Preparation method of composite functional fresh-keeping paper based material with enhanced slow release function

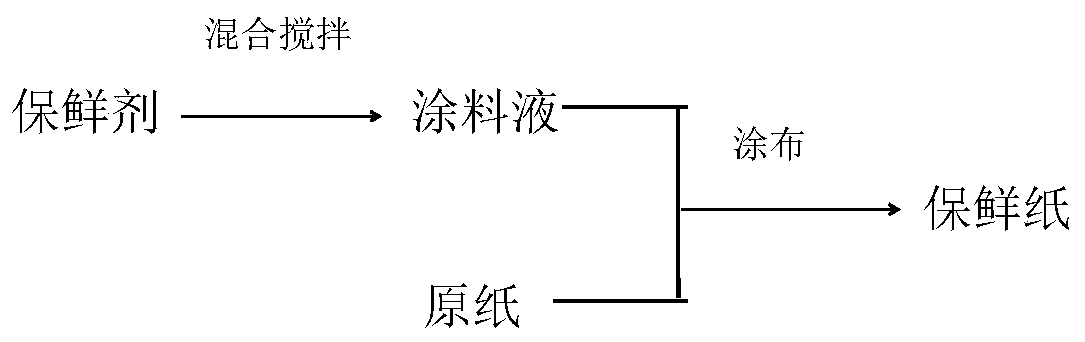

A base material and fresh-keeping paper technology, applied in the field of packaging paper, can solve the problems of uneven distribution of antifungal agents and easy loss of active ingredients, and achieve the effects of prolonging the storage period of fruits and vegetables, enhancing the slow-release effect, and protecting active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

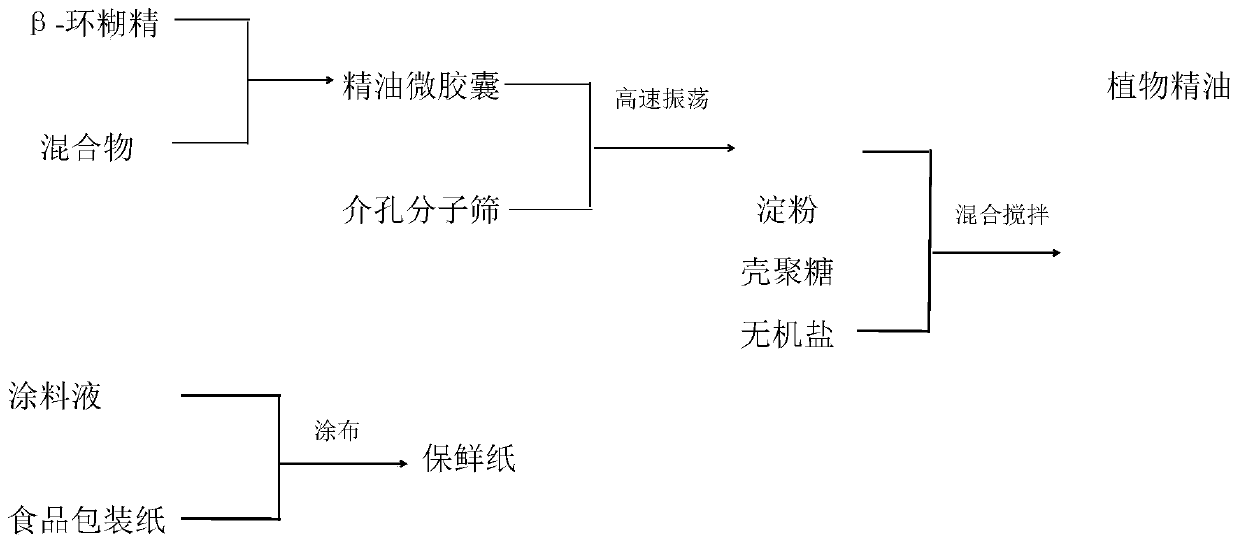

[0033] (1) Weigh 100g of β-cyclodextrin, dissolve it in 400ml of deionized water and stir thoroughly to prepare a saturated cyclodextrin aqueous solution. Then weigh 7g of cinnamon essential oil and 3g of peppermint essential oil, and dissolve them in 100g of absolute ethanol at a mass ratio of 1:10 to obtain an essential oil solution. Slowly pour 50g of essential oil solution into 250g of saturated cyclodextrin solution at a uniform speed, stir at 45°C for 4h, take it out, cool to room temperature, and put it in a refrigerator at 4°C for 24h. After taking it out, vacuum filter it, dry it in a 50°C drying oven to constant weight, and the obtained white powdery substance is the essential oil microcapsule;

[0034] (2) Mix 5 g of essential oil microcapsules and 5 g of mesoporous molecular sieves according to a mass ratio of 1:1, add 90 g of water, and vibrate at a high speed of 800 rpm for 10 minutes to prepare molecular sieves loaded with essential oil microcapsules;

[0035](...

Embodiment 2

[0040] (1) Weigh 100 g of β-cyclodextrin, dissolve it in 450 ml of deionized water and stir thoroughly to prepare a saturated cyclodextrin aqueous solution. Then weigh 5g of cinnamon essential oil and 5g of clove essential oil and mix them, and dissolve them in 150g of absolute ethanol at a mass ratio of 1:15 to obtain an essential oil solution. Slowly pour 50g of essential oil solution into 300g of saturated cyclodextrin solution at a uniform speed, stir at 50°C for 5h, take it out, cool to room temperature, and put it in a refrigerator at 4°C for 36h. After taking it out, vacuum filter it, dry it in a 60°C drying oven to constant weight, and the white powdery substance obtained is the essential oil microcapsule;

[0041] (2) Mix 6.7g of essential oil microcapsules and 3.3g of mesoporous molecular sieve according to the mass ratio of 2:1, add 90g of water, shake at a high speed of 900rpm for 12min, and prepare the molecular sieve loaded with essential oil microcapsules;

[0...

Embodiment 3

[0047] (1) Weigh 100 g of β-cyclodextrin, dissolve it in 500 ml of deionized water and stir thoroughly to prepare a saturated cyclodextrin aqueous solution. Then weigh 4g of cinnamon essential oil, 3g of oregano essential oil and 3g of tea tree essential oil and mix them, and dissolve them in 100g of absolute ethanol at a mass ratio of 1:10. Slowly pour 50g of essential oil solution into 350g of saturated cyclodextrin solution at a uniform speed, stir at 45°C for 6h, take it out, cool to room temperature, and put it in a refrigerator at 4°C for 24h. After taking it out, vacuum filter it, dry it in a 50°C drying oven to constant weight, and the obtained white powdery substance is the essential oil microcapsule;

[0048] (2) Mix 6 g of essential oil microcapsules and 4 g of mesoporous molecular sieves according to the mass ratio of 3:2, add 90 g of water, shake at a high speed of 1000 rpm for 15 minutes, and obtain molecular sieves loaded with essential oil microcapsules;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com