Patents

Literature

49results about How to "Less glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

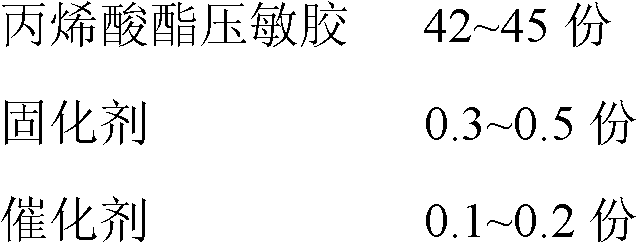

Solvent-based reticulated pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

ActiveCN102504732AStrong adhesionStrong initial adhesionFilm/foil adhesivesEster polymer adhesivesSolvent basedUltimate tensile strength

The invention discloses a solvent-based reticulated pressure-sensitive adhesive for a polyethylene protective film and a preparation method thereof. The solvent-based reticulated pressure-sensitive adhesive comprises the following components in parts by weight: 42-45 parts of acrylate pressure-sensitive adhesive, 0.3-0.5 part of curing agent, 0.1-0.2 part of catalyst and 54-57% of solvent. The solvent-based reticulated pressure-sensitive adhesive disclosed by the invention has good adhesion to a polyethylene protective film and can realize good balance among Initial adhesion, peel strength and cohesion.

Owner:无锡达美新材料有限公司

Environment-friendly starch adhesive for cementing corrugated boards at low temperature and preparation method of environment-friendly starch adhesive

InactiveCN106085289ALess glueFacilitates quick dryingNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryAdhesive

The invention relates to an environment-friendly starch adhesive for cementing corrugated boards at a low temperature and a preparation method of the environment-friendly starch adhesive. The starch adhesive is prepared from the following raw materials in parts by weight: 15 to 30 parts of starch, 60 to 80 parts of water, 0.2 to 1 part of sodium hydroxide, 0.05 to 0.2 part of oxidizing agent, 0.1 to 0.5 part of cross-linking agent, 0.1 to 0.5 part of stabilizing agent, 2 to 10 parts of drier, 1 to 5 parts of reinforcing agent and 0.1 to 1 part of penetrating agent. Under the oxidation of the oxidizing agent, besides hydroxyl, groups such as carboxyl and carbonyl are added on molecular chains of the starch, so that the initial adhesion of the adhesive is improved, the cementing quantity is reduced, and the rapidness in drying is facilitated; by adding the penetrating agent, the adhesive can rapidly penetrate through paper and destroy fibers; by adding the cross-linking agent and the reinforcing agent, the adhesive can be instantaneously cross-linked to form a mass structure, the rapid dryness of the adhesive is facilitated, and the adhesive can also be cross-linked with groups on the paper fibers so as to increase the cementing strength and the water resistance of paper boards; and by adding the drier, the drying speed of the starch adhesive can be increased, so that the steam pressure of a paper machine is reduced.

