3D printed diabetic foot insole based on plantar pressure distribution and air permeability and preparation method thereof

A kind of diabetic foot, 3D printing technology, applied in the field of diabetic foot, can solve the problems of aggravating foot edema, poor air permeability, erosion between the toes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method for 3D printing diabetic foot insoles, comprising the steps of:

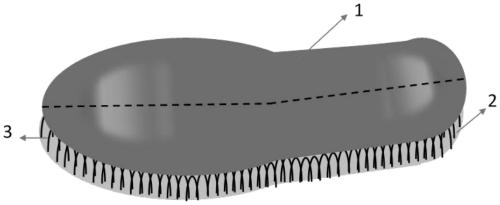

[0046] 1) Perform 3D scanning on the patient's sole, collect medical image data of the patient's foot skeletal-muscular system, and model the patient's foot to obtain the patient's foot model and the shape of the lower insole (2);

[0047] 2) Use the plantar pressure tablet device to collect plantar pressure distribution data when the patient is standing and walking;

[0048] 3) After the patient's foot model is positioned within the insole contour, Boolean operations are performed to simulate the state of compression and deformation of the foot after stepping on the insole, and determine the shape of the upper insole (1) matching the patient's foot;

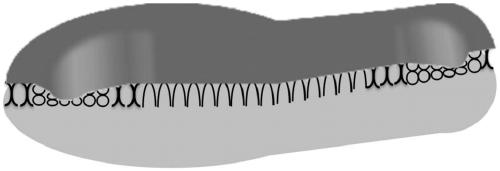

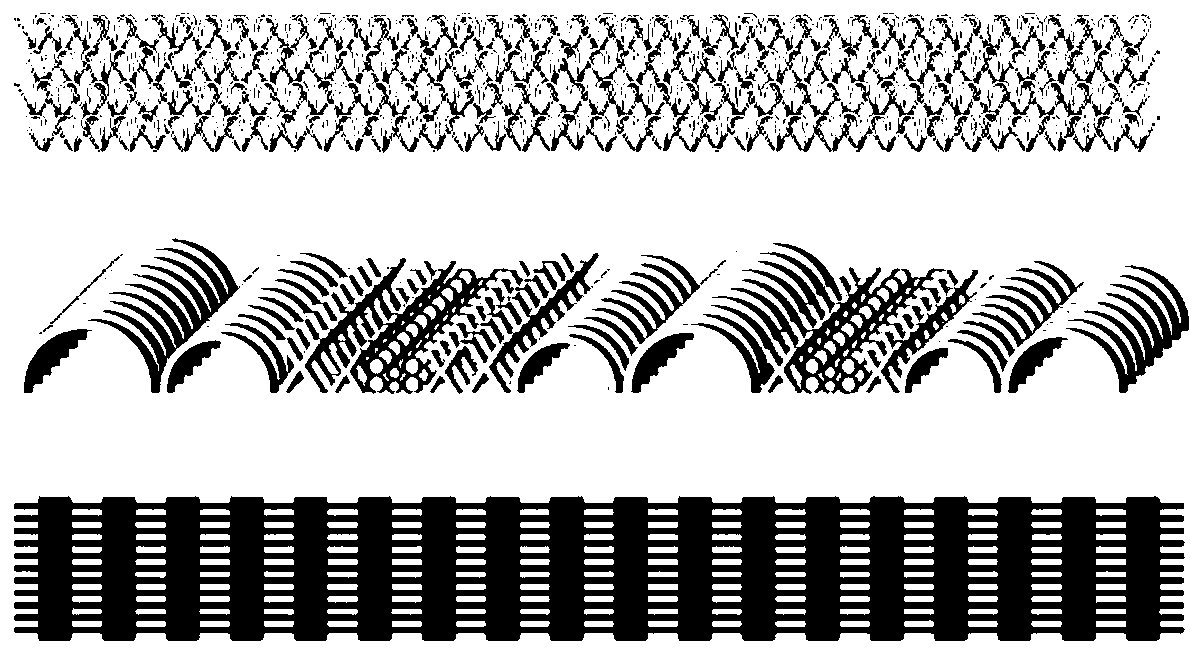

[0049] 4) Import the insole profile and plantar pressure distribution data matching the patient's foot shape, and determine the internal shape and density of each area of the spacer silk layer (3) matching the patient's foot;

[0050...

Embodiment

[0059] The preparation method of the 3D printing diabetic foot insole based on plantar pressure distribution and air permeability of the present invention, its preferred embodiment is:

[0060] 1. Use the Footscan 3D foot shape scanner to collect foot shape data. The insole user stands barefoot and scans, adjusts the position of the feet, keeps the center of gravity balanced and the body upright. Through the software, the foot point cloud data scanned by the scanner is output as a foot model in STL format.

[0061] 2. 3D digital modeling of insoles: the length of the foot, the length of the first metatarsophalange, the length of the fifth metatarsal toe, the inner width of the first metatarsophalange, the outer width of the fifth metatarsophalangeal, and the inner width of the waist fossa obtained from the three-dimensional foot shape scanner The modeling of the last shape of the insole is deduced from indicators such as the outer width of the waist, the width of the toes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com