A gravure gluing device and gluing method for fancy reflective fabric with large patterns

A gravure and reflective technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven thickness of the adhesive layer of the product, large area of the printed pattern, and small amount of glue, so as to improve the continuity of production and production efficiency, solve the effect of uneven pattern depth and uniform glue layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

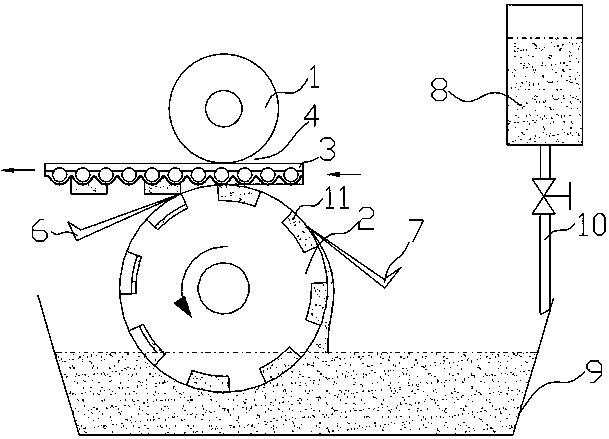

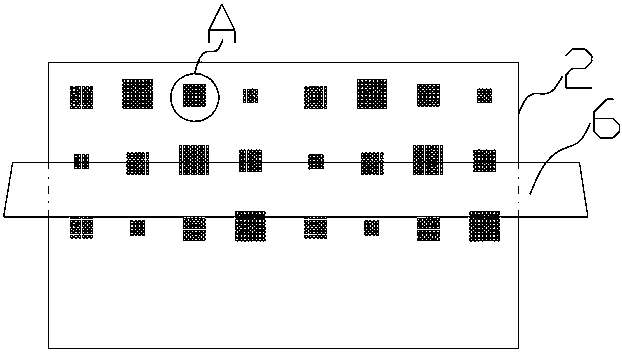

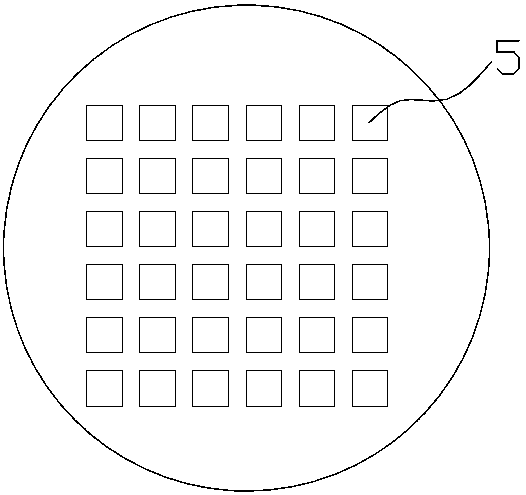

[0034] Such as figure 1The gravure gluing device for a fancy reflective fabric with a large pattern is shown, including an upper pressing roller 1, an intaglio upper rubber roller 2, a squeegee and a glue supply mechanism for storing and supplying glue, the upper pressing roller and the gravure The upper rubber roller is set up and down and a gap is set between the upper pressure roller and the gravure upper rubber roller. The gap forms a transmission channel 4 for passing through the bead planting film 3. The bead planting film is in contact with the upper pressure roller and the gravure upper rubber roller respectively. The squeegee includes a first squeegee 6 for cutting off the glue string between the bead-planting film and the gluing groove and a second squeegee 7 for scraping off the glue overflowing after gluing the gluing groove. The first squeegee is set at the detachment between the bead planting film and the gluing groove after glue transfer and is opposite to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com