Rapid-bonding paper can labeling adhesive

A paper can, fast technology, applied in the direction of adhesives, wax adhesives, rosin adhesives, etc., can solve the problems of low molecular penetration product quality, large amount of glue, low product quality, etc., to overcome the penetration quality problems, The effect of improving the melting speed and reducing the production cost

Inactive Publication Date: 2017-02-01

浙江固特新材料科技股份有限公司

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] (1) The softening point is high, so the melting speed is slow and the energy consumption of the equipment is high;

[0004] (2) The initial bonding effect is not good, it needs to be fixed for a long time, and the amount of glue applied is large;

[0005] (3) Low molecular penetration will occur at high temperature after bonding, resulting in product quality problems;

[0006] (4) The product quality is not high and easy to age

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

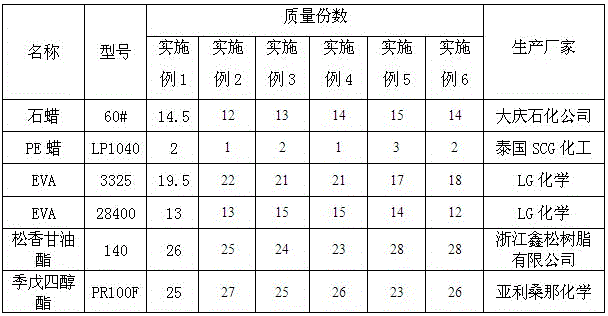

[0034] The formulation components and parts by mass of the present embodiment are shown in the table below.

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides rapid-bonding paper can labeling adhesive, prepared from the following formula components in parts by mass: 12-15 parts of paraffin of model 60, 1-3 parts of polyethylene (PE) wax LP1040, 17-22 parts of ethylene-vinyl acetate copolymer (EVA) 3325, 10-15 parts of EVA 28400, 22-28 parts of rosin glycerin ester and 22-27 parts of pentaerythritol ester PR100F. The rapid-bonding paper can labeling adhesive is reasonable in design, accelerates glue-smelting speed, is better in initial sticking effect and more uniform in gluing, reduces the energy consumption of production equipment, and lowers the production cost.

Description

technical field [0001] The invention relates to a fast-adhesive paper can labeling adhesive, which is mainly used for laminating and bonding the wrapping paper on the outer layer of the paper can. Background technique [0002] Currently commonly used paper can labeling glue has the following defects: [0003] (1) The softening point is high, so the melting speed is slow and the energy consumption of the equipment is high; [0004] (2) The initial bonding effect is not good, it needs to be fixed for a long time, and the amount of glue applied is large; [0005] (3) Low molecular penetration will occur at high temperature after bonding, resulting in product quality problems; [0006] (4) The product quality is not high and it is easy to age. Contents of the invention [0007] The technical problem to be solved by the present invention is to overcome the above-mentioned deficiencies in the prior art, and to provide a fast-bonding paper can labeling glue with reasonable des...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J193/04C09J123/08C09J191/06C09J11/08C09J11/06

CPCC09J193/04C08L2205/02C08L2205/025C08L2205/035C09J11/06C09J11/08C08L23/0853C08L23/06C08L91/06

Inventor 陈慧王欣蕊沈杰一繁张海斌高大兵

Owner 浙江固特新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com