Patents

Literature

443 results about "Di n butyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl phthalate (C16H22O4), or DBP, is an odorless and colorless to faint yellow oily liquid; the molecular weight is 278.35 g/mol. Dibutyl phthalate is also known as di-n-butyl phthalate. Dibutyl phthalate has various industrial uses; it is used to make flexible plastics that are found in a variety of consumer products.

Anti-skid sole material

The invention relates to the field of a formula for a sole material, especially to an anti-skid sole material. The anti-skid sole material comprises, by mass, 30 to 40 parts of butadiene rubber, 10 to 20 parts of butadiene-acrylonitrile rubber, 5 to 8 parts of white carbon black, 1 to 2 parts of magnesium oxide, 3 to 4 parts of stearic acid, 2 to 5 parts of polyethylene glycol, 1 to 2 parts of zinc oxide, 1 to 2 parts of machine oil, 5 to 7 parts of dibutyl phthalate, 0.5 to 1.3 parts of an antioxidant and 0.8 to 2.4 parts of an activator. The anti-skid sole material has a wet antiskid coefficient of 0.8 and a wet antiskid coefficient of 0.6; and the antiskid performance of the sole material is improved, so safety in usage of the sole material is guaranteed.

Owner:TONGXIANG YIYUAN SHOES

Diamond resin grinding wheel and preparation method thereof

ActiveCN102814759ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesIron powderHeat resistance

The invention discloses a diamond resin grinding wheel and a preparation method of the diamond resin grinding wheel. The diamond corundum resin grinding wheel is prepared from the following components by weight, 50-60 parts of diamond grinding material, 10-20 parts of silicon carbide powder, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of dibutyl phthalate, 5-10 parts of nano fluorite powder, 5-10 parts of fungacetin, 2-5 parts of black manganese ore and 2-5 parts of scrap iron powder. According to the diamond resin grinding wheel, as the ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, cracks formed by rigid grinding are reduced, and the use efficiency and service life of the resin grinding wheel are improved further; in addition, as the iron power is added, fast heat dissipation effect is achieved, a great deal of heat generated in the cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is lowered.

Owner:安徽威铭耐磨材料有限公司

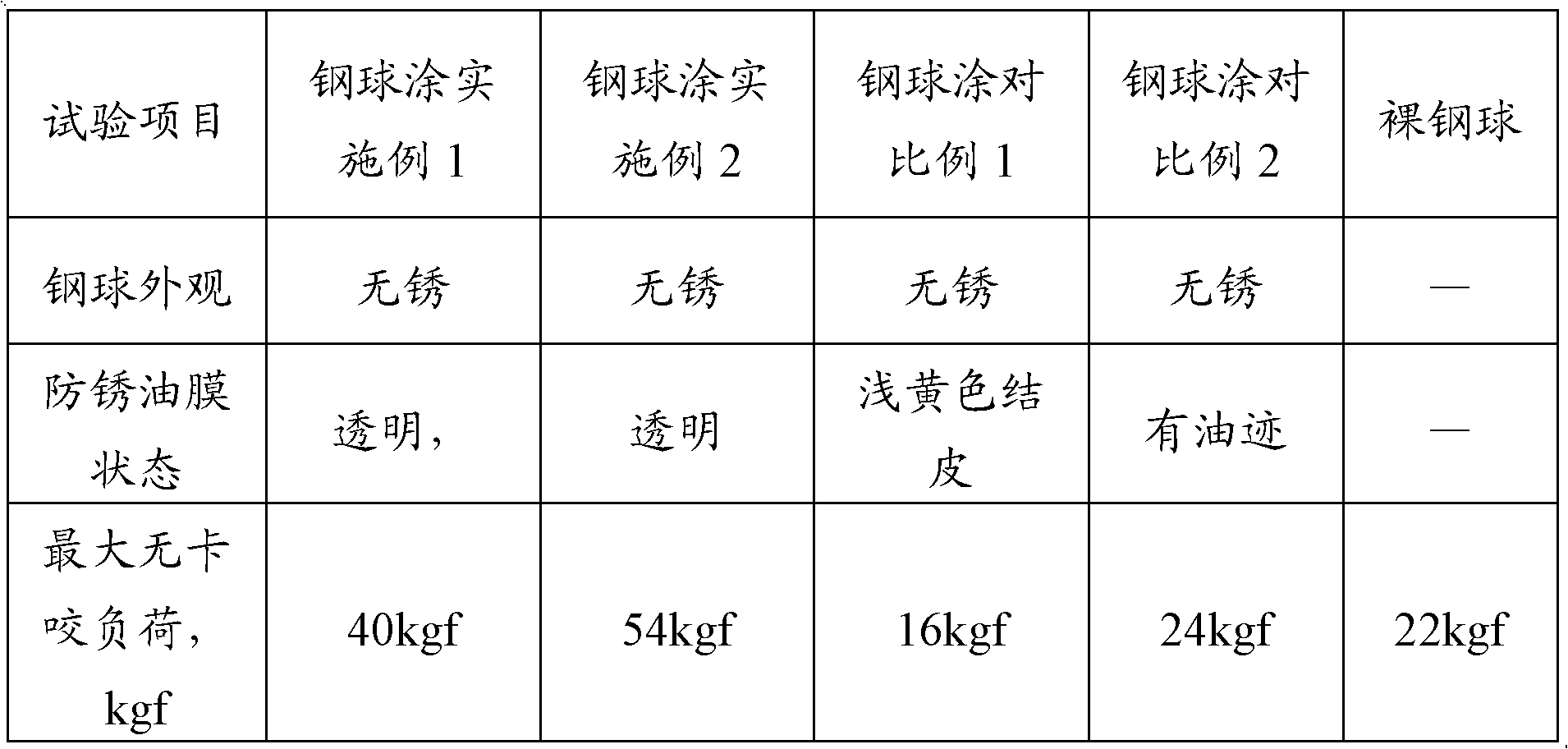

Antirust oil and preparation method thereof

The invention provides antirust oil, which comprises the following components in percentage by weight: 75 to 87.5 percent of base oil, 1 to 3 percent of complex ester, 4 to 10 percent of barium petroleum sulfonate, 2 to 6 percent of barium dinonyl sulfonate, 0.5 to 1.5 percent of dodecylene succinic acid, 0.3 to 0.8 percent of benzotriazole and 3 to 6 percent of di-n-butyl phthalate, wherein the complex ester is obtained by reacting raw materials comprising polyalcohol and dicarboxylic acid. The antirust oil provided by the invention has the advantages of oil-film antirust oil and soft-film antirust oil and long antirust time. A workpiece coated with the antirust oil can be directly put into use without being cleaned or being provided with an additional lubricating additive. The antirust oil can be applied to long-term rusting protection of metal workpieces, such as internal surface rusting protection of engines, gearboxes and pumps.

Owner:KASONG SCI & TECH

Polymer cement based composite waterproof coating material for construction and its preparation

InactiveCN1472259AMake up for lack of flexibilityCompensation for re-swelling of polymer emulsion filmAntifouling/underwater paintsPaints with biocidesPliabilityPropanediol

A composite water-proof cement-base polymer paint for building is composed of the organic liquid (component A) prepared from acrylate emulsion, siloxane emulsion, dibutyl phthalate, propanediol, sodium tripolyphosphate, and tributyl phosphate, and the inorganic powder (component B) prepared from silicate cement, talk powder and pigment. Said two components are proportionally mixing before it is used. Its advantages are better elasticity and flexibility, high adhesion, and no environmental pollution.

Owner:TONGJI UNIV

Manufacture method of white latex

ActiveCN102250564AGood for full aggregationReduce volatilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDi n butyl phthalatePolyvinyl acetate

The invention discloses a manufacture method of white latex, which is composed of the following raw materials and components: 40-50 parts of poly(vinyl acetate), 3-6 parts of poly(vinyl alcohol), 3-5 parts of dibutyl phthalate, 0.5-2 parts of octanol, 0.1-0.5 part of ammonium persulfate and 40-50 parts of water. The manufacture method comprises: dissolving dibutyl phthalate in octanol, dissolving poly(vinyl acetate) in a 66-69 DEG C poly(vinyl alcohol) solution, mixing the above two solutions, then adding ammonium persulfate, and carrying out emulsion polymerization. In the manufacture method, non-toxic, odorless and non-corrosive poly(vinyl acetate) is used to replace toxic and irritant vinyl acetate, so that the white latex is safer and more healthy for human bodies and is a pollution-free environmentally-friendly product.

