Heat-resistant impregnated synthetic fiber canvas and formula of impregnating adhesive solution needed by impregnation process

A technology of synthetic fiber and impregnation process, applied in the field of formula of impregnating glue, can solve the problem of severe shrinkage of canvas, and achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

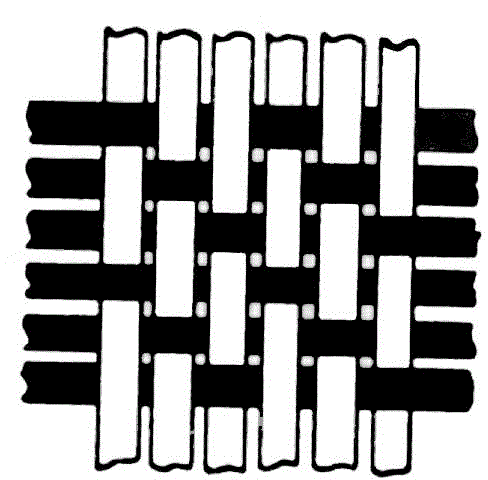

Image

Examples

Embodiment 1

[0020] This embodiment provides a heat-resistant dipping synthetic fiber canvas, including warp yarns and weft yarns. Cloth is machine woven into fabric and treated through a dipping process.

[0021] The linear density of the warp yarn is 1100dtex, the warp yarn is twisted from 4 strands of low-shrinkage activated polyester industrial filament, the linear density of the weft yarn is 930dtex, and the weft yarn is 2 strands of high-strength polyadipyl adipamide The amine fiber is twisted, the density of the warp yarn is 13.4 / cm, and the density of the weft yarn is 5.2 / cm.

[0022] A formula for impregnating glue required for a heat-resistant dipping synthetic fiber canvas dipping process, the formula for said impregnating glue includes a first bath formula and a second bath formula, and the formula is as follows in parts by weight:

[0023] A first bath recipe includes the following:

[0024] The formula of the isocyanate solution is: 538 parts of soft water, 105 parts of iso...

Embodiment 2

[0033] This embodiment provides a heat-resistant dipped synthetic fiber canvas, including warp yarns and weft yarns, the warp yarns are low-shrinkage activated polyester industrial filaments, the weft yarns are high-strength polyhexamethylene adipamide fibers, and the warp yarns and weft yarns are passed through the weaving Woven into fabric and treated through a dipping process.

[0034] The linear density of the warp yarn is 1100dtex, the warp yarn is twisted from 4 strands of low-shrinkage activated polyester industrial filament, the linear density of the weft yarn is 930dtex, and the weft yarn is 2 strands of high-strength polyadipyl adipamide The amine fiber is twisted, the density of the warp yarn is 13.4 / cm, and the density of the weft yarn is 5.2 / cm.

[0035] A formula for impregnating glue required for a heat-resistant dipping synthetic fiber canvas dipping process, the formula for said impregnating glue includes a first bath formula and a second bath formula, and the...

Embodiment 3

[0046] This embodiment provides a heat-resistant dipped synthetic fiber canvas, including warp yarns and weft yarns, the warp yarns are low-shrinkage activated polyester industrial filaments, the weft yarns are high-strength polyhexamethylene adipamide fibers, and the warp yarns and weft yarns are passed through the weaving Woven into fabric and treated through a dipping process.

[0047] The linear density of the warp yarn is 1100dtex, the warp yarn is twisted from 4 strands of low-shrinkage activated polyester industrial filament, the linear density of the weft yarn is 930dtex, and the weft yarn is 2 strands of high-strength polyadipyl adipamide The amine fiber is twisted, the density of the warp yarn is 13.4 / cm, and the density of the weft yarn is 5.2 / cm.

[0048] A formula for impregnating glue required for a heat-resistant dipping synthetic fiber canvas dipping process, the formula for said impregnating glue includes a first bath formula and a second bath formula, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com