Production method of special polyester staple fiber for high-strength medium-elongation nonwoven fabric

A technology of polyester staple fiber and production method, which is applied in the field of chemical fiber production, can solve the problems of reducing elongation at break, low dry heat shrinkage, loss of breaking strength, etc., so as to increase the elongation at break and reduce the dry heat shrinkage. , the effect of reducing thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to a production method of polyester staple fibers specially used for high-strength medium-stretch non-woven fabrics. Described method mainly comprises following technological process:

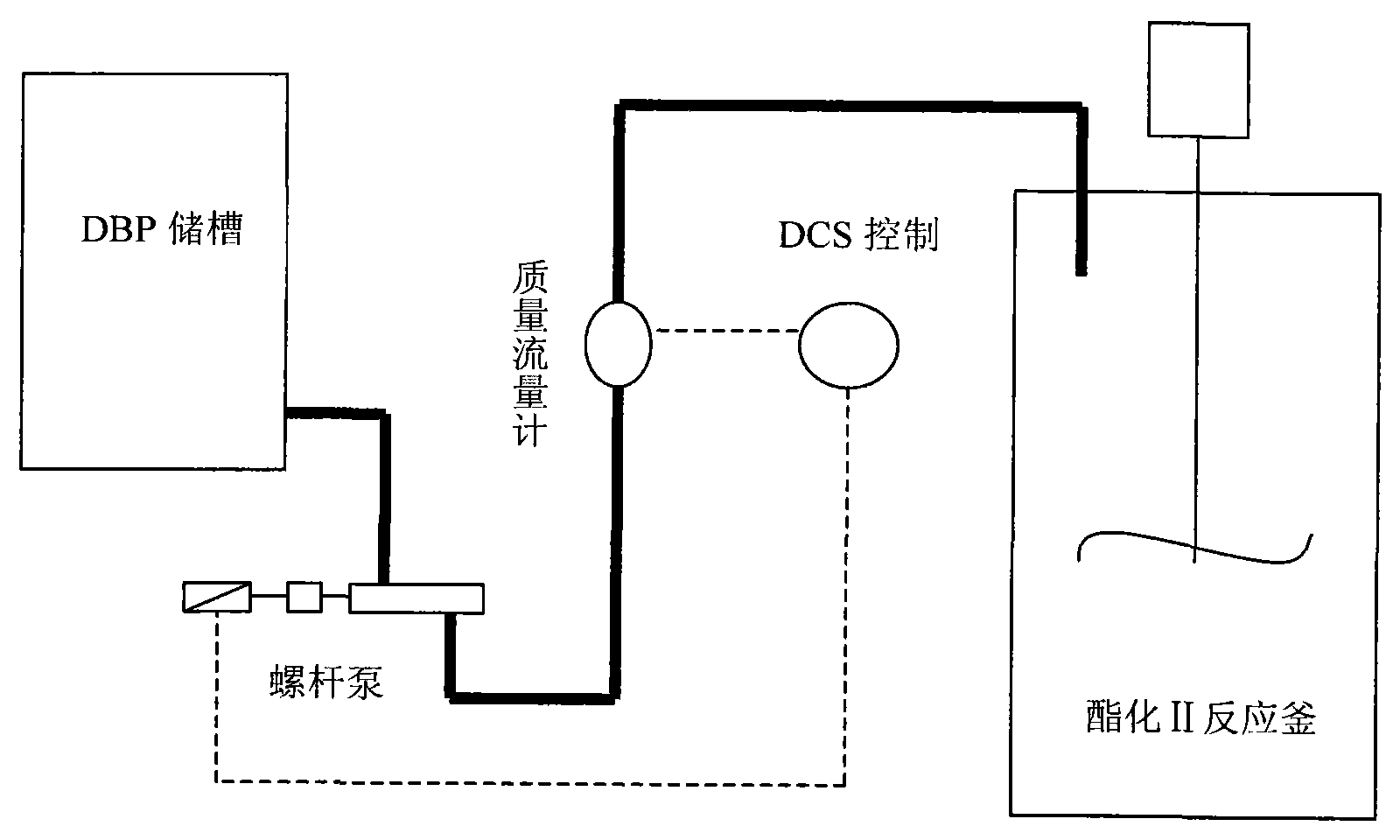

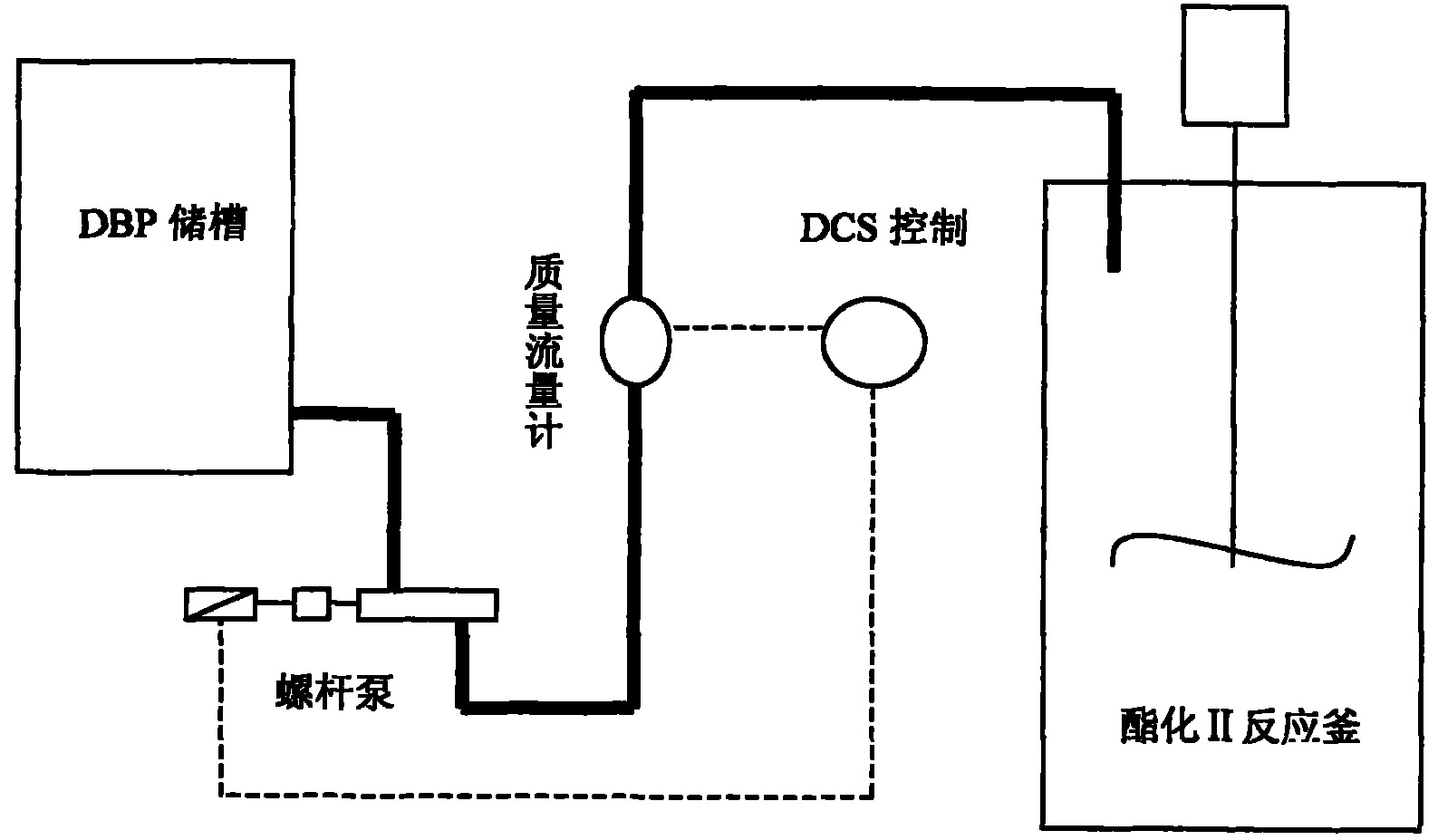

[0018] After mixing and stirring the raw materials terephthalic acid and ethylene glycol according to a certain ratio (molar ratio 1:1.6~1.7), they first enter the primary esterification reactor (reaction temperature 260~275°C, time 1~2 hours) and the secondary esterification reactor (reaction temperature 265-280°C, time 1-2 hours) for esterification, and then enter the primary polycondensation reactor (reaction temperature 270-285°C, time 1-2 hours), and the secondary The polycondensation reactor (reaction temperature 270-285°C, time 1-2 hours) and the final polycondensation reactor (reaction temperature 280-290°C, time 2-3 hours) carry out polycondensation reaction, and the produced polyester melt is spun , cooling, winding, silk filling, clustering, drafting, te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com