Owner:明辉大秦(上海)环保科技股份有限公司

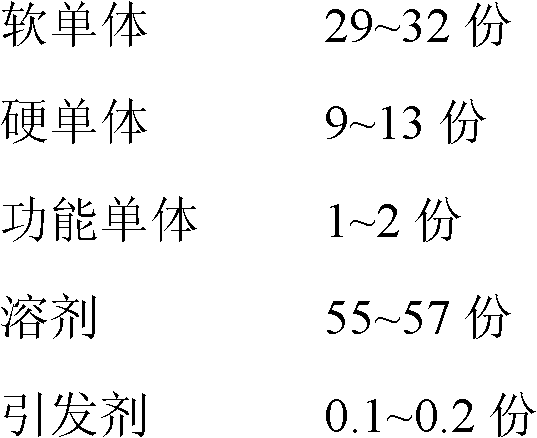

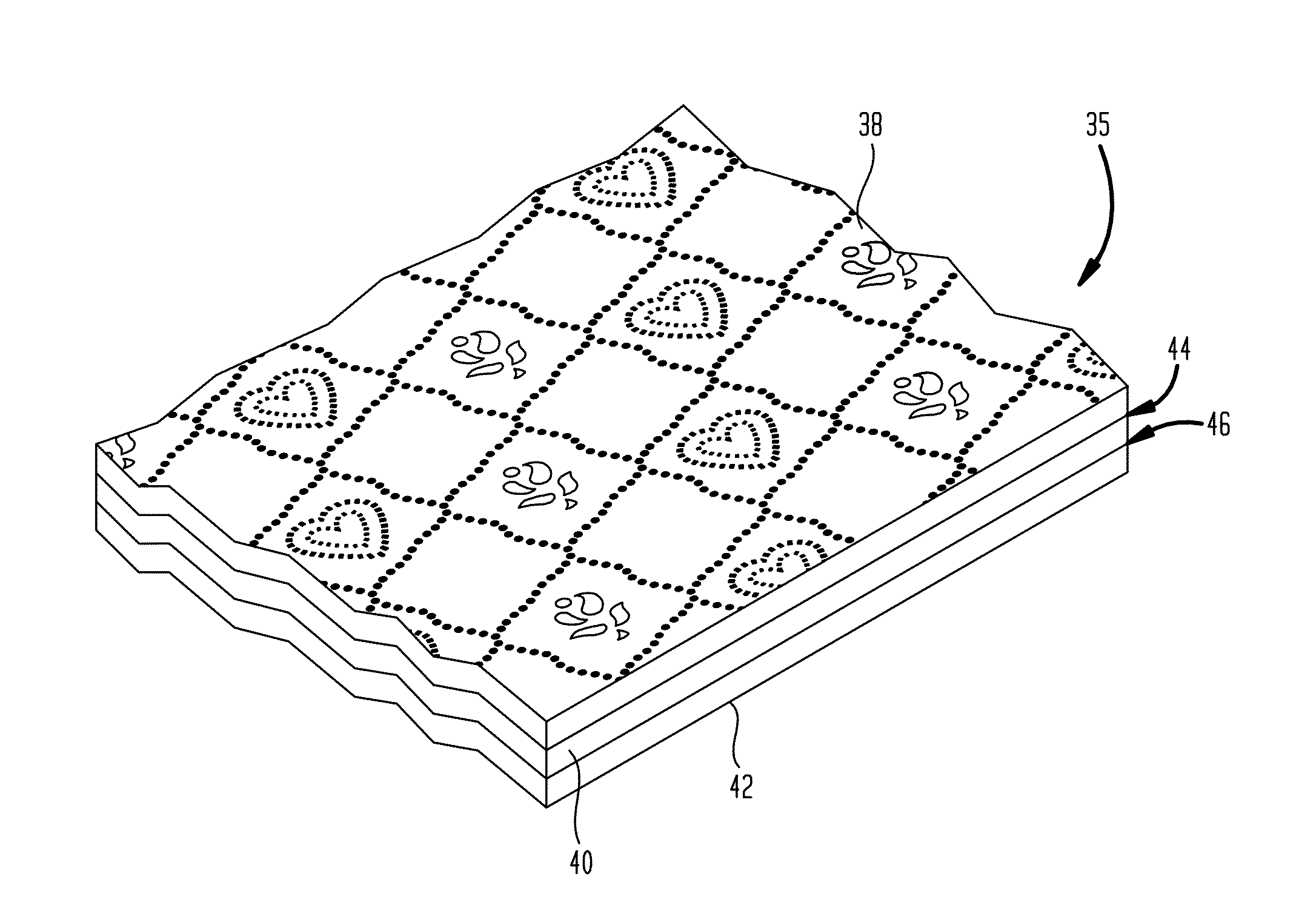

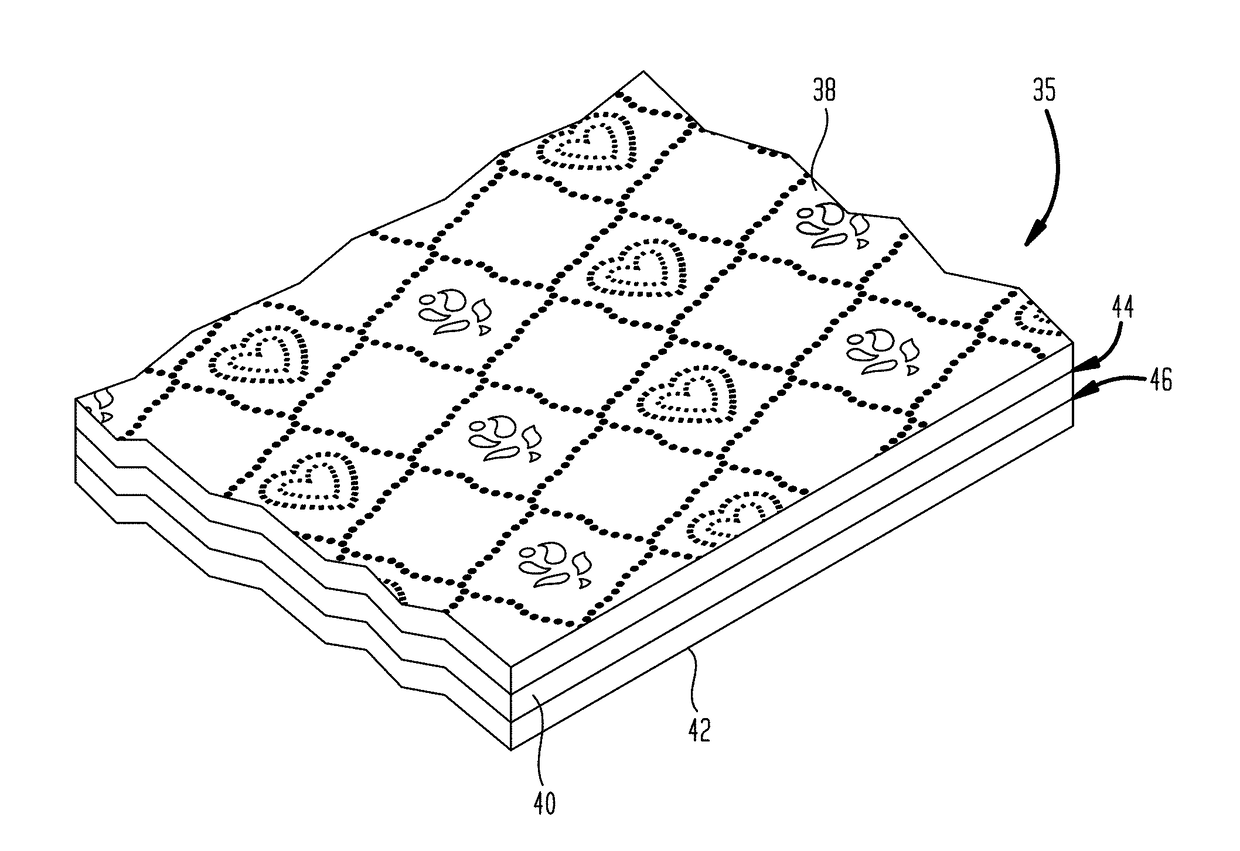

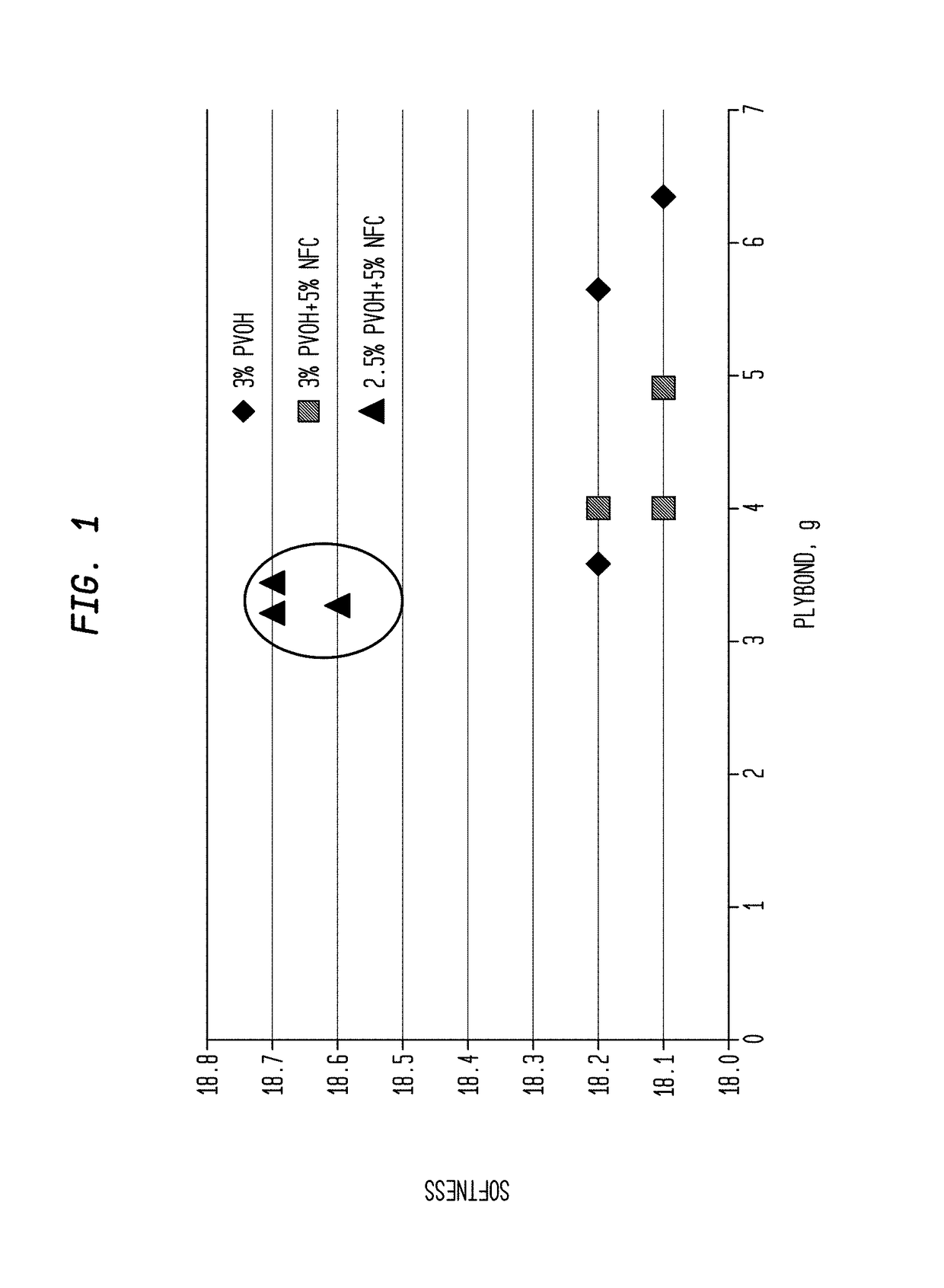

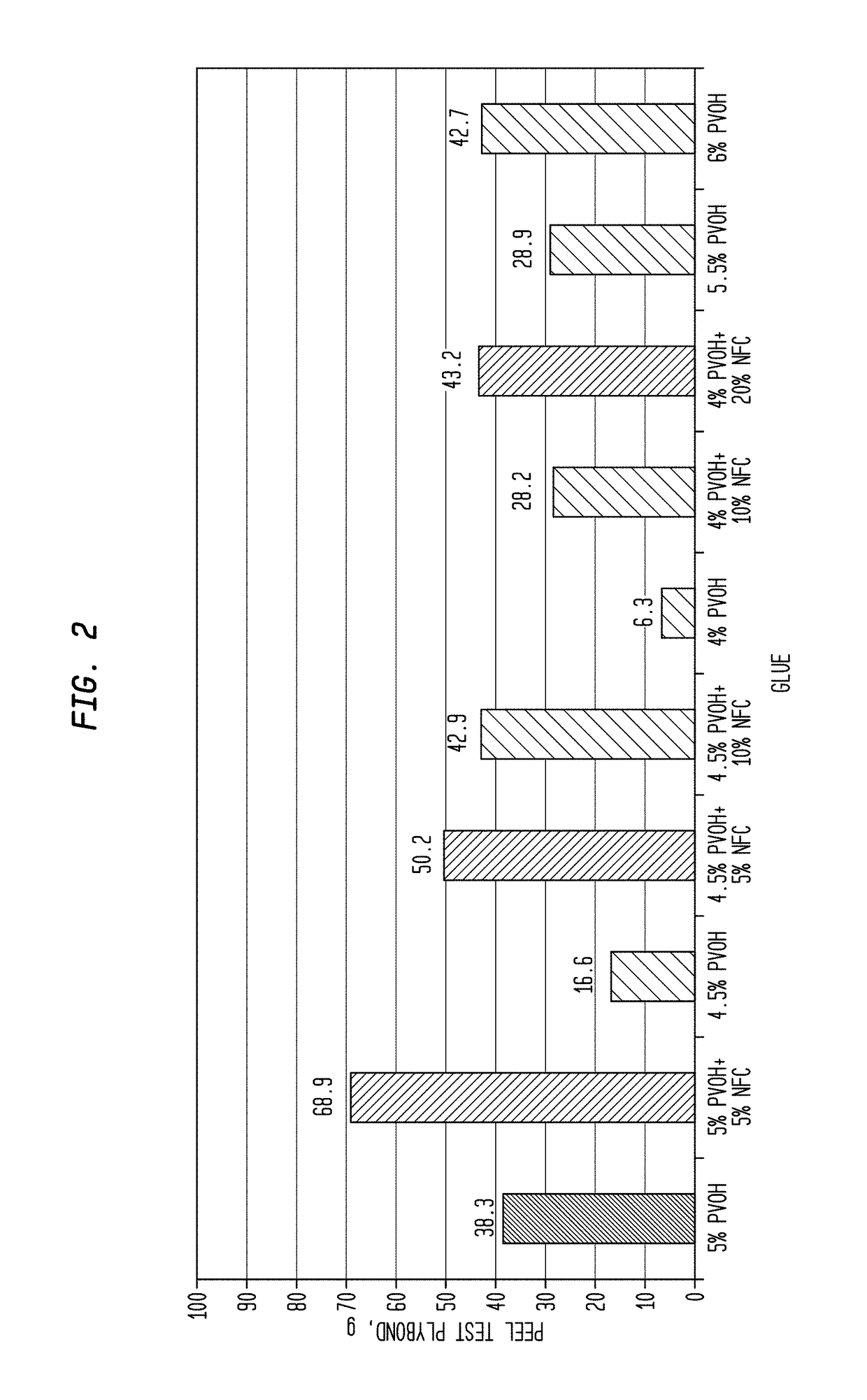

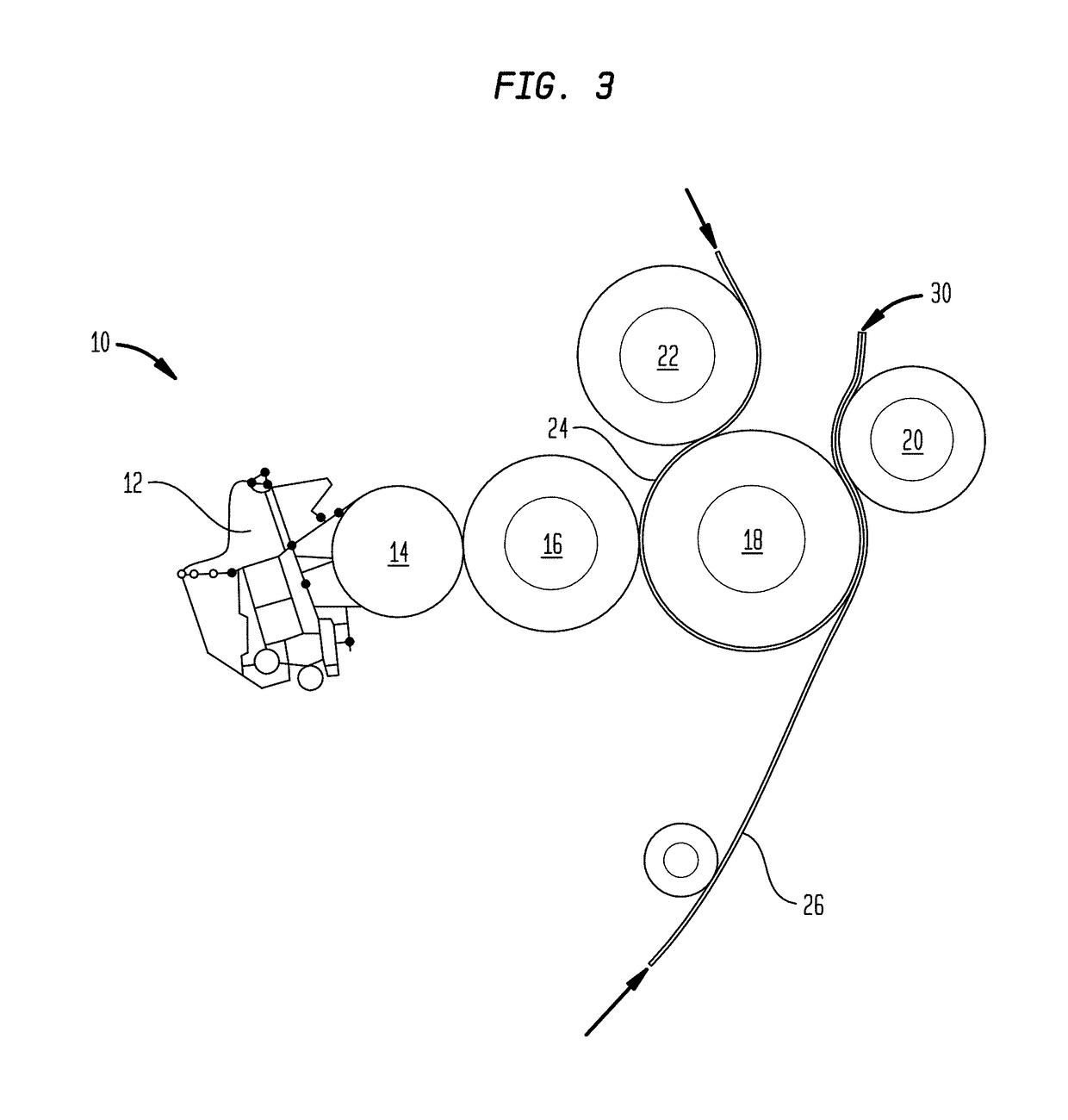

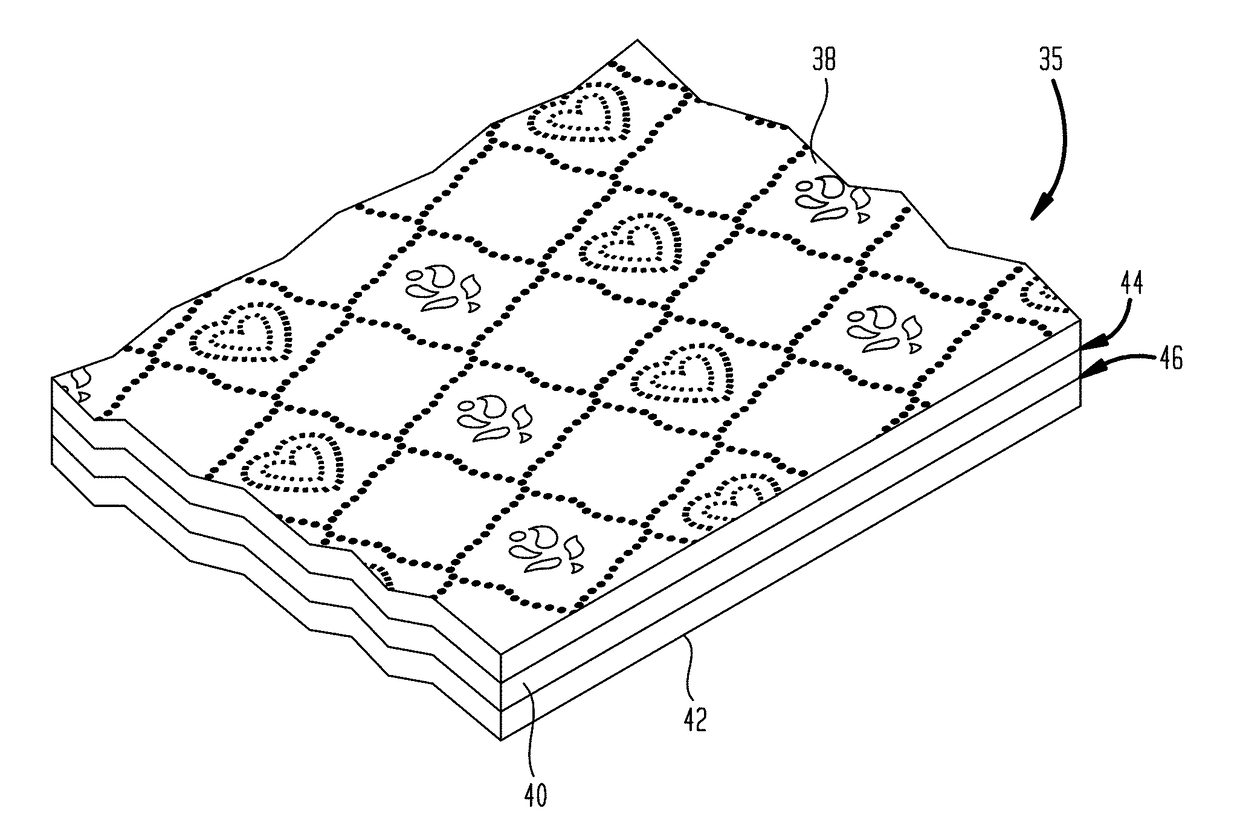

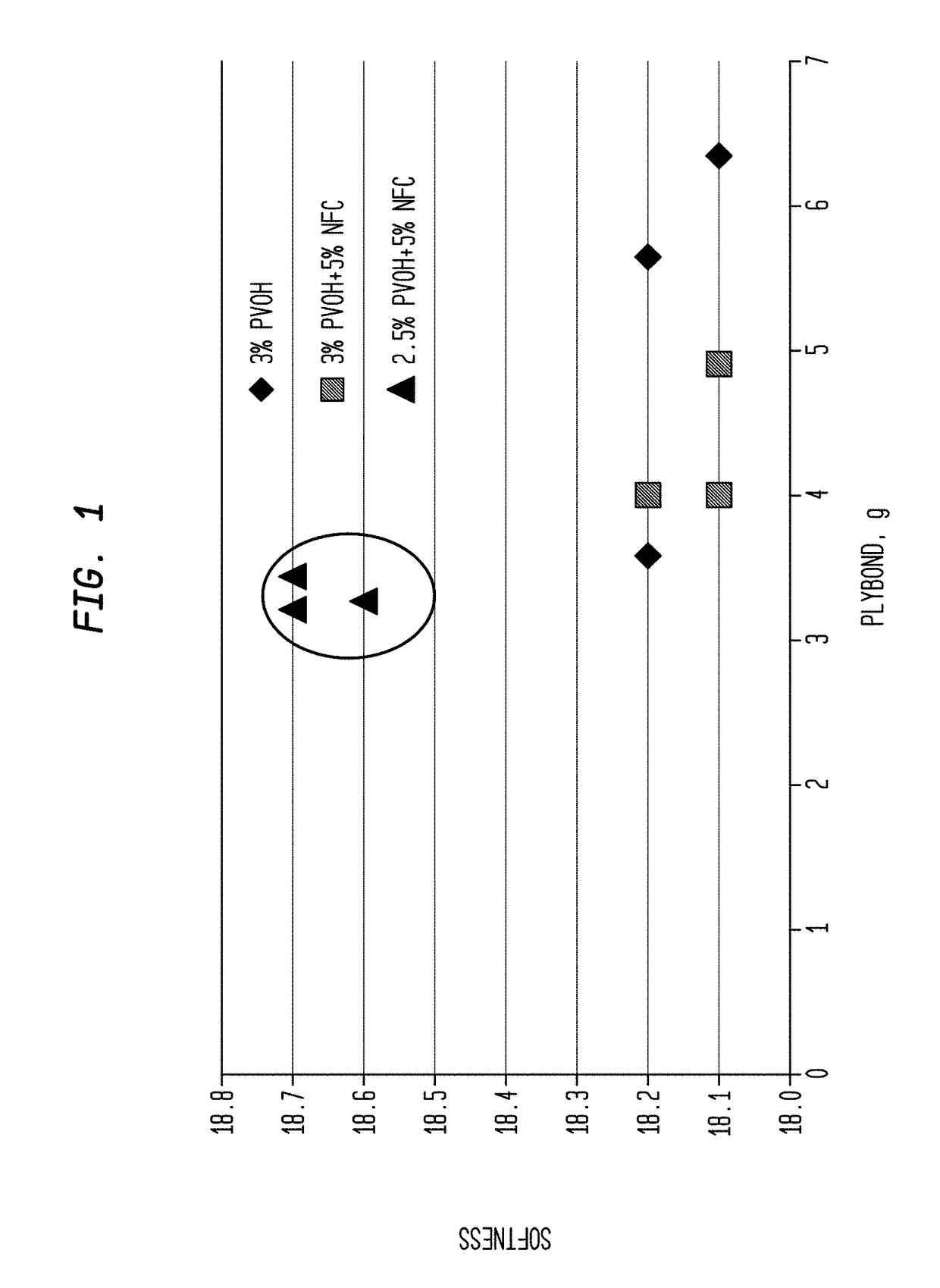

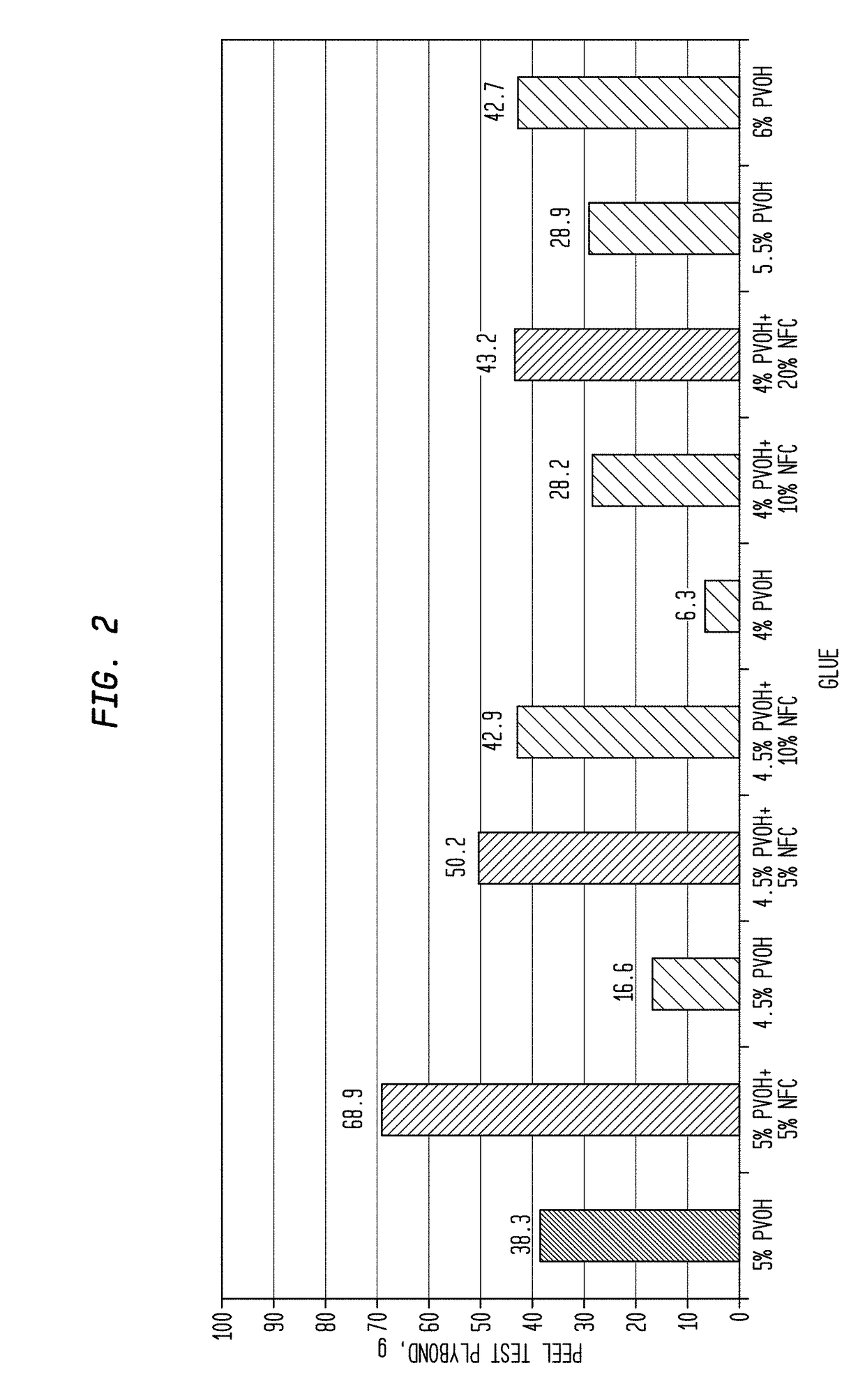

Glue-Bonded Multi-Ply Absorbent Sheet and Polyvinyl Alcohol Ply Bonding Adhesive

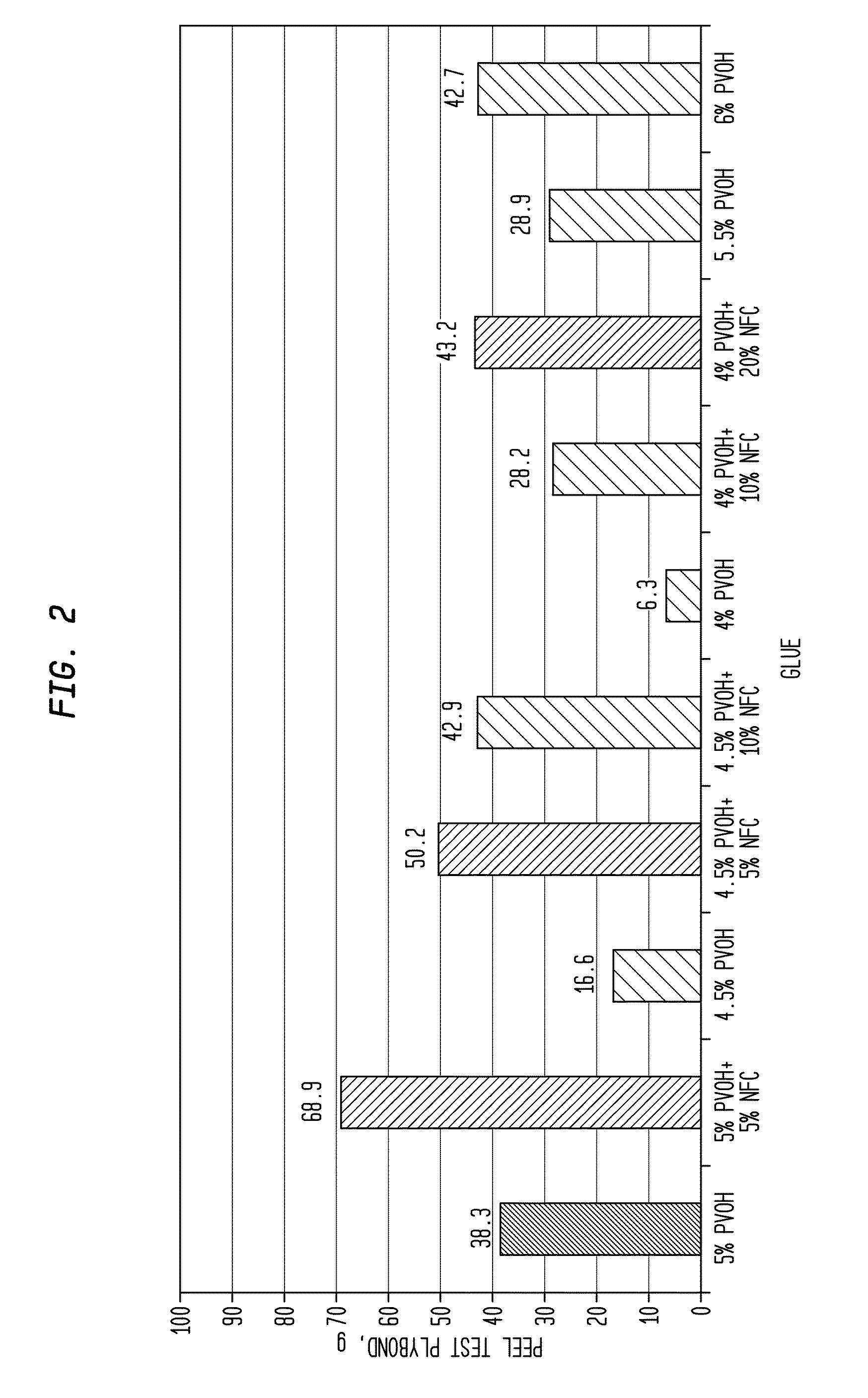

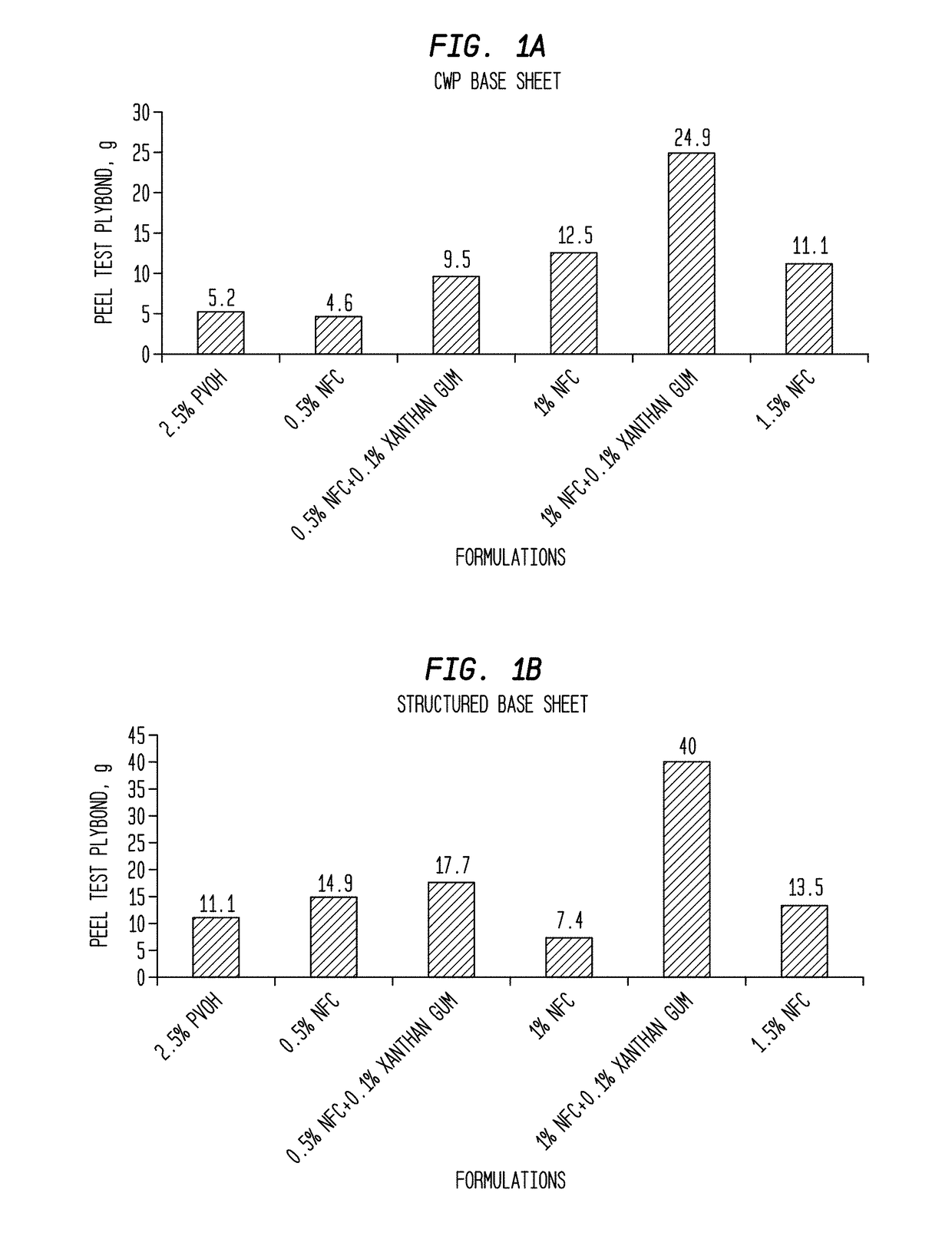

ActiveUS20160215179A1Less glueRecovers viscosityDomestic applicationsCellulose adhesivesCellulosePolymer chemistry

A multi-ply absorbent sheet includes a first absorbent ply of cellulosic sheet; a second absorbent ply of cellulosic sheet; and a ply bonding adhesive interposed between the first absorbent ply and the second absorbent ply, the ply-bonding adhesive thereby adhering said absorbent plies together. The ply-bonding adhesive comprises polyvinyl alcohol and nanofibrillated cellulose. In a particularly preferred embodiment the adhesive is applied as a dilute aqueous composition to tissue plies and the nanofibrillated cellulose has a Characteristic Breaking Length of 6.5 km or above.

