the raw material tank 1 are not operated in backflow, and the discharge valve 11 is connected to the microcirculation pump 12 and the circulating liquid outlet 16 . This process requires that the feed pump 3 and the micro-circulation pump 12 cooperate with each other to maintain a stable internal pressure of the equipment. details as follows:

[0100] The above-mentioned device was used to conduct the experiment, and the concentration and filtration of PVDF emulsion wastewater with a concentration of 0.1% and a minimum particle size of 0.73 were carried out.

[0101] (1) System preparation

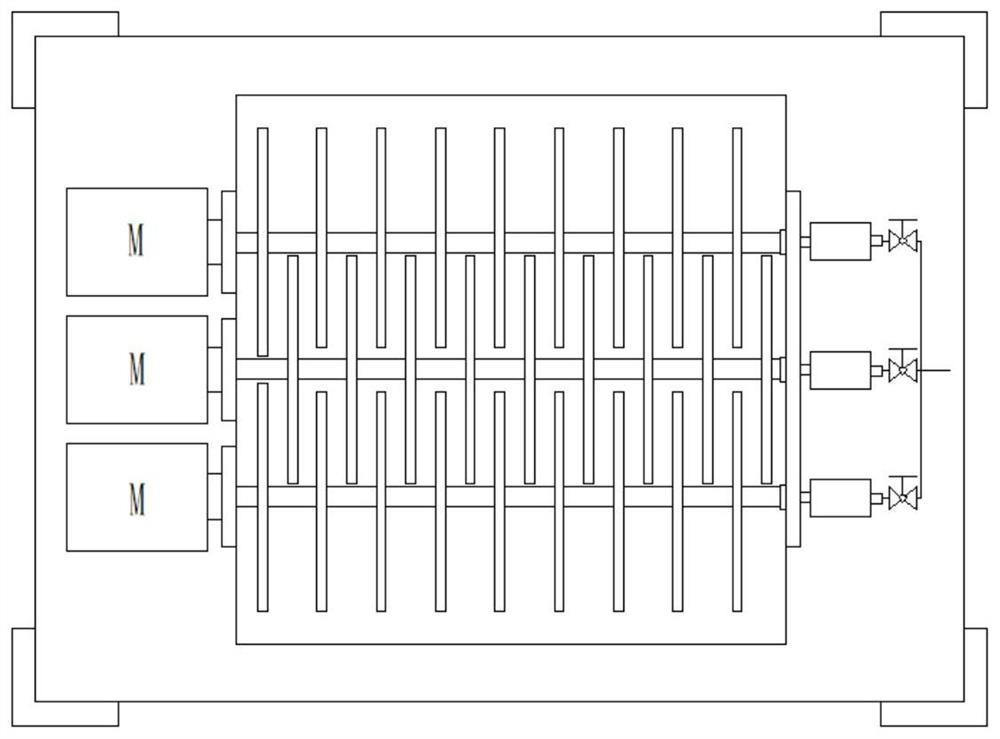

[0102] Add PTFE emulsion waste water material to raw material tank 1, install the ceramic membrane filter medium 17 of 0.5 micron interception precision on the rotating shaft 15, adopt such as figure 2 Install in the manner shown, and then con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com