Owner:淮安奥正网络科技有限公司

Fire-resistant rubber

Owner:山东中一橡胶有限公司

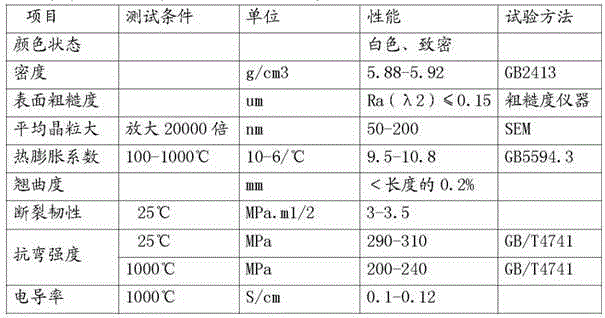

Coating preparation method for flakey aluminum oxide ceramic

The invention provides a coating preparation method for flakey aluminum oxide ceramic, which comprises the following steps of: providing 60-70wt% of alumina powder material, 15-25wt% of organic solvent, 0.61-2.92wt% of cosolvent, 0.4-1.5wt% of dispersing agent, 3.0-5.0wt% of binding agent and 2.0-6.0wt% of plasticizer, wherein the organic solvent adopts a binary azeotropy mixing organic solvent system, such as isopropanol and ethyl acetate; two dispersing agents are adopted, such as castor oil and polycarboxylic acid; the binding agent adopts two different polyvinyl butyral (PVB) with a short molecular chain and a short molecular chain; and the plasticizer adopts polyethylene glycol (PEG) and dibutyl phthalate (DBP). The flakey aluminum oxide ceramic prepared with the coating preparation method disclosed by the invention has the advantages of good evenness and surface quality and small thickness size fluctuation, and the quality requirement of a subsequent printing circuit can be satisfied.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

Coating preparation method for flaky zirconium oxide ceramic

The invention provides a coating preparation method for flaky zirconium oxide ceramic. According to the method, 60 to 65 mass percent of zirconium oxide ceramic powder, 20 to 25 mass percent of organic solvent, 1.2 to 1.8 mass percent of dispersant, 4.0 to 6.0 mass percent of adhesive, and 2.5 to 7.0 mass percent of plasticizer are provided. The organic solvent is a binary azeotropic mixed organic solvent system such as butanone and ethanol; the dispersant comprises fish oil and oleic acid; the adhesive comprises two kinds of different polyvinyl butyral (PVB) with long and short molecular chains; and the plasticizer comprises polyethylene glycol (PEG) and dibutyl phthalate (DBP). The flaky zirconium oxide ceramic prepared by adopting the method is high in flatness and surface quality and low in thickness fluctuation, and can meet the quality requirement of subsequent processing.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

Epoxy resin adhesive

InactiveCN102850981AHigh strengthGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyGreen environment

The invention provides an epoxy resin adhesive, which comprises the following components, by weight, 35-45 parts of an epoxy resin, 4-6 parts of diethylenetriamine, and 6-8 parts of dibutyl phthalate. The epoxy resin adhesive of the present invention has the following technical effects that: a high strength can be achieved after curing at a room temperature three days, an adhesion effect is good, and green environment protection is provided.

Owner:NANTONG HONGYU CHEM

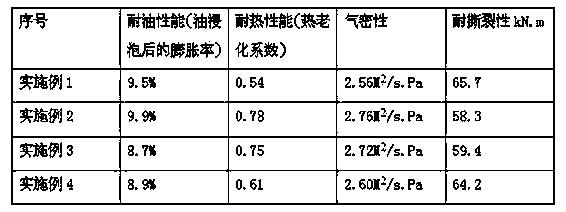

Oil-resistant rubber

The invention belongs to the field of rubber, and particularly relates to an oil-resistant rubber. The oil-resistant rubber comprises the following components in parts by weight: 80-200 parts of epichlorohydrin rubber, 50-200 parts of fluorinated silicone rubber, 2-10 parts of nano zinc oxide, 1-4 parts of stearic acid, 15-50 parts of carbon black N100, 2-5 parts of paraffin, 4-15 parts of coumarone resin, 2-10 parts of sulfur, 1-5 parts of an antiager, 1-8 parts of calcium carbonate, 1-6 parts of hydroxy silicone oil, 1-5 parts of hydrosilicone oil, 1-5 parts of white carbon black, 1-5 parts of dimethyl silicone oil, 1-4 parts of dibutlyl phthalate, 1-4 parts of zinc diethyl dithiocarbamaate and 1-4 parts of 2-imidazolidinethione. The invention has the benefits that the oil-resistant rubber prepared by the formula has the advantages of good oil resistance, high temperature resistance, corrosion resistance and the like and can effectively meet the requirements in production life.

Owner:山东中一橡胶有限公司

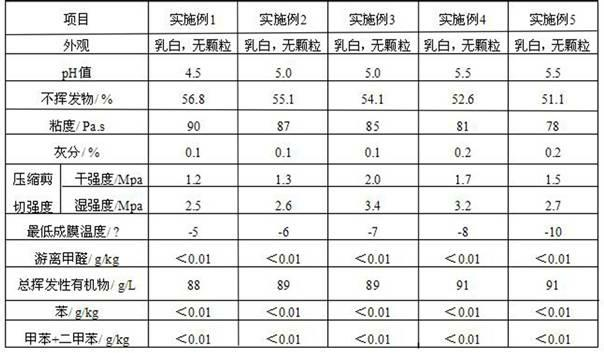

EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and preparation method thereof

ActiveCN101928529AHigh affinityWide operating temperature rangeMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesPolymer scienceDi n butyl phthalate

The invention discloses an EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and a preparation method thereof, belonging to the field of water-based adhesives. The invention adopts the technical scheme that an EVA emulsion is modified by utilizing a rosin tackifying resin emulsion and a polyurethane emulsion together to prepare the EVA emulsion all-purpose adhesive. The all-purpose adhesive comprises the following components in parts by weight: 65-80 parts of EVA emulsion, 5-15 parts of rosin tackifying resin emulsion, 5-15 parts of polyurethane emulsion and the balance of auxiliary agent, wherein the auxiliary agent comprises an antifreeze agent, a plasticizer, a mildew-proof agent, a wetting agent and a pH regulator. When making, the preparation method comprises the following steps of: adding the EVA emulsion to a dispersion kettle with a stirrer, and uniformly stirring; adding the polyurethane emulsion, and stirring and mixing for 1.0-1.5h; then adding the rosin tackifying resin emulsion, the plasticizer of dibutyl phthalate, the antifreeze agent of glycol, the mildew-proof agent of Kathon and the wetting agent, and stirring and uniformly mixing; adding the pH regulator, such as ammonia water or triethylamine to regulate pH value to be 4.5-5.5, and filtering and discharging. The obtained all-purpose adhesive has indexes which reach or exceed common white latexes, convenient use and wide applicability, and can be widely used for architectural decoration, furniture making, cases, and the like and used at normal temperature but also at the low temperature from 5 DEG C to 5 DEG C below zero.