Owner:GPCP IP HLDG LLC

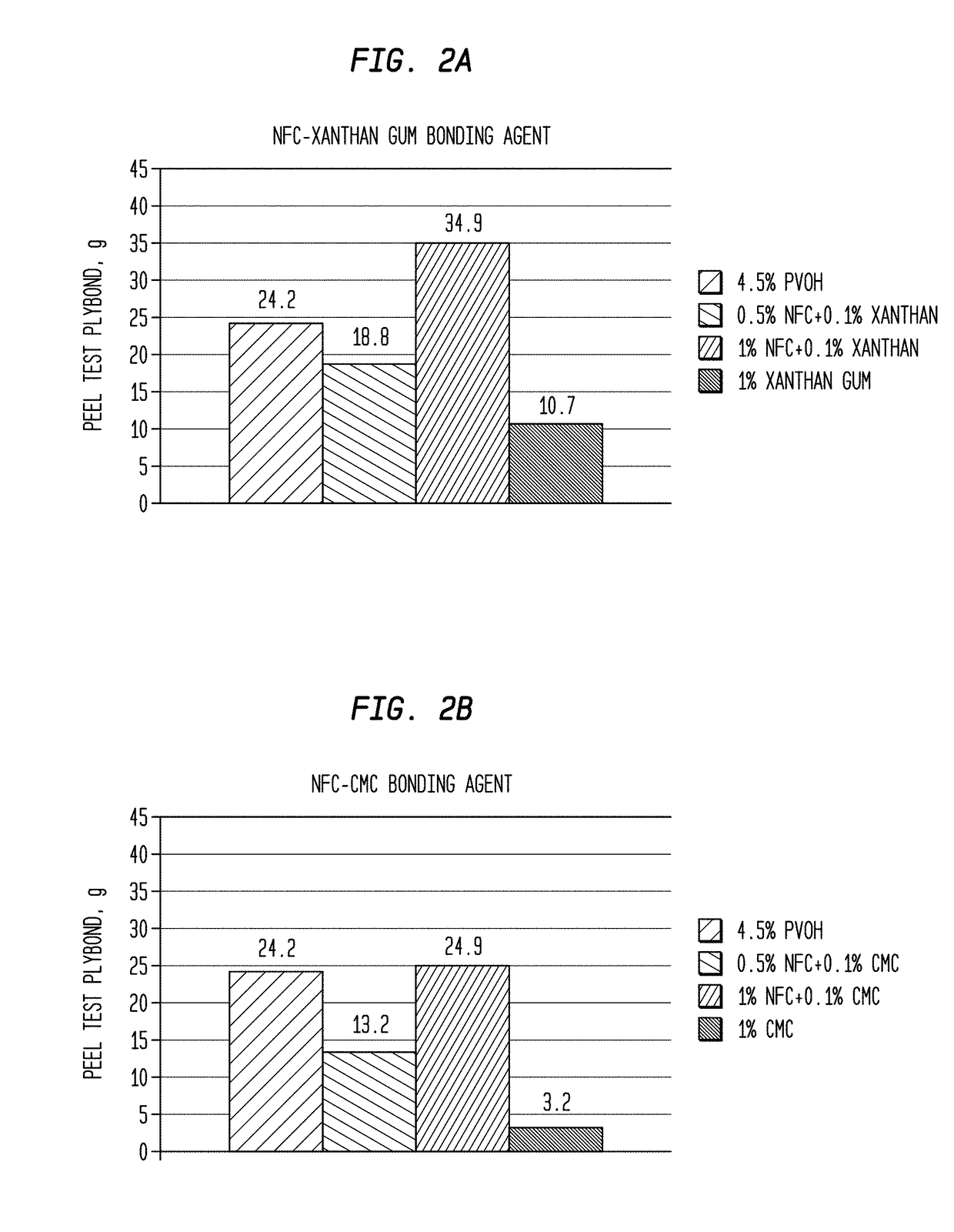

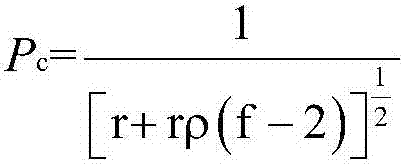

Nanofibrillated Cellulose Ply Bonding Agent Or Adhesive and Multi-Ply Absorbent Sheet Made Therewith

ActiveUS20170204567A1More surface areaHigh viscosityAdhesive processesFilm/foil adhesivesPolymer sciencePolyol

A ply-bonding agent or adhesive composition characterized by a viscosity and a surface tension for the manufacture of paper tissue and paper towel, includes: (a) water; (b) nanofibrillated cellulose; and (c) one or more modifiers effective to modify either or both of (i) the viscosity of the composition or (ii) the surface tension of the composition, wherein the one or more additional modifiers are selected from the group consisting of components (iii), (iv), (v), (vi), (vii) or (viii), wherein: (iii) is PVOH and a viscosity modifier; (iv) is a viscosity modifier; (v) is a viscosity modifier and a surface tension modifier other than PVOH; (vi) is a water-soluble cellulose derivative; (vii) is a water soluble polyol; and (viii) is a surface tension modifier other than PVOH. The compositions are particularly useful for ply-bonding multi-ply absorbent sheet when the plies are treated with debonder.

Owner:GPCP IP HLDG LLC

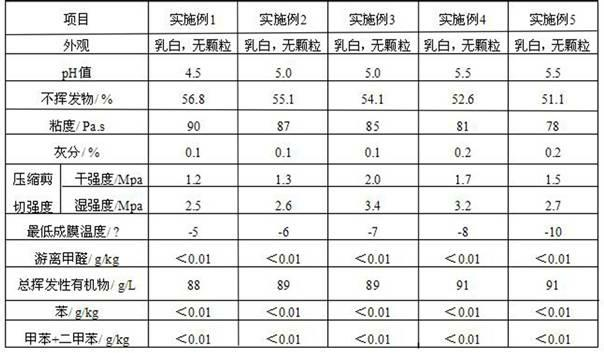

EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and preparation method thereof

ActiveCN101928529AHigh affinityWide operating temperature rangeMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesPolymer scienceDi n butyl phthalate

The invention discloses an EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and a preparation method thereof, belonging to the field of water-based adhesives. The invention adopts the technical scheme that an EVA emulsion is modified by utilizing a rosin tackifying resin emulsion and a polyurethane emulsion together to prepare the EVA emulsion all-purpose adhesive. The all-purpose adhesive comprises the following components in parts by weight: 65-80 parts of EVA emulsion, 5-15 parts of rosin tackifying resin emulsion, 5-15 parts of polyurethane emulsion and the balance of auxiliary agent, wherein the auxiliary agent comprises an antifreeze agent, a plasticizer, a mildew-proof agent, a wetting agent and a pH regulator. When making, the preparation method comprises the following steps of: adding the EVA emulsion to a dispersion kettle with a stirrer, and uniformly stirring; adding the polyurethane emulsion, and stirring and mixing for 1.0-1.5h; then adding the rosin tackifying resin emulsion, the plasticizer of dibutyl phthalate, the antifreeze agent of glycol, the mildew-proof agent of Kathon and the wetting agent, and stirring and uniformly mixing; adding the pH regulator, such as ammonia water or triethylamine to regulate pH value to be 4.5-5.5, and filtering and discharging. The obtained all-purpose adhesive has indexes which reach or exceed common white latexes, convenient use and wide applicability, and can be widely used for architectural decoration, furniture making, cases, and the like and used at normal temperature but also at the low temperature from 5 DEG C to 5 DEG C below zero.

Owner:东莞市山力高分子材料科研有限公司

Puffed food gas packing composite film suitable for plateau areas and preparation method thereof

InactiveCN108943953AIncrease polarityStrong tear resistanceSynthetic resin layered productsBagsComposite filmAdhesive

Owner:湖北宏裕新型包材股份有限公司

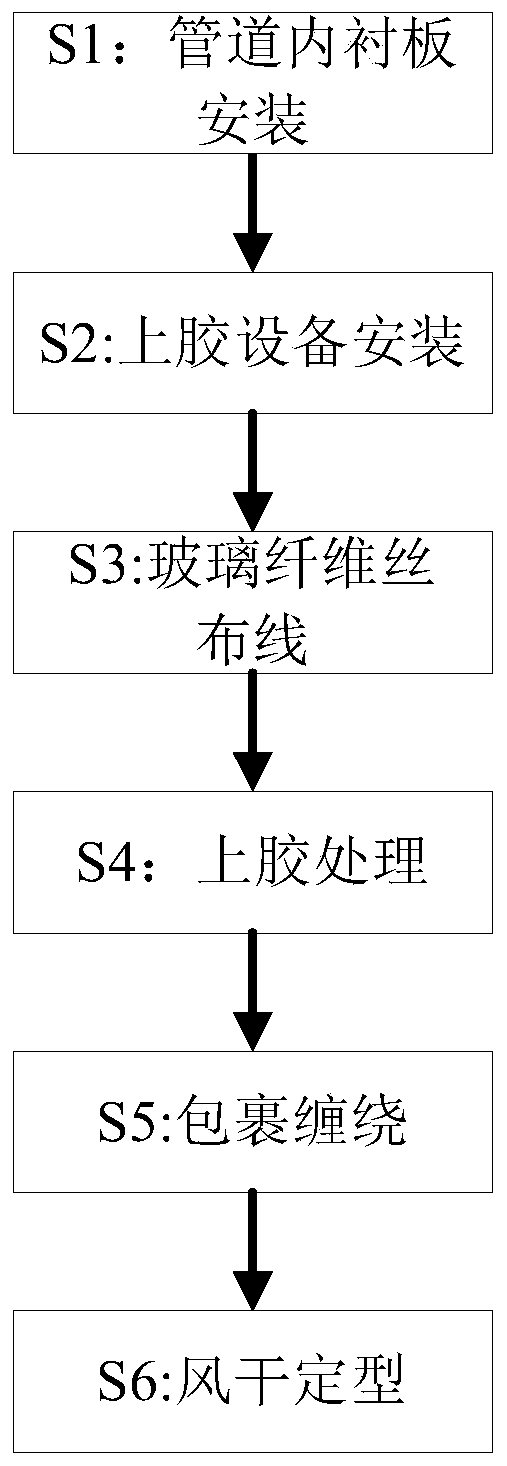

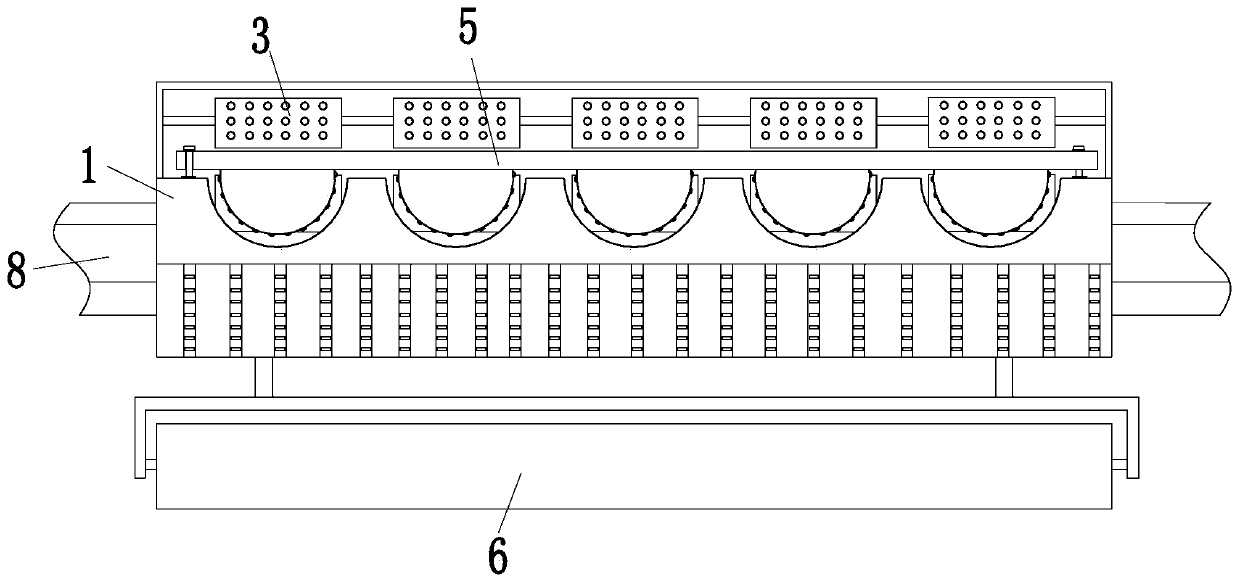

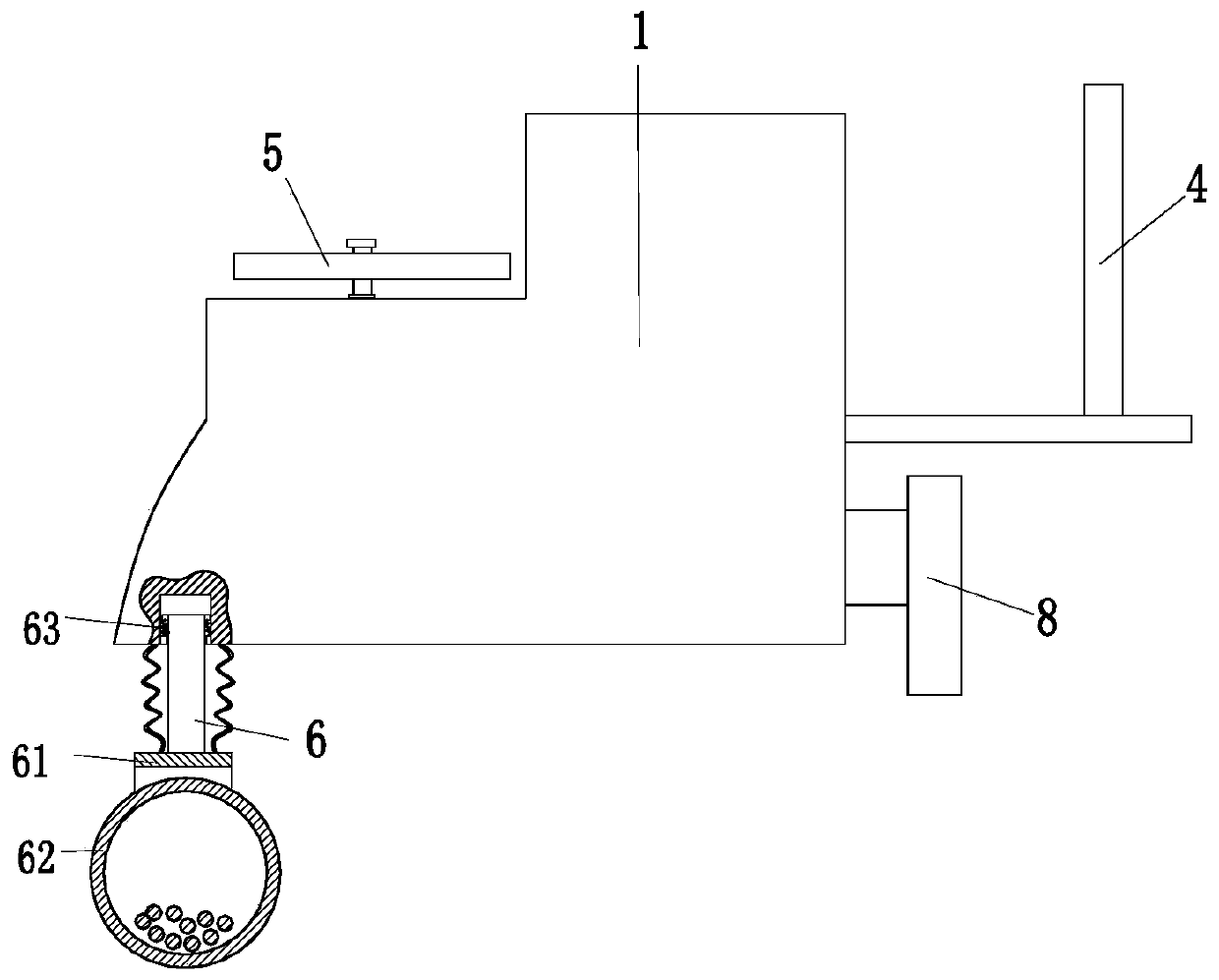

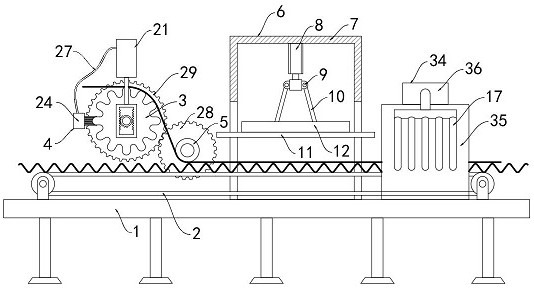

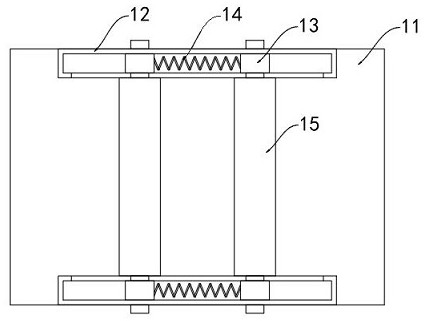

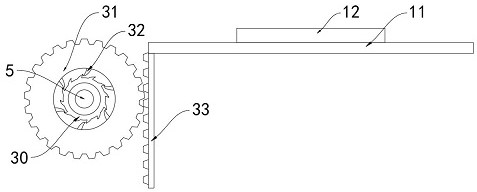

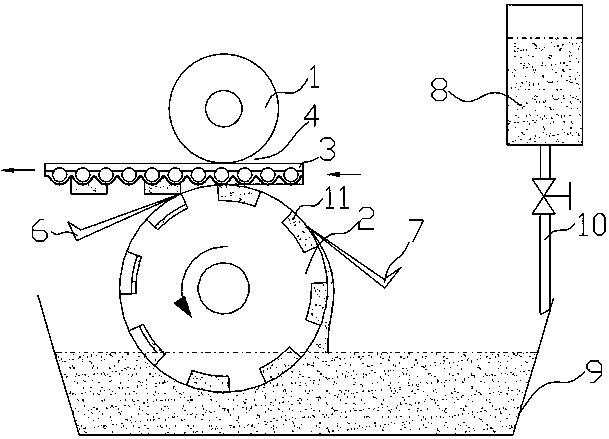

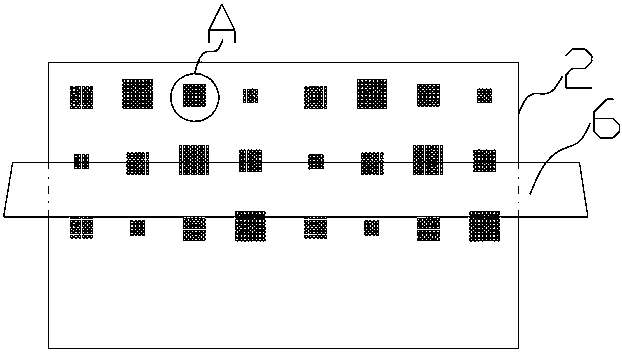

Glass fiber reinforced plastic pipeline production method

ActiveCN110293694ALess glueUniform amount of gluingCoatingsTubular articlesEngineeringConductor Coil

The invention provides a glass fiber reinforced plastic pipeline production method. The glass fiber reinforced plastic pipeline production method is characterized in that a shell, a gluing device, conveying guide wheels, a coiled material barrel set, a downward pressing frame, a gravity roller set, a driving device and an electric sliding block cooperate with one another to complete the operation.The glass fiber reinforced plastic pipeline production method can solve the problems as follows, glass fiber filaments need to be glued before winding, according to the existing gluing process, usually the glass fiber filaments penetrate through a glue liquid surface when being conveyed so that the effect of gluing can be achieved, but the gluing amount often can not be controlled, the glued glass fiber filaments are often tangled up, the glass fiber filaments are not orderly arranged to cause different thickness of winding layers generated in the later winding process, so that the quality ofa glass fiber reinforced plastic pipeline is influenced, and in the winding process, the glass fiber filaments likely wind loosely around a lining layer of the pipeline, so that the surface of the formed glass fiber reinforced plastic pipeline is rough.

