Pavement structure for orthotropic steel bridge deck plate reinforcing and construction method

A steel bridge deck, orthotropic technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of bridge deck pavement diseases, fatigue cracking of orthotropic steel bridge decks, etc., to prolong the service life and ensure the road surface. The effect of using performance and improving overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

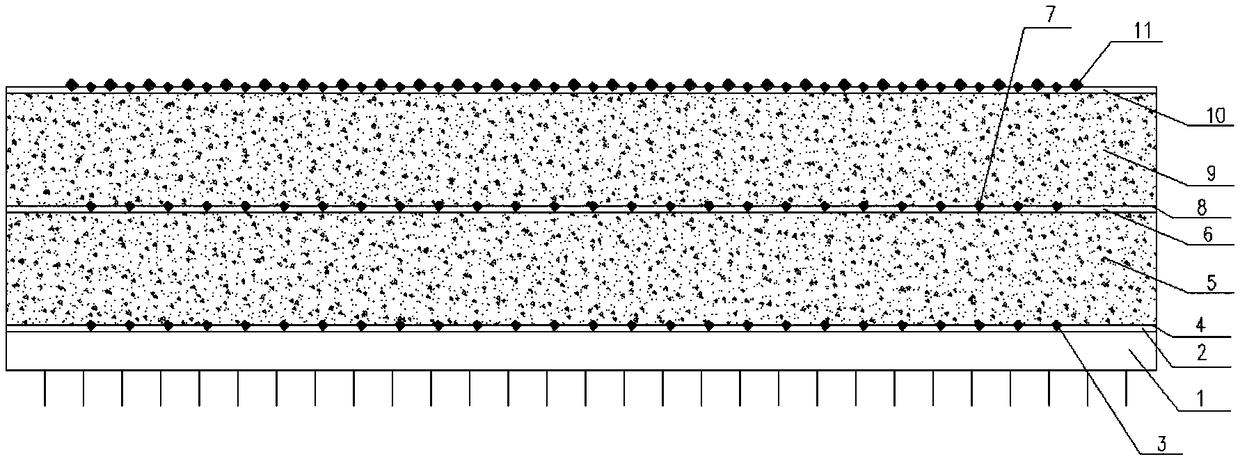

[0035] Such as figure 1As shown, a pavement structure used for reinforcement of orthotropic steel bridge decks, on the surface of the bridge deck steel plate 1, the resin asphalt waterproof and anti-skid adhesive layer, the first resin asphalt adhesive layer 4 are laid sequentially from bottom to top , resin asphalt concrete lower layer 5, resin asphalt waterproof adhesive layer, second resin asphalt adhesive layer 8, resin asphalt concrete upper layer 9, resin asphalt anti-slip overlay; the resin asphalt waterproof and anti-slip adhesive layer It is composed of the first resin asphalt binder 2 spread on the surface of the bridge deck steel plate and the first crushed stone 3 that is densely and evenly spread and embedded in the lower surface of the lower surface of the resin asphalt concrete layer; the resin asphalt waterproof adhesive layer It is composed of the second resin asphalt binder 6 and the second crushed stone material 7 densely and evenly spread and embedded in th...

Embodiment 2

[0041] For the construction method of embodiment one orthotropic steel bridge deck reinforced pavement structure, the specific steps are as follows:

[0042] ① First, mill the asphalt concrete of the old bridge deck, and sandblast and derust the surface of the bridge deck steel plate 1, requiring the cleanliness to reach Sa2.5 level and the roughness to reach 120 μm.

[0043] ②Spray a layer of 1.1kg / m within one hour after the sandblasting and derusting treatment of bridge deck steel plate 1 2 The first resinous asphalt binder 2.

[0044] ③ The 3-5mm diabase / basalt gravel that is evenly spread immediately after the first resin asphalt binder 2 is sprayed is the first crushed stone material 3, and the amount of crushed stone is 3.5kg / ㎡.

[0045] ④ After the first resin asphalt binder 2 is cured for two days, apply 0.5 kg / m2 resin asphalt binder to form the first resin asphalt binder layer 4 .

[0046] ⑤Pave a 3.5cm thick layer of resin asphalt concrete lower layer 5, this lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com