Owner:东莞市山力高分子材料科研有限公司

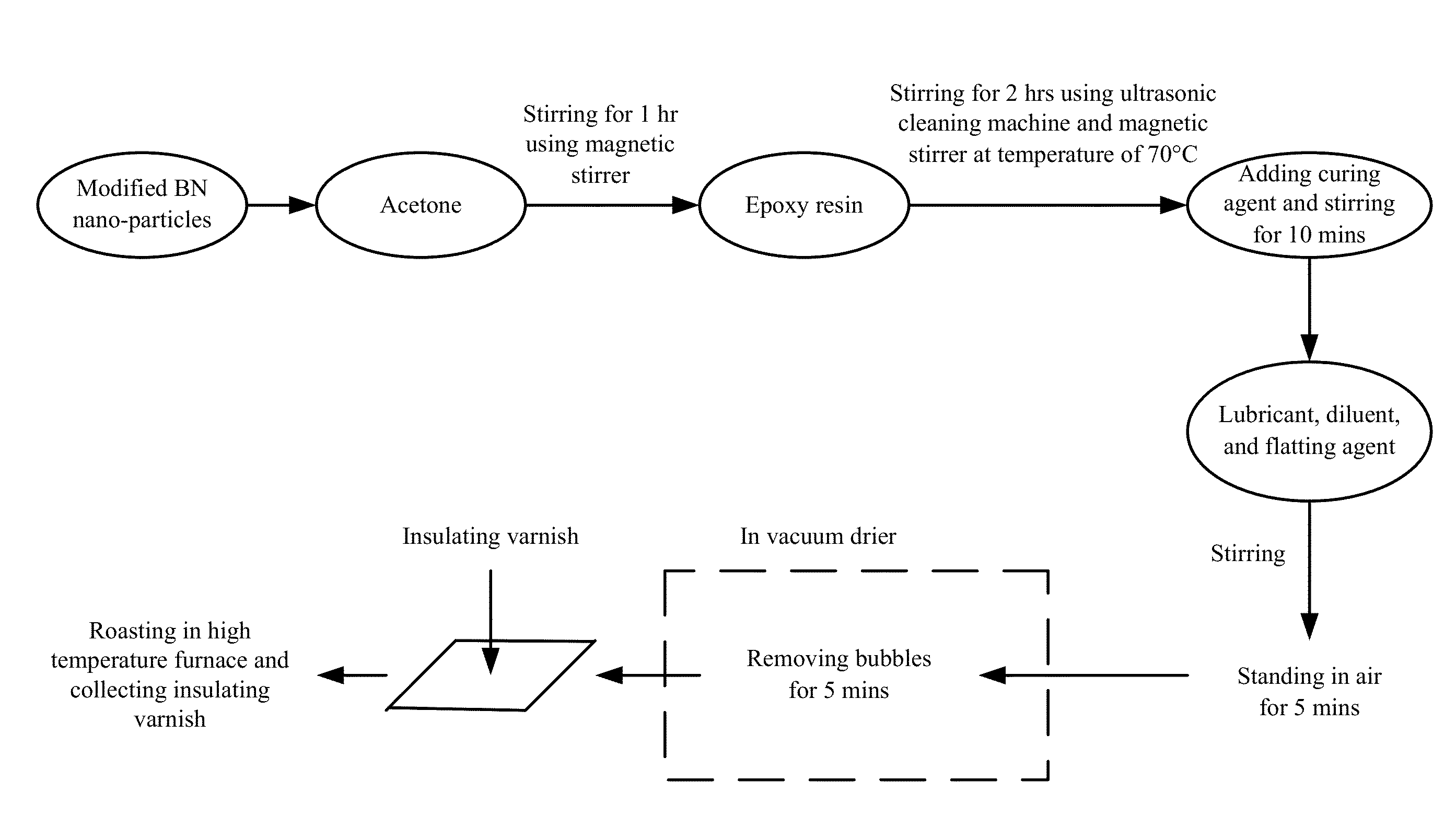

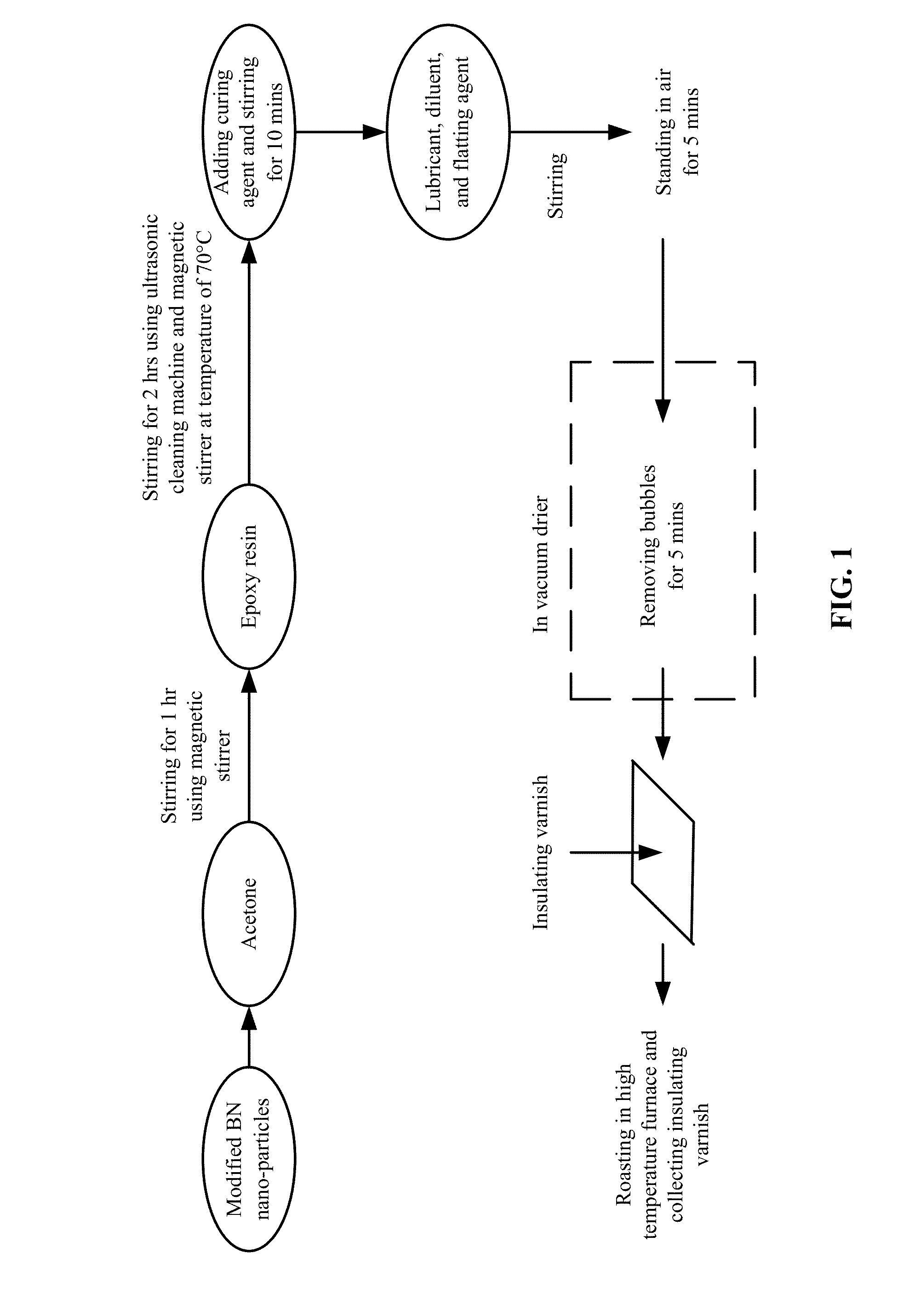

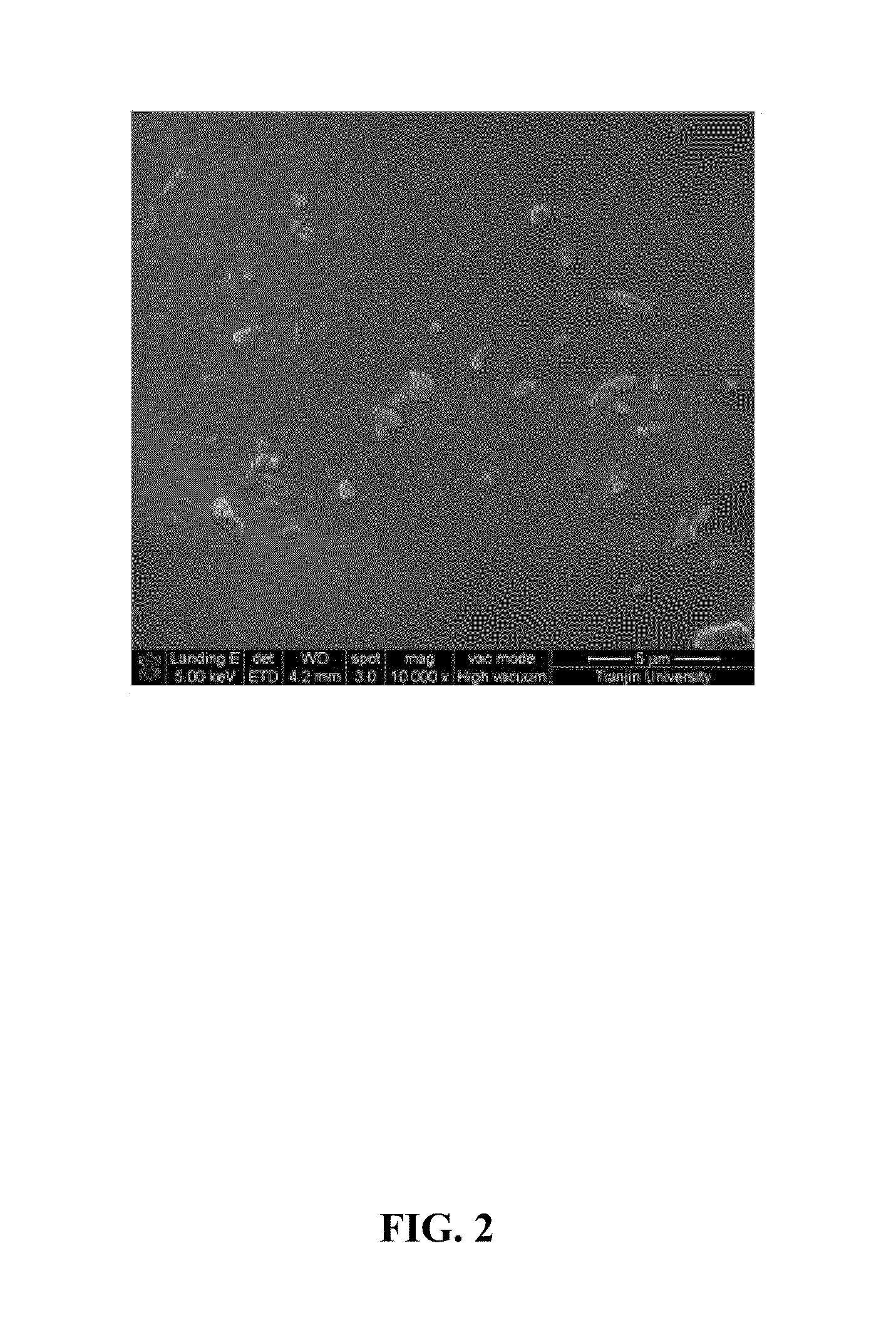

Method for preparing insulating varnish

ActiveUS20140045972A1High practicabilityImprove thermal conductivityShaking/oscillating/vibrating mixersPlastic/resin/waxes insulatorsEpoxyDi n butyl phthalate

A method for preparing an insulating varnish. The method includes: providing equivalence of an epoxy resin solution having a concentration exceeding 99 wt. % and acetone solution having a concentration of 40 wt. %, adding silane coupling agent-modified hexagonal boron nitride (BN) having a particle size of between 200 and 250 nm to the acetone solution and stirring; mixing the epoxy resin solution and the acetone solution and stirring, and dispersing the resulting mixture; adding to the mixture, low molecular weight polyamide resins as a curing agent, and stirring to uniformly disperse the curing agent; adding n-butane as a lubricant to the mixture and stirring, cooling the mixture to room temperature, adding di-n-butyl phthalate as a diluent to the mixture and stirring; and allowing the mixture to stand in a vacuum drier to remove bubbles to yield the insulating varnish, which is free of bubbles.