Owner:福建纳川管业科技有限责任公司

Glue-bonded multi-ply absorbent sheet

ActiveUS9822285B2Less glueSimple interfaceOther chemical processesCellulose adhesivesCelluloseAdhesive

A multi-ply absorbent sheet includes a first absorbent ply of cellulosic sheet; a second absorbent ply of cellulosic sheet; and a ply bonding adhesive interposed between the first absorbent ply and the second absorbent ply, the ply-bonding adhesive thereby adhering said absorbent plies together. The ply-bonding adhesive comprises polyvinyl alcohol and nanofibrillated cellulose. In a particularly preferred embodiment the adhesive is applied as a dilute aqueous composition to tissue plies and the nanofibrillated cellulose has a Characteristic Breaking Length of 6.5 km or above.

Owner:GPCP IP HLDG LLC

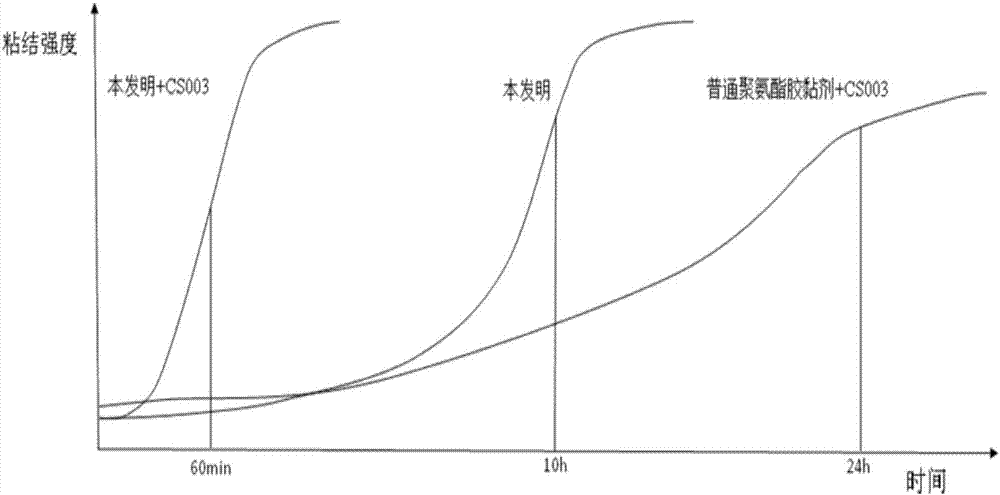

One-component polyurethane adhesive with normal temperature rapid solidification and preparation method thereof

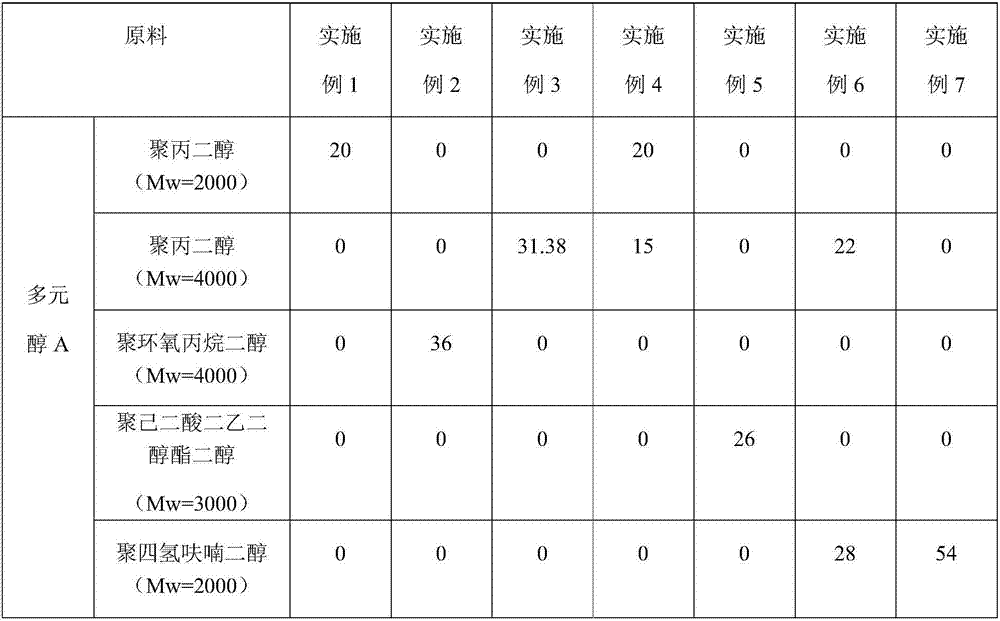

InactiveCN106978126ALow viscosityIncrease crosslink densityPolyureas/polyurethane adhesivesPolyolPolyurethane adhesive

The invention discloses a one-component polyurethane adhesive with normal temperature rapid solidification and a preparation method thereof, and belongs to the technical field of polyurethane adhesives. The adhesive comprises the following formula components in parts by mass: 20-50 parts of polyol A, 5-30 parts of polyol B, 0-60 parts of isocyanate A, 0-60 parts of isocyanate B, 0.01-1 part of a catalyst, and 0.1-3 parts of an auxiliary agent; the usage amounts of isocyanate A and isocyanate B are not zero at the same time; the viscosity of the adhesive at a normal temperature is 3000-30000mPa.s, and the content of NCO group is 7-25%. Polyol whose functionality is 3 is used, so that average functionality of the adhesive is higher than 2; during solidification, net crosslinking is generated, the solidification rate is faster, the bonding strength is higher, and solidification time is further shortened by using an activator; the product has the characteristics of low viscosity at a normal temperature, good stability of roller coating, and the like.

Owner:佛山市顺德区巴德富实业有限公司

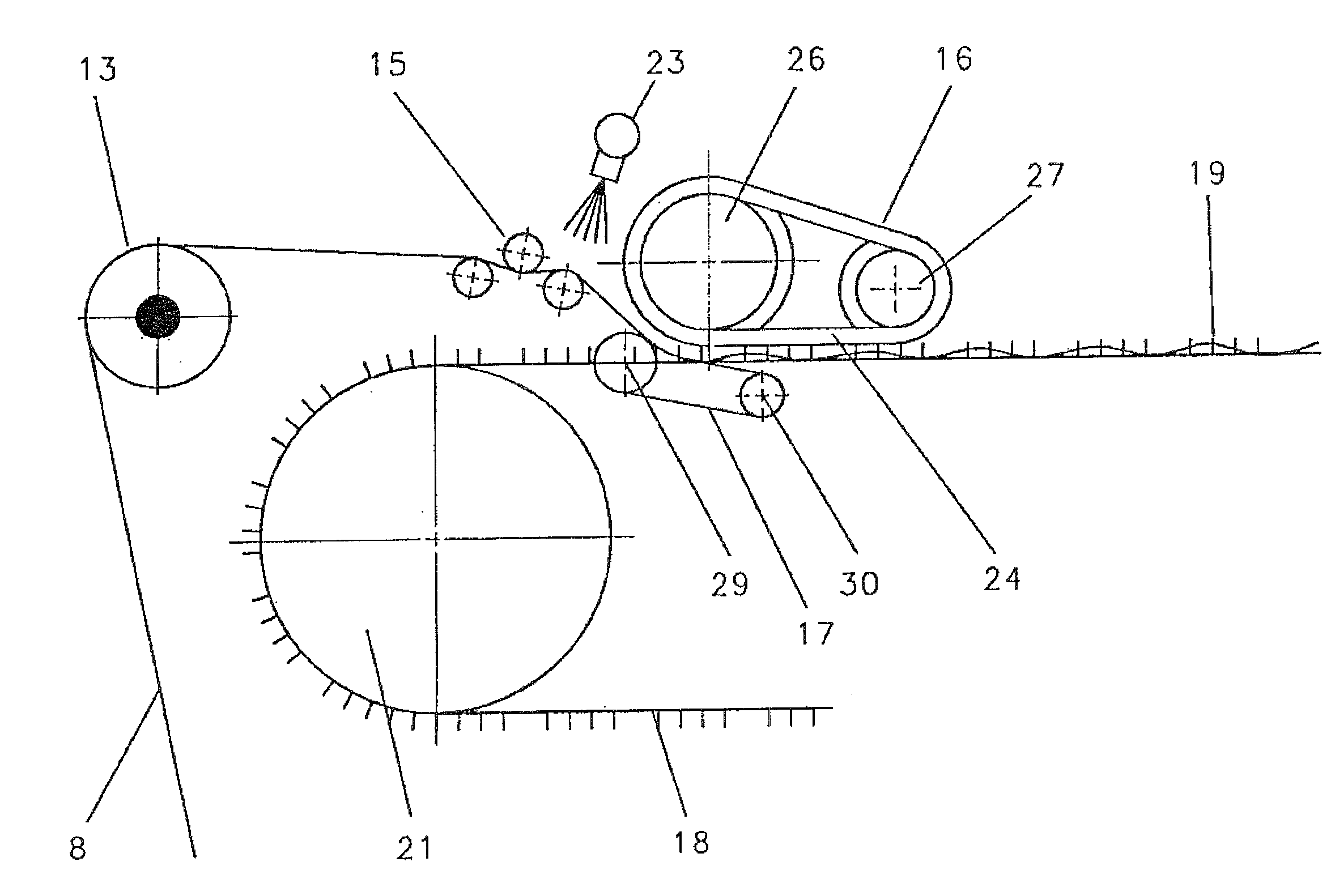

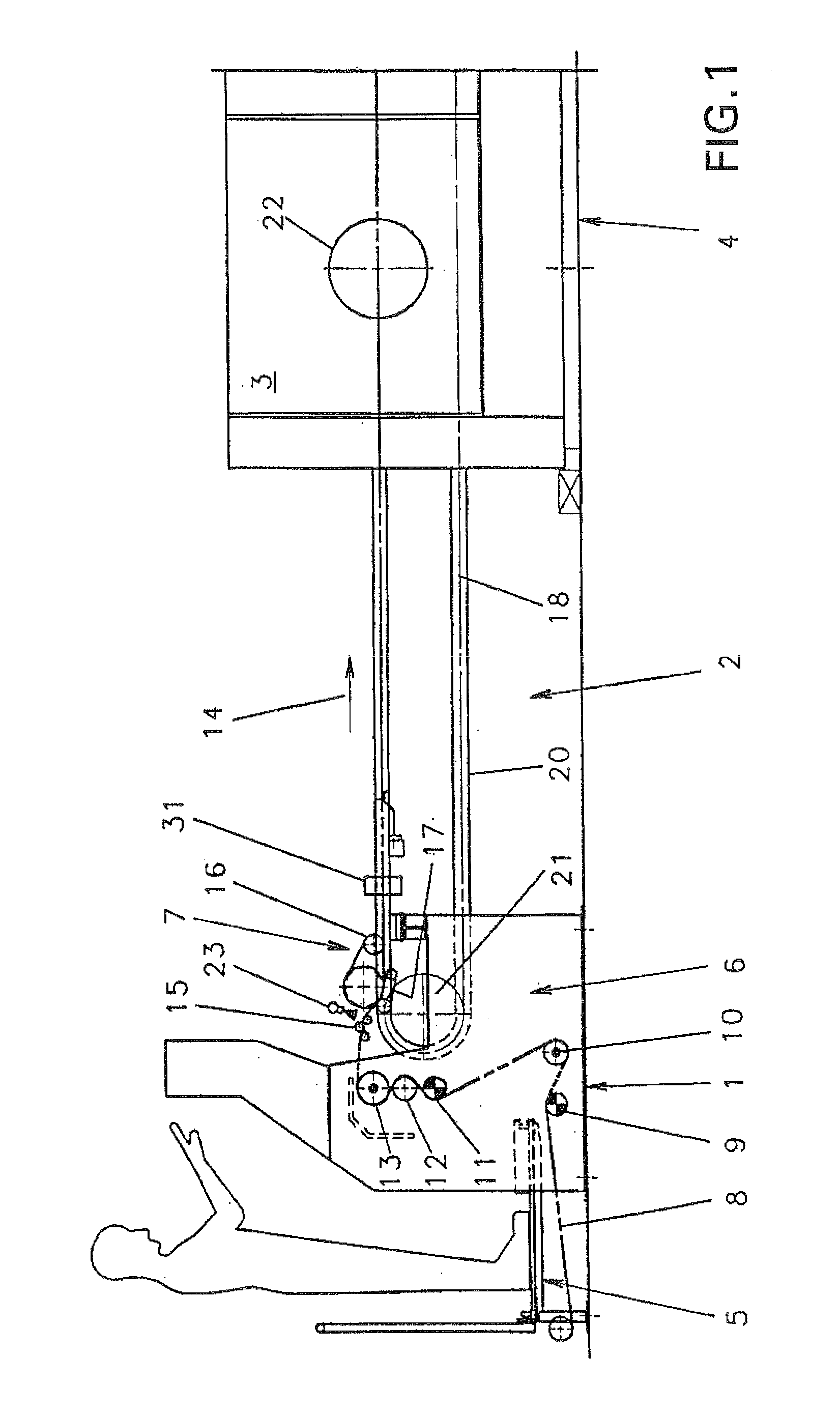

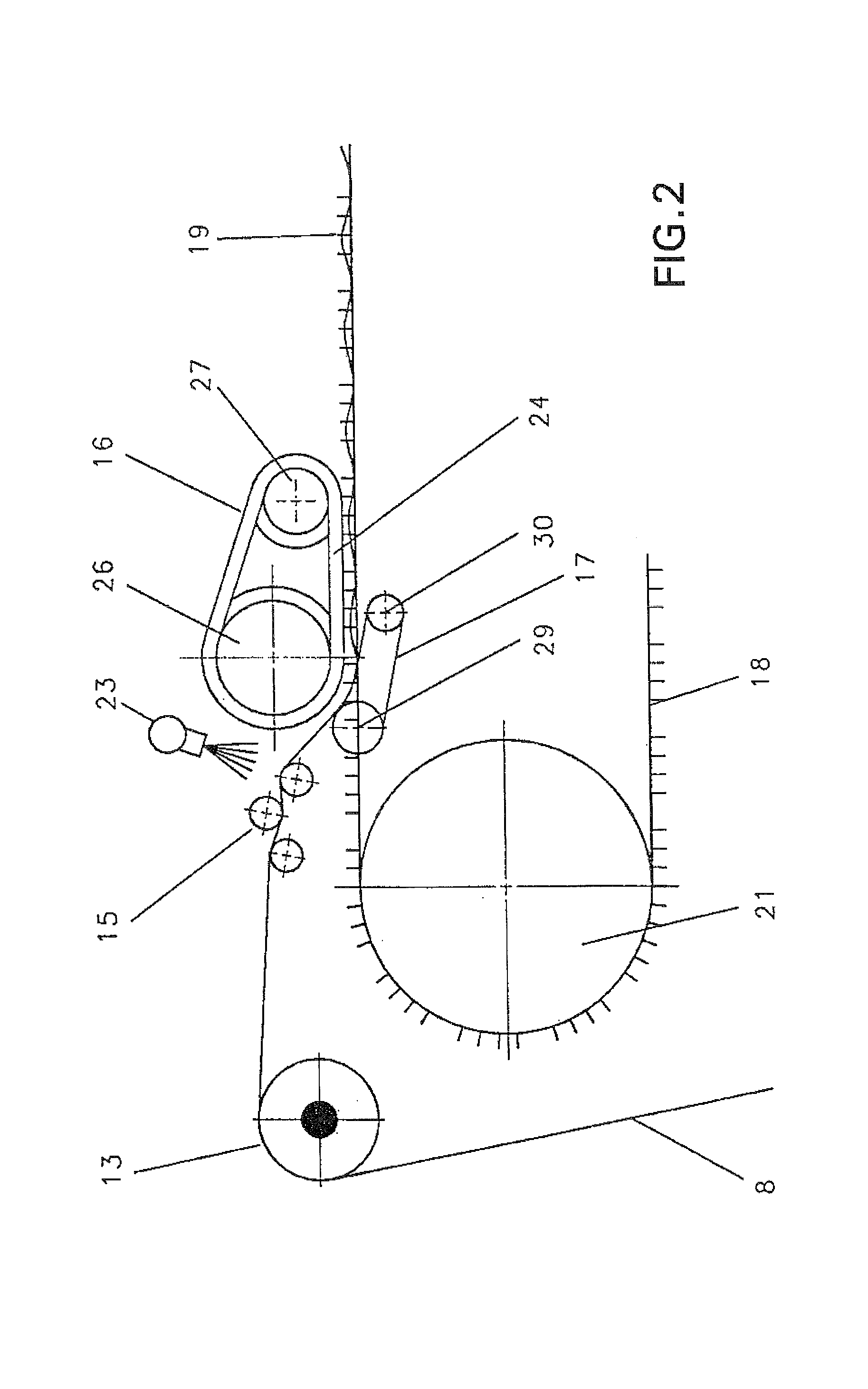

Method of edge glueing, and a tensioning aggregate with a device for edge glueing

InactiveUS7322312B1Less glueLess drying energyLiquid surface applicatorsTextile selvedgesEngineering

Owner:BABCOCK TEXTILMASCH

Novel production process for reconstituted bamboo and reconstituted wood

InactiveCN105382891ALess glueReduce production processCane mechanical workingWood veneer joiningVolumetric Mass DensityManufacturing engineering

The invention discloses a novel production process for reconstituted bamboo and reconstituted wood. According to the process, coating glue and spraying glue which are free of gum dipping and drying are adopted, the gluing amount can be reduced by at least 50%, each wooden veneer and each wooden sheet can be coated and sprayed with original glue without being dried or aired, and production working procedures are reduced. The reconstituted bamboo manufactured through the process can be used for floor decoration materials, floors, reconstituted bamboo furniture and outdoor floor materials and does not contain broken bamboo shreds or building formworks or carriage boards or container bottom boards formed by pressing bamboo chips and bamboo strips, and the density of the manufactured reconstituted wood which is put in a mold to be cold-pressed can reach over 0.9.

