Impact-resistant flexible protective material as well as preparation method and application thereof

A flexible protection and impact-resistant technology, applied in offensive equipment, weapon accessories, fuzes, etc., can solve the problems of poor impact resistance of fuzes, and achieve the effects of excellent dynamic mechanical properties, obvious vibration effects, and large stiffness and damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of RIRM materials

[0054] ①According to the RIRM material process flow and the goal of a silicon-boron ratio of 3:1, predetermine the formula and ratio of raw materials; ②Prepare 50g of petroleum ether, 36.6g of diphenylsilanediol, and 13.35g of methyltriethoxy Silane and 5.55g hydroxy silicone oil are placed in the round bottom flask successively;

[0055] ③Add 50mL of distilled water into the round bottom flask, and stir well with a glass rod to obtain the A mixture; ④Heat the A mixture for 4 hours at 80°C oil bath temperature to obtain the B mixture;

[0056] ⑤ Weigh 6.2g of boric acid and add it to the mixed solution of B, and stir with a glass rod to obtain the mixed solution of C after mixing evenly;

[0057] ⑥Heating and reacting the mixed liquid C for 7 hours at an oil bath temperature of 85°C to obtain the mixed liquid D;

[0058] ⑦ Cool the D mixture to room temperature of 25°C, and then wash it with deionized water several times to obtain the...

Embodiment 2

[0067] The SR-RIRM-CNT composite material prepared in Example 1 was cooled to room temperature, and part of the SR-RIRM-CNT composite material was put into a mold, and pressed into a 0.63cm thick, 1.46cm diameter Cylindrical specimens for dynamic mechanical performance analysis;

[0068] The specific method is as follows:

[0069] ①Experimental preparation: Prepare the experimental samples in advance, turn on the power of the instrument and the computer software control interface;

[0070] ② Instrument calibration and sample installation: calibrate the instrument, install the sample and measure its size;

[0071] ③Start the experiment: After completing the setting of the instrument parameters and experimental test parameters, conduct a dynamic mechanical experiment on the sample;

[0072] ④ End the experiment: sort out the experiment platform and analyze the experiment results.

