Preparation method of static-conductive PVC (polyvinyl chloride) mining pipe

A technology of static conduction and PVC resin, which is applied in the field of preparation of static conduction PVC mine pipes, which can solve the problems of uneven resistance distribution of static conduction mine pipes, large amount of carbon nanotubes added, and poor differentiation, and achieve low price , Conducive to cost, improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

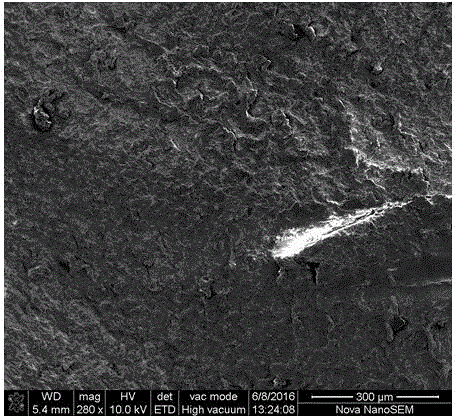

Image

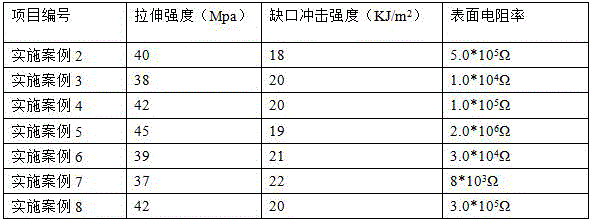

Examples

Embodiment 1

[0030] A preparation method of static-conductive PVC mine pipe, comprising the steps of:

[0031] (1) Add PVC resin and powder nano-carbon material with two-dimensional planar structure into a kneader and knead to obtain PVC / nano-carbon masterbatch; wherein, the nano-carbon material is graphene, few-layer graphene or graphite nano The graphene refers to the graphene powder with 1-2 layers, and the few-layer graphene refers to the graphene powder with 2-10 layers.

[0032] The specific process of this step is: first add PVC resin into the kneader, then add the nano-carbon material into the kneader several times at room temperature for pre-coating kneading, the time of pre-coating kneading is 10min-2h, Then knead at 80-100°C for 1-5 hours to obtain a PVC / nano-carbon masterbatch with a nano-carbon material content of 5%-20%.

[0033] (2) Take 5-15 parts by mass of PVC / nano-carbon masterbatch and add it to the reactor, then add 75-85 parts of PVC resin and 0.5-1.5 parts of conduc...

Embodiment 2

[0036] A preparation method of static-conductive PVC mine pipe, comprising the steps of:

[0037](1) First add a certain quality of PVC resin into the kneader, and then add a certain quality of graphene powder into the kneader three times at room temperature for pre-coating and kneading. The pre-coating and kneading time is 10 minutes. Then kneading at 80° C. for 1 h to obtain a PVC / nano-carbon masterbatch with a graphene content of 5%.

[0038] (2) Take 5 parts by mass of PVC / nano-carbon masterbatch and add it to the reactor, then add 85 parts of PVC resin, 1.5 parts of conductive carbon black, and 5 parts of chlorinated polyethylene to the PVC / nano-carbon masterbatch , 1 part of barium laurate, 0.5 part of stearic acid and 2 parts of acrylic polymer; after adding each component, first stir and mix in the reactor at a rate of 1r / min for 3min, and then at a rate of 300r / min Stir and mix for 5 minutes. When stirring and mixing, control the temperature of the material below 120...

Embodiment 3

[0040] A preparation method of static-conductive PVC mine pipe, comprising the steps of:

[0041] (1) First add a certain quality of PVC resin into the kneader, and then add a certain quality of graphene powder into the kneader four times at room temperature for pre-coating and kneading. The pre-coating and kneading time is 2h , and then kneaded at 100°C for 5h to obtain a PVC / nanocarbon masterbatch with a graphene content of 20%.

[0042] (2) Take 15 parts by mass of PVC / nano-carbon masterbatch and add it to the reactor, then add 75 parts of PVC resin, 0.5 parts of conductive carbon black, methyl methacrylate to the PVC / nano-carbon masterbatch— 1 part of butadiene-styrene copolymer, 5 parts of zinc stearate, 3 parts of glyceryl stearate and 0.5 part of thermoplastic polyurethane; after adding each component, first stir in the reaction kettle at a speed of 300r / min Mix for 5 minutes, then stir and mix at a rate of 2000r / min for 20 minutes. When stirring and mixing, control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com