Owner:宋建平

Method for processing recombined bamboo with small-diameter bamboo wood

InactiveCN103350441AReduce yieldKeep basic featuresWood working apparatusDomestic articlesSugarComputer science

The invention relates to a method for processing a recombined bamboo with small-diameter bamboo wood, belonging a green removing process being dominated by a green scraping method and providing a whole set of method suitable for processing the recombined bamboo with small-diameter bamboo wood. The method comprises following eight sequential steps of: A. sawing off an original bamboo with a disk saw; B. slicing the sawn bamboo wood with a multichip slicer; C. scraping green on bamboo sheets; D. rolling the bamboo sheets with green scraped through a primary rolling wheel set into flexible bamboo sheets connected with each other; E. boiling the rolled bamboo sheets to remove sugar; F. drying the rolled bamboo sheets; G. coating glue on the dried bamboo sheets; and H. carrying out cold forming or hot-press gluing on the bamboo sheets with glue so as to form novel recombined bamboo. According to the method, problems of difficulty in removing green, low use ratio of the bamboo wood, high production cost, and difficulty in processing small-diameter bamboos in the prior art are solved.

Owner:CHONGQING JINDIAN FORESTRY

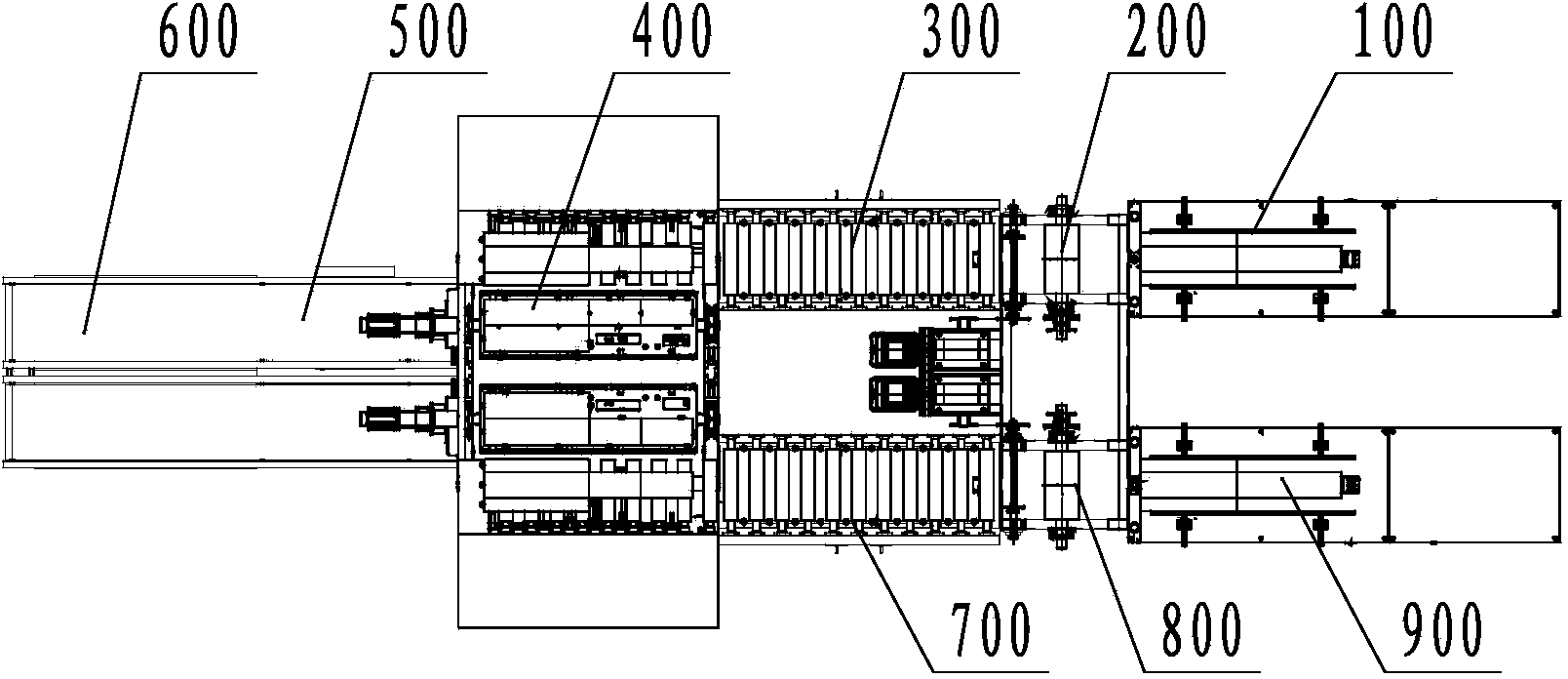

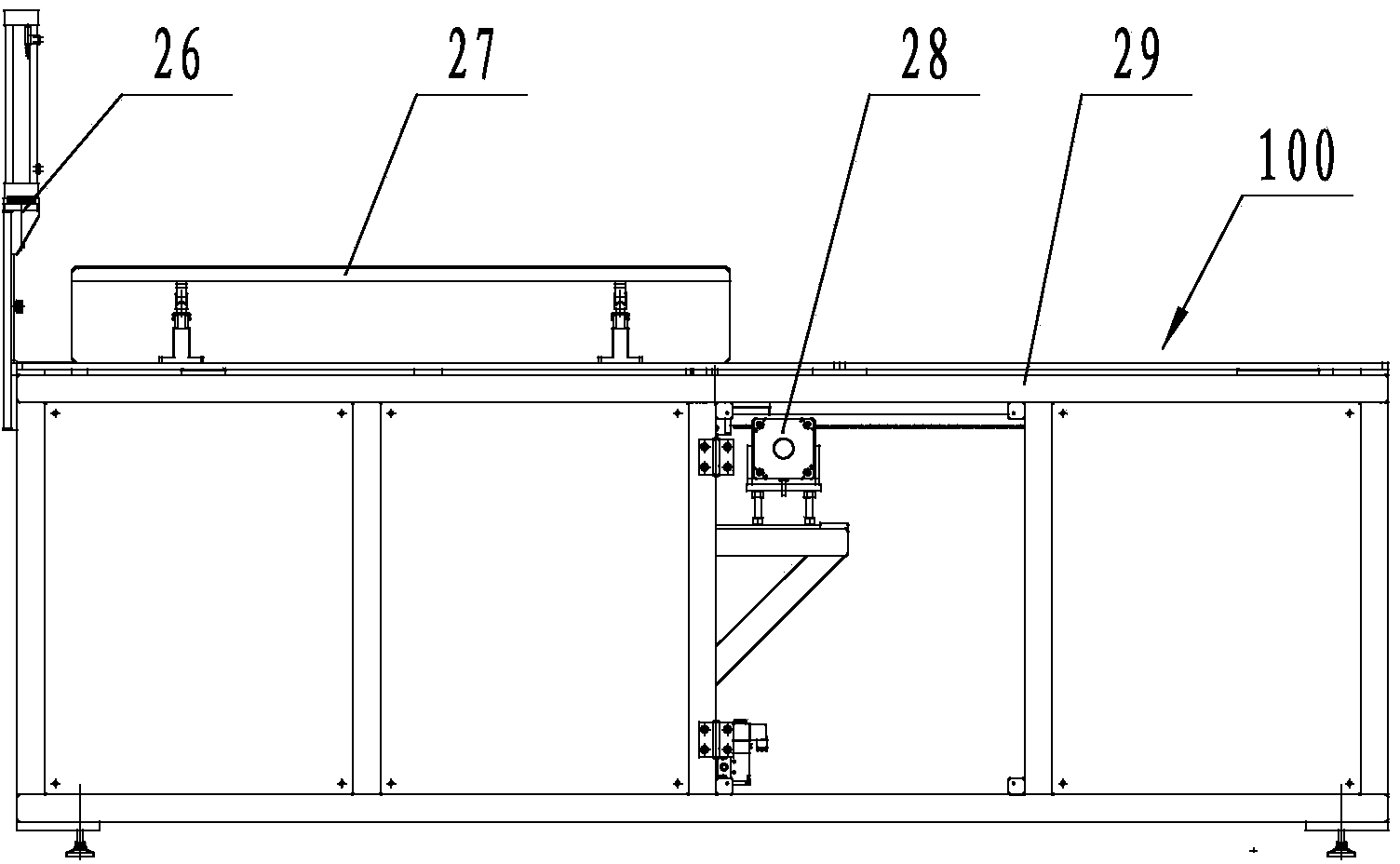

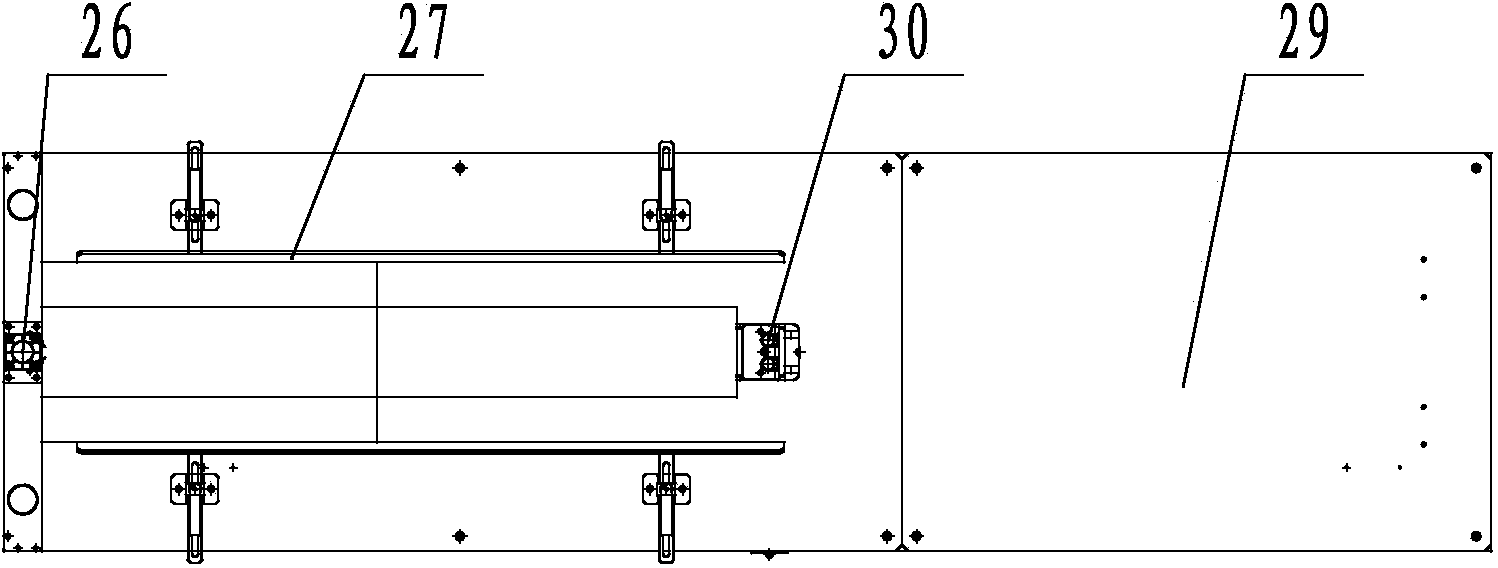

PVC (polyvinyl chloride) floor fitting device

ActiveCN103722863AGuaranteed fitting accuracyShorten the timeLamination ancillary operationsLaminationPolyvinyl chlorideEngineering

The invention relates to a PVC (polyvinyl chloride) floor fitting device which comprises a high-speed fitting machine, wherein a surface material loading gluing device and a base material loading gluing device are arranged at the feeding end of the high-speed fitting machine, and a belt conveying line and a pressure applying and maintaining machine are arranged at the discharging end of the high-speed fitting machine; the surface material loading gluing device and the base material loading gluing device are respectively provided with a feeding device, a gluing machine and a conveying device; the high-speed fitting machine comprises a surface material fitting roller and a base material fitting roller which are arranged in parallel and are rotatably mounted on a surface material fitting roller moving mechanism and a base material fitting roller moving mechanism respectively; a surface material conveying roller and a surface material loading mechanism are respectively arranged on the outer side of the surface material fitting roller; a base material conveying roller and a base material loading mechanism are arranged on the outer side of the base material conveying roller. According to the PVC floor fitting device, the product fitting operation is finished by adopting the high-speed fitting machine with the two opposite rotatable fitting rollers, the loading and unloading operations can be performed at the same time, and the fitting efficiency is improved.