Owner:TIANJIN JINGWEI HUIKAI OPTOELECTRONICS CO LTD

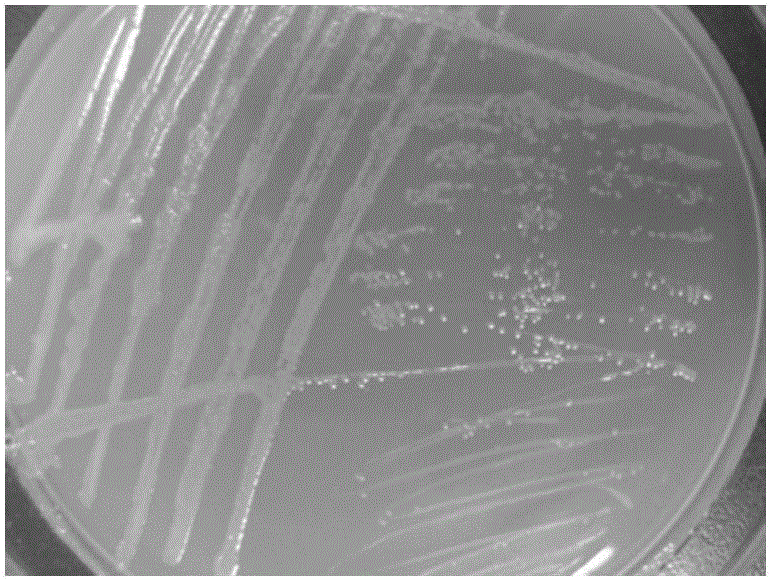

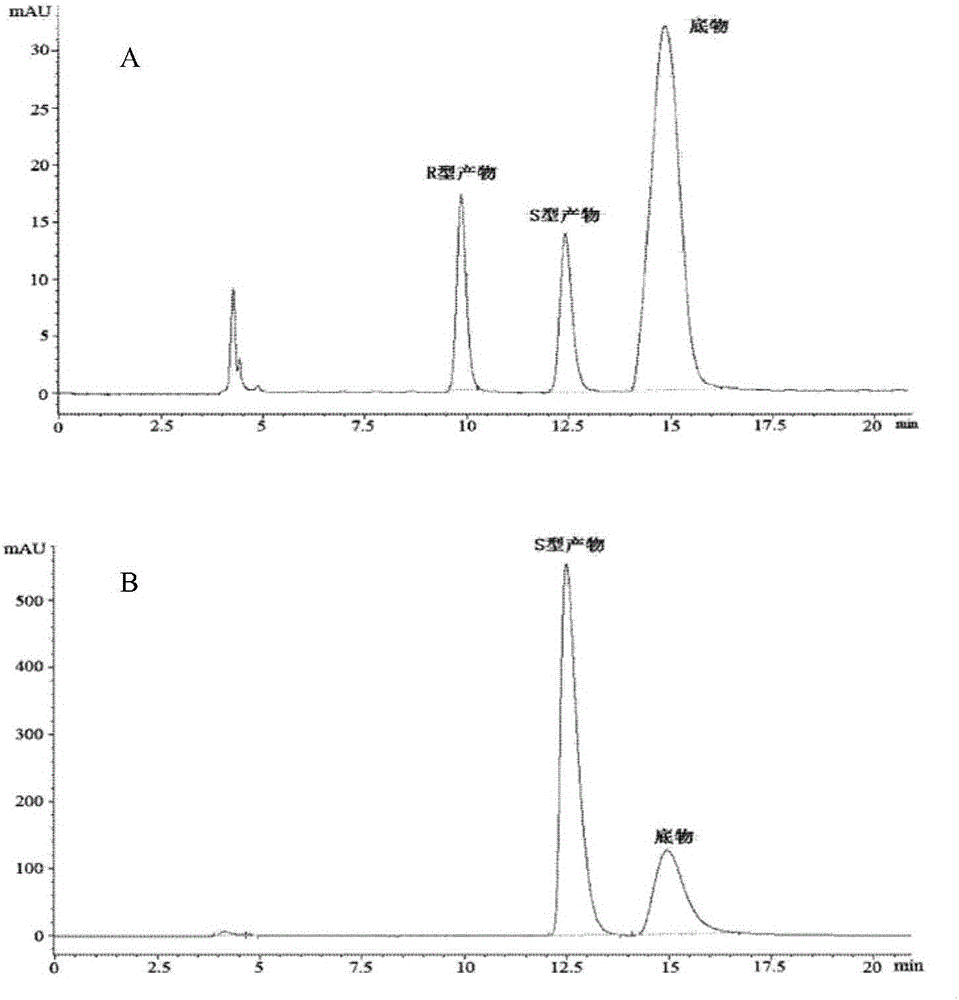

Pseudomonas aeruginosa ZJPH1504 and application thereof in preparation of sitagliptin chiral intermediate

InactiveCN105925506AHigh optical purityHigh catalytic efficiencyBacteriaMicroorganism based processesSitagliptinDi n butyl phthalate

The invention discloses a pseudomonas aeruginosa ZJPH1504 and an application of pseudomonas aeruginosa ZJPH1504 in preparation of a sitagliptin chiral intermediate. The pseudomonas aeruginosa ZJPH1504 can be used for asymmetric reduction of a prochiral ketone compound (II) with high stereoselectivity to prepare a sitagliptin chiral intermediate (I-a) compound, the product prepared by using the pseudomonas aeruginosa ZJPH1504 is high in optical purity, and the e.e. (Errors Excepted) value is greater than 99.9%, 9g / L of a substrate is added in a phosphate buffer solution system of which the pH is 7.5, and reacted for 30 hours, and the yield of an S-reduction product is 60.2%. When an organic solvent is added in a reaction system, the catalytic efficiency can be effectively improved, the reaction yield can be increased, and the reaction time can be shortened, especially when di-n-butyl phthalate is added in the reaction system, the reaction yield can be increased to 75.6%, the reaction time can be shortened to 24 hours and the e.e. value is greater than 99.9%.

