Corrugated carton penetrant made of tannin of natural quebrachos and preparation method of corrugated carton penetrant

A penetrating agent and hardwood technology, which is applied in the field of natural hardwood denim corrugated carton penetrating agent and its preparation, can solve problems such as inability to bond, poor adhesion of high-quality paper, etc., to avoid degumming, solve degumming phenomenon, and increase vehicle speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

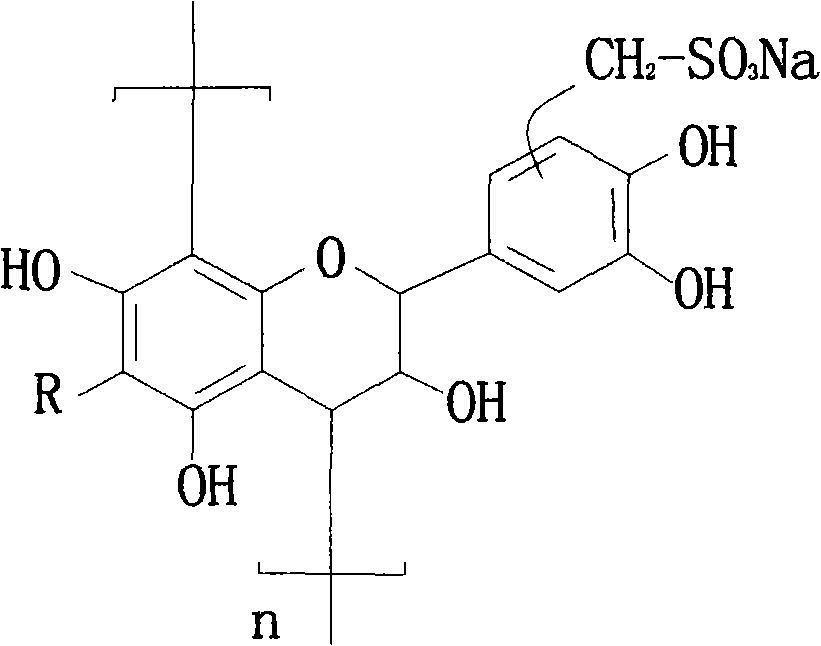

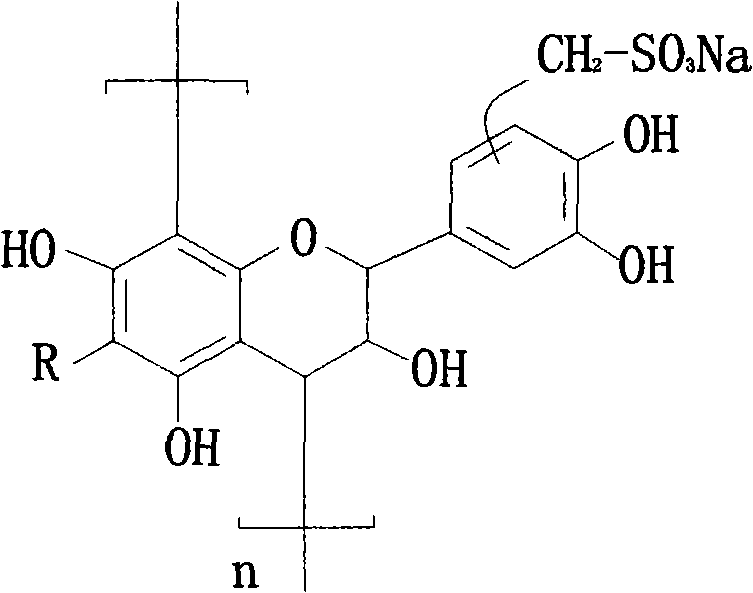

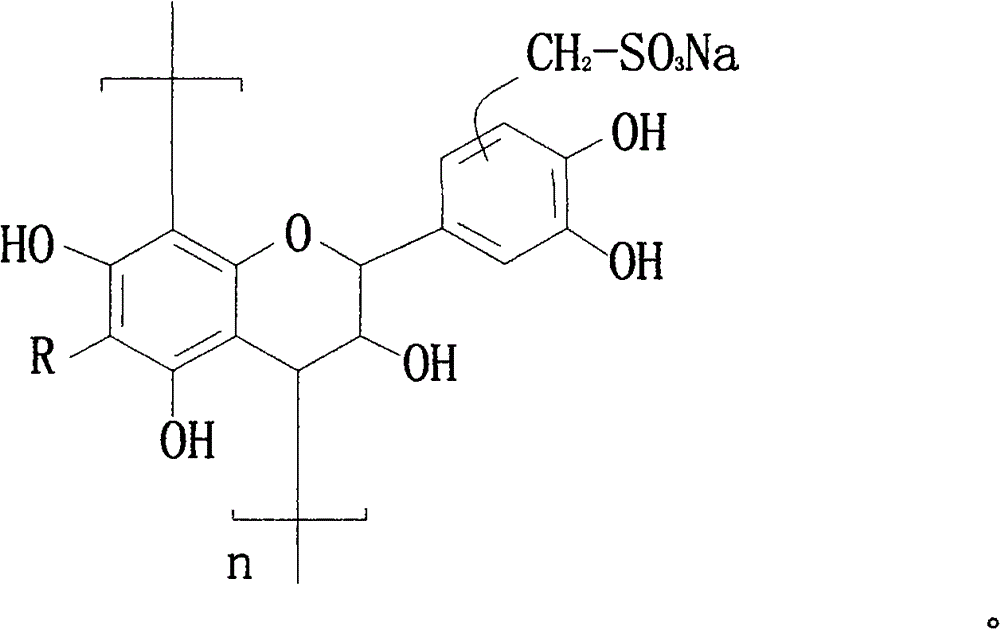

[0019] A natural hardwood tannin corrugated carton penetrant is a chemically modified tannin, which is a sulfurous acid polymer, and its structural formula is:

[0020]

Embodiment 2

[0022] A preparation method of a natural hardwood tannin corrugated box penetrating agent, comprising the following steps:

[0023] A. Add 89% tannin and 11% sodium sulfite to the mixing box to stir, the temperature in the box is controlled at 100-120°C, and stir for 30 minutes;

[0024] B. Add the above-mentioned substances into the SS304 reactor for chemical reaction, control the temperature at 90-100°C, and react for 8 hours;

[0025] C. Spray drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com