Owner:WUXI WOGE SOFTWARE

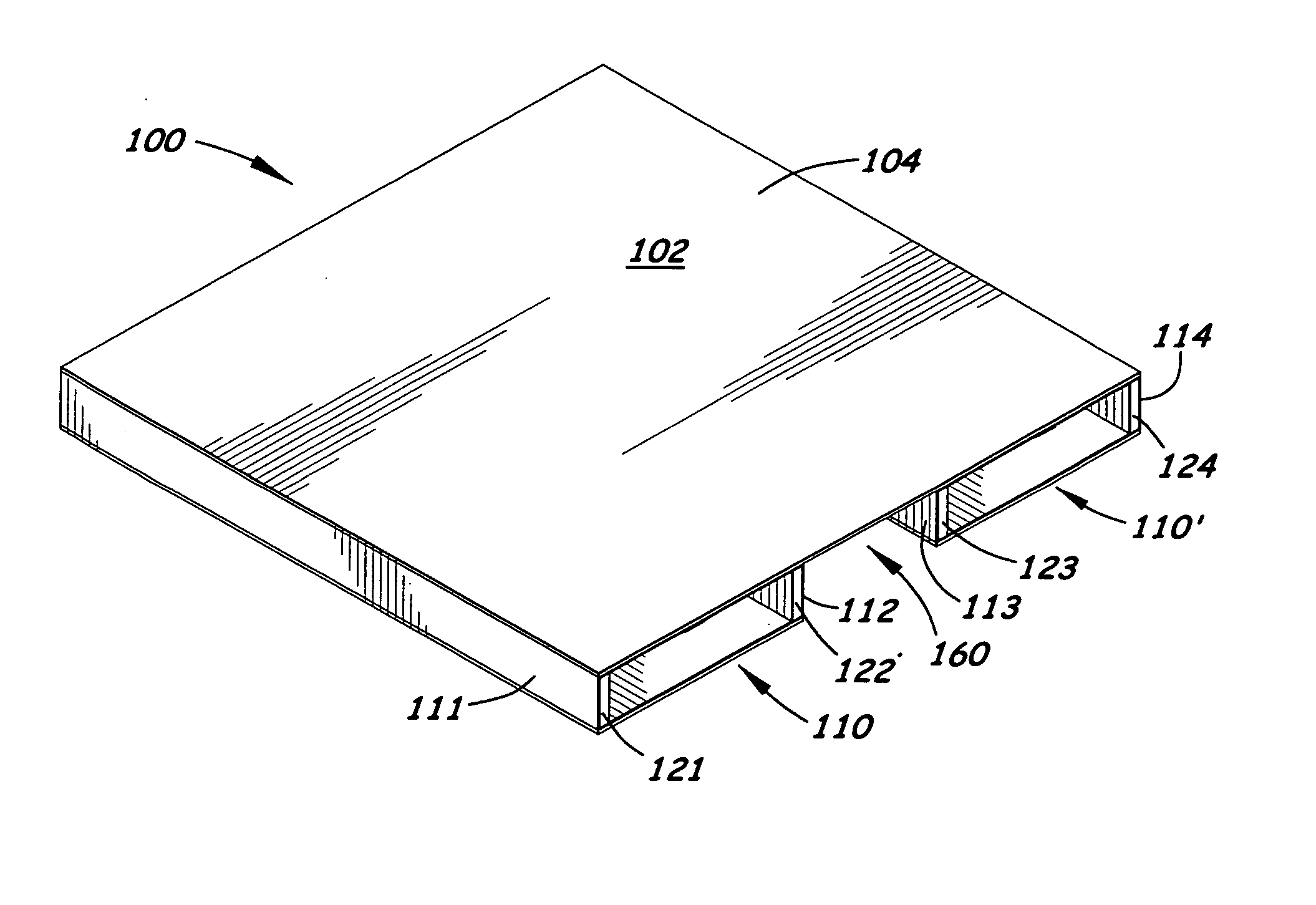

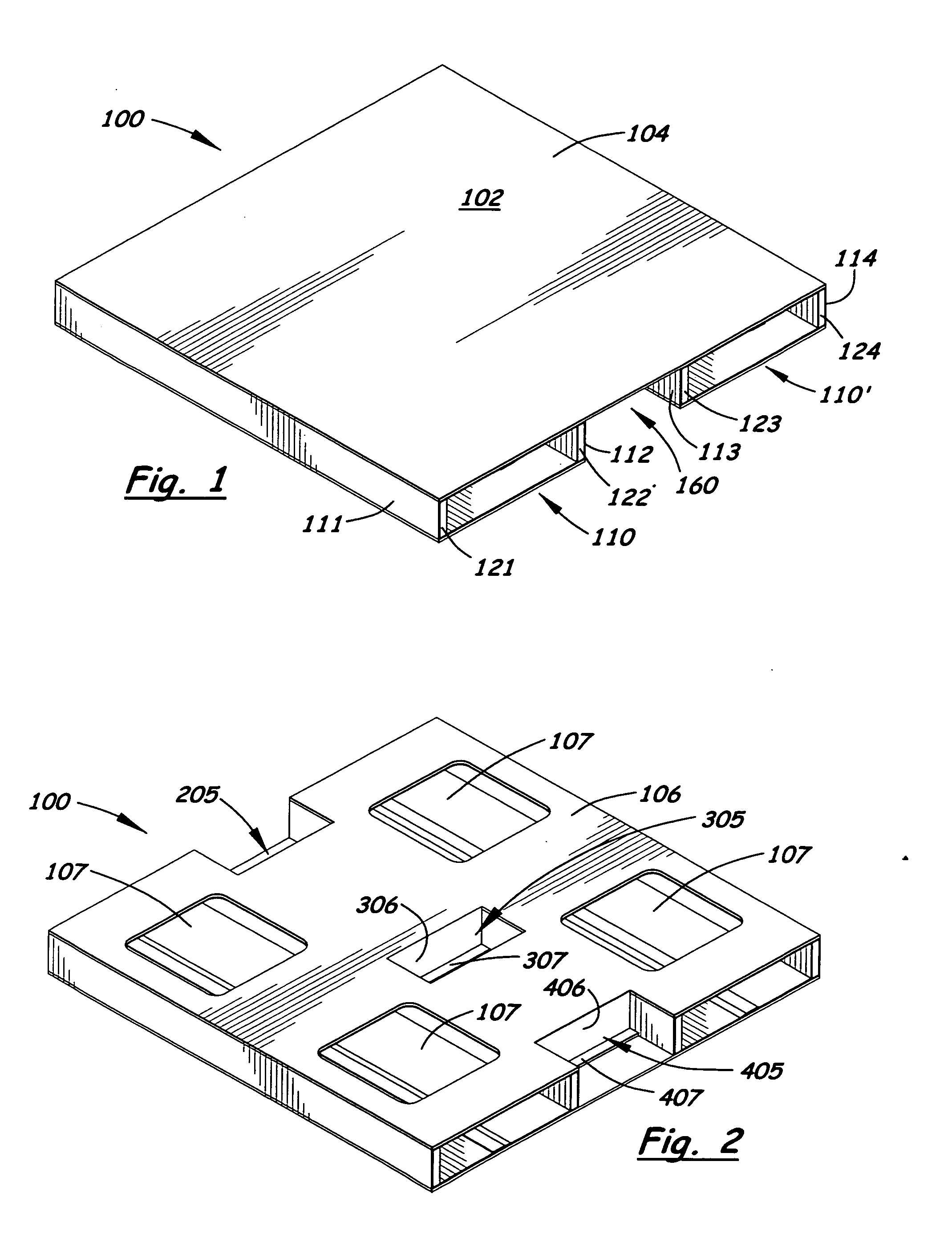

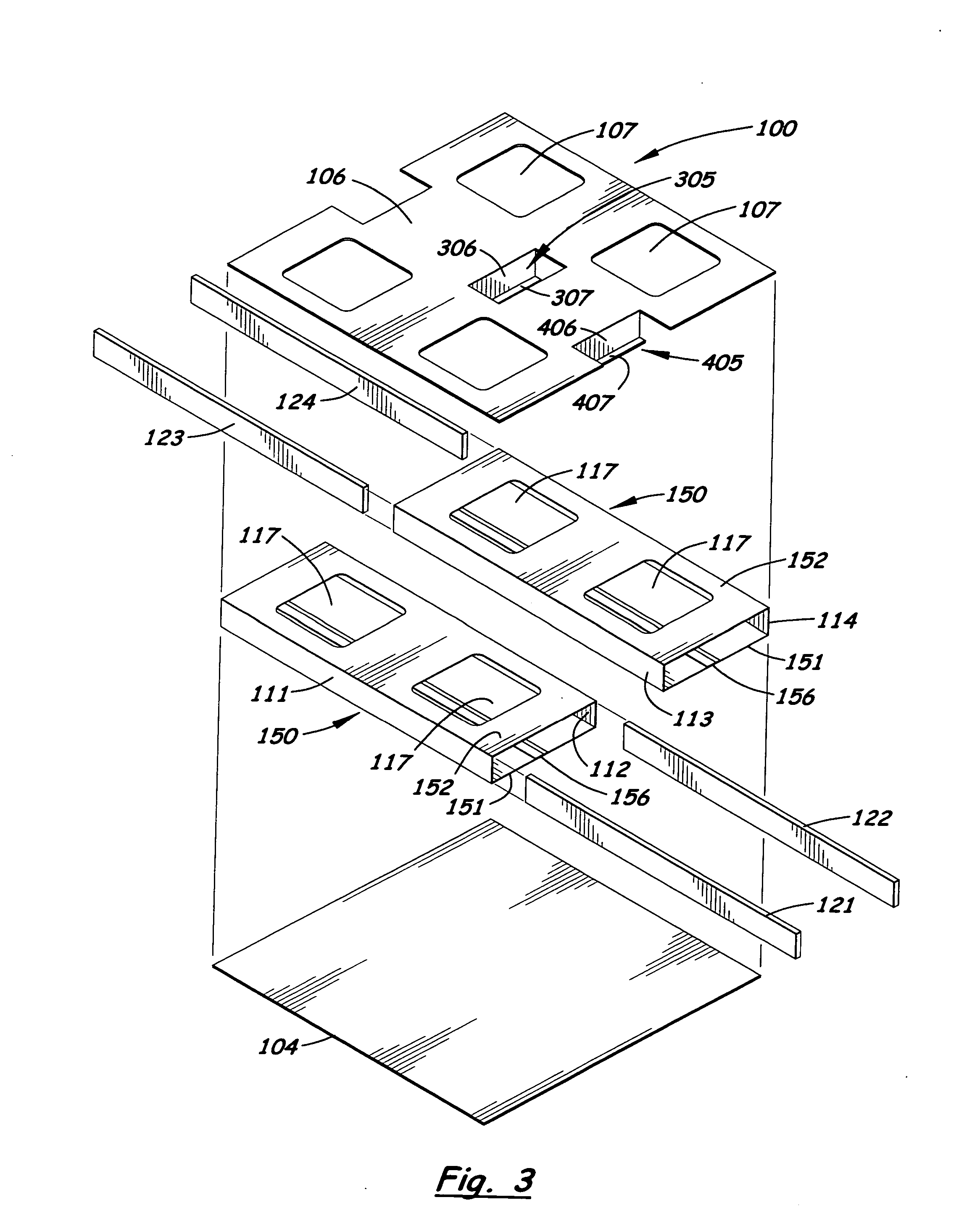

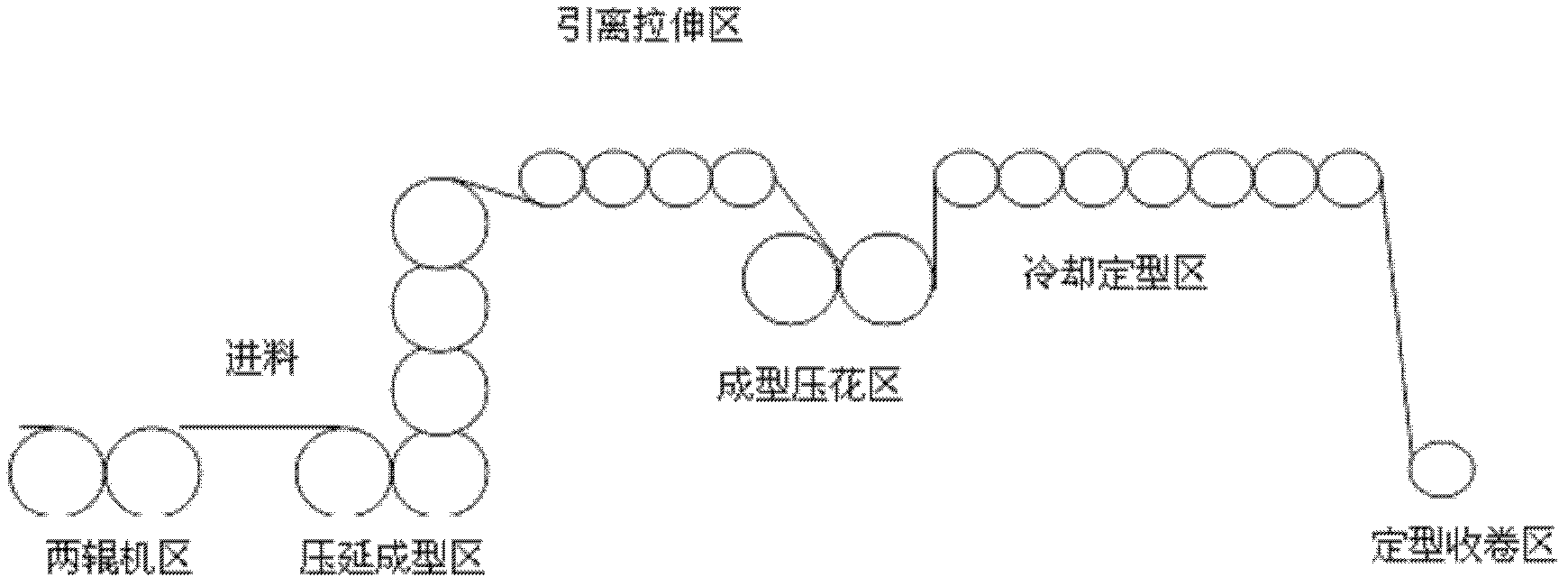

Pallet having corrugated components and modular method of making same

A pallet is made substantially or entirely of corrugated material such as corrugate cardboard. Wooden, plastic, dense foam, or composite material runners may be inserted into sleeves in the pallet, or, in other embodiments, runner channel assemblies are provided that are preferably entirely corrugate paper. Simple, modular structure allows the pallet to be made of few parts, with many of the parts being identical. Vertical securement flaps may extend between at least two of the sleeves or runner channel assemblies, thus, providing for reinforcing / securing of the relative position of the sleeve units or channel assemblies, the deck panel, and the bottom panel, to further ensure that the pallet will not collapse in use. By providing multiple longitudinal runner assemblies, with at least one transverse wall extending between two of the runner assemblies, a strong and yet lightweight pallet is provided, which may be recycled and which tends to be safe and easy to handle.

Owner:DIXON DOUGLASS W

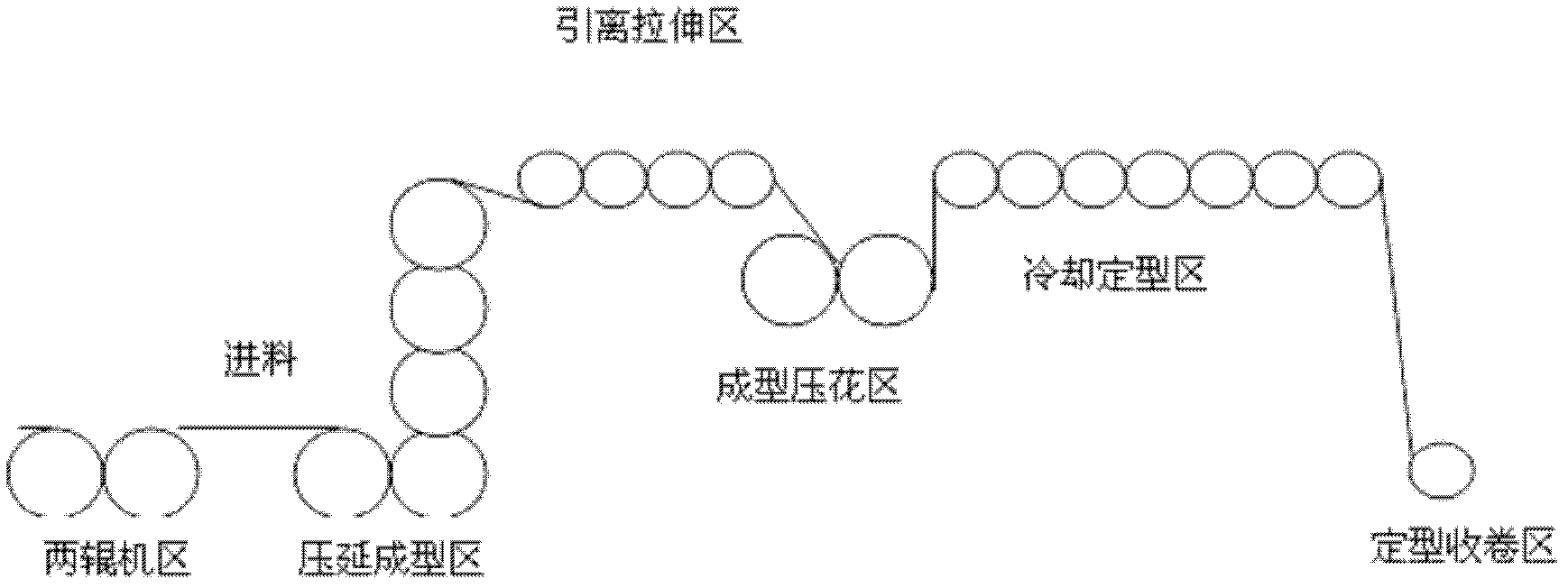

Method for producing PVC-B (polyvinyl chloride-board) magnetic card surface course

ActiveCN102350797AStable thickness controlStable performance such as thickness controlSheet filmKnurling

The invention relates to a technological process for producing a PVC magnetic card base material, and aims at providing a method for producing a PVC-B magnetic card surface course with stable performances such as high production efficiency, low cost, beautiful, fine and smooth surface stripes, controllable superthin material thickness and the like. The method for producing the PVC-B magnetic cardsurface course comprises the following production steps of: 1) metering and stirring raw materials, and feeding in an extruder; 2) putting the extruded materials in a two-roller area, and uniformly plastifying PVC powder; 3) entering a calendaring area, thus primarily forming the PVC powder in shape of a film; 4) entering a centrifuging stretching area, thus causing the formed PVC film to achievethe desired size; 5) entering a moulding knurling area, thus knurling and shaping the PVC film; 6) entering a cooling shaping area, thus cooling, flattening and shaping the PVC film; and 7) entering a shaping coiling area, thus coiling the formed PVC film.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

Gluing and compounding device for packaging corrugated boards

PendingCN114228262ALarge and uniform contact areaNot prone to deformation and wrinklesMechanical working/deformationCardboardAdhesive

The invention belongs to the technical field of corrugated board production and processing, and particularly relates to a packaging corrugated board gluing and compounding device which comprises a rack, a conveying belt used for conveying corrugated paper is arranged on the rack, a gluing roller is arranged on the rack, a gluing mechanism is arranged on the gluing roller, a guide roller is arranged on the output side of the gluing roller, and a gluing mechanism is arranged on the guide roller. A compounding mechanism is arranged on the output side of the guide roller; the compounding mechanism comprises a compounding chamber fixed to the rack, an air cylinder is installed on the top face of the compounding chamber, and the output end of the air cylinder is fixedly connected with a hinge base. The gluing mechanism and the compounding mechanism are in close fit operation, the contact area of a pressing plate and corrugated paper is large and uniform, deformation and wrinkles are not prone to occurring, cardboard paper and the corrugated paper are tightly glued and bonded, the product quality is guaranteed, an adhesive is sucked through an adhesive suction barrel and conveyed to a gluing channel, and the production efficiency is improved. And the adhesive is uniformly coated on the convex teeth on the surface of the glue coating roller by the bristles on the brush plate, so that the cardboard paper can be uniformly and effectively glued.

Owner:张美皊

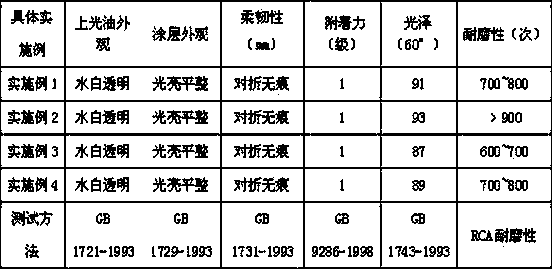

High-performance water-based UV cured glazing oil for paper and preparation method thereof

ActiveCN103821028AAddress flexibility issuesSolve the problem of using reactive diluentsDefoamers additionPaper/cardboardEpoxyPolymer science

The invention provides high-performance water-based UV cured glazing oil for paper and a preparation method thereof. The high-performance water-based UV cured glazing oil for paper is characterized in that a water-based polyurethane-epoxy acrylate UV cured prepolymer is adopted as main resin, and is added with a photoinitiator, an auxiliary agent, water or ethanol water for compounding, so that the water-based UV cured glazing oil for paper can be prepared. The preparation method is characterized by comprising the following specific steps: step 1, synthesis of a polyurethane prepolymer; step 2, synthesis of polyurethane modified epoxide resin; step 3, synthesis of a polyurethane-epoxy acrylate prepolymer; step 4, synthesis of the high-performance waterborne polyurethane-epoxy acrylate UV cured prepolymer; step 5, compounding of the waterborne polyurethane-epoxy acrylate UV cured resin with the photoinitiator, the auxiliary agent, water or ethanol water. The high-performance waterborne UV cured glazing oil for paper has the advantages that energy conservation and environmental protection are achieved; the levelling property is excellent; high smoothness, high abrasion resistance and high resistance to viscidity are achieved; a good coating effect can be achieved with smaller gluing amount.