Owner:ZHEJIANG UNIV OF TECH

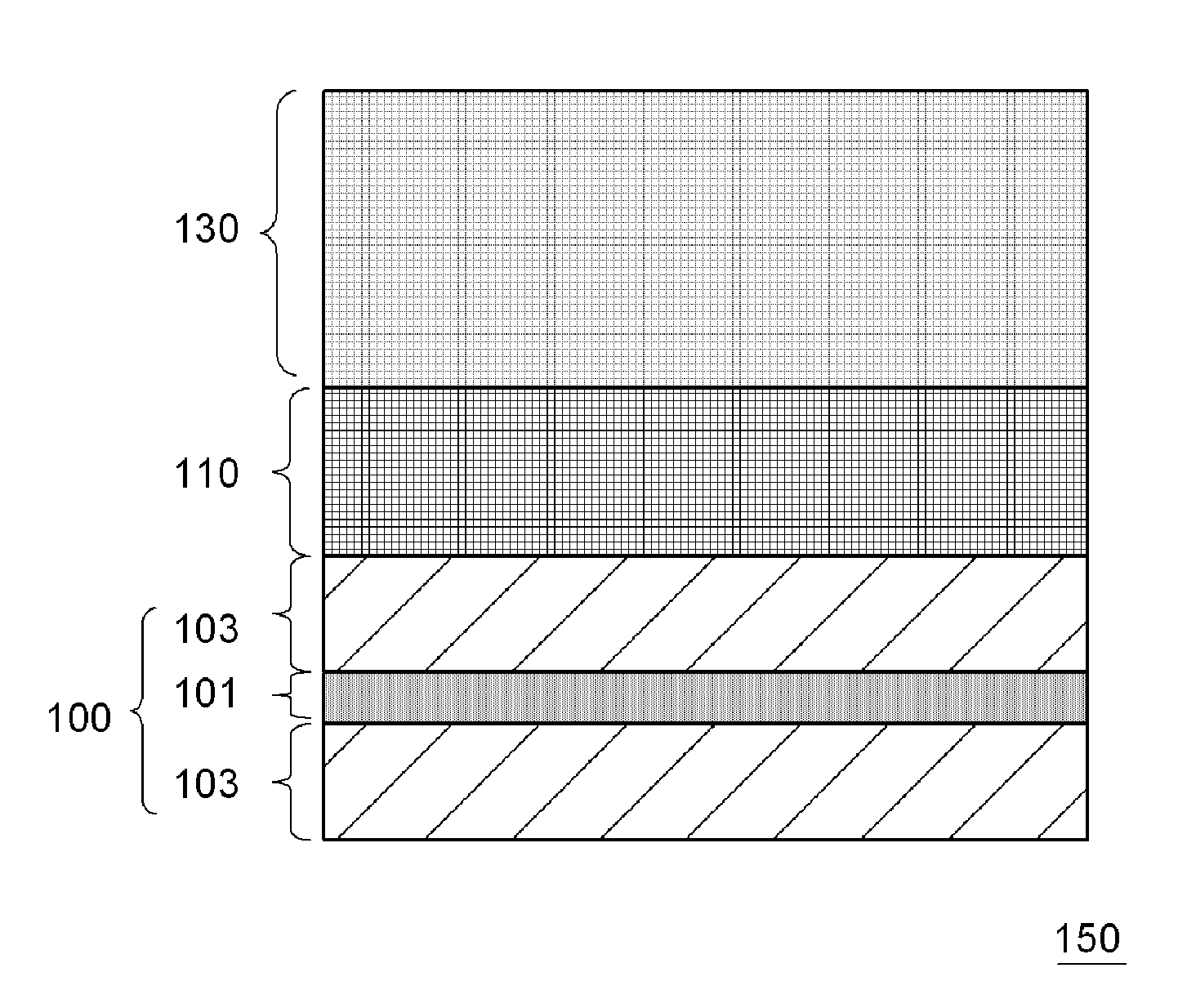

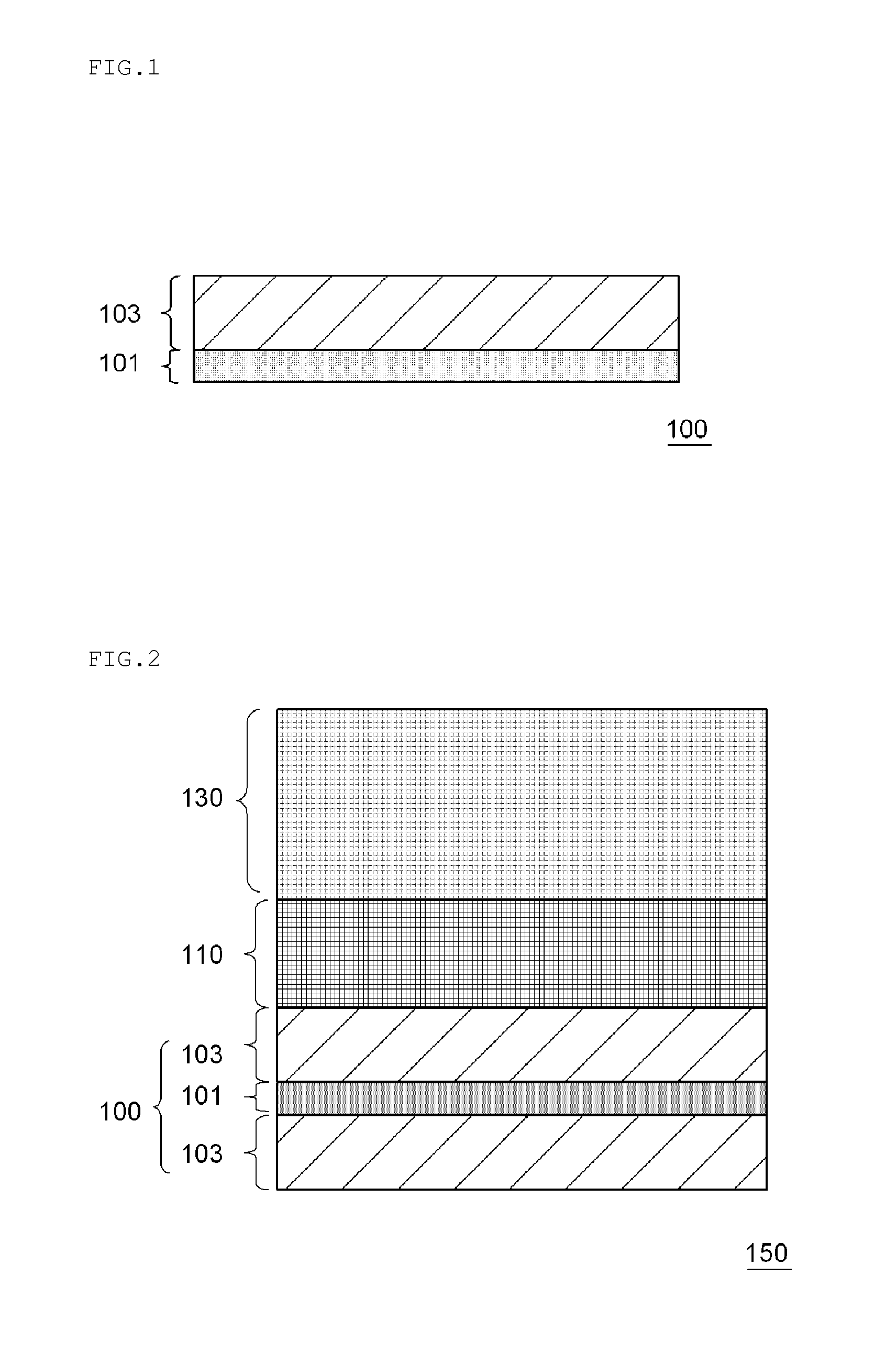

Negative electrode for lithium ion secondary battery, negative electrode slurry for lithium ion secondary battery, and lithium ion secondary battery

A negative electrode for a lithium ion secondary battery according to the present invention includes a negative electrode active material and a binder, in which the negative electrode active material satisfies the following requirements (A), (B), and (C):(A) graphite powder is used as a core material, and at least a part of a surface of the graphite powder is coated with a carbon material having lower crystallinity than the graphite powder;(B) a specific surface area measured using a nitrogen adsorption BET method is more than or equal to 0.8 m2 / g and less than or equal to 5.3 m2 / g; and(C) an amount of dibutyl phthalate absorption measured according to JIS K 6217-4 is more than or equal to 32 cm3 / 100 g and less than or equal to 45 cm3 / 100 g.

Owner:NEC ENERGY DEVICES LTD

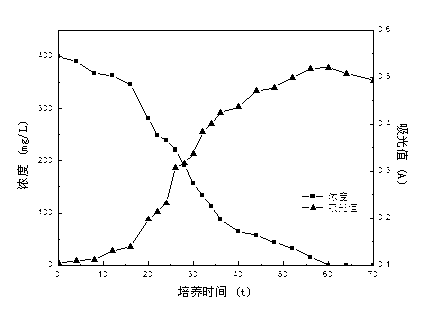

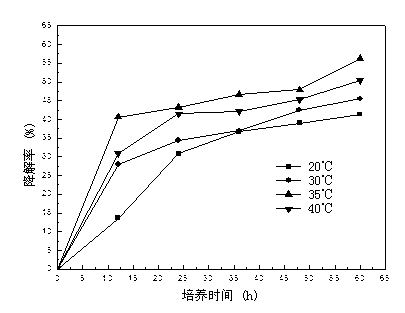

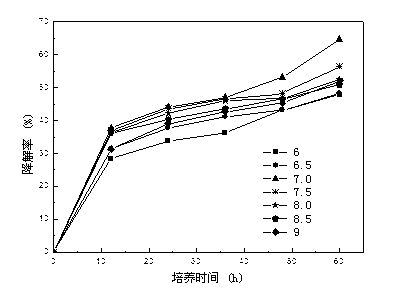

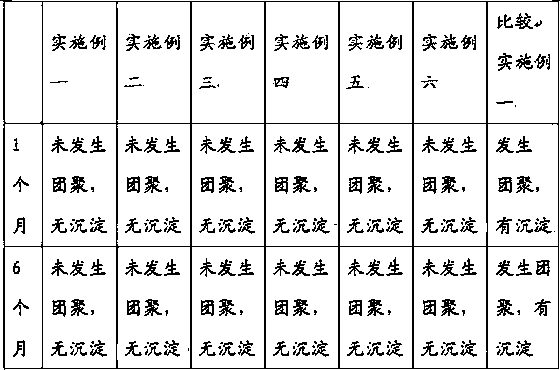

Dibutyl phthalate degrading bacteria and application of dibutyl phthalate degrading bacteria

InactiveCN102703347AGood bioaugmentation effectEfficient degradation abilityBacteriaWater contaminantsBiotechnologyBacterial strain

The invention discloses a strain of dibutyl phthalate degrading bacteria and application of the dibutyl phthalate degrading bacteria. The strain of dibutyl phthalate degrading bacteria D8 provided by the invention belongs to Elizabethkingiasp and is preserved in the China Center for Type Culture Collection, wherein the preservation date is March 23 2012; the preservation number is CCTCCNO:M2012088, and the GenBank accession number of a bacterial strain 16SrDNA is JQ673498. The bacterium is Gram-negative bacterium; the bacterial colony is yellow, round, smooth and humid; the brim is regular, and the centre protrudes. The bacterium utilizes dibutyl phthalate as sole carbon source and energy source to grow and breed. The bacterium can completely degrade 400mg / L of DBP (dibutyl phthalate) within 60 hours when being purely cultivated. The bacterial strain D8 can tolerate DBP of which the concentration can be up to 2000mg / L, and has excellent degradation effect on high-concentration DBP industrial wastewater. The bacterium is applied to bioaugmentation treatment of refinery waste water, pesticide wastewater, brewery wastewater and coking wastewater, and has excellent application prospect.