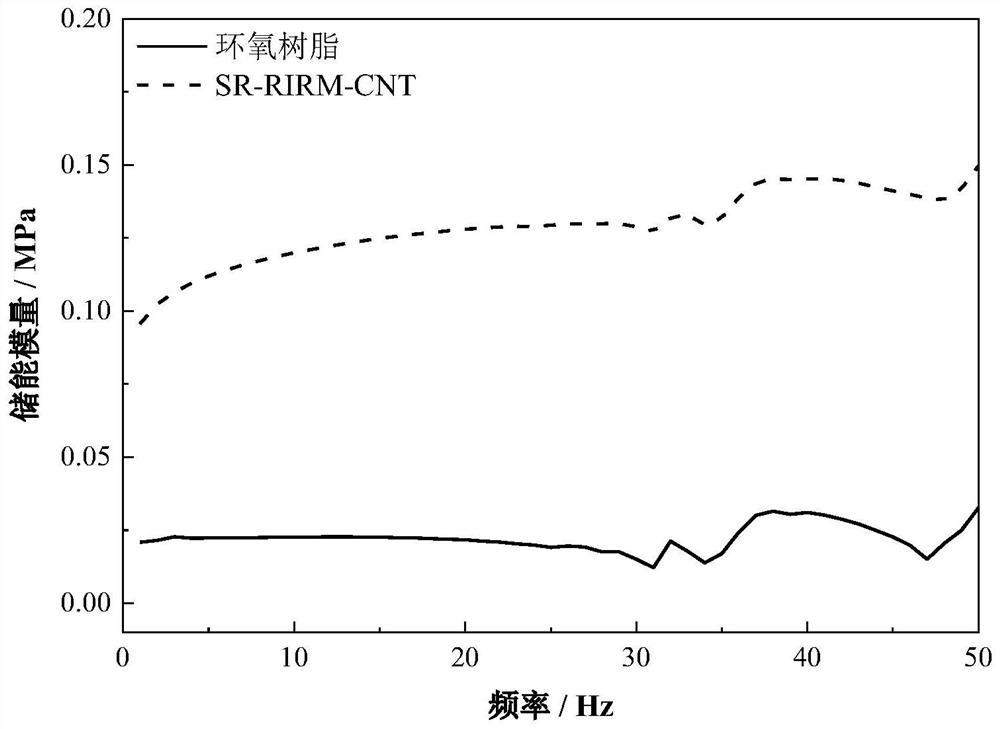

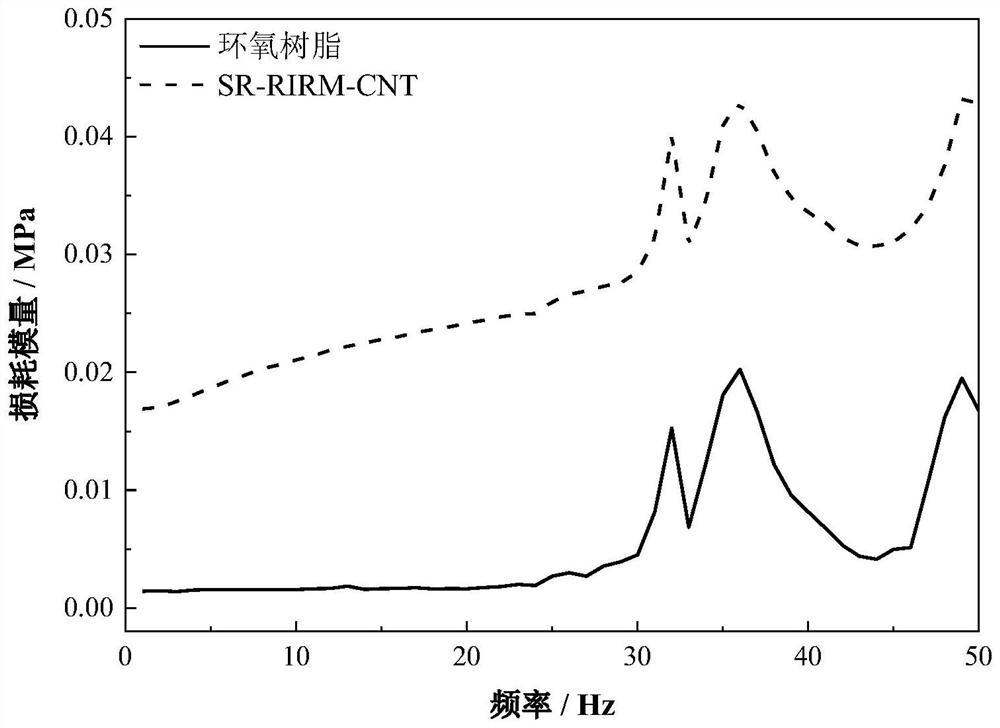

[0073] Storage modulus refers to the energy stored in a material due to elastic deformation und...

Embodiment 3

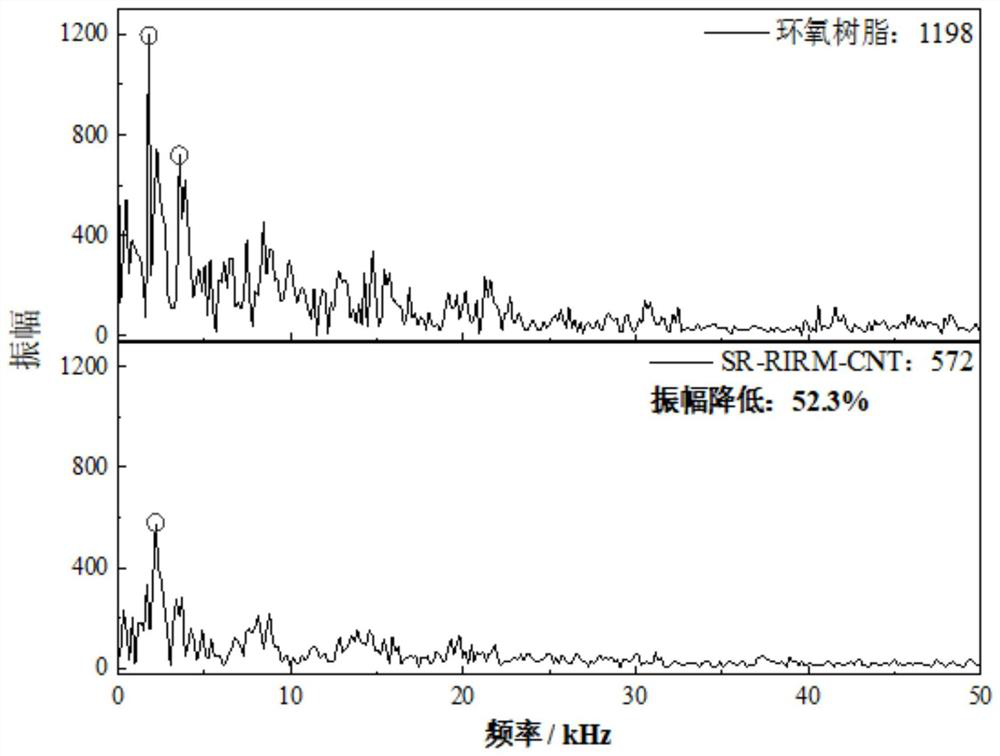

[0075] The SR-RIRM-CNT composite material prepared in Example 1 was filled into the fuze structure for fuze protection, and the shock resistance and vibration suppression performance test was carried out using the shock vibration test platform.

[0076] The specific method is as follows:

[0077] ① Filling the protective material of the fuze: according to the structure of the fuze, pour the protective material to the designated position in the fuze;

[0078] ② Install the acceleration sensor: install the acceleration sensor in the fuze and connect it to the oscilloscope;

[0079] ③Installing the fuze: fix the fuze measuring tool structure, and fix the fuze shell at the tail of the incident rod;

[0080] ④ Prepare the bullet launch system: fill the bullets according to the strike order and push them into the air gun barrel;

[0081] ⑤Installing the energy-absorbing device: install the energy-absorbing buckling cylinder on the energy-absorbing device, and adjust the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com