Owner:江门市邦德涂料有限公司

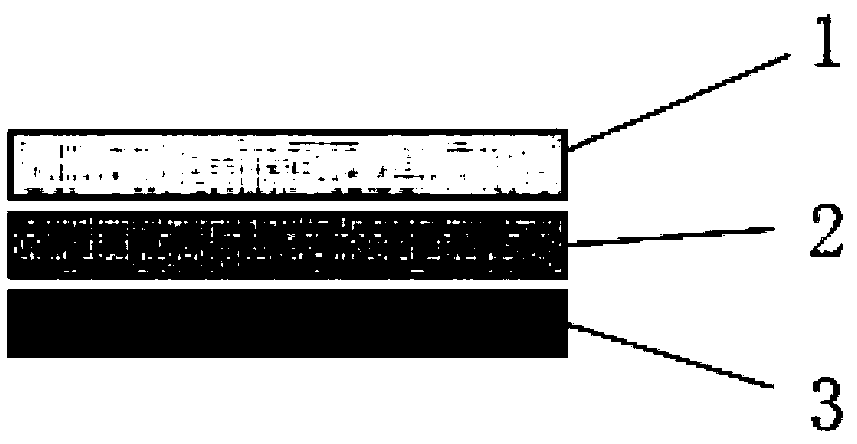

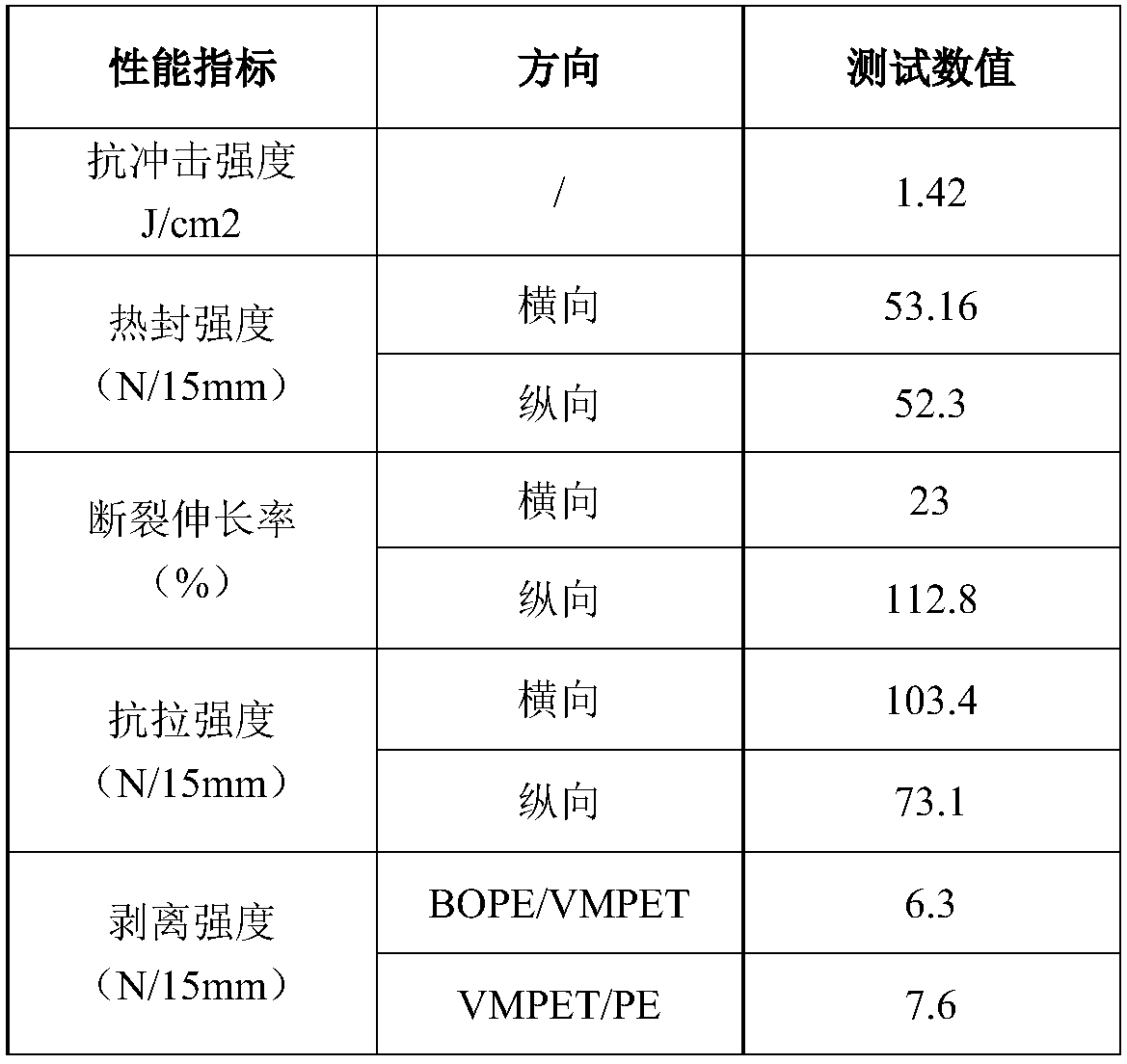

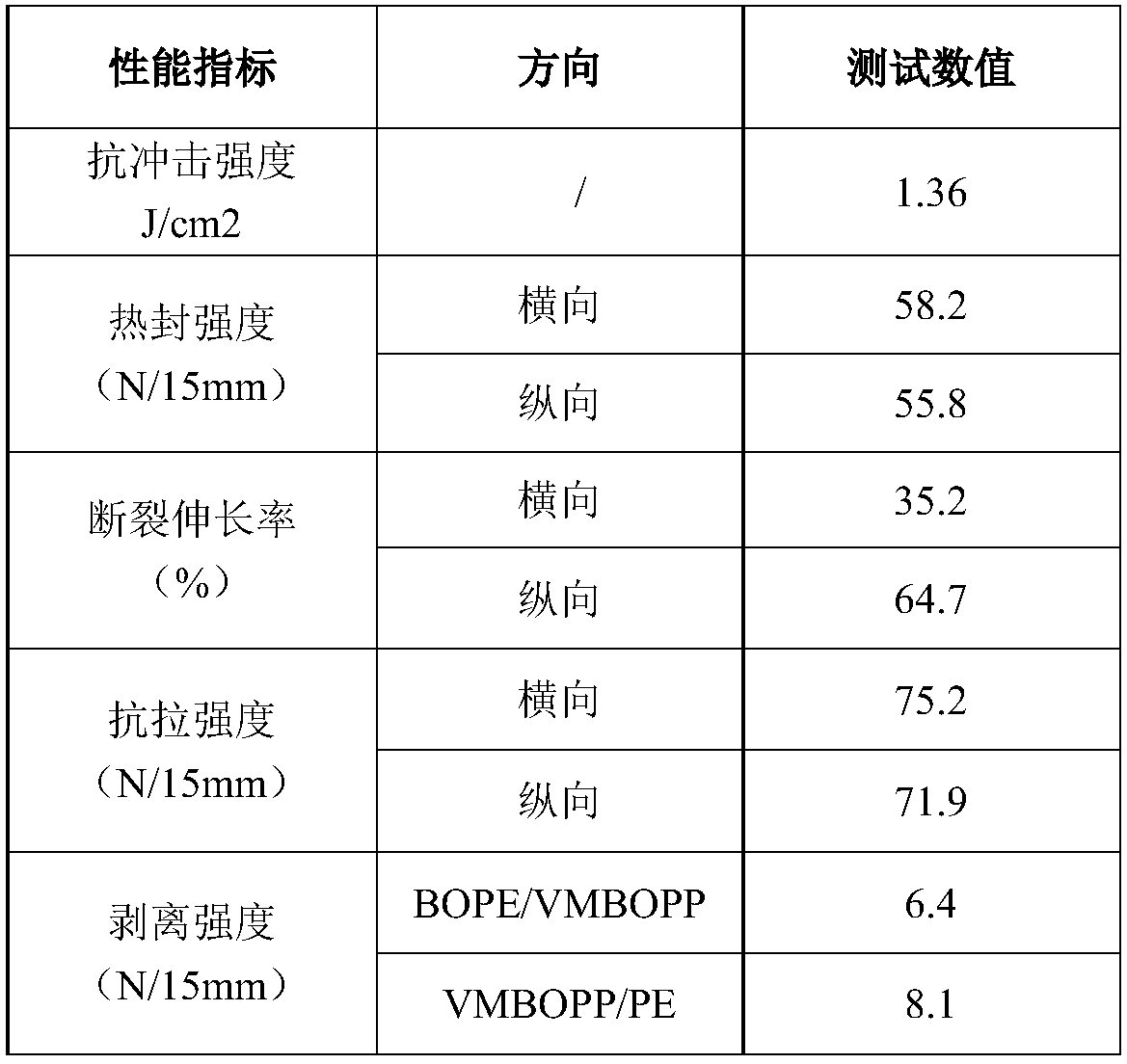

Water-based coated composite environment-friendly packaging material and preparation process thereof

PendingCN113071175AOptimized formulaMeet the needs of health, sanitation and environmental protectionFlexible coversWrappersPolyolefinAdhesive

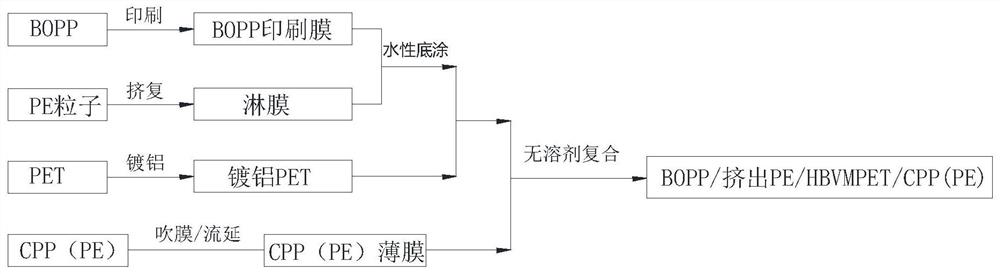

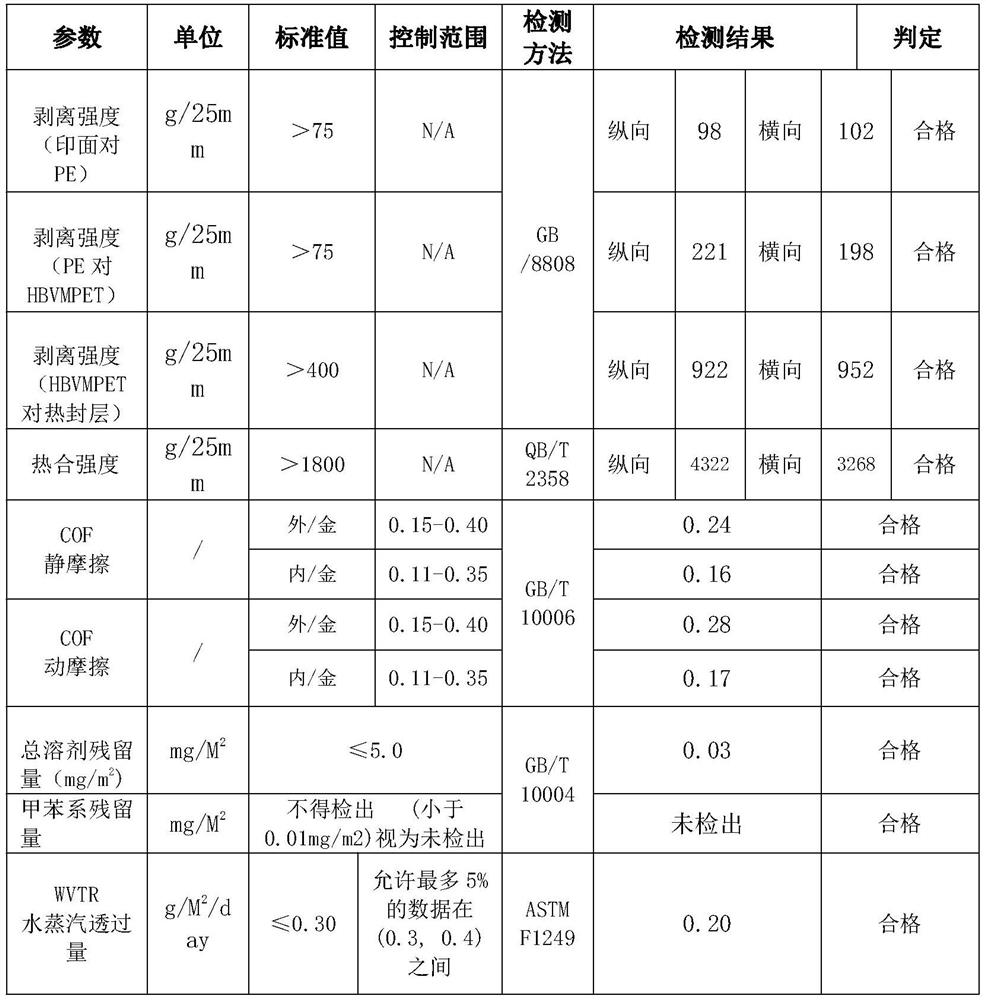

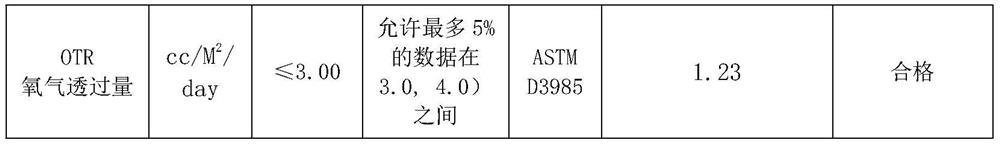

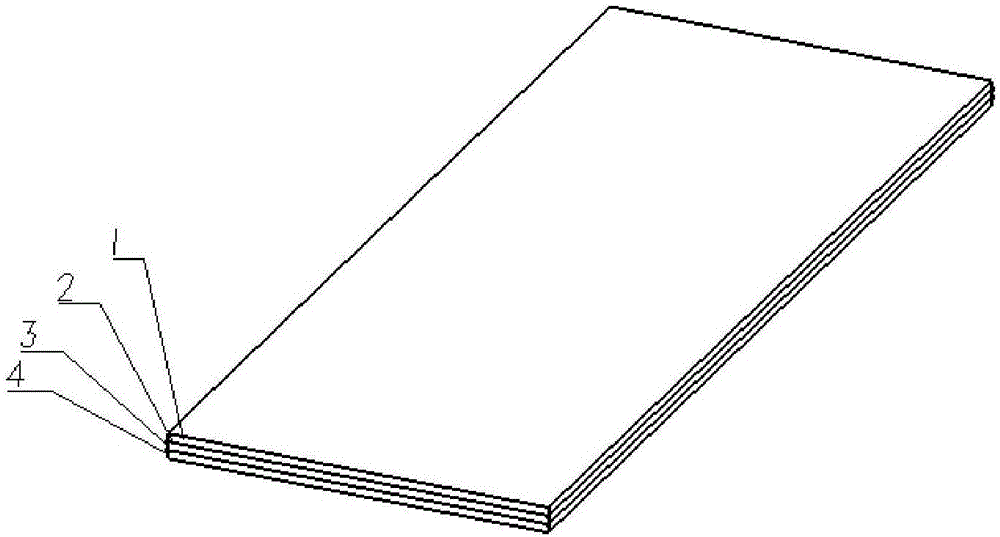

The invention provides a water-based coated composite environment-friendly packaging material and a preparation process thereof, and belongs to the technical field of packaging. The composite environment-friendly packaging material comprises a second composite film, the second composite film is obtained by a first composite film and a polyolefin film through a solvent-free extrusion compounding technology, the first composite film comprises a BOPP printing layer and an aluminum-plated PET layer, the BOPP printing layer and the aluminum-plated PET layer are bonded into a whole through a spraying film, the BOPP printing layer and the spraying film are bonded into a whole through an upper adhesive layer, the upper adhesive layer is a water-based primer adhesive, the BOPP printing layer is prepared by printing a BOPP film by adopting a satellite type flexographic printing machine, and the aluminized PET layer is connected with the polyolefin film. Starting from VOCS emission treatment and aluminum layer protection, the green and environment-friendly composite packaging material without VOCS emission and without aluminum layer delamination is prepared by adopting the water-based primer adhesive, optimizing a lamination layer formula, adopting a solvent-free compounding mode and the like, and the requirements of markets and consumers for health, sanitation and environmental protection are met.

Owner:永新股份(黄山)包装有限公司

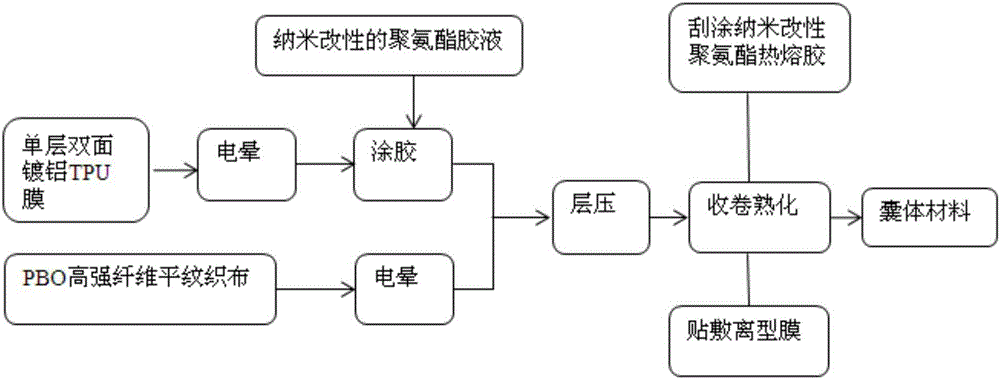

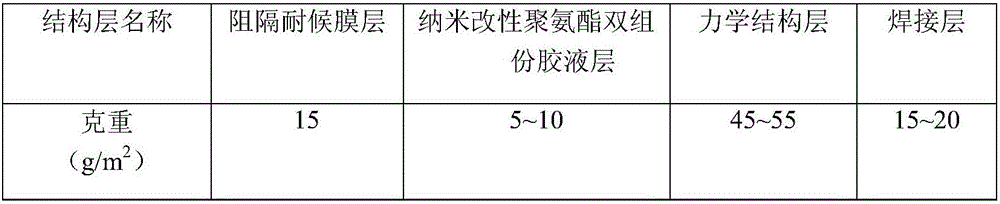

Nanometer modified capsule material for high-altitude aerostat and preparation method thereof

ActiveCN106393902AHigh strengthLight in massLamination ancillary operationsSynthetic resin layered productsPlain weaveNanometre

The invention specifically relates to a nanometer modified capsule material for a high-altitude aerostat and a preparation method thereof, belonging to the field of aerospace materials. The capsule material comprises a blocking weather-proof film, a nanometer modified glue solution layer, a mechanical structure layer and a nanometer modified welding glue solution layer, wherein one surface of the mechanical structure layer is connected with the blocking weather-proof film through the nanometer modified glue solution layer while the other surface of the mechanical structure layer is connected with the nanometer modified welding glue solution layer; the mechanical structure layer is a PBO high-strength fiber plain weave fabric; and the nanometer modified welding glue solution layer is a polyurethane hot melt adhesive with a nano-material. The capsule material prepared in the invention has the beneficial effects of high strength, light weight, low helium permeability, good weatherability, strong performance in preventing a capsule from absorption of sun light energy in flight during daytime; and the preparation method is easy to operate and control.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

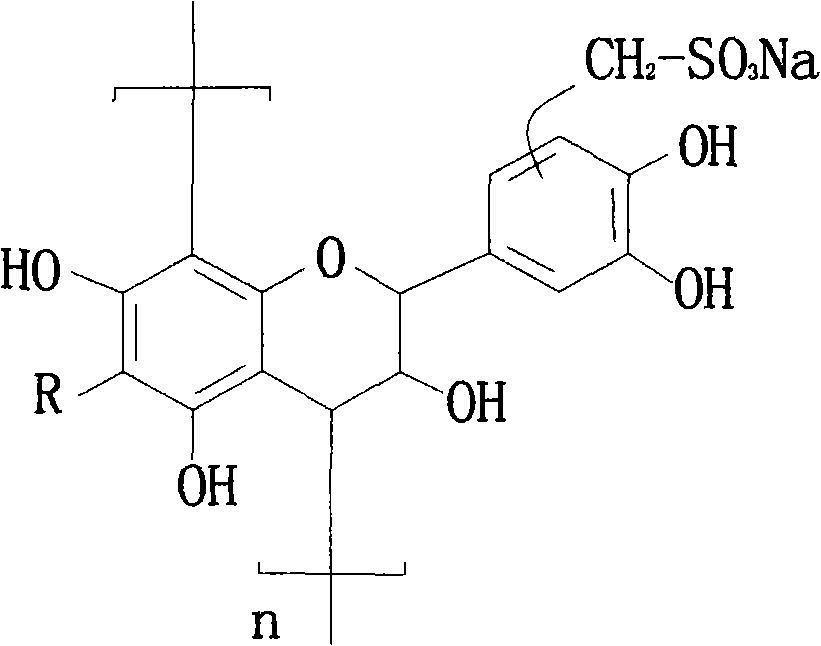

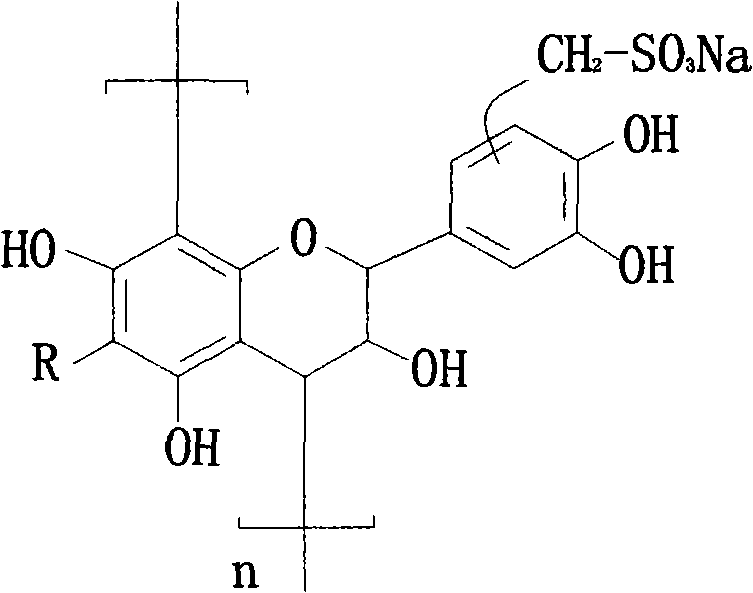

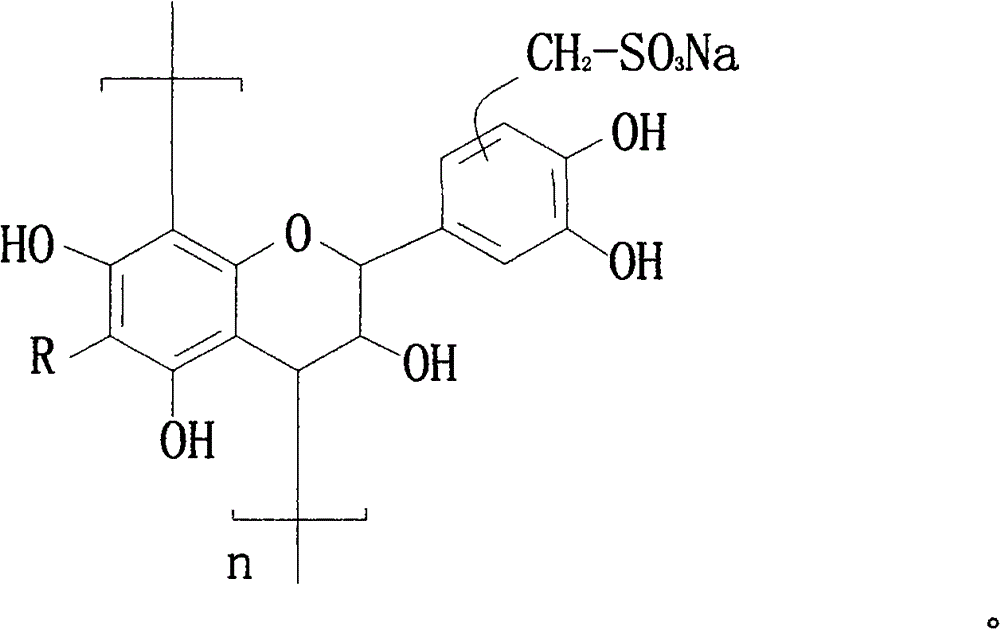

Corrugated carton penetrant made of tannin of natural quebrachos and preparation method of corrugated carton penetrant

InactiveCN102746806AAvoid degummingReduce surface tensionMacromolecular adhesive additivesCardboardNatural product

The invention relates to the technical field of corrugated board processing, in particular to a corrugated carton penetrant made of tannin of natural quebrachos and a preparation method of the corrugated carton penetrant. The corrugated carton penetrant made of the tannin of the natural quebrachos is a natural board degumming prevention agent obtained after special chemical modification of a tannin product of a natural polyphenol structure extracted from the natural quebrachos grown in northeast of Argentina, is a natural product integrating unique penetrability, water resistance and natural viscosity, and is widely applied to corrugated boards with the degumming problem due to high fiber density and overlarge paper surface tension. Besides, the unique natural penetrability of the corrugated carton penetrant perfectly solves the problem of degumming of the corrugated boards.

