EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and preparation method thereof

A composite emulsion, low temperature resistant technology, applied in the direction of adhesive types, adhesives, rosin adhesives, etc., to achieve the effect of improving adhesive strength, reducing the amount of glue applied, and expanding the use temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

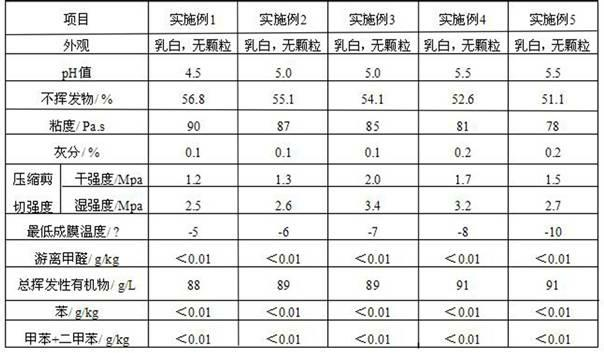

Examples

Embodiment 1

[0029] The preparation of polyether type polyurethane emulsion comprises the following raw materials:

[0030] 14 parts toluene diisocyanate

[0031] Polyether diol 90 parts

[0032] 1,4-butanediol 1.5 parts

[0033] Trimethylolpropane 0.2 parts

[0034] 2.5 parts of triethylamine

[0035] Tetraethyl orthosilicate 2.3 parts

[0036] Dimethylol propionic acid 3.5 parts

[0037] Ethylenediamine 0.5 parts

[0038] Proper amount of acetone

[0039] 200 parts of water

[0040] The specific preparation method is as follows:

[0041] A certain proportion of toluene diisocyanate (TDI) and polyether diol (N240, =4000) into a reaction kettle with a reflux condenser and a stirrer, stirred at a constant speed, and reacted at 85°C for 3 hours. Cool the reaction down to about 70°C, add dimethylolpropionic acid (DMPA) and a small amount of stannous octoate (T-9), and add a small amount of acetone at the same time. Control the reaction temperature at 75°C, react for 1.5 hours; add...

Embodiment 2

[0067] Prepare polyether type polyurethane emulsion raw material and specific method with embodiment 1.

[0068] Preparation of polyester polyurethane emulsion raw materials and specific methods are the same as in Example 1.

[0069] The preparation of EVA emulsion type universal adhesive comprises the following raw materials:

[0070] EVA emulsion 80 parts

[0071] Rosin tackifying resin emulsion 10 parts

[0072] Polyester polyurethane emulsion 5 parts

[0073] Ethylene glycol 1 part

[0074] Dibutyl phthalate 0.5 parts

[0075] Kason 2 servings

[0076] Wetting agent 0.6 parts

[0077] Appropriate amount of pH adjuster

[0078] The specific preparation method is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0080] Prepare polyether type polyurethane emulsion raw material and specific method with embodiment 1.

[0081] Preparation of polyester polyurethane emulsion raw materials and specific methods are the same as in Example 1.

[0082] The preparation of EVA emulsion type universal adhesive comprises the following raw materials:

[0083] EVA emulsion 70 parts

[0084] Rosin tackifying resin emulsion 10 parts

[0085] Polyether polyurethane emulsion 10 parts

[0086] Polyester polyurethane emulsion 5 parts

[0087] Ethylene glycol 1 part

[0088] Dibutyl phthalate 0.5 parts

[0089] Kason 2 servings

[0090] Wetting agent 0.6 parts

[0091] Appropriate amount of pH adjuster

[0092] The specific preparation method is the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com