Owner:WUHAN UNIV OF SCI & TECH

Mildew-resistant and antibacterial nano-silver decorative laminated board

ActiveCN103862988AAdequate defense against invasionImprove adhesionNon-macromolecular adhesive additivesSpecial ornamental structuresPolymer sciencePolyolefin

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Fire-retarding alkyd resin anticorrosive paint

InactiveCN103122207AImprove fire resistanceWith anti-corrosion functionFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention discloses a fire-retarding alkyd resin anticorrosive paint. The paint is characterized by comprising the following components in parts by weight: 80-95 parts of alkyd resin, 10-20 parts of aldehyde ketone resin, 5-20 parts of cellulose acetate fiber, 10-15 parts of styrene-acrylic emulsion, 3-10 parts of dibutyl phthalate, 2-8 parts of phthalic anhydride, 0.2-4 parts of a preservative, 10-20 parts of a fire retardant and 3-9 parts of a dispersant. The fire-retarding alkyd resin anticorrosive paint disclosed by the invention has good fire resistance, excellent flame resistance, corrosion resistance and good adhesive force.

Owner:宿迁市英杰装饰材料有限公司

Waterborne polyurethane dampproof anticorrosive coating and preparation method thereof

ActiveCN104789100AImprove wear resistanceGood chemical resistanceAntifouling/underwater paintsPaints with biocidesDi n butyl phthalateEmulsion

The invention discloses waterborne polyurethane dampproof anticorrosive coating and a preparation method thereof. The waterborne polyurethane dampproof anticorrosive coating comprises modified polyurethane composite emulsion, packing, hydroxyethyl cellulose, a preservative, methylsilicone oil, phthalic acid dibutyl ester, a zirconium-aluminic acid ester coupling agent, pigment, a hardening agent, an acrylic ester solution, a dispersing agent, additives and water. The preparation method comprises the following steps: uniformly stirring the water, dispersing agent, pigment, packing, zirconium-aluminic acid ester coupling agent and methylsilicone oil, and dispersing for 61-70 minutes by using a sand mill so as to prepare pigment packing slurry; adding the modified polyurethane composite emulsion into a container, adding the pigment packing slurry, the preservative, the acrylic ester solution and the additives when stirring for 21-30 minutes at the stirring speed of 410-450r / minute, and after stirring for 5-10 minutes, adding hydroxyethyl cellulose; finally, filtering by using a silk filtering net of 160 meshes, and mixing and stirring the obtained filtrate with 5-7 parts of the hardening agent, thereby obtaining the waterborne polyurethane dampproof anticorrosive coating. The waterborne polyurethane dampproof anticorrosive coating has the characteristics of good chemical resistance, good water resistance, good damproof effect, high glossiness, long film service life and the like.

Owner:黎芷杉

Composite separator for batteries and preparation method thereof

InactiveCN104037376AImprove thermal stabilitySmall thermal expansionCell component detailsCell seperators/membranes/diaphragms/spacersPolyvinylidene fluorideDi n butyl phthalate

The invention relates to the technical field of lithium ion battery materials and technologies, and concretely relates to a composite separator for batteries and a preparation method thereof. The composite separator is characterized in that a membrane layer with the thickness of 20-100 mu m is prepared from a slurry by employing a wet-process roller scraping continuous-coating method, and also the composite separator possesses a three-dimension porous structure prepared by employing a phase separation technology; and the slurry comprises the following compositions: 70%-80% of polyvinylidene fluoride, 3%-5% of a coupling agent, 3%-5% of a plasticizer and 10%-15% of a framework filling material, wherein the coupling agent is one or a mixture of vinyltrisilane, polysiloxane, polydimethylsiloxane and methacryloxysilane, the plasticizer is one of dibutyl phthalate, dioctyl phthalate and dibutyl isophthalate, and the framework filling material is one of nanometer-level silicon dioxide, titanium dioxide and aluminium oxide. The composite separator for batteries is high in porosity, high in liquid absorbency and retention rate, large in specific surface area and good in heat stability.

Owner:山东威高新能源科技有限公司

Dyeing process of micro-denier acrylic fiber wool top

InactiveCN105274867AHigh color fastnessImprove dyeing uniformityDyeing processPyrophosphateSodium sulfate

The invention discloses a dyeing process of a micro-denier acrylic fiber wool top. The dyeing process comprises the following steps: (1) adding 0.6 part by mass of sodium persulfate, 1.3 parts by mass of tristyrylphenol polyoxyethylene ether sulfonated ammonium, 2.1 parts by mass of dibutyl phthalate, 1.8 parts by mass of garden balsam extract, 9 parts by mass of natural plant pigment, 22 parts by mass of water, 0.7 parts by mass of sodium pyrophosphate and 2.4 parts by mass of cocoanut fatty acid diethanolamide and stirring the raw materials evenly; (2) soaking the wool top to a dye vat for 50 minutes; (3) drying the soaked wool top at 75 DEG C; (4) immersing the dried wool top into clean water and rinsing for 5 minutes; and (5) taking out the rinsed wool top and naturally airing. According to the dyeing process of the micro-denier acrylic fiber wool top, the color fastness of the dyed wool top is high; the dyeing uniformity is good; and dyeing defect is avoided.

Owner:常熟市新华源有色毛条厂

Nano silicon micronization modified double components, solventless polyurethane adhesive and preparation method thereof

InactiveCN101037580ALittle change in tensile shear strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention relates to a nano silicon micro-powder modified double-component and solvent-free polyurethane adhesive and preparing method thereof. The adhesive is constituted of component A and component B, wherein the component A is constituted of toluene diisocyanate, polyhydric polyether and trimethylolpropane, and the component B is constituted of liquid amino resin, dibutylphthalate, fire retardant and nano silicon micro-powder. The prepared adhesive possesses character of high strength, and moisture and heat proof; and is mainly used for bonding soft materials, or hard materials such as metal, plastic, and glass with the soft materials, and occasion of high demanding strength and moisture and heat proof.

Owner:HUNAN SHENLI IND

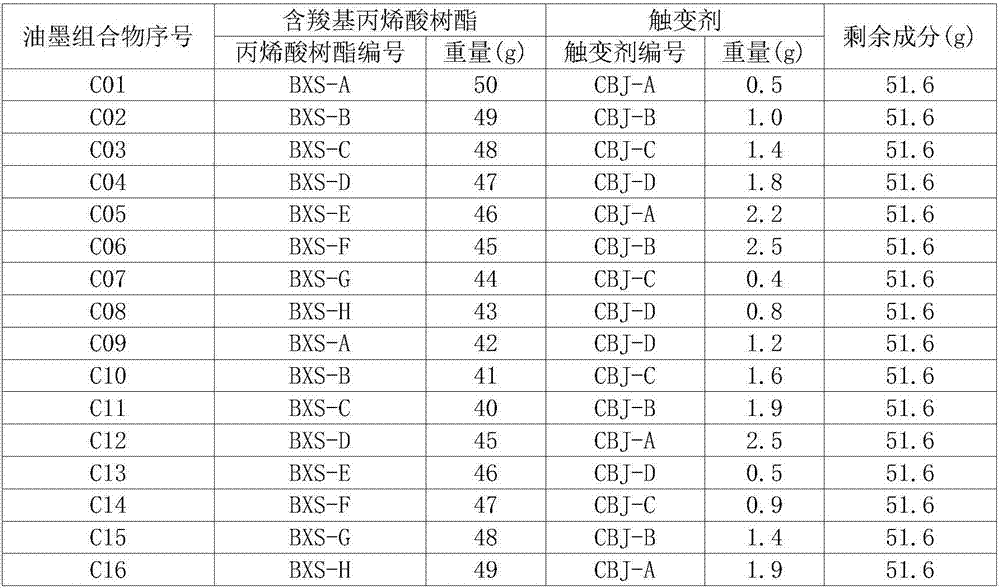

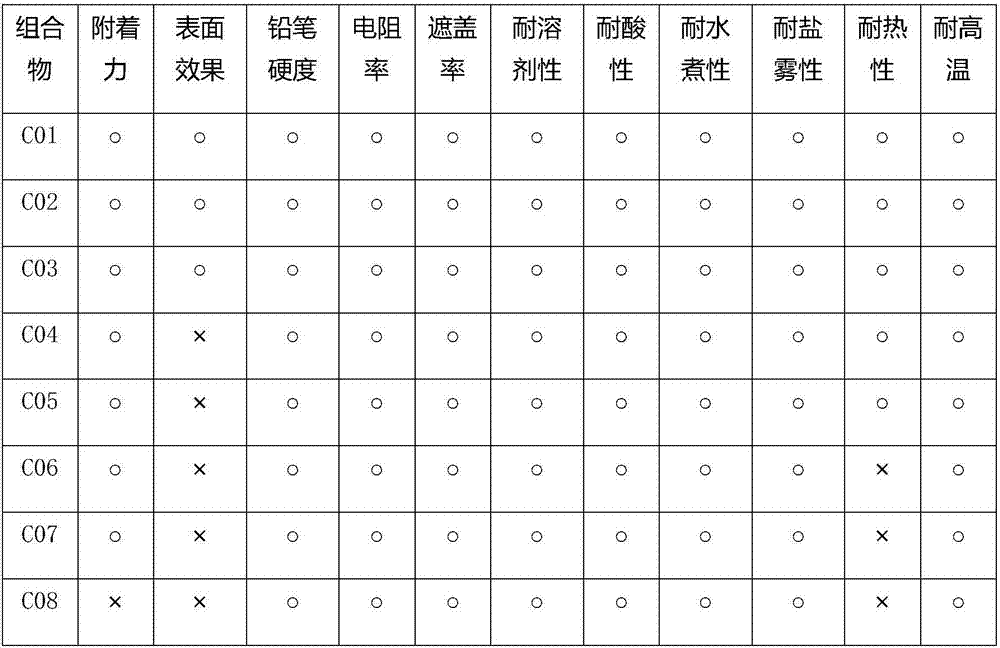

3D Glass light-sensitive black ink composition and preparation method thereof

The invention relates to 3D glass light-sensitive black ink composition and a preparation method thereof; the 3D glass light-sensitive black ink composition comprises acrylic resin, a thixotropic agent, epoxy resin and a black pigment and is characterized in that the acrylic resin is carboxyl-containing acrylic resin, a side chain of each polymer unit of a main chain of the carboxyl-containing acrylic resin has more than one carboxyl group, the carboxyl-containing acrylic resin has an acid value of 50-200 mgKOH / g, the carboxyl-containing acrylic resin has a weight-average molecular weight of 4000-8000, the thixotropic agent contains silicon dioxide or organic silicon, wherein silicon accounts for 20-46% by weight of the thixotropic agent, and the thixotropic agent has DBP (di-n-butyl phthalate) absorption value of 150-300 g / 100 ml. coating film prepared with the 3D glass light-sensitive black ink composition has the advantages of high light-sensitivity, high precision, high shaking power, high adhesion and the like, has the excellent effects of boiling resistance, salt spray resistance, acid and alkali resistance, aging resistance and the like, and also has the properties of no wrinkling upon heating and no shedding at high temperature.

