Highly sealing rubber material and preparation technology thereof

A rubber material, high sealing technology, applied in the field of nitrile rubber, to achieve the effect of long service life, improved electrical properties and good mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of high sealing rubber material, its raw material comprises by weight:

[0023] 82 parts of powdered nitrile rubber, 23 parts of p-tert-butylphenol formaldehyde resin, 35 parts of epoxidized natural rubber, 1.2 parts of anti-aging agent RD, 0.8 parts of anti-aging agent 4010NA, 0.75 parts of stearic acid, 0.5 parts of sulfur powder, micro 1.25 parts of crystal wax, 3 parts of zinc oxide, 55 parts of fast extruded carbon black, 32 parts of gas-mixed carbon black, 21 parts of triethyl citrate, 1.4 parts of dibutyl phthalate, 0.8 parts of dioctyl oxalate 1.3 parts of accelerator TMTD, 1.05 parts of accelerator CZ, 1.2 parts of accelerator DM, 1.25 parts of nano barite, 2 parts of chalk, 1.85 parts of high styrene resin, and 2.65 parts of benzoic acid.

[0024] Among them, the content of acrylonitrile in the powdered nitrile rubber is 38%, the Mooney viscosity (ML1+4, 100%) is 73; the content of bound styrene in the high styrene resin is 62%.

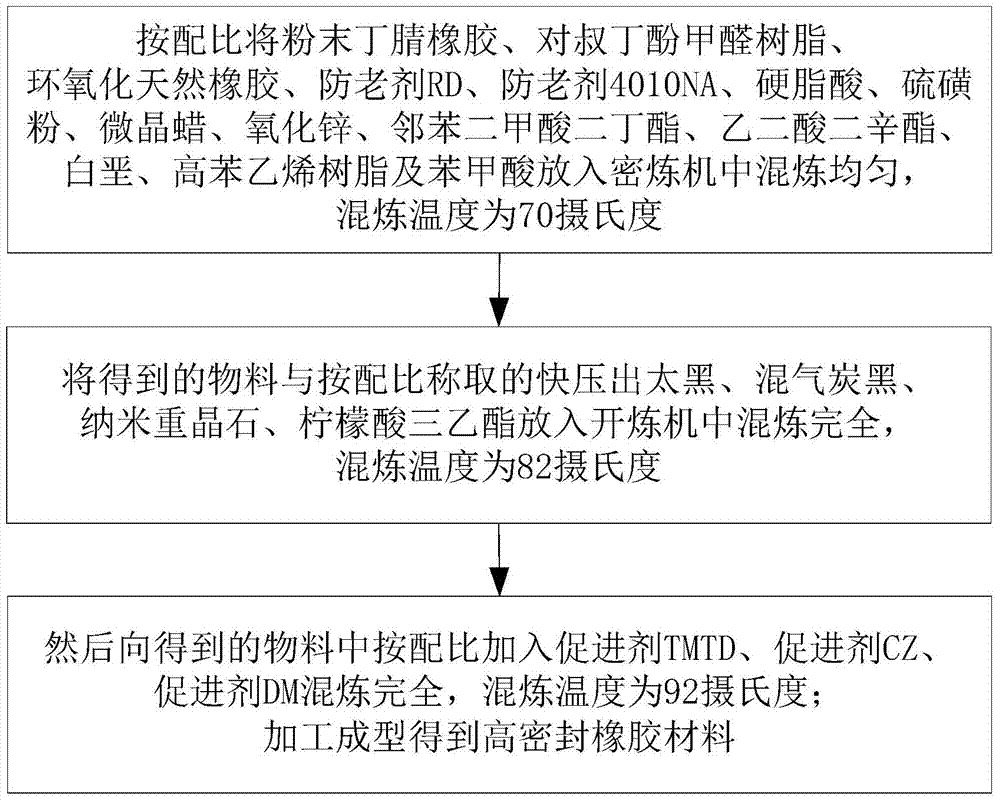

[0025] refer to figu...

Embodiment 2

[0033] A kind of high sealing rubber material, its raw material comprises by weight:

[0034] 78 parts of powdered nitrile rubber, 40 parts of p-tert-butylphenol formaldehyde resin, 33 parts of epoxidized natural rubber, 1.4 parts of anti-aging agent RD, 0.9 parts of anti-aging agent 4010NA, 0.7 parts of stearic acid, 0.45 parts of sulfur powder, micro 1.2 parts of crystal wax, 3.5 parts of zinc oxide, 42 parts of fast extruded carbon black, 38 parts of gas-mixed carbon black, 23 parts of triethyl citrate, 2.4 parts of dibutyl phthalate, 0.85 parts of dioctyl oxalate 1.3 parts of accelerator TMTD, 1.25 parts of accelerator CZ, 1.15 parts of accelerator DM, 1.5 parts of nano barite, 2 parts of chalk, 2.1 parts of high styrene resin, and 2.5 parts of benzoic acid.

[0035] Among them, the content of acrylonitrile in the powdered nitrile rubber is 39.5%, the Mooney viscosity (ML1+4, 100%) is 79; the content of bound styrene in the high styrene resin is 63%.

[0036] The preparat...

Embodiment 3

[0043] A kind of high sealing rubber material, its raw material comprises by weight:

[0044]87 parts of powdered nitrile rubber, 34 parts of p-tert-butylphenol formaldehyde resin, 37 parts of epoxidized natural rubber, 1.5 parts of anti-aging agent RD, 0.75 parts of anti-aging agent 4010NA, 0.6 parts of stearic acid, 0.4 parts of sulfur powder, micro 1.2 parts of crystal wax, 3.5 parts of zinc oxide, 60 parts of fast extruded carbon black, 32 parts of gas-mixed carbon black, 25 parts of triethyl citrate, 1.8 parts of dibutyl phthalate, 0.6 parts of dioctyl oxalate 1.4 parts of accelerator TMTD, 1.25 parts of accelerator CZ, 1.15 parts of accelerator DM, 2.5 parts of nano barite, 1.5 parts of chalk, 1.8 parts of high styrene resin, and 2.4 parts of benzoic acid.

[0045] Among them, the content of acrylonitrile in the powdered nitrile rubber is 39%, and the Mooney viscosity (ML1+4, 100%) is 75. The bound styrene content of the high styrene resin is 62%.

[0046] The preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com