Owner:上海荷沪生物科技有限公司

Glue-Bonded Multi-Ply Absorbent Sheet and Polyvinyl Alcohol Ply Bonding Adhesive

ActiveUS20180037781A1Less glueSimple interfaceCellulose adhesivesUnsaturated alcohol polymer adhesivesCelluloseAdhesive

A multi-ply absorbent sheet includes a first absorbent ply of cellulosic sheet; a second absorbent ply of cellulosic sheet; and a ply bonding adhesive interposed between the first absorbent ply and the second absorbent ply, the ply-bonding adhesive thereby adhering said absorbent plies together. The ply-bonding adhesive comprises polyvinyl alcohol and nanofibrillated cellulose. In a particularly preferred embodiment the adhesive is applied as a dilute aqueous composition to tissue plies and the nanofibrillated cellulose has a Characteristic Breaking Length of 6.5 km or above.

Owner:GPCP IP HLDG LLC

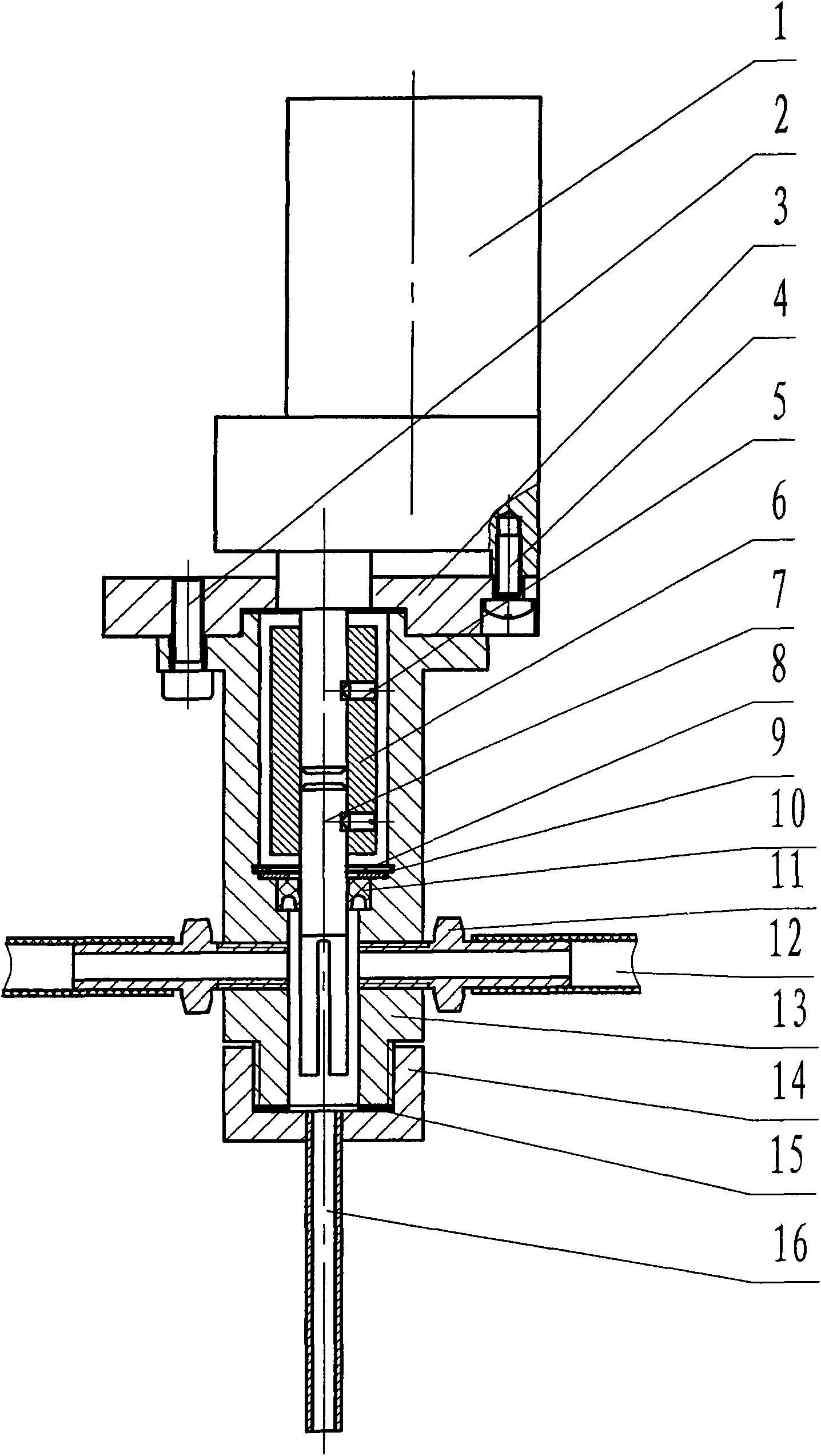

Glue pushing device

Owner:太仓路华机械制造有限公司

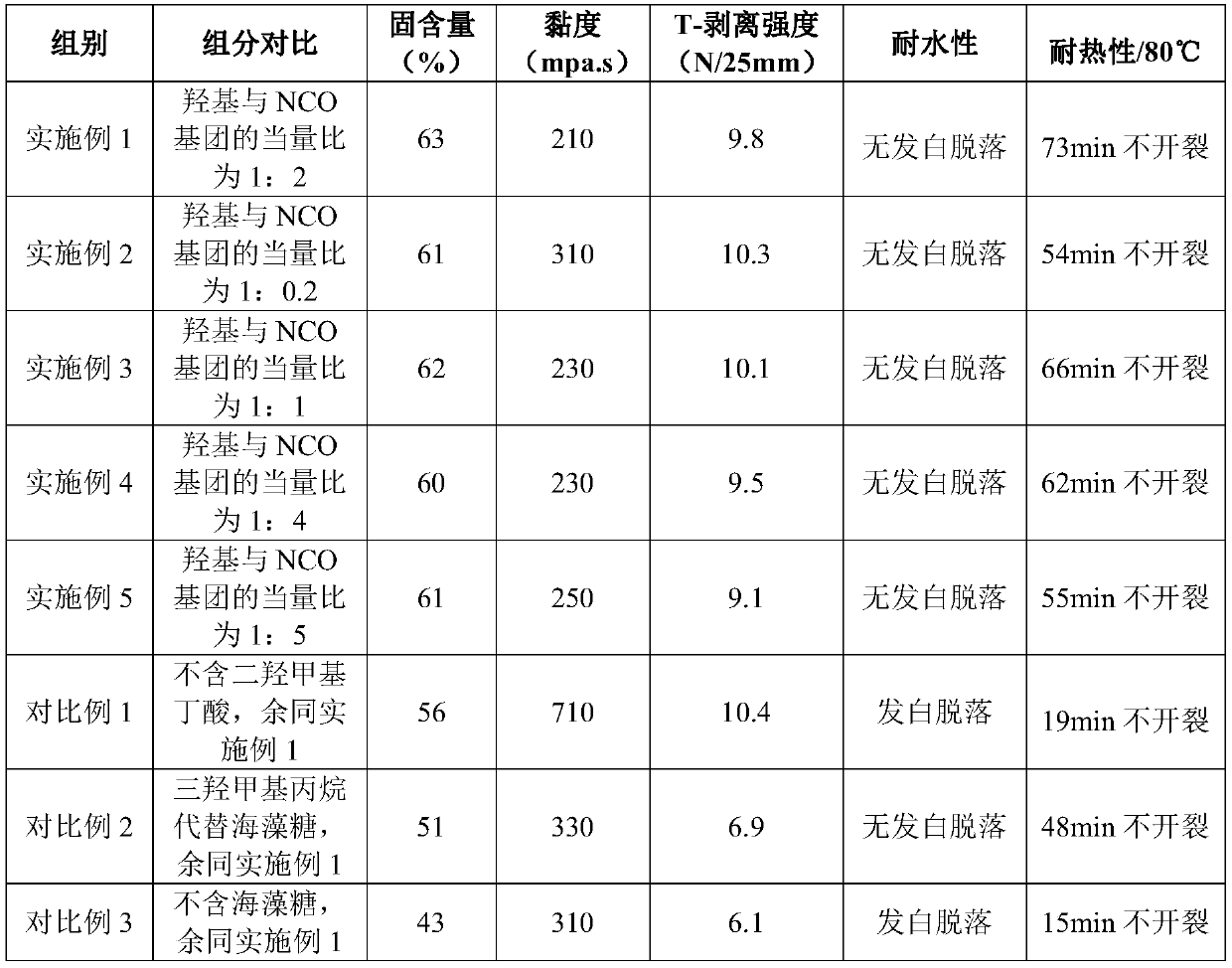

High-performance bi-component polyurethane adhesive and preparation method thereof

ActiveCN111394040AHigh solid contentHigh bonding strengthPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention belongs to the technical field of polyurethane adhesives, and particularly relates to a high-performance bi-component polyurethane adhesive and a preparation method thereof. The bi-component polyurethane adhesive comprises a component A and a component B, wherein the component A comprises isophorone-diisocyanate, sulfonated polyether polyol, polycaprolactone glycol, dibutyltin dilaurate, dimethylolbutyric acid, acetone, a waterborne anionic polyurethane dispersion, triethylamine and ethylenediamine, and the component B comprises isophorone-diisocyanate, poly(1,6-hexamethylene adipate) and trehalose. The bi-component polyurethane adhesive disclosed by the invention has the characteristics of high solid content, low viscosity, high bonding strength, good heat resistance and water resistance and no pollution. The preparation method is simple in process and convenient to operate, the solvent is easy to recycle, and the cost is saved.

Owner:骏能化工(龙南)有限公司

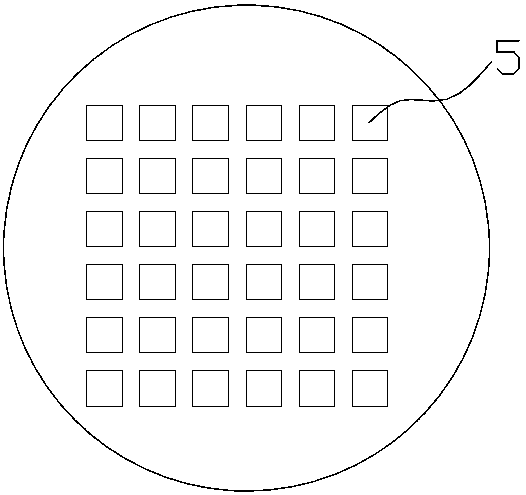

A gravure gluing device and gluing method for fancy reflective fabric with large patterns

ActiveCN106334649BUniform thicknessEven amount of glueLiquid surface applicatorsCoatingsTransmission channelLight reflection

The invention discloses a gravure gluing apparatus of a large pattern of a fancy light reflection fabric. The apparatus comprises an upper pressure roller, a gravure gluing roller, a glue scraper knife and a glue supply mechanism, the upper pressure roller and the gravure gluing roller are arranged up and down, a transmission channel is arranged between the upper pressure roller and the gravure gluing roller, a bead planting membrane is in contact with the roller surface of the upper pressure roller and the gravure gluing roller respectively, the glue scraper knife is positioned at one side of the gravure gluing roller, the glue scraper knife is in contact with the surface of the gravure gluing roller, the surface of the gluing roller is provided with a printing pattern, the printing pattern is composed of a plurality of uniformly-distributed isotropic gluing grooves used for accommodating printing glue, and the bottom of the gravure gluing roller is placed in the glue supply mechanism and is in contact with the glue in the glue supply mechanism. The apparatus can effectively solve the problems of glue spilling and glue discontinuity, allows the thickness of a glue layer to be uniform, has no restriction on the size of the printing pattern, and can be used to produce large-pattern products. The invention also provides a gluing method of the large pattern of the fancy light reflection fabric. The method has the advantages of simple steps, good production continuity and suitableness for industrial production.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Quick rubber mixing and coating gun

InactiveCN101590464AMix quicklySimple structureLiquid surface applicatorsCoatingsEngineeringMixing chamber

The invention discloses a quick rubber mixing and coating gun, which comprises a motor and a connecting plate, wherein the motor is arranged on one side of the connecting plate; the other side of the connecting plate is connected with a rubber mixing chamber; the lateral surface of the rubber mixing chamber is provided with two or more rubber inlets; each rubber inlet is provided with a joint and is connected with a rubber pipe; the end part of the rubber mixing chamber is connected with a nut, a sealing washer and a rubber outlet pipe; an output shaft of the motor is connected with a shaft-like leaf blade; the shaft-like leaf blade is positioned in the rubber mixing chamber; the shaft-like leaf blade and the rubber mixing chamber are provided with sealing gaskets; and the sealing gaskets are fixed by gaskets and stop collars. The leaf blade extends into a small rubber mixing chamber. The inner diameter of the small rubber mixing chamber is small, and is slightly larger than the diameter of the shaft-like leaf blade, so the residual rubber is less after rubber coating is completed. A rubber sending device presses two or more kinds of rubber into the small rubber mixing chamber in proportion through the rubber pipe and pipe joints in working. At that time, the shaft-like leaf blade is driven by the motor to rotate, evenly and fully mixes the rubber and presses the rubber out of the rubber pipe.

Owner:SOUTHEAST UNIV

Water-based lamination adhesive for furniture

InactiveCN107502251AEffectively adjust contentHigh peel strengthNon-macromolecular adhesive additivesOil/fat/wax adhesivesWater basedCross-link

The invention discloses a water-based lamination adhesive for furniture. The water-based lamination adhesive is prepared from components in parts by weight as follows: 40-50 parts of triethyl citrate, 2-10 parts of an acrylate compound, 10-15 parts of a functional aid, 0.1-0.3 parts of a buffering agent, 2-10 parts of an emulsifier, 0.5-4 parts of an initiator, 15-30 parts of deionized water, 0.1-1.5 parts of an oxidizing agent and 0.1-1.5 parts of a reducing agent. With the addition of the functional aid, content of each raw material component is effectively adjusted, meanwhile, the emulsion is a self-crosslinking type, macromolecules of the emulsion are automatically cross-linked during compounding, and peel strength is high; the water-based lamination adhesive belongs to water-based glue, is environmentally friendly, solvent-free, non-flammable, non-explosive, safe to use, low in adhesive application quantity and low in use cost.

Owner:NANTONG JIE GAO FURNITURE CO LTD

Water-based film laminating adhesive

InactiveCN107779140AEffectively adjust contentHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedAdhesive

The invention discloses a water-based laminating adhesive. The water-based laminating adhesive is prepared from the following components in parts by weight: 40-50 parts of butyl acrylate, 2-10 parts of acrylate compounds, 10-15 parts of functional Sexual aids, 0.1-0.3 parts of buffering agent, 2-10 parts of emulsifier, 0.5-4 parts of initiator, 15-30 parts of deionized water, 0.1-1.5 parts of oxidizing agent and 0.1-1.5 parts of reducing agent. The present invention effectively adjusts the content of each raw material component by adding functional additives. At the same time, the emulsion of the present invention belongs to the self-crosslinking type, and its macromolecules are automatically crosslinked during compounding, and the peeling strength is high; the present invention belongs to the water-based adhesive Glue, environment-friendly, solvent-free, non-flammable, non-explosive, safe to use, less glue applied, and low cost of use.

Owner:JIANGSU GUOJIAO CHEM TECH

Flame-retardant cured filter paper and preparation method thereof

ActiveCN109610238AImprove flame retardant performanceHigh filtration precisionPaper coatingPaper/cardboardCross-linkPolyetherimide

The invention relates to the technical field of cured filter paper. In order to improve flame retardancy of filter paper and meet application requirements of the filter paper on an engine, the invention provides flame-retardant cured filter paper and a preparation method thereof. The flame-retardant cured filter paper is prepared by the following steps: dipping a raw paper body in a dipping liquid, then taking out the raw paper body, and then carrying out heating and curing, wherein the raw paper body is prepared from composite wood pulp, polyetherimide powder, polyethyleneimine, melamine resin, a compatibilizer, a succinimide ashless dispersant and a defoaming agent, and the dipping liquid is prepared from thermosetting phenolic resin, a polymer of cyclohexanedimethanol terephthalic acid(PCTA), a cross-linking agent, a flame retardant, a styrene-acrylic emulsion, methanol, isopropyl acetate and an organic sodium silanolate. The flame-retardant cured filter paper disclosed by the invention is high in flame retardancy and is resistant to high temperature, high-temperature dimension stability is high, strength and filtering precision of the filter paper are high, the preparation method has few steps and concise processes and is easier to operate, and the obtained cured filter paper is suitable for being used as a filter element of an air filter of an engine.

Owner:杭州特种纸业有限公司

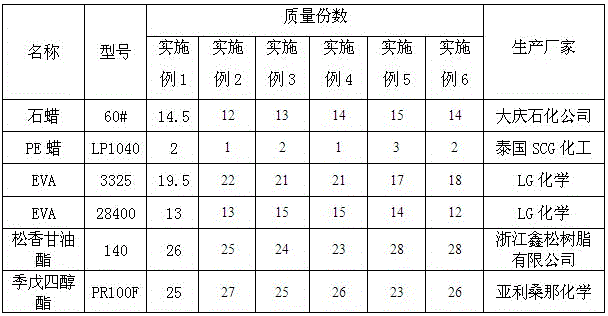

Rapid-bonding paper can labeling adhesive

InactiveCN106367022AFast melting speedReduce energy consumptionNon-macromolecular adhesive additivesWax adhesivesPentaerythritolAdhesive

The invention provides rapid-bonding paper can labeling adhesive, prepared from the following formula components in parts by mass: 12-15 parts of paraffin of model 60, 1-3 parts of polyethylene (PE) wax LP1040, 17-22 parts of ethylene-vinyl acetate copolymer (EVA) 3325, 10-15 parts of EVA 28400, 22-28 parts of rosin glycerin ester and 22-27 parts of pentaerythritol ester PR100F. The rapid-bonding paper can labeling adhesive is reasonable in design, accelerates glue-smelting speed, is better in initial sticking effect and more uniform in gluing, reduces the energy consumption of production equipment, and lowers the production cost.

Owner:浙江固特新材料科技股份有限公司

Environment-friendly damp-proof UV gloss oil and preparing method thereof

InactiveCN110105865ASmall particlesStrong glossAluminium compoundsPolyurea/polyurethane coatingsDefoaming AgentsPhoto curing

The invention discloses an environment-friendly damp-proof UV gloss oil and a preparing method thereof. The environment-friendly damp-proof UV gloss oil comprises a polyurethane-acrylate prepolymer, anano-bimetallic oxide adsorption material, a photoinitiator, a stabilizer, a flatting agent and a defoaming agent. The preparing method of the environment-friendly damp-proof UV gloss oil includes the steps of weighing all the raw materials, and putting all the raw materials into a high-speed disperser to be dispersed to obtain the environment-friendly damp-proof UV gloss oil. The polyurethane-acrylate prepolymer does not contain volatile organic matter or reactive diluents and is harmless to a human body and environmentally friendly; the nano-bimetallic oxide adsorption material has strong adsorption performance and can adsorb damp water and prevent water mist; the compound photoinitiator has the advantages of being short in curing time and large in absorption wavelength and has the optimal photo-curing speed; the environment-friendly damp-proof UV gloss oil is high in adhesive force, high in curing speed and almost free of water mist.

Owner:江苏美乔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com