High-frequency coil provided with auxiliary heating cylinder

A high-frequency coil and auxiliary heating technology, applied in crystal growth, electrical components, self-area melting method, etc., can solve the problems of slow heating of raw material rods, affecting the progress of the operation, etc., to increase the hot-melting speed and fast drawing production speed. , the effect of fast hot melt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

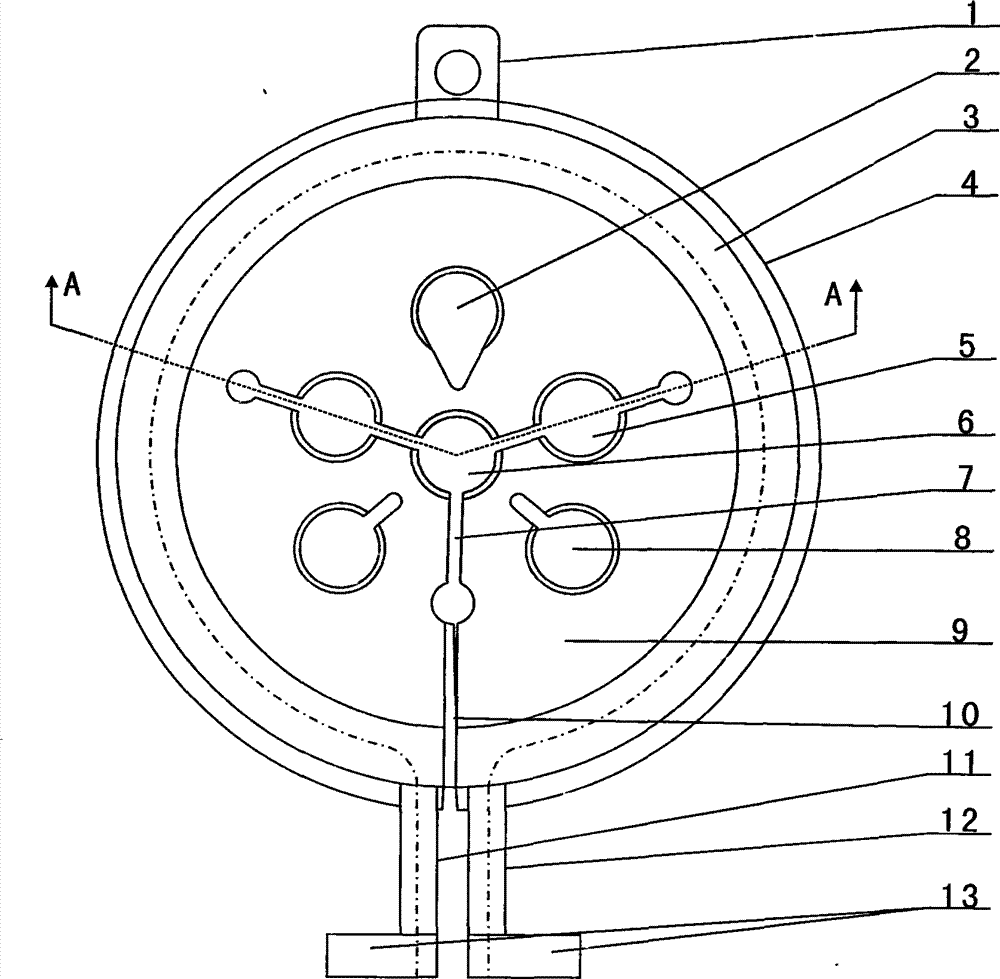

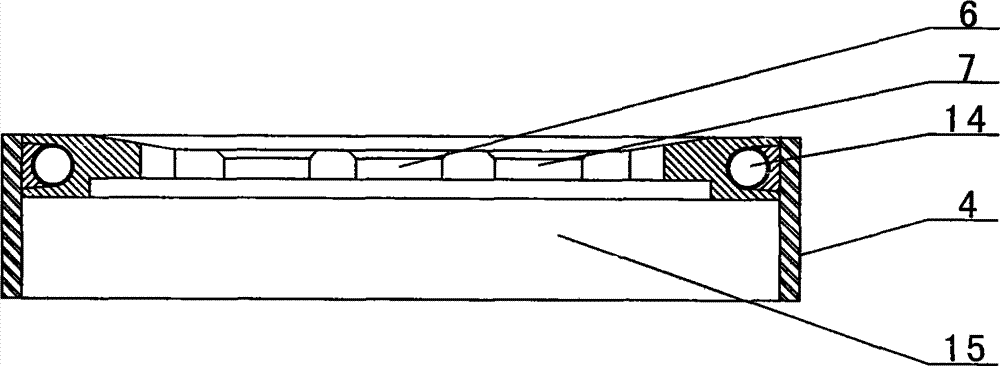

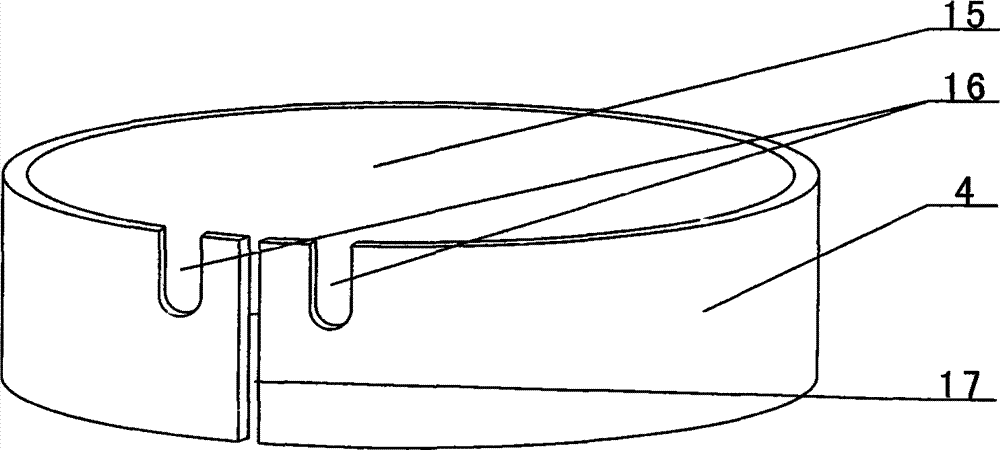

[0018] combined with figure 1 , 2 Or the high-frequency coil with auxiliary heating cylinder described in 3, including high-frequency coil 3, cooling water channel 14, tungsten or molybdenum cylinder 4, connecting seat 13 and ground wire connection mechanism, and a drawing is arranged in the middle of high-frequency coil 3 A hole or chemical material hole 6, the drawing hole or chemical material hole 6 is provided with a plurality of surrounding drawing holes 5, and the drawing hole 5 is a circular drawing hole 5; or a racket-shaped drawing hole 8 or any one of the three kinds of drop-shaped drawing holes 2, or the drawing hole 5 is a circular drawing hole 5; or a racket-shaped drawing hole 8; or at least one of the water-drop-shaped drawing holes 2 A combination of the two; the groove of the racket-shaped d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com