Owner:深圳市容大感光科技股份有限公司 +1

Water-resistant paint for steel structure color steel tile

ActiveCN103275582AAvoid sun and rainPrevent precipitationAnti-corrosive paintsCelluloseThermal insulation

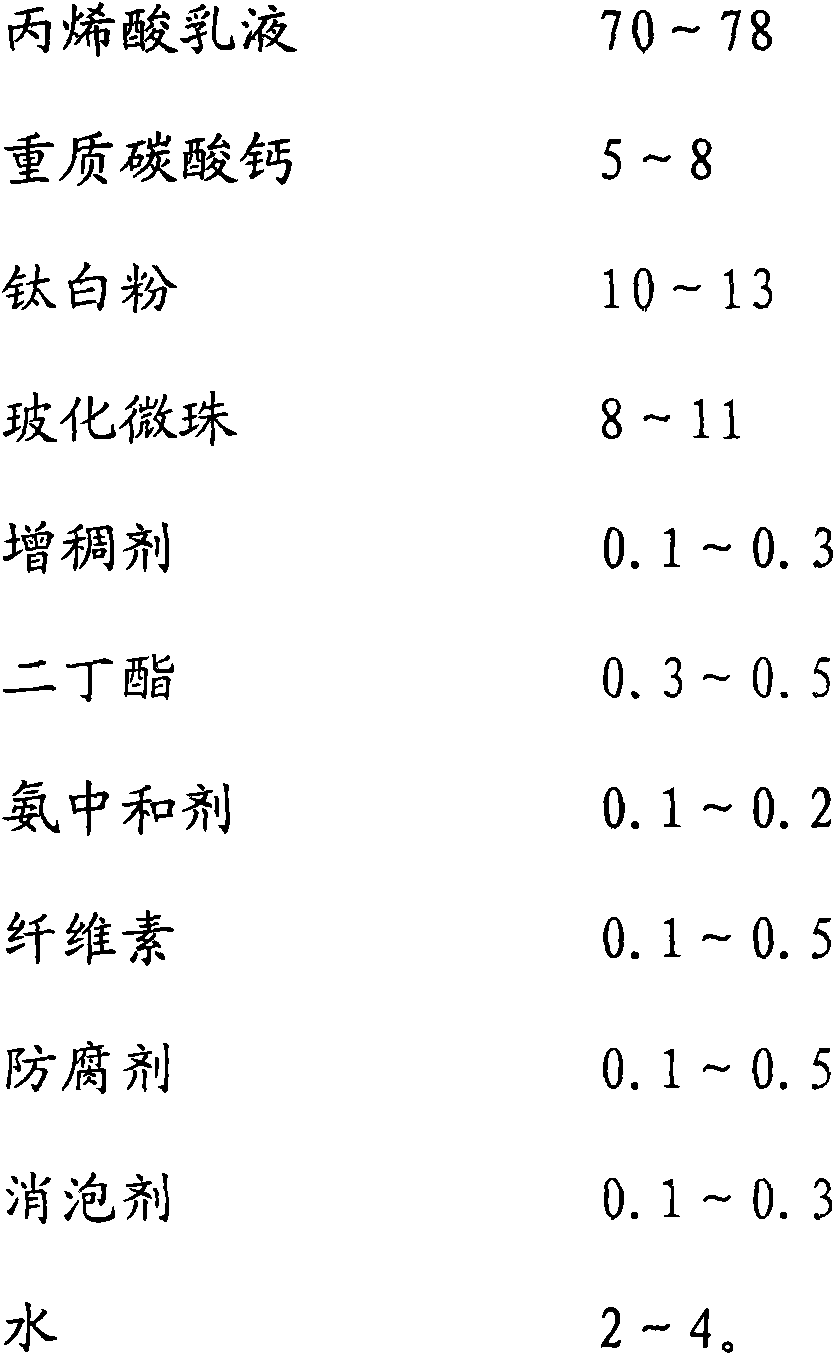

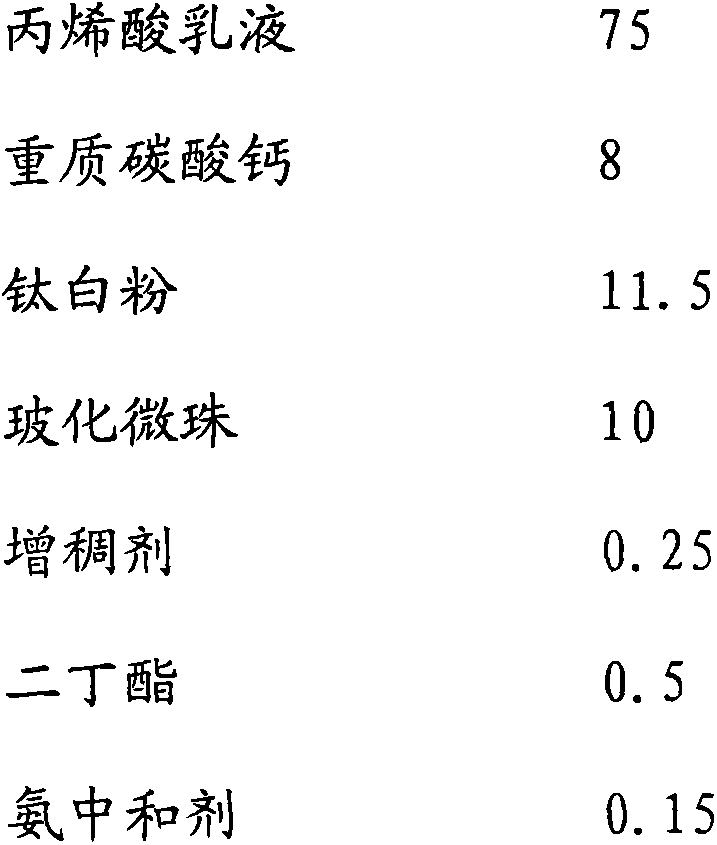

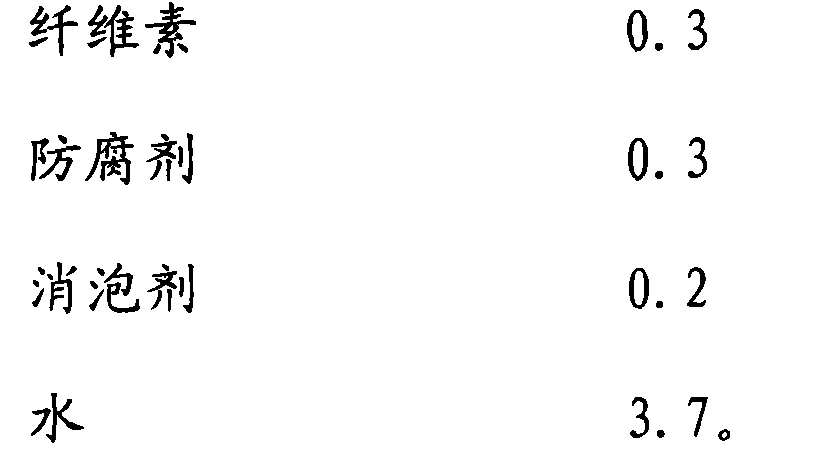

The invention discloses a water-resistant paint for steel structure color steel tile. The water-resistant paint for steel structure color steel tile comprises the following ingredients in weight parts: 70-78 parts of propenoic acid latex, 5-8 parts of heavy calcium carbonate, 10-13 parts of titanium dioxide, 8-11 parts of glass beads, 0.1-0.3 part of thickener, 0.3-0.5 part of di-n-butyl phthalate, 0.1-0.2 part of ammonia neutralizer, 0.1-0.5 part of cellulose, 0.1-0.5 part of preservative agent, 0.1-0.3 part of foam killer, and 2-4 parts of water. The water-resistant paint has the benefits that the problems of high water seepage maintenance cost and short service life which are caused by the rusting of iron nails on the conventional metal color steel tile roof are solved; the structure performance of the water-resistant paint is improved; a waterproof layer with good overall performance is formed on a metal steel structure construction; and the water-resistant paint has the characteristics of good waterproof quality, high temperature resistance, no crack at 80 DEG C, good fire resistance, good thermal insulation, good corrosion prevention, good oxidation prevention, good rust prevention, good age resistance and long service life.

