One-step method production process of ultra-low contract terylene industry fiber

A production process and technology for industrial fibers, applied in the field of industrial fibers, can solve the problems of low production process speed, inability to meet requirements, low production efficiency, etc., and achieve the effects of eliminating internal stress, reducing shrinkage, ensuring stability, and improving drawing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

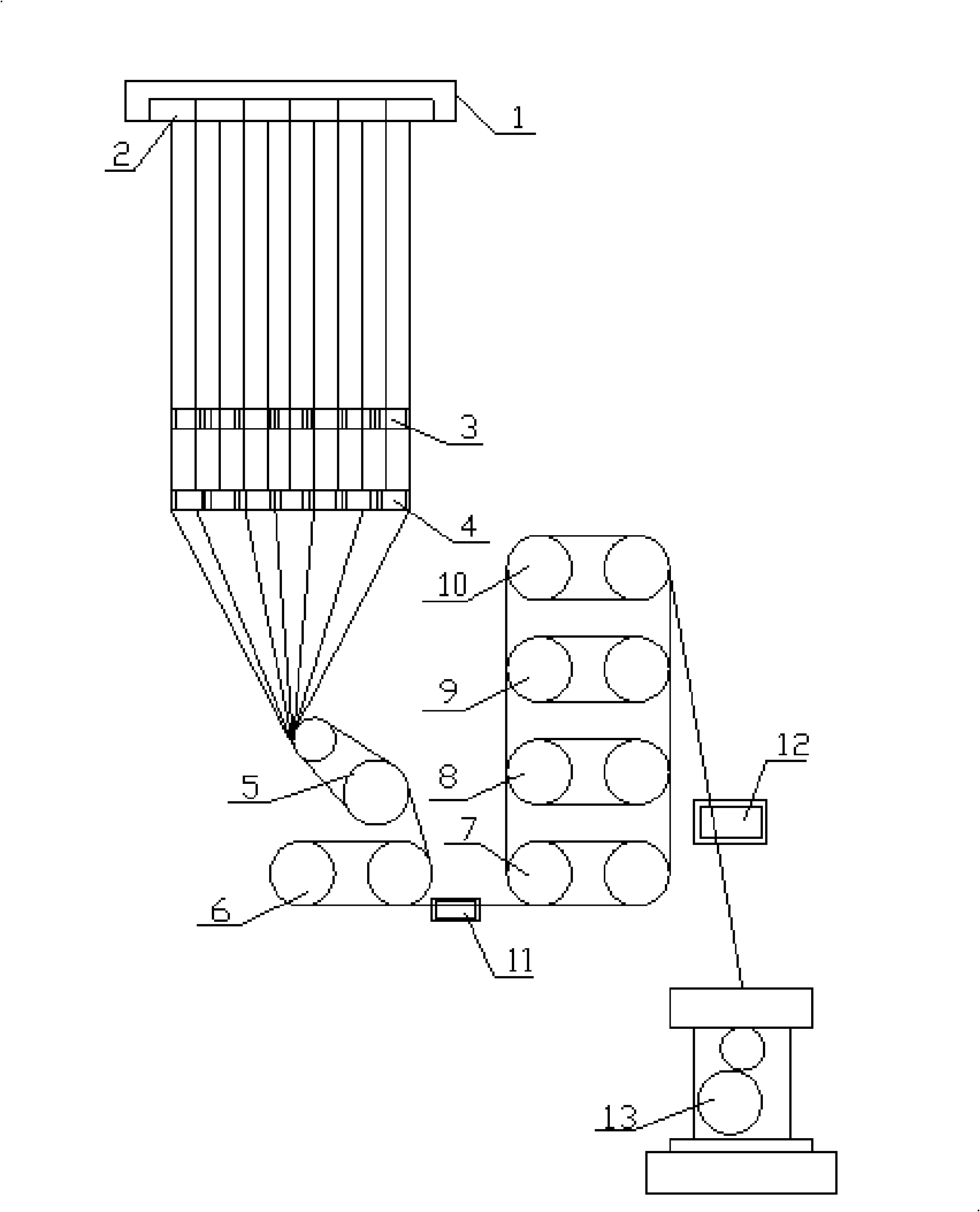

[0026] Concrete embodiment 1 of the present invention: the one-step production process of ultra-low shrinkage polyester industrial fiber of the present invention comprises the following steps:

[0027] A. Preparation of high-viscosity slices: Low-viscosity slices are subjected to solid-state polymerization to obtain high-viscosity slices with a viscosity of 0.99±0.015, control carboxyl content ≤ 16, dust content ≤ 100ppm, moisture content ≤ 40ppm;

[0028] B. Melt spinning: The high-viscosity chips are melted and extruded by the screw extruder to become a high-viscosity melt, which is metered into the spinning box 1 by a metering pump. The pressure before the metering pump is 55-75Bar, and the high-viscosity melt enters The spinning assembly 2 carries out high-pressure spinning with 6 or 12 heads. The filaments are slowly cooled by a slow cooler at a temperature of 300-400°C, cooled by side air blowing, and then formed with a flow viscosity of 20-60mm at 30°C. 2 / s ester smoot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com