One-step high temperature and high pressure melt spinning equipment and production method of polymer fiber

A high temperature and high pressure, melt spinning technology, applied in the direction of melt spinning, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problems of high melt viscosity and poor fluidity, and achieve high crystallinity, operation Convenience and stable spinning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

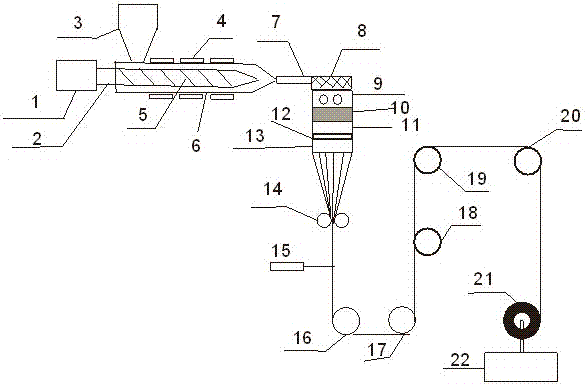

[0022] see figure 1 , a one-step high temperature and high pressure melt spinning equipment, the spinning equipment includes a driving device, an extruder system, and a spinning device. The drive device includes a drive motor 1 and a deceleration device 2. The extruder system includes an extruder screw 5, a barrel 6, a feeding hopper 3, an electric heater 4 and an extruder head 7. A feeding hopper 3 and an electric heater 4 are arranged on the barrel of the extruder. One end of the extruder screw 5 is connected to the drive motor 1 through a deceleration device 2, and the other end is matched with the extruder head 7. The spinning equipment It also includes a filter device 8, a metering pump 9, a spinning box 10 and a spinning assembly 11. The spinning device is followed by a filter device 8, a metering pump 9, a spinning box 10, a spinning assembly 11, and a spinneret. 12. Slow cooling device 13, multifilament bundling device 14, oiling device 15, guide device 16, yarn separ...

Embodiment 2

[0024] see figure 1, as an improvement of the present invention, the spinning equipment also includes a stainless steel melt filter 8 , which is installed between the extruder head 7 and the metering pump 9 . The stainless steel filter 8 can remove gel and mechanical impurities from the polymer melt. The rest of the structure and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0026] see figure 1 , as an improvement of the present invention, the guide device includes a guide roller 16 and a spinning roller 17, the drafting device includes a first drafting roller 18, a second drafting roller 19 and a third drafting roller 20, The second drafting roll 19 is arranged between the first drafting roll 18 and the third drafting roll 20 . The drafting device gradually draws the raw filaments at different temperatures to increase the drafting ratio and the degree of molecular orientation of the fibers, thereby improving the properties of the fibers and avoiding the uneven orientation of the fibers or the breakage of the virgin yarns caused by excessive drafting ratios at one time. The prior art generally cannot directly draw high-performance polymer virgin yarns in-line. The rest of the structure and advantages are exactly the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com