Owner:XIAMEN LIKASAM WATERPROOF ENG

Conductive rubber roller and transfer roller

InactiveUS20080159791A1Small fluctuationSmall variationLiquid surface applicatorsShaft and bearingsPolymer scienceNitrogen

A conductive rubber roller having a rubber layer on a conductive core material. The rubber composition constituting the rubber layer contains a rubber component and a filler. The rubber component contains an epichlorohydrin rubber. The filler includes carbon black (A) having a nitrogen adsorption specific surface area (N2SA) of 20 m2 / g to 40 m2 / g and having a dibutyl phthalate (DBP) oil absorption of 80 ml / 100 g to 100 ml / 100 g and carbon black (B) having a nitrogen adsorption specific surface area (N2SA) of 15 m2 / g or less and having a dibutyl phthalate (DBP) oil absorption of 40 ml / 100 g or less. The carbon black (A) is in a content of 10 parts by mass to 30 parts by mass and the carbon black (B) is in a content of 20 parts by mass to 60 parts by mass or less, based on 100 parts by mass of the rubber component.

Owner:CANON KK

Moldproof rubber

Owner:中山市和鑫橡塑电子有限公司

High-temperature-resistant oil-resistant rubber composition and preparation method thereof

ActiveCN104341613AImprove high temperature resistanceGood oil resistanceSOYBEAN SEED OILDi n butyl phthalate

The invention discloses a high-temperature-resistant oil-resistant rubber composition and a preparation method thereof. The high-temperature-resistant oil-resistant rubber composition comprises the following compositions in parts by weight: 100 parts of natural rubber, 30 parts of tetrapropyl fluoro elastomer, 16 parts of ethylene-propylene-diene rubber, 2 parts of benzoyl peroxide, 12 parts of dibutyl phthalate, 5 parts of an anti-ageing agent NBC, 6 parts of zinc oxide, 33 parts of calcium carbonate, 2.1 parts of phenol formaldehyde, and 3.6 parts of epoxy soybean oil. The prepared rubber employs natural rubber as the main raw material, is prepared by adding tetrapropyl fluoro elastomer with high-temperature resistance and ethylene-propylene-diene rubber with oil resistance, has good high-temperature resistance and oil resistance, and is further improved in mechanical properties and heat resistance. The preparation method is simple and low in cost.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint

The invention provides a thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint. The paint is of a three-component reaction type and comprises a component A, a component B and a component C, wherein the ratio of the component A to the component B to the component C is 100 to (50-200) to (5-30); and the paint is formed by mixing the three components. The component A is MMA resin liquid modified by thermoplastic elastomer and tackifying resin, the component B is graded waste tire rubber particles, and the component C is formed by mixing and dissolving 2 to 3 parts of benz peroxide and 10 to 30 parts of dibutyl phthalate. The thermoplastic-elastomer-modified polymethyl methacrylate color antiskid paint has beneficial effects that an energy-saving, high-efficient and durable color antiskid paint for roads and bridges is provided, the cost can be reduced, the energy consumption can be reduced, the economic benefit and social benefit can be improved, and various technical indexes of the paint can reach or exceed that of the color antiskid paint sold in the market.

Owner:广东立得新材料科技有限公司

Fatigue-resistant rubber

ActiveCN103665459AImprove heat aging resistanceGood dynamic fatigue resistanceSodium stearateStearic acid

Owner:佛山市嘉翔新材料有限公司

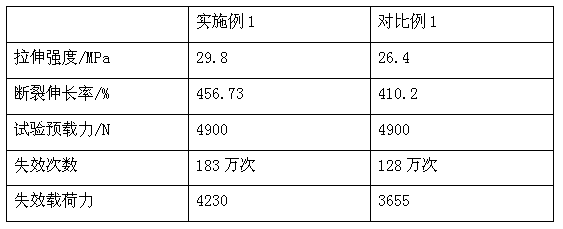

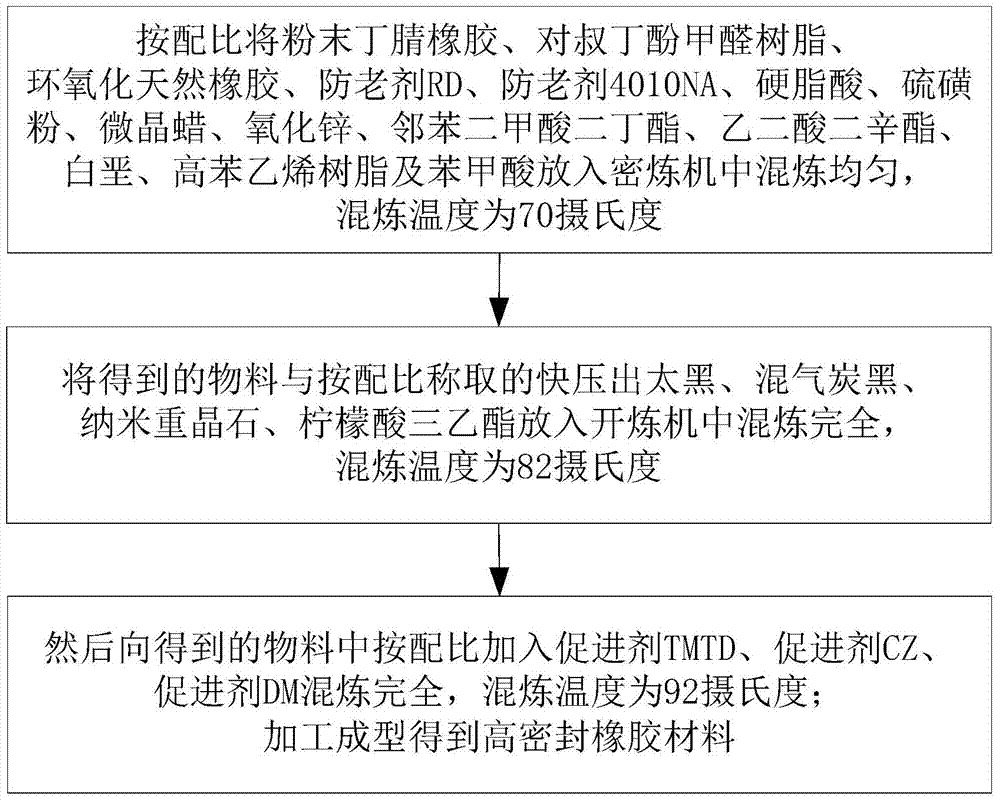

Highly sealing rubber material and preparation technology thereof

The invention discloses a highly sealing rubber material. The rubber material comprises the following raw materials in parts by weight: 75-90 parts of powdery nitrile rubber, 20-40 parts of para-tertiary butyl phenol formaldehyde resin, 20-40 parts of epoxidized natural rubber, 0.8-1.7 parts of antiager RD, 0.5-1.3 parts of antiager 4010NA, 0.4-0.8 part of stearic acid, 0.4-0.6 part of sulphur powder, 0.9-1.3 parts of microcrystalline wax, 3-4 parts of zinc oxide, 40-60 parts of fast extruding furnace black, 30-40 parts of mixed gas carbon black, 20-25 parts of triethyl citrate, 1.2-2.7 parts of phthalic acid dibutyl ester, 0.4-0.9 part of dioctyl adipate, 1.2-1.4 parts of accelerator TMTD, 1-1.3 parts of accelerator CZ, 1.1-1.3 parts of accelerator DM, 1-3 parts of nanometer barite, 1-2 parts of chalk, 1.5-2.3 parts of high styrene resin, and 2.2-2.8 parts of benzoic acid. The invention also discloses a preparation technology for the highly sealing rubber material. The highly sealing rubber material has excellent bonding and sealing performances, good elasticity and warping strength, and long service life.

Owner:ANHUI SHENGDONG CHEM

Preparation method of sheath material of ethylene-propylene rubber insulated polychloroprene sheathed cable

InactiveCN106117825AImprove waterproof performanceImprove aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsSodium BentoniteBenzoyl peroxide

The invention discloses a preparation method of a sheath material of an ethylene-propylene rubber insulated polychloroprene sheathed cable, comprising the following steps: mixing ethylene-propylene rubber, polychloroprene, hydrogenated nitrile-butadiene rubber, fluorine rubber and styrene-butadiene rubber for 1-2min; adding modified quicklime, coumarone resin, calcined pottery clay, nano titanium dioxide, bentonite, hollow microspheres, zirconia, RF-90 resin, microcrystalline cellulose, thiuram disulfide and hexamethylenetetramine, mixing uniformly and discharging the material, wherein the mixing temperature is 105-110DEG C; adding an anti-aging agent RD, an anti-aging agent H, an anti-aging agent 4010NA, process oil, pine tar oil and dibutyl phthalate and uniformly mixing, adding benzoyl peroxide and aluminum hydroxide, curing at the curing temperature of 158-163DEG C for 1-2min, and discharging and cooling the material to obtain the sheath material of the ethylene-propylene rubber insulated polychloroprene sheathed cable.

Owner:ANHUI DEYUAN CABLE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com