Universal aluminium alloy air-conditioner foil and manufacturing method thereof

A manufacturing method and technology of air-conditioning foil, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of complex production of air-conditioning foil and difficulty in forming a unified one

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

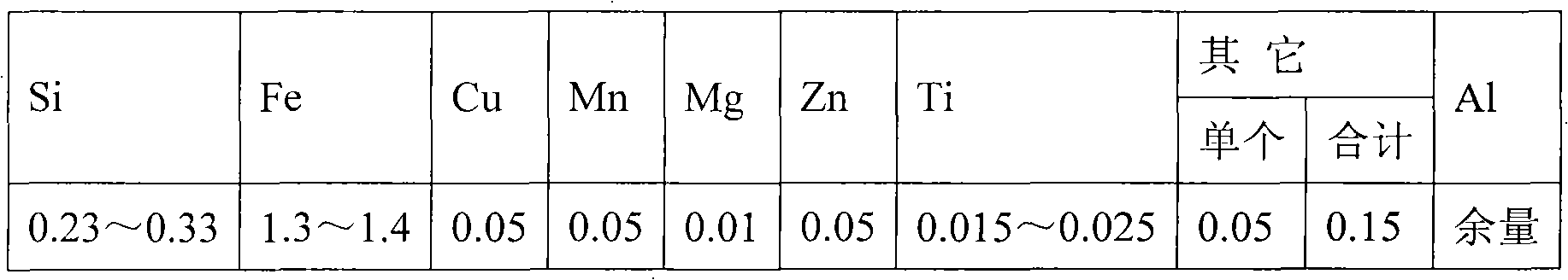

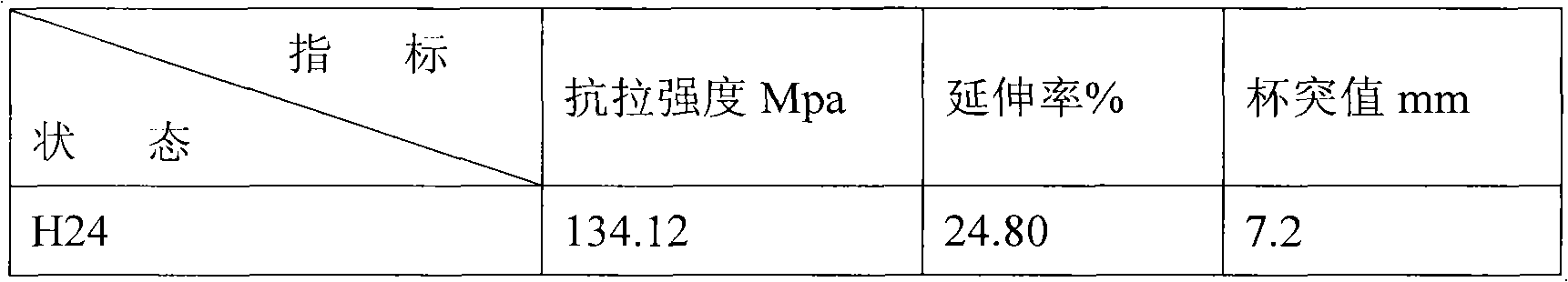

[0020] In the research and development of "full-adaptive air-conditioning foil", the general technical idea is to adjust the synergistic alloying elements and their content in the aluminum matrix to obtain a balance in the mechanical properties or changes in mechanical properties of the air-conditioning foil Effect, so it is suitable for stamping processing of various punching machines.

[0021] In alloyed aluminum foil, the analysis of the role of each alloying element is as follows:

[0022] Fe within a certain range can promote grain refinement, improve structure uniformity and increase strength; Si can improve plasticity and Fe together can effectively reduce the second phase size and grain size in the casting and rolling process; Cu and Mn form a solid solution However, the addition of Cu makes the substrate easy to crack. Although the addition of Mn can refine the grains and strengthen the alloy, it is easy to make the grain size difficult to control in different content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com